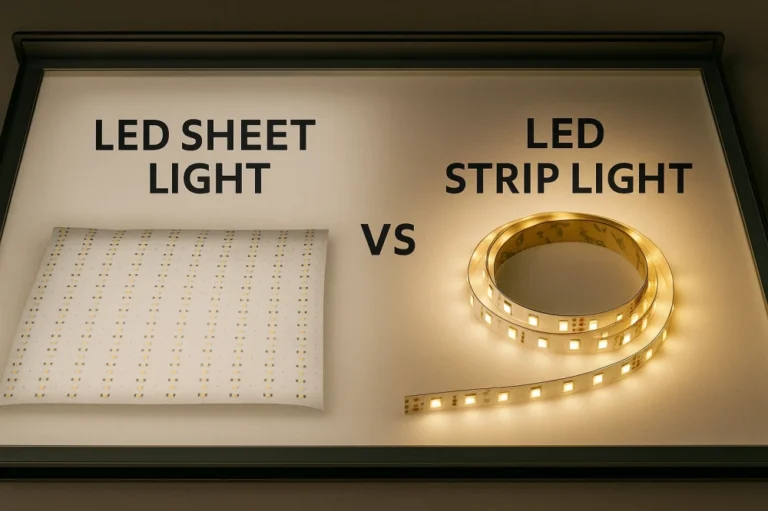

건축 백라이트는 호텔 로비와 기업 사무실에서 박물관 갤러리 및 소매 쇼케이스에 이르기까지 공간을 풍부하게 하는 현대적인 디자인의 특징이 되었습니다. 조명 옵션 중에서 LED 시트 조명- LED 조명 시트, LED 시트 모듈, LED 라이트 시트 패널 또는 LED 라이트 보드라고도 하는 - 맞춤형 건축 조명을 위한 우아하고 유연한 솔루션으로 두드러집니다. 기존의 LED 패널 조명과 달리 이 초박형 및 유연한 LED 시트 패널은 고밀도 레이아웃과 균일한 밝기 LED 시트를 결합하여 원활한 조명을 보장합니다. 최소한의 두께, 절단 가능한 LED 시트 조명 및 적응형 형태는 디자이너와 계약자가 질감이 있는 벽을 밝히거나, 돌이나 유리를 밝히거나, 간판 조명 설치에 통합하는 등 창의적인 비전을 실현할 수 있도록 합니다.

LED 시트 조명은 무엇이며 어떻게 작동합니까?

LED 시트 조명은 무엇입니까?

