LED Tri-Proof Lights — designed to be waterproof, dustproof, and corrosion-resistant — have become essential for environments such as factories, warehouses, parking lots, tunnels, and food processing facilities. Their robust construction ensures stable lighting performance even under harsh conditions. However, selecting the wrong type of LED Tri-Proof Light can result in costly maintenance, inadequate brightness, reduced lifespan, or unnecessary power consumption. To achieve optimal performance and long-term reliability, it’s important to choose a fixture that matches the specific requirements of each installation. This guide will explain how to select the right LED Tri-Proof Light based on IP rating, wattage, and type, helping you make the most efficient and durable lighting choice for any industrial or commercial space.

Understand What a LED Tri-Proof Light Is and Its Core Functions

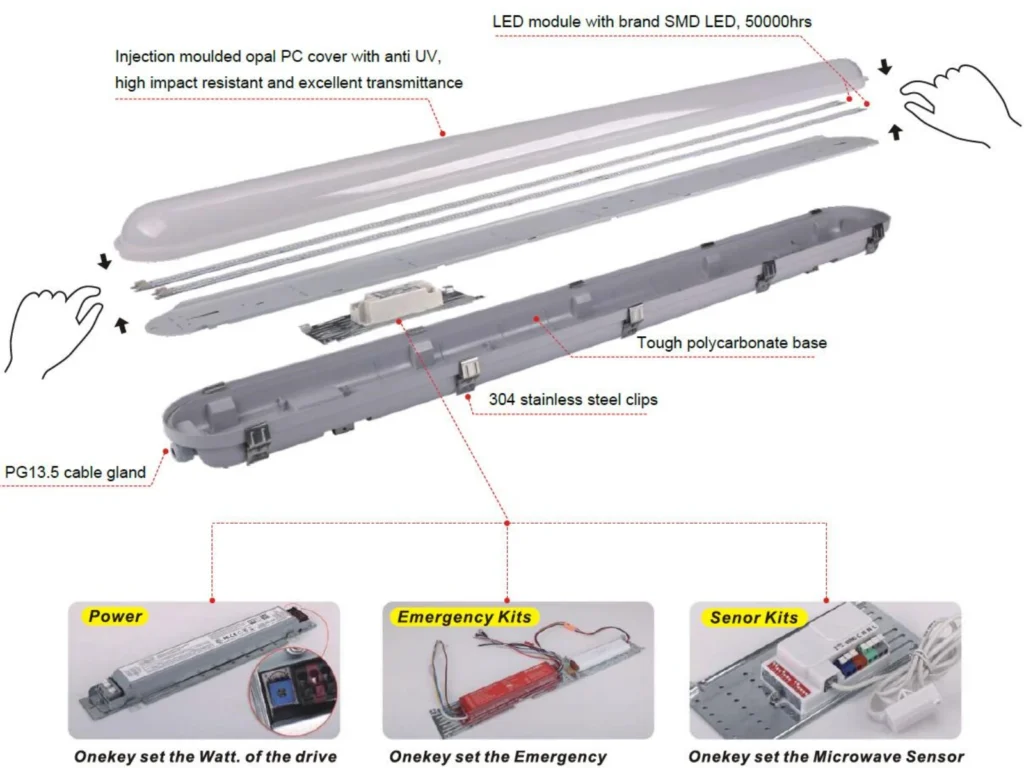

The term “Tri-Proof” refers to three essential protective features: waterproof, dustproof, and corrosion-resistant. A LED Tri-Proof Light is specifically engineered to withstand moisture, dust particles, and chemical vapors that can damage conventional lighting fixtures. Its sealed design with durable housing and silicone gaskets prevents water ingress and dust accumulation, making it ideal for demanding environments such as factories, tunnels, or parking areas.

Beyond protection, the core function of a LED Tri-Proof Light is to provide consistent, energy-efficient illumination in areas exposed to humidity, dirt, or corrosion. With high luminous efficiency and long lifespan, it ensures reliable performance and reduced maintenance frequency, helping maintain productivity and safety in industrial and commercial spaces.

IP Rating: How Waterproof and Dustproof Do You Really Need?

What Is IP Rating?

The IP (Ingress Protection) rating measures how well a lighting fixture resists dust and water intrusion. It consists of two digits: the first indicates protection against solids (like dust), and the second shows protection against liquids. Common LED Tri-Proof Light ratings include IP65, which resists low-pressure water jets and dust; IP66, which offers stronger water protection; and IP69K, the highest level, designed to endure high-temperature, high-pressure water cleaning in environments such as food processing plants.

Common Purchasing Challenges

One of the biggest challenges when selecting a LED Tri-Proof Light is determining which IP rating is truly needed. A rating that’s too low can lead to product failure, corrosion, or frequent maintenance, while choosing an unnecessarily high IP level can increase purchase costs without adding real value. Balancing protection level with project environment is key to cost-effective lighting.

