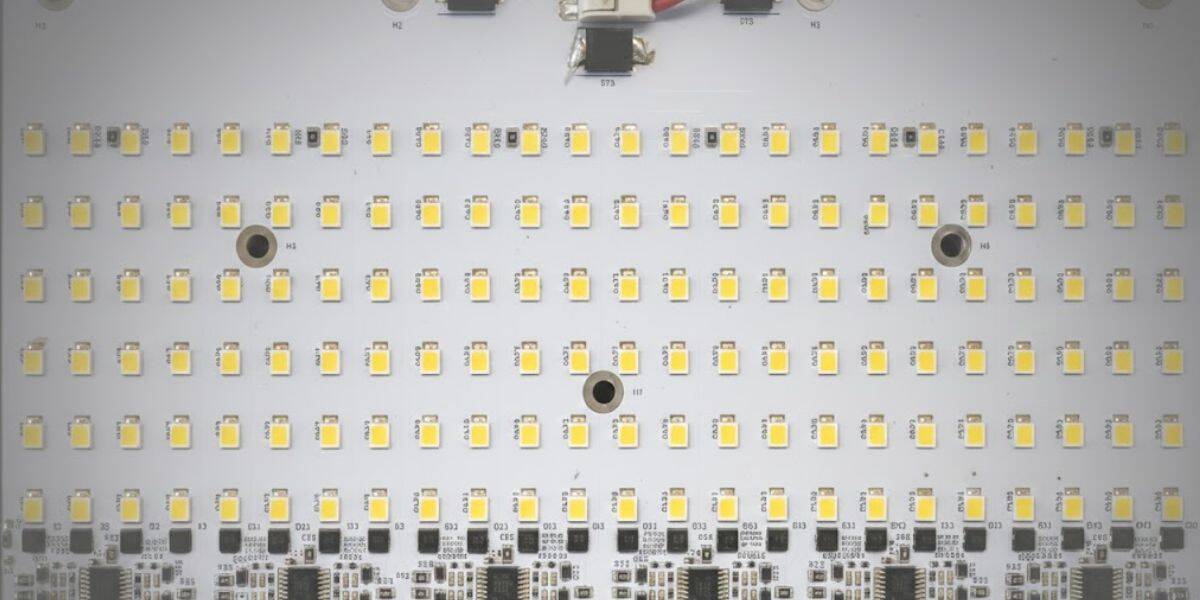

L'assemblaggio di PCB LED per l'illuminazione connessa intelligente è il processo di integrazione di LED, elettronica di controllo e connettività wireless su un'unica piattaforma PCB affidabile. A differenza delle schede LED standard, questi gruppi combinano componenti di illuminazione ad alta potenza con microcontrollori, sensori e moduli RF. Ciò rende l'assemblaggio specializzato perché il controllo termico, l'integrità del segnale e la regolazione della potenza devono funzionare insieme per un funzionamento stabile a lungo termine.

Che cos'è il gruppo PCB LED per l'illuminazione connessa intelligente?

L'assemblaggio a LED standard si concentra principalmente sul posizionamento e sull'alimentazione di componenti ad emissione luminosa. L'illuminazione connessa intelligente va oltre. Il PCB non è più solo una superficie di montaggio per LED. Diventa il sistema centrale in cui l'illuminazione, il controllo e la comunicazione coesistono.

Nell'illuminazione intelligente, l'assieme LED PCB supporta allo stesso tempo LED, logica di controllo e connettività. Questo cambia il modo in cui le schede vengono disposte, assemblate e testate. L'elettronica di controllo gestisce l'attenuazione, la pianificazione e l'automazione, mentre la connettività consente l'accesso remoto e il coordinamento del sistema. Poiché tutto ciò avviene su una scheda PCB LED, la qualità dell'assemblaggio influisce direttamente sul modo in cui l'intero sistema di illuminazione si comporta in ambienti reali.