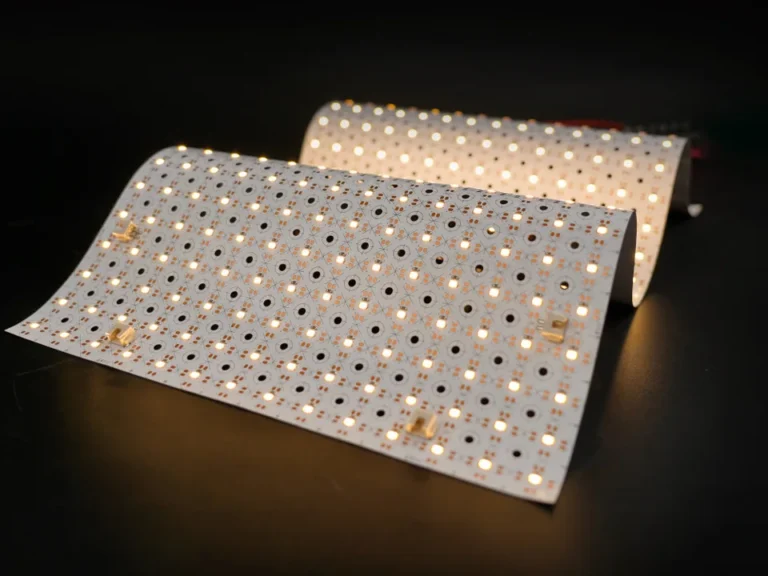

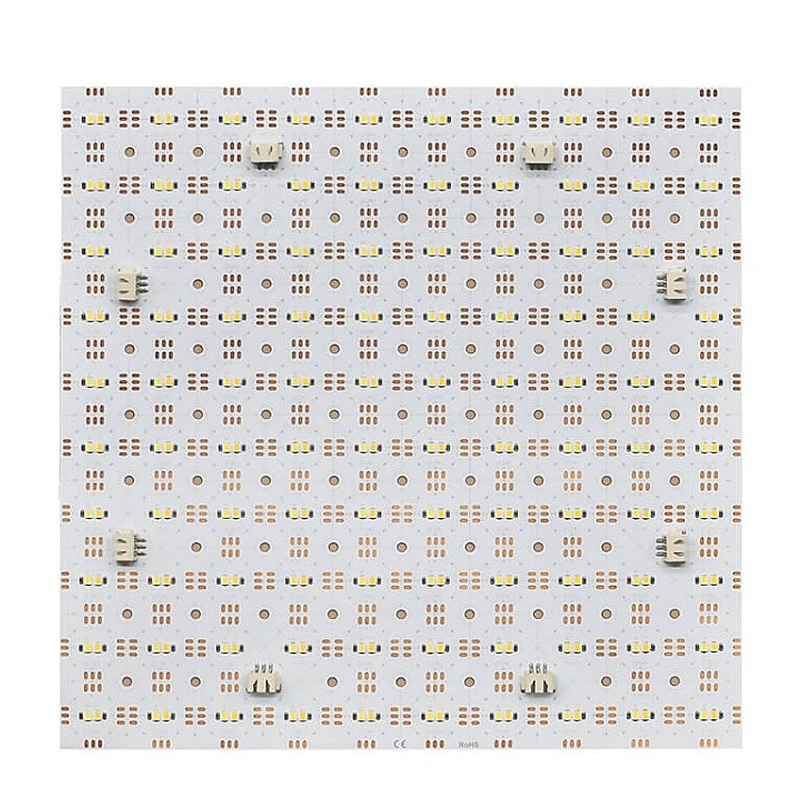

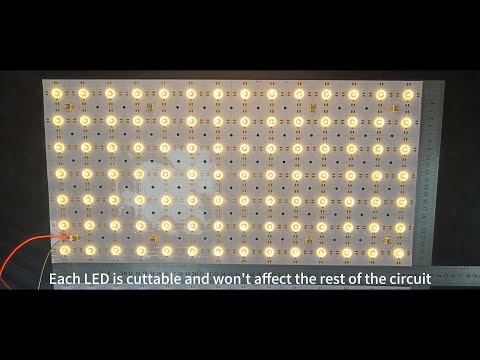

LED 시트 조명은 평평한 PCB 보드에 LED 칩이 장착된 유연한 LED 시트 패널로 설계된 초박형 LED 시트입니다. 이 구성을 통해 고밀도 LED 시트로 작동하여 전체 표면에 걸쳐 균일한 밝기 LED 시트 성능을 제공합니다. 각 패널은 표시된 격자선 덕분에 절단 가능한 LED 시트 조명으로 작동할 수 있으므로 불규칙한 건축 모양에 이상적입니다. 간판용 백라이트 LED 시트 패널, 유리 및 석재 표면용 LED 라이트 보드 또는 벽 기능의 LED 시트 모듈로 사용되든, 이 제품은 건축가와 디자이너에게 다용도 백라이트 솔루션을 제공합니다.

LED 시트 조명은 어떻게 작동합니까?

