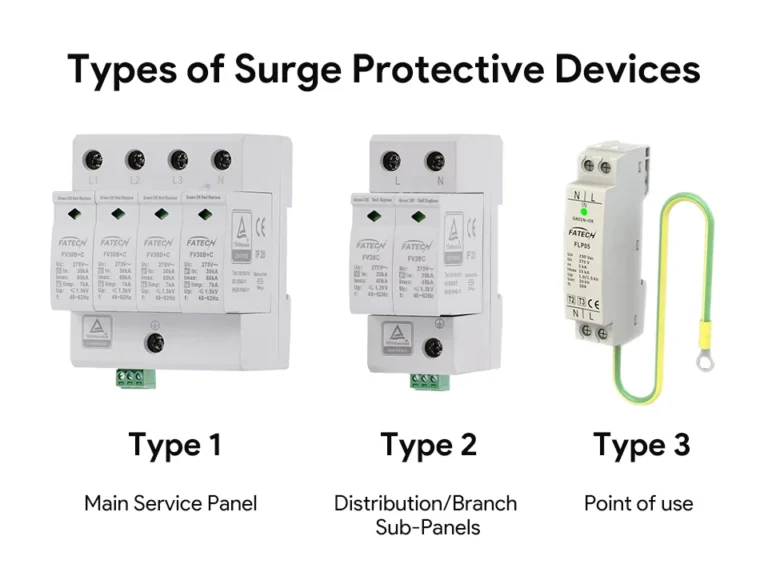

For most three-phase industrial panels, the best choice is usually a Type 2 surge protection device installed at the panel (distribution level), coordinated with upstream protection and good grounding. A 유형 1 unit becomes the better choice at the 서비스 입구 when incoming surge exposure is high, while 유형 3 devices are mainly for sensitive endpoints and are not the primary option for panel protection.

This article will discuss how to choose the right SPD type for a three-phase industrial panel, what practical factors matter most, and how installation details affect real-world performance.

What “Best” Means for a Three-Phase Industrial Panel

In industrial power systems, “best” does not mean “largest” or “highest rating.” It means the device and installation approach that delivers repeatable surge limiting under real operating conditions.

For a three-phase panel, “best” typically means:

- Reliable operation under frequent switching events

- Coordinated protection between main and downstream panels

- Repeatable performance over many surge events (not just one big event)

- Maintainability, including clear status indication and practical replacement

- Effective handling of switching surges from motors, contactors, and VFD-driven loads

A practical solution must fit the panel’s electrical topology and be installable with short, low-inductance connections.

Surge Sources Common in Industrial 3-Phase Panels

Industrial surges are often created inside the facility, not only from lightning. Even when there is no storm activity, switching operations can generate fast transient overvoltages that stress drives, PLC power supplies, control transformers, and instrumentation.

Common surge sources include:

- Motor switching (across-the-line starts, contactor operations, overload trips)

- VFD activity (rapid switching edges, DC bus interactions, braking events)

- 커패시터 뱅크 스위칭 and power factor correction steps

- Utility disturbances (fault clearing, reclosing, feeder switching)

- Long cable runs that behave like antennas and increase coupling of transients

A key point in industrial environments is repetition: small and medium surges can occur many times per day.

Typical surge contributors in factories include:

- Switching of large inductive loads (motors, solenoids, cranes)

- VFD input switching and drive line-side events

- Transformer energization and inrush-related transients

- Utility feeder switching and fault-clearing operations

- Long feeders to remote MCCs or sub-panels

Type 2 SPD: The Most Practical Choice for Industrial Panels

A 유형 2 서지 보호 장치 is generally the most practical option for three-phase industrial panels because it is designed for distribution-level installation and for handling repetitive switching transients.

In real industrial panels, the most frequent problem is not a single extreme surge, but a long series of smaller transients. Type 2 devices are commonly selected for this duty because they are intended to clamp surges that appear at the panel bus and protect multiple downstream branch circuits.

Why Type 2 is usually the best fit at the panel

A Type 2 unit installed at the panel can:

- Protect multiple loads connected downstream of the panel

- Reduce stress on control power supplies, PLC I/O modules, and instrumentation

- Help stabilize transient voltage levels that cause nuisance trips or controller resets

- Provide a practical protection layer in MCCs, distribution panels, and machine panels

Practical installation notes that affect performance

For panel-level protection, the device selection matters, but the wiring layout often matters more.

Placement near busbars:

A panel SPD performs best when connected as close as possible to the phase bus and neutral/ground bar connection points. Long wire length increases inductive voltage drop during a fast surge.

Short leads:

The shorter and straighter the conductors, the lower the effective impedance during a surge. Excess conductor length can significantly raise the let-through voltage seen by equipment.

