Commercial lighting procurement is not a design decision. It is a risk decision. Illumination performance, compliance exposure, operating cost, and long-term maintenance all depend on measurable technical specifications. Marketing summaries are irrelevant at this level.

For B2B buyers, the LED light sheet is the primary validation document. It contains the photometric, electrical, and environmental metrics that determine whether a product will perform as specified once installed.

This guide explains the seven technical specifications that directly affect performance, lifecycle reliability, and project risk when sourcing a LED light sheet or related systems. Each metric can be verified in the technical documentation. Each has measurable commercial benchmarks.

7 Technical Specifications Every B2B Buyer Should Check

1. Luminous Efficacy (lm/W)

Luminous efficacy measures how efficiently electrical power is converted into visible light. It is expressed in lumens per watt (lm/W). This metric is often confused with brightness, but brightness is measured in lumens. Efficacy measures efficiency, not output.

In commercial-grade systems, realistic ranges for an LED light sheet are typically 110–160 lm/W at the system level, depending on driver quality and thermal management. Figures significantly above this range often reflect chip-level laboratory values rather than integrated system performance.

In real installations, efficacy directly affects operating cost and heat load. A sheet operating at 95 lm/W will consume substantially more energy to achieve the same lumen density as one operating at 140 lm/W. Over large retail or signage rollouts, that difference compounds into measurable cost increases.

If ignored, procurement teams risk approving products that meet brightness targets but fail energy modeling assumptions. To verify, check the “System Luminous Efficacy” or “Lumens per Watt” field in the LED light sheet, not just LED chip specifications.

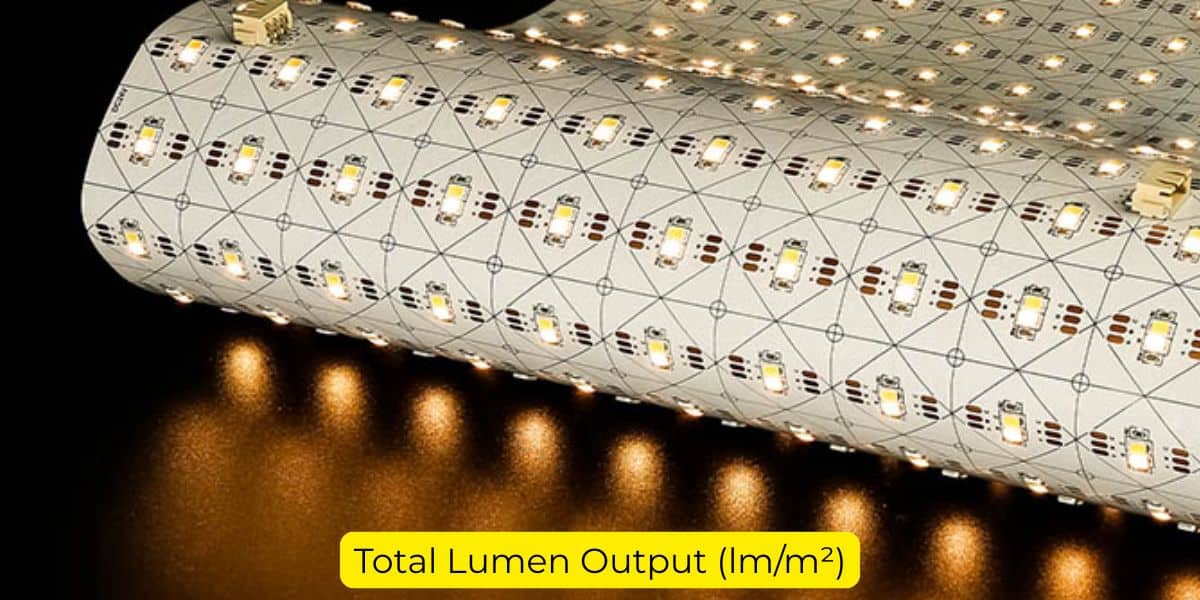

2. Total Lumen Output (lm/m²)

Total lumen output per square meter determines usable brightness density. For sheet-based systems, lumen density is more relevant than total lumens per strip because installation area drives visual performance.