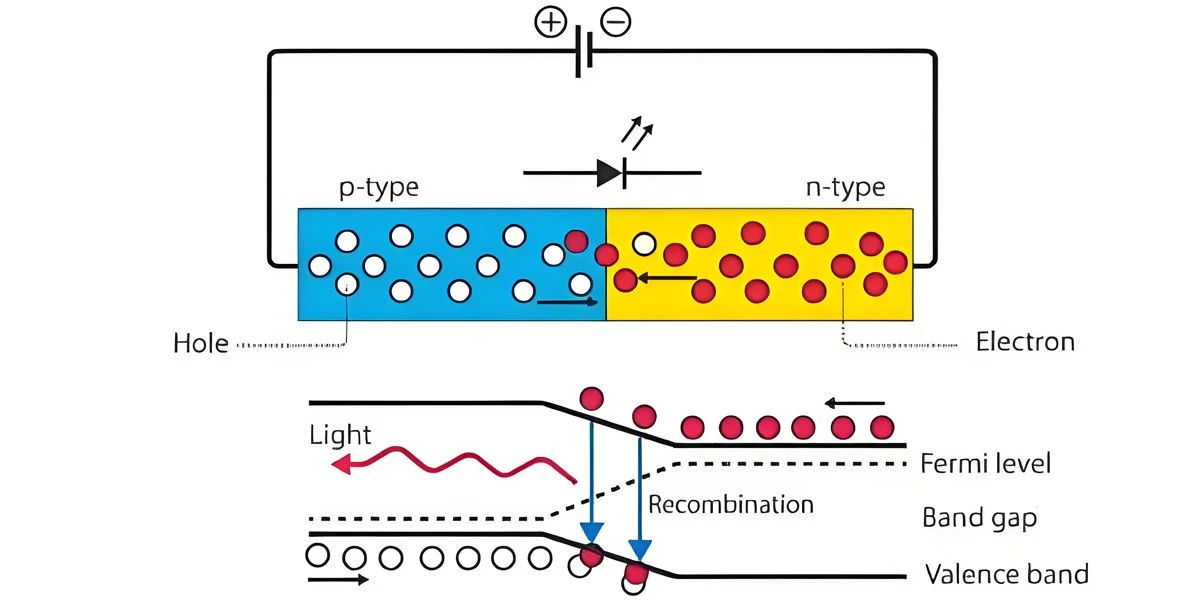

LED 시트 조명은 전계 발광 원리에 따라 작동합니다. 각 LED 칩은 두 개의 층으로 만들어진 반도체 다이오드입니다.

N형 반도체(전자가 풍부)

P형 반도체(양전하를 띤 구멍이 풍부)

전류가 다이오드를 통해 흐를 때 전자는 n형 측에서 p형 쪽으로 이동하고 p-n 접합에서 구멍과 재결합합니다. 이 재결합은 광자 - 가시광선의 형태로 에너지를 방출합니다.

시트에서 수백 개의 이러한 작은 다이오드가 격자에 배열되어 표면 전체에 빛을 고르게 퍼뜨립니다. 디퓨저 또는 반사 레이어와 결합된 이 디자인은 눈부심, 그림자 또는 고르지 않은 밝기 없이 균일한 백라이트를 보장합니다. 이는 정면 조명, 천장 설치 및 로고 간판의 핵심 요구 사항입니다.

LED 시트 조명이 작동하는 방식: 전자와 정공이 P-N 접합에서 재결합하여 에너지를 빛으로 방출합니다.

LED 시트의 종류

단색 LED 라이트 시트

2700K 웜 화이트에서 6500K 순백색까지 제공되는 이 LED 시트 모듈은 벽 액센트, 주변 조명 및 로고 백라이트에서 일반적으로 사용됩니다. 고밀도 레이아웃(3500+ LED/m²)은 핫스팟 없이 부드러운 조명을 보장합니다.

단색 LED 라이트 시트

크기(L x W): 250mm x 250mm/490mm x 245mm

LED 유형: 2835 SMD

LED 수량: 100pcs/242pcs

작동 전압: DC 24V

전력: 12W/28W

색상: 2700K/3000K/4000K/6000K

광속: 1200lm/m/2800lm/m

CRI: >80ra

최소 절단 길이: 25mmx25mm /22.3mmx22.3mm

디밍 가능: 예

빔 각도: 120°

조정 가능한 흰색 LED 시트

이 유연한 LED 시트 패널은 2700K에서 6500K까지 조정 가능한 CCT를 지원하며, 인간 중심의 조명 개념에 맞춰 조정됩니다. 사무실, 호텔 및 주거 공간에서 사용되는 이들은 분위기와 시간 요구 사항을 조정합니다.