Grounding and bonding quality:

Even a high-quality surge protection device will perform poorly if the panel grounding and bonding are inconsistent, loose, or routed through long paths.

Type 2 is also typically easier to coordinate across multiple panels: one at the main distribution point, then additional units at downstream sub-panels feeding sensitive loads.

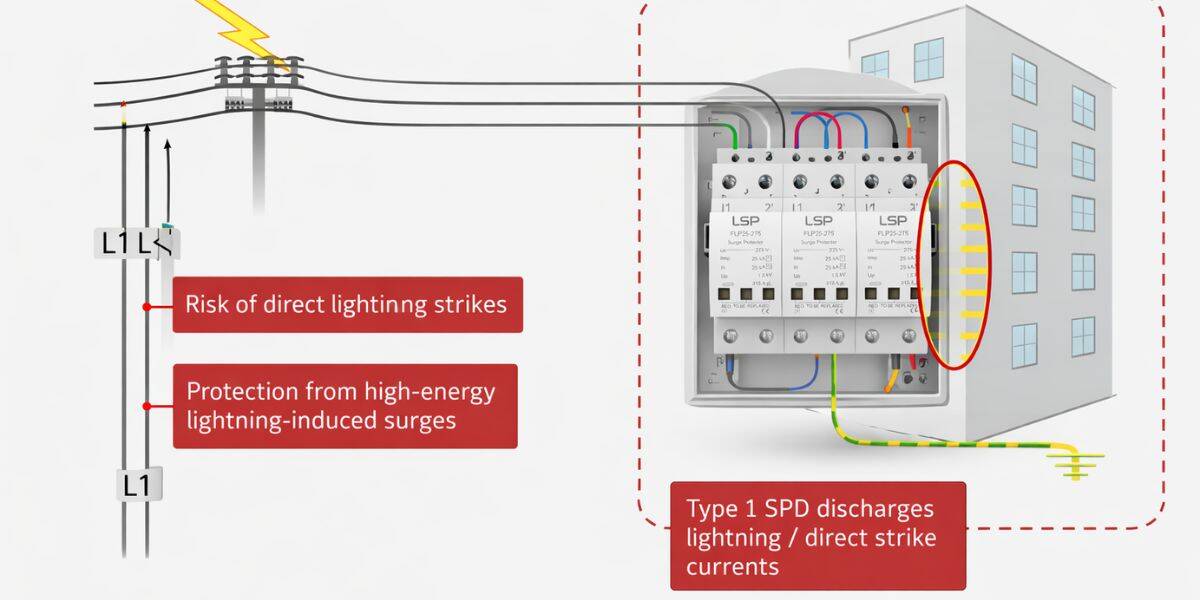

When a Type 1 SPD Becomes the Better Choice

A 유형 1 서지 보호 장치 becomes the better choice when the installation point is at the 서비스 입구 or the facility has high exposure to incoming surges. This can occur in plants with overhead utility lines, long service conductors, outdoor equipment, or frequent utility switching activity.

Type 1 devices are commonly used where the surge energy arriving at the building service is higher and where protection is needed before downstream distribution wiring spreads the surge through the facility.

Service entrance exposure and incoming surge energy

At the service entrance, surges can be higher in magnitude and energy. This is the location where a facility may want the most robust “first line” of protection.

However, installing a Type 1 device at the service entrance does not eliminate the need for Type 2 units in distribution panels. The goal is coordination, not a single-device strategy.

Coordination with Type 2

A common industrial approach is:

- Type 1 at service entrance (incoming protection layer)

- Type 2 at major distribution panels and MCCs (equipment-level protection layer)

This reduces the surge stress at the main entry point and further limits transients near the loads.

A Type 1 device is typically the better choice when:

- The SPD is installed at the service entrance or main disconnect location

- The site has overhead supply lines or frequent storm exposure

- There are long service conductors feeding the main switchboard

- The facility experiences repeated utility switching disturbances

- You need a strong upstream layer before downstream distribution protection

Where Type 3 Fits

Type 3 devices are mainly intended for point-of-use protection near sensitive electronics. In industrial settings, they can help protect specific endpoints such as instrumentation power supplies, PLC racks, or communication devices.

They are not a replacement for a 서지 보호 장치 for electrical panel installation. Panel-level protection must be addressed at the distribution point first, because that is where surges enter and propagate to multiple circuits.