Interior architectural backlighting commonly requires 3,000–6,000 lm/m², depending on diffusion depth. Retail signage and lightbox applications may require 6,000–10,000+ lm/m², especially in high ambient environments. This is where a high brightness LED light sheet becomes necessary.

If lumen density is underspecified, the result is uneven illumination, shadowing behind graphics, or visible hot spots. Overcompensating with additional sheets increases power consumption and wiring complexity.

Verification appears in the LED light sheet under “Total Lumen Output,” “Luminous Flux per Area,” or photometric test results. Buyers should confirm testing distance and measurement conditions.

3. CRI & LED Binning Consistency

Color Rendering Index (CRI) measures how accurately a light source renders colors compared to natural light. For most commercial environments, CRI ≥80 is the baseline. Retail, fashion, and branded environments often require CRI ≥90.

Beyond CRI, binning consistency is critical. LED manufacturers classify diodes into bins based on chromaticity. If bin tolerance is not tightly controlled, multi-site rollouts can show visible color variation between installations.

In real-world deployment, inconsistent binning creates brand inconsistency across store networks. Walls installed months apart may not match visually. That is a procurement failure, not an installation issue.

The LED light sheet should specify CRI value and chromaticity tolerance, often expressed as SDCM (Standard Deviation of Color Matching). A commercial benchmark is ≤3 SDCM for uniform appearance.

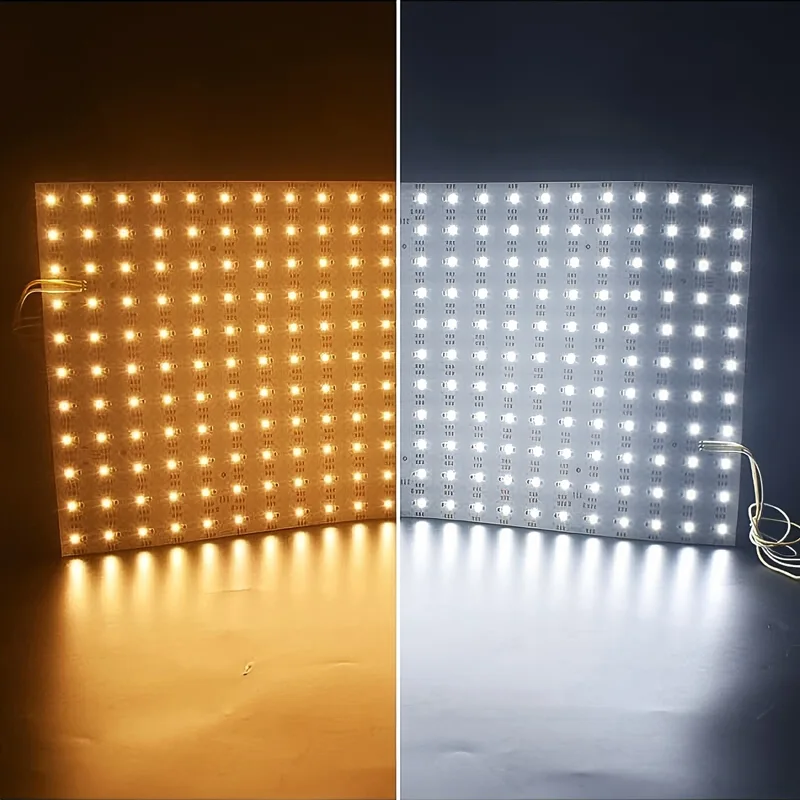

4. Color Temperature (CCT) Accuracy

Correlated Color Temperature (CCT) defines the perceived warmth or coolness of white light. Commercial standards typically include:

- 3000K for hospitality and warm retail environments

- 4000K for offices and general commercial interiors

- 6500K for high-visibility or technical spaces

Accuracy matters as much as nominal value. A 4000K system with ±500K tolerance may produce noticeable variation between batches.

In architectural installations, incorrect CCT shifts alter material perception and brand identity. In multi-phase projects, mismatched temperature ranges create visible segmentation between sections.

The LED light sheet should state nominal CCT and tolerance range. Look for ±100K to ±300K tolerance in commercial-grade products. Wider tolerances increase visual inconsistency risk.

