Due to its adaptability, energy economy, and simplicity of installation, LED Neon Flex is a popular modern lighting solution. Small, flexible LED lights enclosed in a silicone or PVC jacket make up this flexible substitute for traditional glass neon lights. We shall examine the operation of LED Neon Flex in this blog post.

Basic

LED Neon Flex imitates the appearance of classic neon lights by employing LED lighting. LED lights are a practical and environmentally responsible choice for illumination because of their high energy efficiency and long lifespan. LED Neon Flex uses linear strips of LED lights that are covered in a flexible silicone or PVC coating. After that, the jacket is cut into the desired form to give it the appearance of a neon tube.

The LED lights used in LED Neon Flex are intended to generate a vivid, brilliant light that resembles classic neon lights in appearance. LED lights emit light when an electric current flows through them, stimulating the electrons inside and leading them to release photons that are responsible for the glow.

Design

The design versatility of LED Neon Flex is one of its main benefits. It is a popular choice for producing detailed and sophisticated designs that are not achievable with standard glass neon because the flexible jacket allows designers to twist and mold the LED lights into any form or shape. LED Neon Flex is a flexible alternative for a range of lighting applications since it can be sliced and shaped to fit into any area or design.

Installation

Compared to conventional glass neon, LED Neon Flex is simpler to install. The flexible jacket has an adhesive backing that makes mounting it on any surface simple. With the aid of scissors or a knife, the strip can be cut to the required length, and the cut end can then be reattached to another portion of the strip using a connector. Due to this, LED Neon Flex is a well-liked alternative for do-it-yourself projects.

Applications

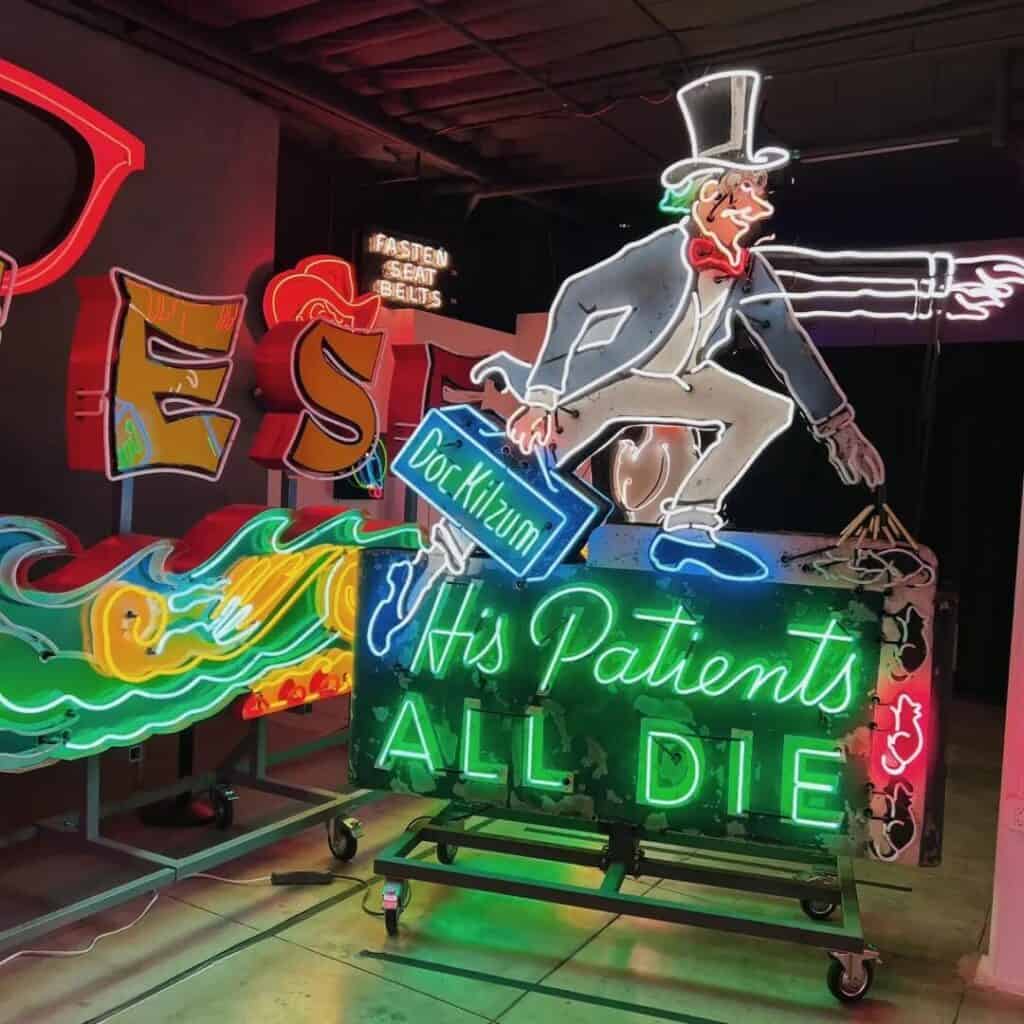

Numerous uses for LED Neon Flex exist, such as ornamental lighting, architectural illumination, signage, and more. It is frequently used to make unique designs and forms, like business logos or product displays. It is a popular choice for producing striking and distinctive lighting displays due to its versatility and capacity to generate intricate designs and shapes.

Given that it may be utilized to draw attention to a building or structure’s distinctive features, LED Neon Flex is also well-liked for architectural lighting. A dynamic and aesthetically appealing impact can be produced by using it to create custom lighting designs that complement the theme or mood of the building.

LED Neon Flex is frequently used for signs in addition to ornamental and architectural lighting. It can be used to make unique signs that are both useful and beautiful. Given that they can be easily molded into any style or shape, LED Neon Flex signs are frequently utilized for advertising or promotional purposes.

In summary, LED Neon Flex is a practical and adaptable lighting option that has numerous benefits over older glass neon lights. It is a well-liked option for many lighting applications due to its adaptable design, energy economy, and simplicity of installation. LED Neon Flex provides a useful and affordable substitute for conventional neon by employing LED lights to provide a similar look to traditional neon lights. LED Neon Flex is certain to stay a well-liked and cutting-edge option for lighting designers and enthusiasts alike as the lighting industry develops.