In the LED lighting industry, especially for LED strip lights, LED modules, COB LED boards, and customized lighting solutions, the PCB is not just a supporting component—it is a critical factor that determines product performance, reliability, lifespan, and cost efficiency.

However, many buyers encounter the same problem when sourcing LED PCBs:

Why do quotes vary so much between PCB manufacturers?

Why does the final cost often differ from the initial quotation?

The answer lies in how accurately the PCB requirements are defined and communicated. An accurate quote is not only about price—it reflects the manufacturer’s understanding of your application, technical capability, and risk control.

The truth is that an accurate custom PCB quote—especially for LED applications—depends on much more than board size and quantity. It requires a clear application definition, precise technical parameters, transparent testing requirements, and the right manufacturing partner.

This article explains, step by step, how to obtain the most accurate and reliable quote for a custom LED PCB.

Clearly Define the LED PCB Application

The first and most critical step is to define where and how the PCB will be used. Different LED applications impose very different requirements on the PCB.

LED PCB Application Selection Comparison Table

| Comparison Dimension | Flexible LED Strip PCBs | Rigid LED Strip/Bar PCBs | Custom LED Boards/Modules |

| Application Scenarios | Bending lighting designs (e.g., curved light strips, decorative lights) | Fixed installation scenarios (e.g., billboards, lighting bars) | High-power density scenarios (e.g., automotive lighting, industrial equipment) |

| Core Requirements | Uniform copper thickness, fine trace control, bending reliability, stable voltage distribution over long runs | Dimensional stability, heat dissipation, uniform LED performance | Strict thermal design, longer lifespan expectations |

| Key Parameters | Bending radius, copper thickness (≥1oz), trace accuracy (±0.1mm) | Thermal resistance (≤0.5℃/W), dimensional tolerance (±0.2mm) | Thermal resistance (≤0.3℃/W), lifespan (≥50,000 hours) |

| Typical Materials | Polyimide (PI), flexible copper foil | FR-4, aluminum substrate | High thermal conductivity ceramic substrate, metal substrate |

| Manufacturing Challenges | Performance stability after bending, multi-layer board alignment accuracy | Heat dissipation structure design, LED welding consistency | Thermal management design, high-density routing |

| Cost Factors | Higher material cost, but batch production can reduce costs | Moderate material cost, mature manufacturing process | High material cost, R&D cost accounts for a large proportion |

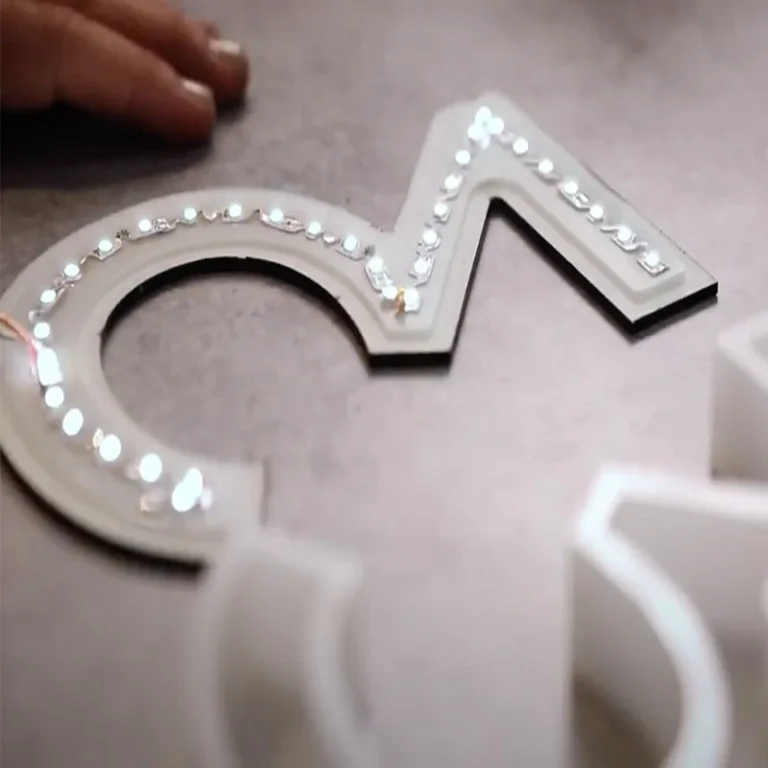

- Flexible LED strip PCBs: Require consistent copper thickness, fine trace control, bending reliability, and stable voltage distribution over long runs.