조정 가능한 흰색 LED 시트

크기 ( LXH ): 250mmx 250mm/ 490mmx245mm

LED 유형: 2835 SMD

LED 수량: 200pcs/484pcs

작동 전압: DC 24V

전원: 16W/40W

색온도 조절 가능 범위: 2700K – 6500K

광속: 1600LM/M/3800LM/M

연색지수: >90RA

최소 절단 길이: 25mmx25mm/22.3mm x22.3mm

디밍 가능: 예

빔 각도: 120°

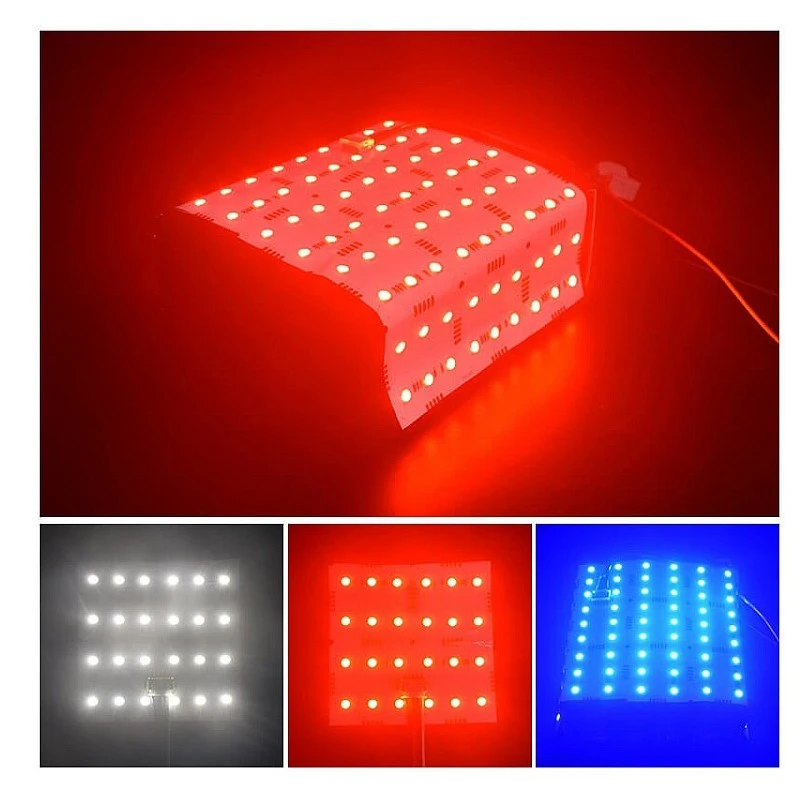

RGBW LED 시트 조명

RGB 색상 믹싱과 전용 화이트 채널을 결합한 이 LED 시트 조명은 장식 효과와 기능적인 흰색 조명을 모두 제공합니다. 전시, 엔터테인먼트 장소 및 축제 조명 프로젝트에 널리 적용됩니다.

RGBW LED 시트 조명

크기(LxW): 250mmx250mm/490mmx250mm

LED 유형: 5050 RGBW 4 in 1 SMD LED

LED 수량: 150LED/288LED

작동 전압: DC 24V

전원: 24W/48W

발광 색상: RGB + 따뜻한 흰색(3000K), RGB + 자연적인 흰색(4000K), RGB + 멋진 흰색(6000K)

빛 효율: 90lm/w

최소 절단 길이: 50mmx50mm/20.4mm x122.5mm

빔 각도: 120°

디밍 가능: 예

주소 지정 가능한 LED 시트

이 커팅 가능한 LED 시트 조명을 통해 디자이너는 애니메이션과 패턴을 프로그래밍할 수 있습니다. DMX512 또는 SPI 컨트롤러와 통합되어 있어 미디어 벽, 테마 외관 및 대화형 간판 프로젝트에 이상적입니다.