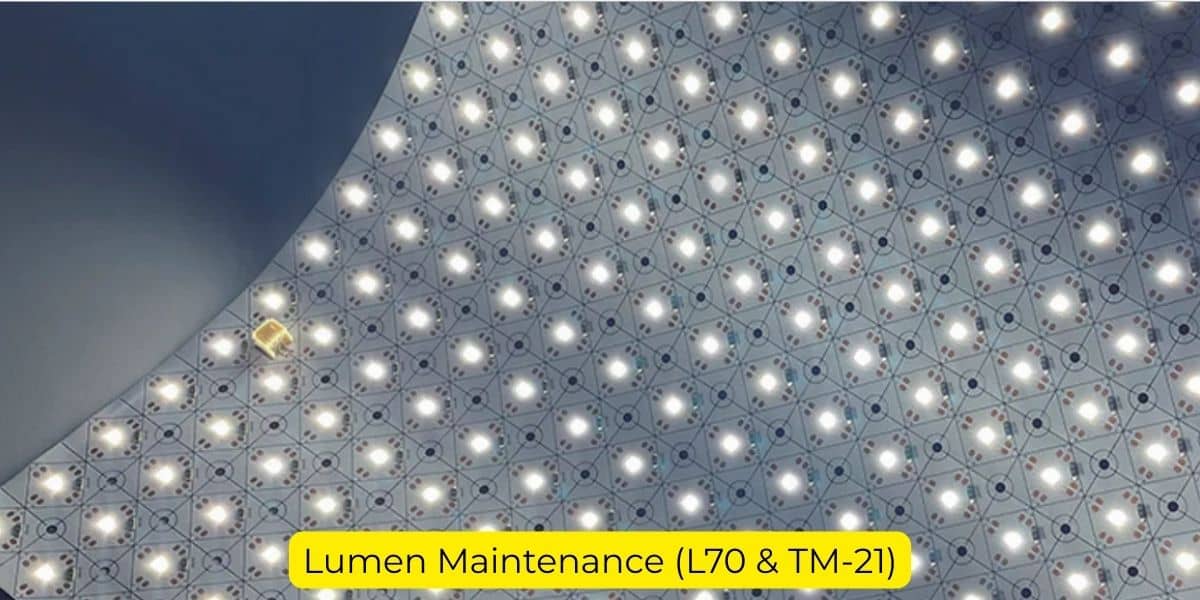

5. Lumen Maintenance (L70 & TM-21)

L70 represents the number of operating hours until light output declines to 70 percent of its original value. It is not a failure point. It is a depreciation threshold.

Manufacturers often state “50,000 hours” without context. The more important validation is LM-80 test data combined with TM-21 projection methodology. TM-21 extrapolates long-term lumen maintenance based on measured performance.

For commercial projects, credible systems provide L70 ≥50,000 hours at specified ambient temperature, supported by TM-21 calculations. Without TM-21, lifespan claims are not technically substantiated.

If ignored, buyers risk premature lumen depreciation, leading to uneven brightness across installed areas. In the LED light sheet, verify LM-80 reference, TM-21 projection report, and test temperature conditions.

6. IP Rating & Environmental Protection

Ingress Protection (IP) rating indicates resistance to dust and moisture. The rating format follows IPXX, where the first digit relates to solids and the second to liquids.

IP20 is typical for indoor dry installations.

IP65 or higher is required for signage, exterior façades, or environments exposed to moisture.

In lightbox or façade applications, condensation can degrade circuitry and shorten operational life. Even interior retail signage near entrances may require elevated IP protection.

If the environmental rating is insufficient, corrosion and driver failure occur before projected lifecycle. The LED light sheet should clearly list IP rating, testing standard, and operating temperature range.

7. Voltage & Dimming Compatibility

Commercial LED sheet systems typically operate at 24V DC, which supports stable distribution across larger panels and reduces voltage drop compared to 12V systems.

Dimming compatibility must align with building control systems. Common commercial standards include 0-10V analog dimming and DALI digital control. Projects incorporating dimmable and rgbw LED light sheets require driver compatibility confirmation.

