In December 2025, we partnered with a North American project contractor to deliver a customized acoustic LED pendant lighting solution for a large office building. The goal of the project was to create a modern workspace that balanced visual comfort, acoustic performance, and architectural aesthetics. As open-plan offices increasingly require both effective illumination and noise control, the client was seeking a lighting solution capable of addressing these two needs simultaneously—without compromising design consistency. This collaboration marked the starting point of a tailored approach that combined high-efficiency lighting with sound-absorbing materials to improve productivity and overall spatial comfort in a high-traffic commercial environment.

クライアントの要件と課題

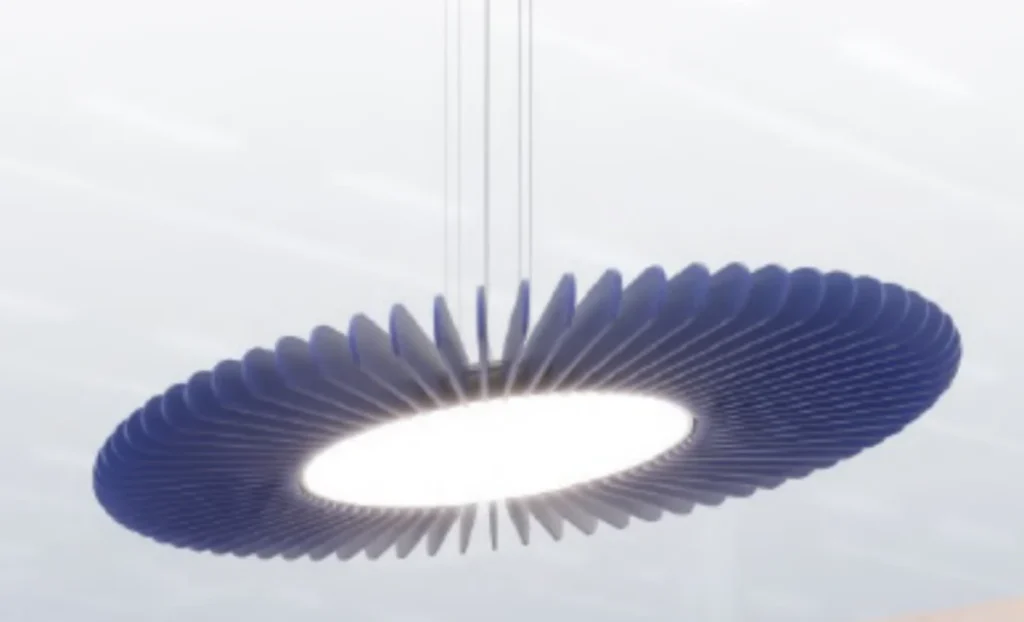

The client envisioned a blue, ultra-slim, elongated circular acoustic LED pendant light that would integrate seamlessly into the contemporary office interior. Beyond its lighting function, the fixture was expected to act as an acoustic element, helping reduce ambient noise in open working areas. The design language emphasized minimal thickness, clean curves, and a refined suspended appearance, making both lighting performance and structural engineering equally critical from the outset.

Challenge 1 – Limited Reference Information

One of the first challenges was the lack of technical reference. The client had only seen a similar product at a local trade show and could provide images without any specifications. There were no drawings, material details, or performance data available. As a result, the development process had to begin with visual analysis, reverse engineering, and multiple rounds of clarification to align expectations regarding dimensions, thickness, lighting output, and acoustic performance.