주소 지정 가능한 LED 시트

크기(LxW): 250mmx250mm

LED: 100개 5050 SMD

IC 유형: 내장 WS2812

IC 수량: 100개

색상: Rgbic

작동 전압: DC 12V

현재: 1.08A

전원: 13W

광속: 20LM/LED

파장: 620-625nm(빨간색), 520-525nm(녹색), 465-470nm(파란색)

빔 각도: 120°

건축 백라이트의 주요 기능

아키텍처 백라이팅 프로젝트를 설계할 때 LED 시트 조명은 다음과 같은 주요 이점을 제공합니다.

- 좁은 건축 공간에 신중한 설치를 위한 초박형 LED 시트.

- 절단 가능한 LED 시트 조명은 불규칙한 모양에 현장 유연성을 제공합니다.

- 균일한 밝기 LED 시트는 핫스팟 없이 매끄러운 빛을 보장합니다.

- 수명이 긴 에너지 효율적인 설계(50,000시간 이상).

- 조정 가능한 흰색, RGBW 및 단색 LED 시트 패널을 포함하여 여러 옵션을 사용할 수 있습니다.

이러한 특성으로 인해 유연한 LED 시트 패널은 내부 및 외부 건축 백라이팅 프로젝트 모두에 큰 영향을 미치는 솔루션입니다.

엘리베이터 인테리어

엘리베이터 내부에서는 공간이 제한되어 있고 눈부심이 일반적인 문제입니다. 초박형 LED 시트는 캐빈 공간을 줄이지 않고 유리 또는 스테인리스 스틸 패널 바로 뒤에 설치할 수 있습니다. 균일한 밝기 LED 패널은 그림자를 제거하여 호텔과 오피스 타워의 엘리베이터를 현대적이고 세련된 느낌으로 제공하면서 에너지를 절약합니다.

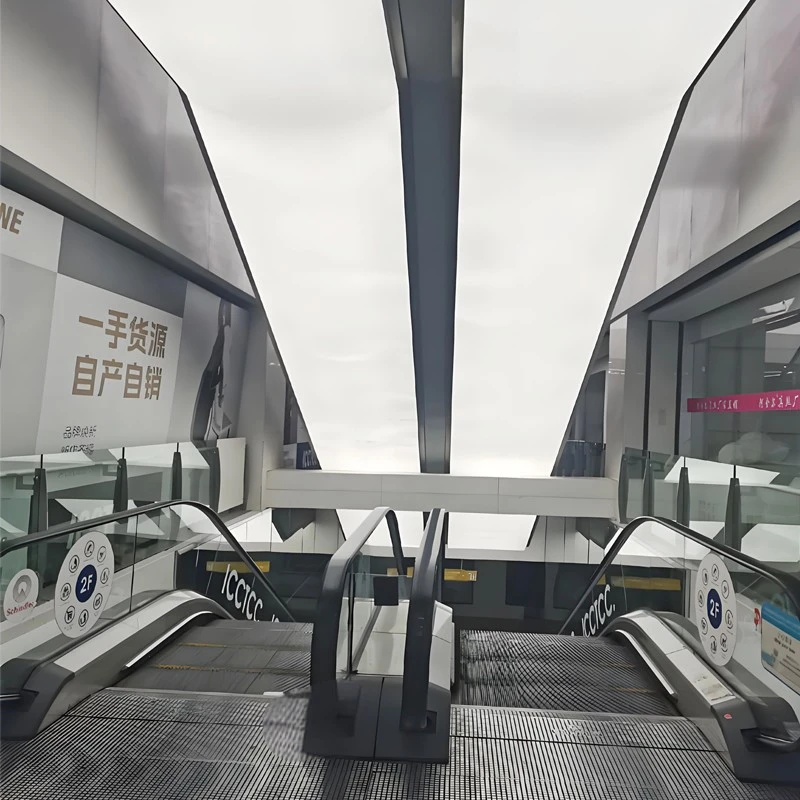

호텔 및 사무실 로비

호텔과 사무실 로비는 대규모의 매끄러운 조명을 요구합니다. 대리석 벽, 젖빛 유리 또는 천장 기능 뒤에 백라이트가 있는 유연한 LED 시트 패널은 넓은 영역 전체에 걸쳐 일관된 밝기를 만듭니다. 호텔의 경우 고급스럽고 따뜻함을 제공하며, 기업 사무실의 경우 전문성과 브랜드 이미지를 강화합니다.