Recommended IP Ratings for Different Applications

In general, indoor dry areas may only need IP65 protection, while humid or outdoor environments require higher ratings. The table below summarizes typical applications and suitable IP levels:

| Application | Recommended IP Rating |

| Warehouse / Parking Garage | IP65 |

| Tunnel / Car Wash Area | IP66 |

| Food Processing Facility | IP69K |

| Outdoor Industrial Site | IP66–IP69K |

Wattage and Luminous Efficiency: Balance Between Power and Performance

Wattage — Choosing the Right Power Output

Many users are unsure how to select the proper wattage for their LED Tri-Proof Lights. The correct power level depends on several factors, including installation height, coverage area, and required brightness. For example, a 40W fixture may be sufficient for a corridor or parking area, while a warehouse with higher ceilings might need 60W or more to achieve uniform illumination. Lighting design software such as DIALux can help simulate real project conditions, ensuring that each area receives the optimal brightness without energy waste or dark spots.

Efficiency — Same Power But Much Brighter

It’s common to notice that two LED Tri-Proof Lights with the same wattage can have very different brightness levels. The key lies in luminous efficiency, measured in lumens per watt (lm/W). A fixture with higher luminous efficacy converts more power into light instead of heat, offering greater brightness and energy savings. Choosing high-efficiency LED Tri-Proof Lights not only reduces electricity bills but also minimizes maintenance and enhances long-term performance in industrial and commercial environments.

Type: Integrated, Split, or Shaped

The market offers various types of LED Tri-Proof Lights, each designed to meet different environmental and budget requirements. While their core functions—waterproofing, dustproofing, and corrosion resistance—are generally similar, choosing the right type can make a big difference in installation convenience, durability, and maintenance costs.

Integrated LED Tri-Proof Light

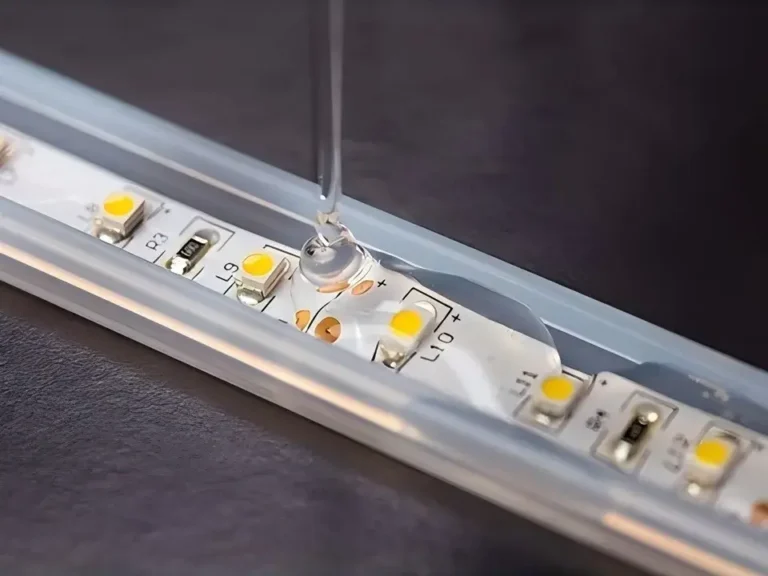

An integrated tri-proof light features a fully sealed structure where the LED chips, driver, and housing are combined into one unit. This design provides superior protection against moisture and dust, ensuring reliable performance in harsh conditions. Integrated models are ideal for environments such as car wash stations, cold storage rooms, or tunnels, where constant exposure to humidity and temperature changes requires maximum durability.

Split LED Tri-Proof Light

A split-type tri-proof light separates the housing and the internal light source, which can be a replaceable LED tube or linear module. This structure allows for easier maintenance and lower replacement costs when a component fails. Although its waterproof level is slightly lower than the integrated type, it offers a more cost-effective solution for applications like workshops, warehouses, or parking areas, where conditions are less extreme but reliability is still essential.

Shaped or Round LED Tri-Proof Light

For projects requiring a distinctive appearance or specific light distribution, shaped tri-proof lights—such as round LED tri-proof lights—are often used. Their unique design fits livestock farms, food plants, or decorative industrial areas, where both aesthetics and performance are important. These lights combine protection with a stylish look, broadening the range of tri-proof applications beyond standard linear designs.

Other Key Factors: Material, Color Temperature, Installation Method, and Flexibility

Material: Aluminum housing offers better heat dissipation and longer lifespan, while PC or ABS materials provide lighter weight and lower cost.

Color Temperature: 4000K neutral white is suitable for work areas, while 5000–6500K delivers higher brightness for industrial or outdoor spaces.

Installation Method: LED Tri-Proof Lights can be surface-mounted, suspended, or linkable, depending on the ceiling height and layout.

Installation Flexibility: Modular designs and quick connectors simplify wiring(daisy chain), making it easier to install or replace lights in large-scale projects.

Conclusion

Choosing the right LED Tri-Proof Light requires careful consideration of IP rating, wattage, size, and type to ensure durability, energy efficiency, and optimal lighting performance. The right fixture not only reduces maintenance and energy costs but also guarantees long-term reliability in demanding industrial or commercial environments.

SignliteLED focuses on manufacturing high-quality LED Tri-Proof Lights designed for harsh conditions. We provide customized lighting solutions based on your specific project requirements, including DIALux simulation reports, tailored optical spectra, and professional installation advice. Whether for factories, warehouses, or cold storage facilities, SignliteLED delivers durable and efficient tri-proof lighting that meets international standards. Contact us today to discuss your project needs.