Componenti chiave integrati in gruppi PCB LED intelligenti

Componenti LED ad alta potenza

I LED ad alta potenza generano calore significativo e sono sensibili alla precisione del posizionamento. durante Assemblaggio LED PCB, anche piccoli errori di allineamento possono influire sull'affidabilità del giunto saldante e sul trasferimento di calore. Il montaggio scadente aumenta lo stress termico, che riduce la durata della vita del LED e provoca il degrado della produzione di luce nel tempo.

Moduli di connettività (Wi-Fi, ZigBee, Bluetooth, Matter)

I moduli wireless sono sensibili al rumore, alla messa a terra e al posizionamento fisico. Nell'illuminazione intelligente, la connettività deve rimanere stabile anche quando i LED si accendono e si spengono a diversi livelli di potenza. Le decisioni di assemblaggio come la clearance dell'antenna, la qualità di riferimento del suolo e la consistenza della saldatura influenzano direttamente la stabilità del segnale.

Microcontrollori e IC di controllo

I microcontrollori agiscono come il cervello del sistema. Gestiscono le curve di dimming, le regole di automazione e la comunicazione con altri dispositivi. Nell'assemblaggio di PCB personalizzato per l'illuminazione intelligente, questi componenti devono essere assemblati con cura per evitare fluttuazioni di alimentazione e problemi di temporizzazione che possono interrompere il comportamento dell'illuminazione.

Sensori utilizzati nell'illuminazione intelligente

L'illuminazione intelligente spesso include movimento, luce ambientale o sensori ambientali. Questi componenti devono essere assemblati per rimanere isolati elettricamente da fonti di calore e rumore a LED. Un assemblaggio scadente può portare a letture false o comportamenti instabili, anche se il sensore stesso è ben progettato.

Considerazioni critiche sull'assemblaggio per l'illuminazione connessa intelligente

Il gruppo di illuminazione intelligente introduce sfide che non sono presenti nelle schede LED di base. I materiali di interfaccia termica devono creare un percorso termico affidabile senza interferire con l'elettronica sensibile. La regolazione della potenza deve gestire sia le correnti LED elevate che gli stati di alimentazione di standby ultra-basso.

L'integrità del segnale è un'altra preoccupazione. I moduli wireless funzionano insieme a tracce LED ad alta corrente, che aumentano il rischio di interferenze. Gli errori di assemblaggio come i vuoti di saldatura, il riflusso irregolare o la contaminazione sono difficili da correggere in seguito perché influiscono sia sull'illuminazione che sulla connettività a livello di sistema.

Nella fase di assemblaggio, l'affidabilità dipende dal bilanciamento:

- Percorsi termici a LED e dissipazione del calore

- Stabilità di potenza attraverso gli stati di dimmer e standby

- Integrità del segnale per la comunicazione wireless

Gestione termica in assemblaggio PCB LED intelligente

La gestione termica è un fattore determinante per l'affidabilità dell'illuminazione intelligente. Molti sistemi LED intelligenti utilizzano substrati in alluminio o mcpcb perché forniscono un'efficiente diffusione del calore per i LED. Tuttavia, le scelte di assemblaggio determinano se tale potenziale termico è effettivamente realizzato.

L'illuminazione intelligente spesso esegue cicli di lavoro più lunghi rispetto all'illuminazione convenzionale. Dimming, rilevamento e connettività mantengono attivo il sistema anche quando l'emissione luminosa è ridotta. Se il calore non viene gestito correttamente durante l'assemblaggio, il funzionamento a lungo termine porta all'invecchiamento accelerato dei componenti e alle prestazioni instabili.

Flusso di lavoro di produzione e assemblaggio per PCB LED intelligenti

Il flusso di produzione per gli assiemi LED intelligenti inizia con la disponibilità del progetto, in cui il posizionamento dei componenti supporta sia la dissipazione del calore che l'integrità del segnale. Questioni di sequenziamento dell'assemblaggio. I LED, i moduli di controllo e i moduli RF possono richiedere diversi profili di gestione e riflusso.

Gli assiemi misti devono bilanciare i requisiti di saldatura a LED con i limiti termici dei componenti di connettività. L'ispezione si concentra non solo sulla qualità della saldatura, ma anche sull'allineamento, la pulizia e la coerenza su tutta la scheda. Questo flusso di lavoro riflette l'integrazione del sistema piuttosto che il semplice collegamento dei componenti.