- Rigid LED strip or bar PCBs: Emphasize dimensional stability, heat dissipation, and uniform LED performance.

- Custom LED boards or modules: Often involve higher power density, stricter thermal design, and longer lifespan expectations.

Without a clear application definition, PCB manufacturers can only provide rough estimates, not accurate quotes.

Prepare Complete and Manufacturable Design Files

Incomplete or unclear design files are one of the most common causes of inaccurate PCB pricing.

For LED PCB projects, you should prepare:

- Gerber files (including solder mask and silkscreen)

- Drill files and board outline

- Stack-up information

- Panelization requirements

- BOM (if PCBA is required)

- Special process notes (ENIG, OSP, HASL, etc.)

When files are incomplete, manufacturers are forced to assume specifications, which often leads to price changes later in the project.

Define All Critical Technical Parameters

In LED PCB manufacturing, small technical differences can result in large cost variations. Key parameters include:

- Base material: FR4, aluminum PCB, copper base

- Copper thickness: 1 oz, 2 oz, or higher

- Board thickness tolerance

- Minimum trace width and spacing

- Surface finish: ENIG, immersion silver, OSP, HASL

- Thermal conductivity (for aluminum PCBs)

For LED strip PCBs in particular, copper thickness and trace design directly affect voltage drop and lumen consistency, making them critical for both performance and pricing.

It is no exaggeration to say that the restrictions on custom PCB specifications will test PCB manufacturers. The better and more comprehensive your information is, the easier, faster, and more accurate your quotation will be.

Three Key Strategies for Selecting the Right PCB LED Supplier

Choosing the right supplier is essential to receiving an accurate and realistic quote.