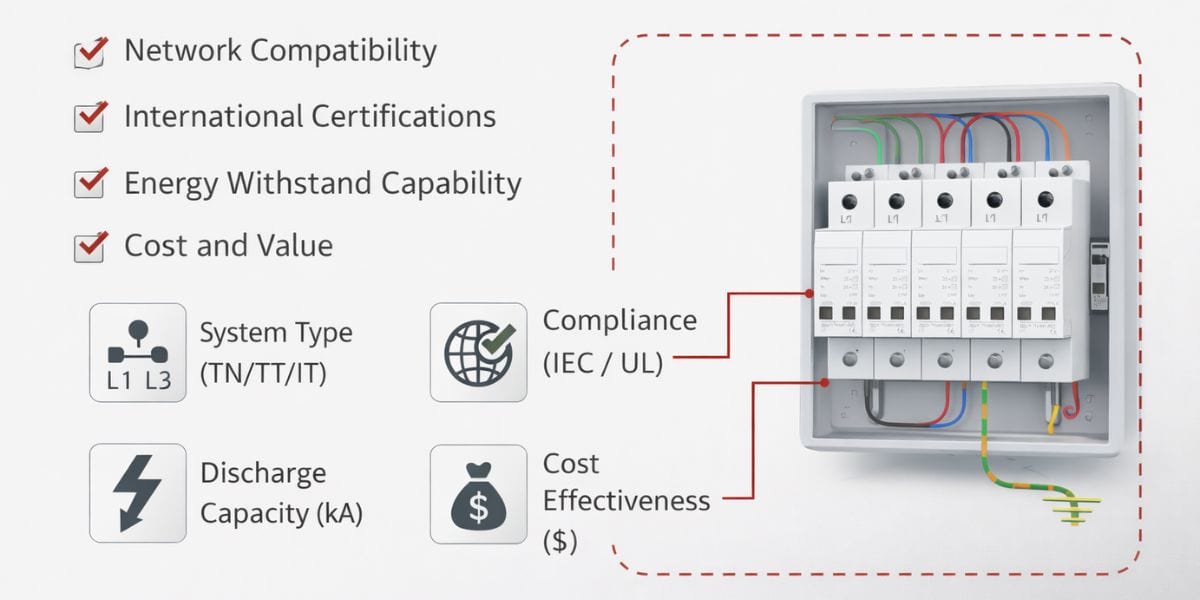

Selection Criteria for the Right 3 Phase Surge Protective Device

This is the most important section because “best” depends on matching the device to the system and installation constraints. A 3상 서지 보호 장치 must be selected based on system topology, expected surge modes, duty cycle, and maintainability.

System voltage and topology (3-wire vs 4-wire)

Start by confirming the distribution configuration:

- 3-wire systems (no neutral): typically delta arrangements

- 4-wire systems (with neutral): typically wye arrangements

This matters because the SPD must be able to address the surge paths present in the system.

Surge modes that matter in three-phase panels

In three-phase panels, surges do not only appear from phase to ground. Common modes include:

- Line-to-line (L–L) surges, especially in three-wire delta systems

- Line-to-ground (L–G) surges, common in grounded systems

- Line-to-neutral (L–N) surges in four-wire systems

A mismatch between SPD configuration and actual surge modes can leave equipment exposed even when a device is installed.

Installation location: main panel vs sub-panel

Where the device is installed changes the stress it sees:

- Main service entrance: higher incoming exposure, more utility-related surges

- Distribution panel / MCC: frequent internal switching surges from motors and drives

- Machine panel: closer to sensitive controls, but limited space and short wiring required

The best overall outcome is usually achieved by placing protection where surges enter 그리고 where sensitive loads are concentrated.

- FDS20C/4-275 클래스 II

- 명칭: 유형2

- 분류: 클래스 II

- 보호 모드: L→PE, N→PE

- 공칭 전압 UN: 230VAC/50(60)Hz

- 최대 연속 작동 전압 UC(L-N): 275VAC/50(60)Hz

- 단락 내성 능력: 20kA

- 연속 작동 전류 IC: <20μA

- 대기 전력 소비 PC: ≤25MVA

- 최대 방전 전류(8/20μs) IMAX: 40kA

- 공칭 방전 전류(8/20μs) 에서: 20kA

- 전압 보호 레벨 업: ≤1.3kV

- 격리 저항: >1000MΩ

- 하우징 재료: UL94V-0

- 보호 정도: IP20

Endurance for frequent switching surges

Industrial panels feeding motors and VFDs often experience repetitive transients. The device should be chosen for durability in that environment, not just for rare extreme events.

A device that performs well in a light commercial setting may not be the best match for a panel that cycles large loads all day.

Monitoring and maintainability

In industrial environments, maintainability matters because protection can degrade over time.

Useful maintainability characteristics include:

- Clear local status indication

- Remote status contacts for alarms (if the facility uses monitoring)

- Practical replacement approach during maintenance windows

Physical wiring constraints and lead length

Surge performance is heavily influenced by wiring geometry:

- Long leads raise let-through voltage

- Loops increase inductive coupling

- Routing alongside noisy conductors can reduce effectiveness

If the panel layout forces long conductor runs, a “better” device on paper may perform worse than a properly installed, well-placed unit.