Challenge 2 – Large Diameter with a Slim Profile

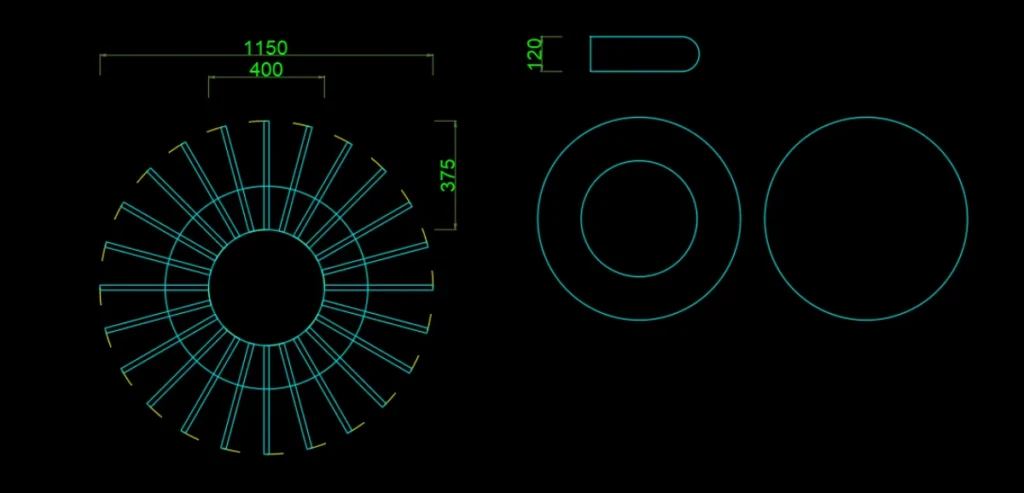

The requested fixture diameter exceeded one meter, while the overall structure needed to remain slim and lightweight. This posed clear challenges related to structural stability, weight distribution, and long-term durability. Careful evaluation was required to ensure that the aluminum frame, suspension system, and internal structure could maintain rigidity and balance without deformation, while still achieving the elegant visual effect desired by the client.

Challenge 3 – Hidden Power Supply Integration

The client also required the power supply to be fully concealed inside the luminaire body, eliminating the need for external driver boxes. This significantly increased design complexity, particularly in terms of internal space allocation, heat dissipation, and future maintenance. The internal layout had to be carefully engineered to ensure reliable operation without affecting the fixture’s slim appearance.

Challenge 4 – Customized Acoustic Material Color

In addition to lighting and structure, the client requested a custom blue acoustic felt color that aligned with the project’s interior branding. This introduced further complexity in material sourcing and color consistency, while still needing to meet acoustic performance requirements and avoid delays in production.

Our Service Approach and Customized Solution

Following the initial inquiry, we engaged in more than ten days of intensive communication with the client through emails and video meetings. During this period, we shared references from similar acoustic lighting projects, evaluated structural feasibility, and clarified design expectations in detail. To address the acoustic requirements, we provided sound absorption test reports for the acoustic material, clearly demonstrating its performance data. Through multiple rounds of proposal refinement, drawing updates, and technical discussions, the client gradually gained confidence in the solution and ultimately confirmed the final design.

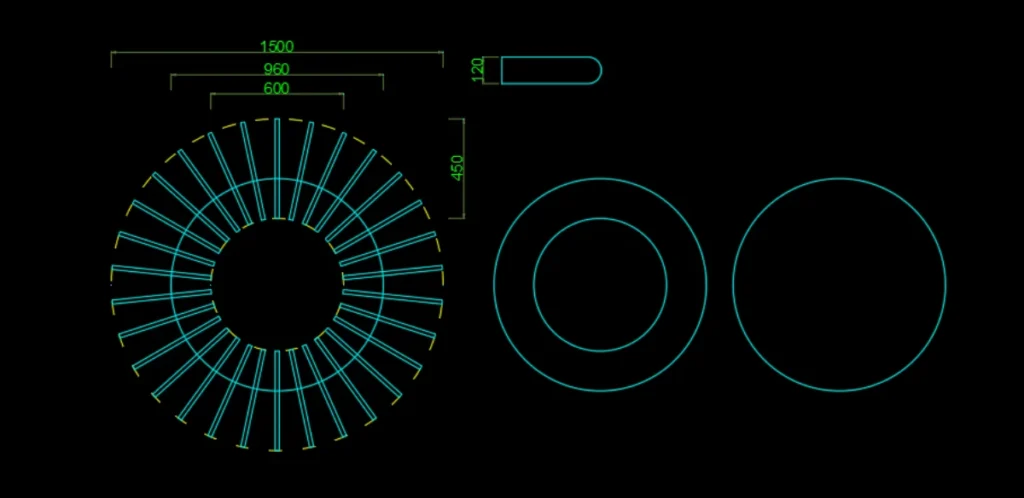

Fixture Geometry and Dimensions

To match the architectural scale of the office space, the final solution included two circular acoustic pendant models with diameters of 1150 mm and 1500 mm, both maintaining a consistent thickness of 120 mm. This ensured visual consistency across different areas while preserving a slim, modern appearance—even at large diameters.