Strategy 1: Prioritize LED-Specific Experience

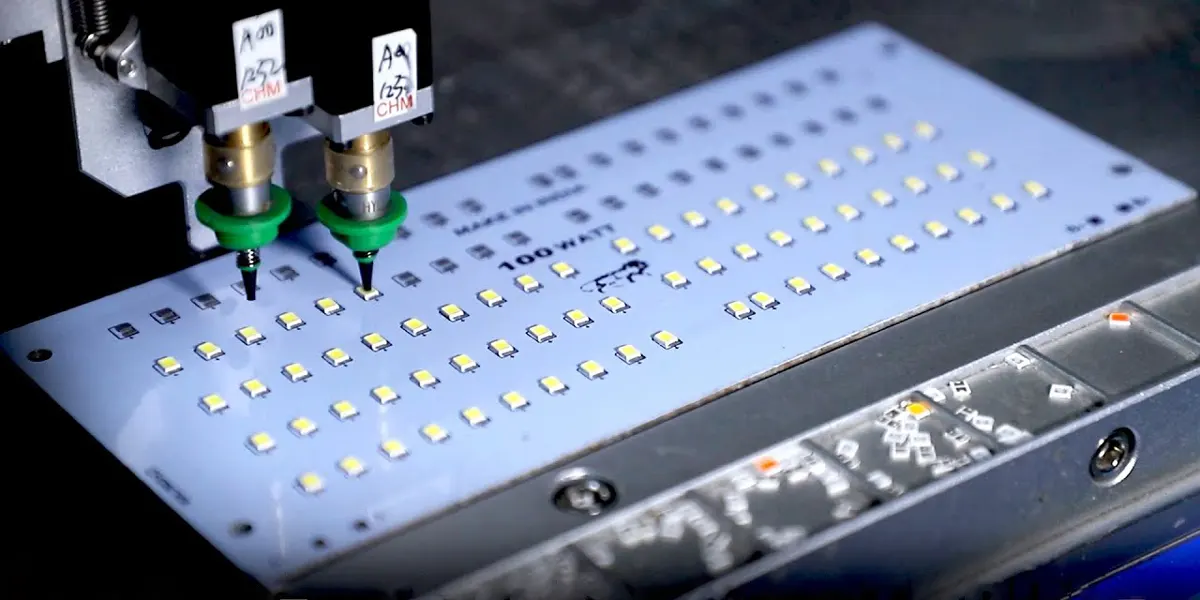

Manufacturers with proven experience in LED strip PCBs and custom LED boards understand thermal management, current distribution, and long-term reliability requirements.

Strategy 2: Verify Quality Systems and Manufacturing Capability

Look for ISO-certified factories with AOI, electrical testing, and reliability testing capabilities. A low quote without proper quality control often leads to higher total cost.

Strategy 3: Evaluate Engineering Support

Suppliers with in-house engineering teams can identify design risks early, helping prevent hidden costs and production delays.

Identify and Avoid Hidden Cost Traps

Low initial quotes often hide future expenses. Common hidden costs include:

- Electrical testing not included

- Lower-grade materials substituted without notice

- Engineering fees added after prototype approval

- Price increases at the mass production stage

An accurate quote should clearly define what is included and what is not, especially for LED applications where reliability is critical.

Leverage Supplier Engineering to Optimize the Design

Experienced LED PCB manufacturers can provide DFM (Design for Manufacturability) support, such as:

- Optimizing trace routing to reduce voltage drop

- Improving copper distribution for better heat dissipation

- Adjusting board structure to reduce cost without sacrificing performance

Design optimization often results in better performance and a more competitive final price.

Clearly Define Testing and Reliability Requirements

For LED lighting products, PCB reliability directly affects product warranty and brand reputation. During the quotation stage, clarify:

- 100% electrical testing

- Thermal stress or aging test requirements

- Compliance with RoHS / REACH standards

- Clear testing requirements ensure the quote reflects the true cost of quality.

Obtain multiple quotations and compare them

It is recommended to collect at least three PCB quotes and compare them carefully. Key comparison points include:

- Material specifications

- Copper thickness and tolerances

- Testing scope

- Delivery lead time

- Engineering and after-sales support

Never compare quotes based on price alone—technical consistency matters.

Communicate Order Volume and Long-Term Forecasts

PCB pricing is highly volume-dependent. If your LED project involves recurring orders or annual forecasts, sharing this information can help suppliers:

- Optimize panelization

- Secure stable material pricing

- Reduce long-term unit cost

This is particularly important for LED strip light and custom LED board projects.

Choose an LED PCB Manufacturer with Strong Engineering Support

Ultimately, the most accurate PCB quote comes from a long-term manufacturing partner, not a one-time transaction. A reliable LED PCB supplier provides:

- Transparent pricing

- Stable quality

- Engineering-driven cost optimization

- Consistent delivery performance

Such partnerships reduce risk and improve product competitiveness over time.

Conclusion

Obtaining the most accurate quote for a custom LED PCB is not simply about requesting prices from multiple suppliers. It is a systematic process involving clear application definition, complete technical documentation, transparent testing requirements, and the right manufacturing partner.

For LED strip lights, rigid LED boards, and custom LED modules, accurate quoting is the foundation of product reliability, cost control, and long-term success.

FAQs

A: Differences usually stem from material grades, copper thickness, testing scope, and engineering capability—not just manufacturing cost.

A: Not necessarily. Low prototype pricing may exclude testing or use lower-grade materials, leading to higher costs at mass production.

A: Not always. In high-power LED applications, aluminum PCBs can reduce thermal issues and overall system cost.

A: Yes. Lifespan requirements directly influence material selection, copper design, and testing standards, which affect pricing accuracy.