유리 및 돌 표면

반투명 대리석, 오닉스 또는 절단 가능한 LED 시트 조명이 있는 젖빛 유리는 깊이와 우아함을 향상시킵니다. 고밀도 LED 시트 보드는 단단한 모듈과 달리 넓은 표면에서 균일한 밝기를 보장하므로 고급 소매점, 호텔 바 및 주거용 벽에 이상적입니다.

간판 및 로고

브랜드 간판 및 로고의 경우 LED 조명 시트는 핫스팟 없이 선명하고 균일한 백라이트를 제공합니다. 유연한 LED 시트 모듈은 불규칙한 모양에 맞아 소매점, 공항 및 기업 브랜딩 프로젝트에서 선호하는 선택입니다.

LED 시트 조명 설치 및 모범 사례

표면 준비 및 절단

장착하기 전에 항상 유리, 금속 또는 아크릴 패널을 철저히 청소하여 먼지와 오일을 제거하여 LED 시트 모듈의 강력한 접착력을 보장합니다. 트리밍 시 정밀 도구를 사용하여 절단 가능한 LED 시트 조명의 지정된 절단선만 절단하여 회로 무결성을 보호하고 가장자리 손상을 방지합니다.

장착 방법(접착식, 나사, 자석)

대부분의 유연한 LED 시트 패널에는 빠른 "필 앤 스틱" 설치를 위해 산업용 등급의 접착제(예: 3M VHB)가 함께 제공됩니다. 영구 또는 구조적 용도의 경우 나사로 보강하고 이동식 시스템의 경우 마그네틱 마운팅이 옵션입니다. 항상 장착 표면이 약간의 팽창을 허용하여 안정성을 유지해야 합니다.

전원 연결 및 배선

소규모 프로젝트의 경우 솔더리스 커넥터를 사용하면 빠른 플러그 앤 플레이 통합이 가능합니다. 맞춤형 설치의 경우 구리 패드에 와이어를 납땜하면 안정적인 설정이 보장됩니다. 항상 드라이버를 LED 라이트 보드의 전압(12V 또는 24V DC) 및 전력 요구 사항과 일치시켜 최소 20% 전원 헤드룸을 남겨두십시오.

장시간 작동의 경우 병렬 연결 또는 추가 전원 공급 장치를 사용하여 전압 강하를 방지하고 여러 LED 시트 조명에서 일관된 밝기를 유지하십시오.

최종 설치 전 시스템 테스트

항상 프로토타입을 먼저 만들려면: LED 시트 패널, 컨트롤러 및 전원 공급 장치를 연결한 다음 밝기와 정확한 색상을 확인합니다. 패널을 영구적으로 고정하기 전에 Dimmers 또는 DMX 시스템과의 호환성을 확인하십시오.

일반적인 문제 해결

- 과열: 환기 및 올바른 전압을 보장합니다.

- 불완전한 조명: 극성과 커넥터 안정성을 확인하십시오.

- 고르지 않은 밝기: 전압 강하로 인한 - 병렬 배선 또는 분산 전력으로 해결.

LED 시트 조명을 자르고, 전원을 연결하고, 유연한 LED 시트 패널을 설정하는 방법을 포함한 단계별 설치 자습서를 보려면 다음을 참조하십시오. LED 시트 조명을 자르고 설치하고 설정하는 방법.

건축 프로젝트에 대한 구매자 팁

프로젝트 요구 사항을 명확하게 정의

LED 시트 조명을 선택하기 전에 프로젝트의 백라이트 목표를 설명합니다. 목표 장식적인 분위기, 기능적 균일성 또는 브랜드 로고가 강조 표시되어 있습니까? 밝기 수준(와트당 루멘), 색온도(2700K–6500K) 및 CRI 요구 사항(호스피탈리티 및 소매 프로젝트의 경우 ≥90)을 명확히 합니다. 이러한 기준을 조기에 정의하면 불일치를 방지하고 건축 조명 프로젝트에 원활하게 통합할 수 있습니다.