Modular Structure for Efficient Logistics

To reduce shipping costs and simplify handling, the fixture was designed with a DIY-style modular structure. The luminaire could be assembled on site, significantly reducing packaging volume and transportation costs. This approach also improved flexibility for storage and installation, especially for large-scale office projects.

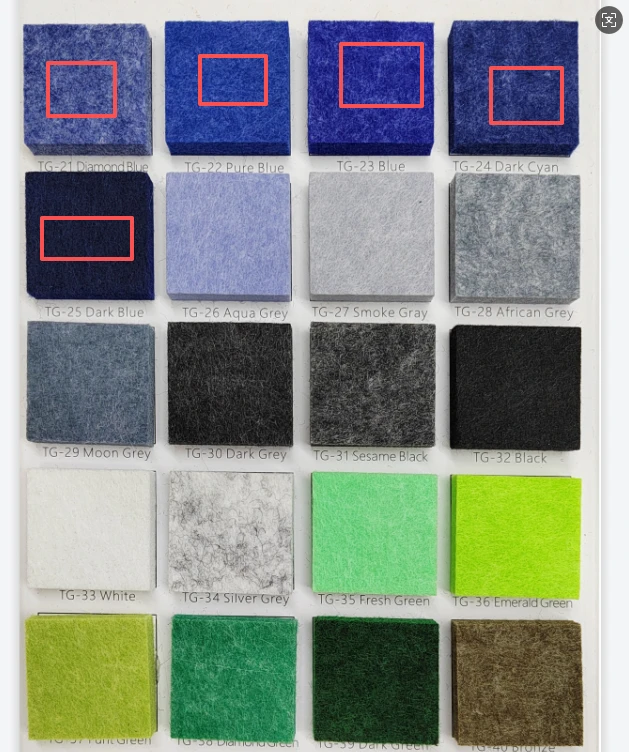

Color Selection and Acoustic Material

While a fully customized blue acoustic felt was initially considered, project timelines played an important role in decision-making. After reviewing multiple options from our existing color range, the client selected TG-24 Dark Cyan, which matched the interior design requirements while ensuring material availability and stable production lead times.

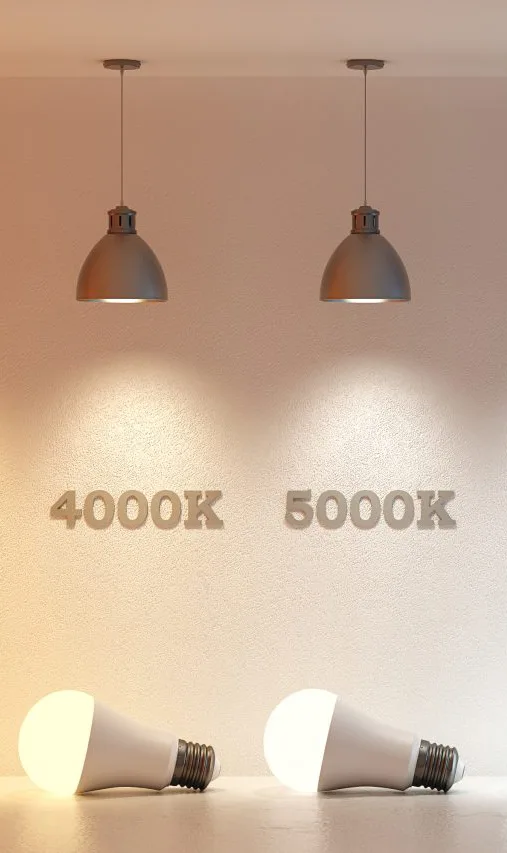

Lighting Performance and Visual Comfort

From a photometric standpoint, the fixture was configured with 40W power consumption, 4000K color temperature, CRI Ra90, and a high efficacy of 130 lm/W. The optical design provided uniform illumination with UGR < 25, ensuring visual comfort suitable for long working hours without glare or uneven light distribution.