Test e affidabilità in gruppi di illuminazione connessi intelligenti

L'ispezione visiva da sola non può convalidare gli assiemi di illuminazione intelligenti. I test funzionali devono confermare che i moduli di connettività comunichino in modo affidabile e che la logica di controllo risponda correttamente sotto carico. Molti dei primi guasti nei sistemi di illuminazione intelligenti provengono da problemi di assemblaggio come giunti di saldatura marginali o interfacce termiche scadenti, non da difetti di progettazione.

I test efficaci in genere si concentrano su:

- Comunicazione stabile sotto le modifiche al carico del LED

- Stabilità di potenza durante le raffiche di comunicazione

- Controllo della risposta durante i cicli di dimmer e di automazione

Il test aiuta a rivelare le interazioni tra illuminazione, controllo della potenza e comunicazione altrimenti invisibili durante l'ispezione di base.

Errori di assemblaggio comuni nei progetti di illuminazione intelligente

Un errore comune è trattare le schede LED intelligenti come assiemi LED standard. Ignorare il comportamento RF durante l'assemblaggio porta a una connettività instabile. Un altro problema è sottovalutare lo stress termico a lungo termine. I sistemi di illuminazione intelligenti funzionano continuamente e i piccoli punti deboli di assemblaggio diventano problemi di affidabilità nel tempo.

Trasformare l'interazione tra l'erogazione di potenza e i circuiti di comunicazione è un altro errore frequente. Questi errori riducono la stabilità del sistema e aumentano i guasti sul campo.

Come l'assemblaggio intelligente di PCB LED supporta i moderni sistemi di illuminazione

L'illuminazione intelligente si basa su un assemblaggio affidabile per offrire prestazioni costanti. Il corretto assemblaggio del LED PCB consente il controllo remoto, l'automazione e la gestione dell'energia senza compromettere la durata dei LED. Quando l'assembly allinea i LED, l'elettronica di controllo e la connettività come un unico sistema, le reti di illuminazione rimangono stabili, prevedibili e scalabili.

Differenze chiave tra l'assemblaggio di PCB LED connesso standard e intelligente

La tabella seguente evidenzia le differenze pratiche tra il gruppo PCB LED standard e il gruppo PCB LED connesso intelligente a livello di sistema.

| Aspetto | Assemblaggio PCB LED standard | Assemblaggio PCB LED connesso intelligente |

| Complessità di montaggio | Da basso a moderato | Alto grazie a componenti misti |

| Integrazione dei componenti | LED e driver di base | LED, ICS di controllo, sensori, moduli RF |

| Bisogni di test | Visual ed Elettrico | Test funzionali, connettivi e di carico |

| Rischio di affidabilità | Per lo più termico | Interazione termica, potenza e segnale |

Conclusione

L'assemblaggio di PCB a LED per l'illuminazione connessa intelligente è un processo a livello di sistema, non solo un compito di produzione. L'illuminazione intelligente affidabile dipende dall'assemblaggio disciplinato che bilancia le prestazioni dei LED, la gestione termica, il controllo della potenza e la connettività. Quando la qualità dell'assemblaggio viene trattata come un fattore di ingegneria di base, i sistemi di illuminazione intelligenti offrono un funzionamento stabile e un'affidabilità a lungo termine.

Domande frequenti

Perché i LED, l'elettronica di controllo e i moduli wireless devono coesistere su una scheda senza interferire tra loro.

I substrati MPCB o in alluminio sono comunemente usati per supportare un'efficace dissipazione del calore.

I moduli wireless richiedono un'attenta posizione di messa a terra e di saldatura per mantenere una comunicazione stabile.

I sistemi intelligenti funzionano più a lungo e includono l'elettronica sempre attiva, aumentando lo stress termico cumulativo.

Le linee di montaggio standard possono gestire progetti LED intelligenti?

Alcuni possono, ma devono essere in grado di gestire componenti LED e RF misti con controlli appropriati.