공급업체 역량 평가

건축 백라이트에서 입증된 실적을 가진 신뢰할 수 있는 LED 시트 조명 공급업체를 선택하십시오. 그들이 다음을 제공하는지 평가하십시오.

- 완전한 사양을 갖춘 기술 데이터시트.

- 안전 및 품질 준수를 위한 LM-80, CE, RoHS 또는 UL 인증.

- 유사한 대규모 외관 또는 로비 프로젝트의 참조.

OEM/ODM 기능을 갖춘 공급업체는 사전 절단 패널 또는 맞춤형 레이아웃과 같은 맞춤형 백라이팅 솔루션을 제공할 수도 있습니다.

비용 대 수명 주기 값 비교

초기 비용이 중요하지만 장기적인 가치는 에너지 효율성, 보증 및 예상 수명에 따라 결정됩니다. 수명 50,000시간 이상 및 3~5년 보증이 적용된 시트 라이트는 처음에는 비용이 더 많이 들 수 있지만 접객 또는 상업 프로젝트에서 유지 보수 빈도와 다운타임을 줄입니다. 구매 가격뿐만 아니라 총 소유 비용(TCO)을 평가합니다.

설치 및 판매 후 지원 확인

건축 프로젝트는 종종 곡선형 벽, 좁은 만 또는 불규칙한 천장 디자인과 같은 복잡한 설치 조건에 직면합니다. 공급업체가 명확한 설치 매뉴얼, 배선도 및 기술 지원을 제공하는지 확인합니다. 결함이 있는 시트를 신속하게 교체하거나 원격 문제 해결과 같은 애프터 서비스는 계약자에게 상당한 시간을 절약하고 프로젝트 마감일을 준수할 수 있습니다.

확장성 및 사용자 정의 고려

호텔 체인, 오피스 타워 또는 쇼핑몰의 경우 확장성이 필수적입니다. 공급업체가 대량 주문, 일관된 배치 품질 및 사용자 정의 레이아웃을 처리할 수 있는지 확인합니다. 커팅 가능한 LED 시트 패널, 모듈식 연결, 넓은 표면에서의 균일한 밝기와 같은 기능은 다중 사이트 롤아웃에서 특히 유용합니다.

기술 사양, 설치 옵션 및 프로젝트 계획 조언에 대한 자세한 내용은 다음을 참조하십시오. 프로젝트 및 구매자를 위한 LED 시트 조명 완전한 가이드.

결론

LED 시트 조명은 건축 백라이트 프로젝트를 위한 혁신적인 솔루션이 되어, 타의 추종을 불허하는 유연성, 일관된 조명 및 복잡한 표면에 대한 적응성을 제공합니다. 호텔 로비와 사무실 천장에서 브랜드 벽과 엘리베이터 인테리어에 이르기까지 이 초박형 패널은 디자이너와 계약자 모두에게 새로운 창조적 가능성을 열어줍니다.

프로젝트 관리자와 건축가에게 올바른 LED 시트 조명 공급자를 선택하는 것은 제품 자체만큼 중요합니다. 신뢰할 수 있는 파트너는 높은 CRI, 긴 수명, 인증 등의 기술적 우수성뿐만 아니라 원활한 설치 지원과 장기적인 가치를 보장합니다.

대규모 백라이트 프로젝트를 계획하고 있고 맞춤형 LED 시트 조명 솔루션을 찾고 있다면 Signlitered가 귀하의 비전을 지원할 준비가 되어 있습니다. 당사의 제품은 내구성, 정밀도 및 에너지 효율성을 위해 설계되어 국제 건축 조명 프로젝트에 신뢰할 수 있는 선택입니다.

사양, 사용자 정의 옵션에 대해 논의하거나 향후 프로젝트에 대한 맞춤형 견적을 요청하려면 오늘 Signaled에 문의하십시오.