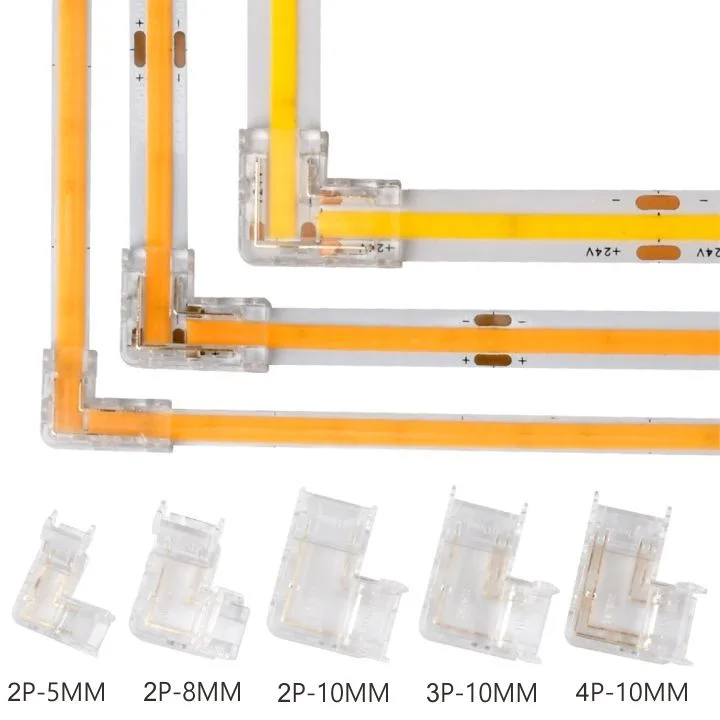

Integrated DALI Driver Design

A DALI dimmable driver was fully integrated into the lamp body to maintain a clean and uninterrupted circular profile. The internal layout was optimized to balance heat dissipation, accessibility, and aesthetics, allowing the power supply to remain invisible while ensuring reliable performance and seamless integration with the building’s lighting control system.

Project Results and Client Feedback

Supported by our mature production process and stable supply chain, the customized acoustic LED pendant lights were completed and delivered within 5–7 days, fully meeting the client’s project schedule. After receiving the products, the client successfully completed the on-site assembly with our guidance. The modular design allowed easy installation without specialized tools or professional installers.

The client expressed strong satisfaction with both the design and usability, commenting:

“The design looks really nice, and it’s very easy to assemble. You don’t need professionals—you can DIY it yourself.”

Following this successful trial, the client is now evaluating final quantities and potential design variations for the full project and plans to proceed with further procurement once the assessment is finalized.

まとめ

Why do professional buyers choose to work with us?

This project highlights our strengths in engineering-driven lighting solutions. From concept development to final delivery, our process emphasizes efficiency, clarity, and reliability. We provide engineering evaluations and quotations within 24 hours, support non-standard, large-size acoustic luminaire customization, and maintain transparent, engineering-oriented communication with clear drawings and specifications. Most importantly, once an order is confirmed, we ensure reliable delivery within 5–7 days, helping clients reduce uncertainty and project risk. For professional buyers, saving time, minimizing trial and error, and maintaining control over outcomes matter far more than price alone.

Behind every order is a foundation of trust. We believe long-term partnerships are built on professionalism, efficiency, and respect for details. If you are looking for customized acoustic LED lighting, large-scale non-standard pendant solutions, or a manufacturing partner that can be deeply involved from the design stage, SignliteLED is ready to help turn your ideas into reliable, deliverable products.