Incompatibility leads to flicker, uneven dimming curves, or integration failure with building automation systems. These issues often surface post-installation when remediation is costly.

The LED light sheet should specify operating voltage, maximum run length, driver type, dimming protocol compatibility, and PWM frequency where relevant.

Tunable White LED Sheets

- Size( L x W ): 250mmx250 mm/ 490mmx245mm

- LED type: 2835 SMD

- LED quantity: 200PCS/484PCS

- Working voltage: DC 24V

- Power: 16W/40W

- Color temperature adjustable range: 2700K-6500K

- Luminous flux: 1600lm/3800lm

- CRI: >90Ra

- Minimum cutting length: 25mmx25mm/ 22.3mmx22.3mm

- Dimmable: YES

- Beam angle: 120°

- Waterproof level: IP20 non-waterproof, IP54 waterproof

- Warranty: 3 years

Summary checklist for B2B Buyers

| Technical Spec | What to Verify | Commercial Benchmark | Risk If Ignored |

| Luminous Efficacy | System lm/W rating | 110–160 lm/W | Higher energy cost, excess heat |

| Total Lumen Output | lm/m² under test conditions | 3,000–10,000+ lm/m² depending on use | Uneven brightness, shadowing |

| CRI & Binning | CRI value, SDCM tolerance | CRI ≥80 (≥90 retail), ≤3 SDCM | Color inconsistency across sites |

| CCT Accuracy | Nominal CCT and tolerance | ±100K to ±300K | Visual mismatch between batches |

| Lumen Maintenance | LM-80 & TM-21 data | L70 ≥50,000 hrs supported by TM-21 | Premature brightness loss |

| IP Rating | IP classification & temp range | IP20 indoor, IP65 signage | Moisture damage, corrosion |

| Voltage & Dimming | 24V spec, control compatibility | 24V, 0-10V or DALI | Flicker, integration failure |

How to Read an LED sheet light spec

The LED light sheet is structured into photometric, electrical, thermal, and compliance sections. Luminous efficacy and total lumen output appear under photometric performance. CRI, CCT, and chromaticity tolerance are typically grouped within color characteristics. Voltage, current, and dimming compatibility are found in the electrical specifications table.

Lumen maintenance claims should reference LM-80 test reports and include TM-21 projections. If lifespan is stated without LM-80 data, the claim lacks technical foundation. Similarly, omission of bin classification or SDCM tolerance indicates potential color inconsistency risk.

Environmental protection appears under mechanical or compliance specifications. If IP rating is listed without reference standard, clarification is required before approval.

Incomplete documentation signals procurement exposure. A commercial supplier should provide a detailed data sheet, not a simplified marketing flyer.

Common Procurement Mistakes

One frequent error is approving products based solely on total lumen output without validating lumen density per area. Another is accepting lifetime claims without verifying TM-21 projection data. Multi-site buyers often overlook bin tolerance, resulting in visible color variation across branches. Voltage compatibility is sometimes assumed rather than confirmed, leading to driver replacement during commissioning.

Each of these failures originates from insufficient review of the LED light sheet.

Conclusion

Commercial LED sheet procurement is a technical evaluation process. Performance, operating cost, and lifecycle reliability depend on measurable specifications, not marketing summaries.

Every approval decision should be supported by a verified LED light sheet. When the documentation confirms efficacy, lumen density, color stability, environmental protection, and electrical compatibility, project risk is significantly reduced.

Never rely on headline claims. Validate the data before deployment.

FAQs

No. Chip efficacy reflects laboratory diode performance. System efficacy accounts for drivers, thermal losses, and optical materials.

≤3 SDCM is typically required to maintain visual consistency across locations.

TM-21 provides mathematically projected lumen maintenance based on LM-80 test data, making the claim verifiable.

Higher operating temperatures accelerate lumen depreciation. L70 must be specified at a defined test temperature.

They can, but 24V systems are preferred to reduce voltage drop and improve stability in larger installations.

Exterior signage, façade lighting, and moisture-prone environments require IP65 or higher.

Lumen density exceeding typical interior benchmarks, often above 6,000 lm/m², designed for high ambient light conditions.

Inconsistent bins create visible color differences between batches installed at different times, impacting brand presentation.