Core Differences

Below is a practical comparison focused on industrial panel decision-making.

| Feature / Criteria | 유형 1 서지 보호 장치 | 유형 2 서지 보호 장치 | Best fit for industrial panels (short answer) |

| Typical installation point | Service entrance / upstream location | Distribution panel / sub-panel / MCC | Type 2 for most panel-level installations |

| Main purpose | First-line defense against incoming surges | Practical clamping at the panel bus for downstream circuits | Type 2 for protecting multiple branch circuits |

| Exposure profile | Higher incoming surge energy | High repetition of switching transients | Type 2 for day-to-day industrial switching |

| Coordination role | Upstream layer to reduce stress downstream | Downstream layer near loads | Use both when exposure is high |

| Wiring sensitivity | Still sensitive to lead length, but often installed at main gear | Very sensitive to lead length due to fast transients at panel level | Type 2 requires careful, short wiring |

| 최고의 사용 사례 | High exposure sites, service entrance protection | Most industrial distribution panels | Type 2 is usually the primary choice |

This table reflects why a Type 2 device is typically the default choice for industrial panels, while Type 1 becomes the preferred option at the service entrance or in high-exposure environments.

설치 모범 사례

Installation quality can decide whether a surge protection device performs as expected. A well-selected device with poor wiring can allow higher transient voltage to reach equipment.

Keep conductors short and direct

Short conductors reduce inductive voltage rise during fast surge events. In practical terms:

- Avoid extra slack or long routing paths

- Use the closest practical connection points

- Keep phase and return paths physically close

Avoid loops and unnecessary bends

Large loops behave like inductors and raise effective impedance during fast transients. Tight, clean routing helps the device clamp surges faster and lower.

Bonding and grounding integrity

A panel SPD depends on a low-impedance path to the reference point (ground/neutral depending on system design). Loose lugs, paint under bonding points, or long bonding jumpers reduce performance.

Correct connection point

Connect as close as possible to the panel bus and grounding/neutral bars, not at the far end of branch wiring.

Coordination with upstream and downstream protection

Industrial facilities often benefit from staged protection. Upstream protection reduces incoming stress; downstream protection limits local switching transients near critical loads.

Panel-level installation best practices include:

- Mount the SPD close to the phase bus connection points

- Keep leads short, straight, and tightly routed

- Avoid routing SPD conductors alongside high-noise power cables

- Ensure solid bonding and correct termination torque practices

- Coordinate main and downstream SPDs for layered protection

Common Mistakes That Reduce SPD Performance

Many “SPD failures” in industrial sites are not caused by defective devices, but by installation choices that increase let-through voltage or stress the device unnecessarily.

Installing too far from the bus

Distance adds impedance. If the SPD is mounted far away and wired with long conductors, the surge voltage seen at the bus can remain high even though the SPD is operating.

Long wires and large loops

Long conductors and loops act like inductors and resist fast surge current changes. This can cause higher voltage to appear at equipment terminals.

Relying on only one device for the entire facility

A single device at the service entrance may not adequately protect distant sub-panels or sensitive loads. Internal switching surges can still occur deep inside the facility.

Ignoring grounding quality

If grounding and bonding are inconsistent, the SPD may not clamp effectively or may create unexpected reference shifts that still stress electronics.

Wrong type selection for the location

Using the wrong device type for the installation point can reduce effectiveness. Service entrance exposure and distribution-level switching environments are different stress profiles.

Common mistakes that reduce performance include:

- Mounting the SPD far from the panel bus connection points

- Using long, loosely routed conductors with unnecessary slack

- Assuming one SPD protects every sub-panel and machine panel equally

- Overlooking grounding and bonding path quality inside the panel

- Selecting a device type that does not match the installation location

결론

For most three-phase industrial panels, a 유형 2 서지 보호 장치 installed at the panel is usually the best practical choice. A 유형 1 unit is most appropriate at the 서비스 입구 when incoming surge exposure is high, often coordinated with Type 2 protection downstream. In real industrial environments, installation quality and wiring layout often matter more than oversizing the device.

자주 묻는 질문

In many facilities, yes. A Type 2 unit at the distribution panel is often sufficient for routine industrial switching surges, especially when grounding and wiring are done correctly.

Use Type 1 when the service entrance has higher incoming exposure, such as overhead utility feeds, outdoor equipment, or frequent utility switching disturbances.

It helps reduce transient stress on VFD input power and PLC/control power supplies, but it does not eliminate all electrical noise issues. Proper grounding, filtering, and wiring practices still matter.

Not reliably. A single device at the main service can reduce incoming surges, but downstream panels and long feeders can still see significant transients. Layered protection is often more effective.

As close as practical to the phase bus and the grounding/neutral termination points, using short, straight conductors with minimal loops.