Why is “What types of LED modules are most suitable for modern lighting projects?” one of the most frequently asked questions today? LED modules have become a key component in modern lighting design, offering flexibility, modularity, and high-quality illumination. Designers and engineers can choose from different module types to meet precise lighting requirements, optimize energy efficiency, and ensure long-term reliability across commercial, residential, and architectural projects.

When chosen correctly, LED modules also simplify installation, reduce maintenance costs, and provide scalable solutions. Modular options, including replaceable and customizable modules, allow projects to adapt over time without major redesigns.

Core Advantages: How Modular LED Systems Deliver Exceptional Value for Modern Lighting Projects

In modern commercial, architectural, and residential lighting projects, traditional integrated lighting solutions often face challenges such as rigid design, high maintenance costs, difficulty in upgrades, and significant waste. Modular LED systems address these issues by offering unmatched flexibility, cost-effectiveness, and sustainability throughout the project lifecycle.

Unmatched Design Flexibility and Future Adaptability

The modular design of LED systems forms the foundation for customization. Unlike traditional lighting fixtures, which require a complete replacement, LED module systems allow for easy adjustments and customization like building with blocks. Whether it’s designing precisely for space dimensions at the project’s onset, or adjusting light intensity, color temperature, or brightness as functional requirements evolve, you only need to replace or add specific modules, without altering the entire system. This flexibility ensures that your lighting investment keeps pace with technological advancements and evolving needs.

Significant Reduction in Lifecycle Costs, Especially Maintenance Costs

One of the biggest advantages of modular LED systems is their ease of maintenance. When traditional fixtures fail, the system often needs to be shut down for complex rewiring or complete fixture replacements. With modular LED systems, individual modules can be easily swapped out, avoiding the need for downtime and minimizing business disruption. This “precise repair” approach significantly reduces maintenance costs, labor, and time required.

Simplified Installation and Faster Project Deployment

Modular LED system components are typically pre-configured at the factory, requiring only quick assembly and connection during installation, eliminating the need for complex on-site assembly and adjustment. Compared to traditional lighting systems, modular systems significantly shorten installation timelines, making them especially suitable for large-scale projects or projects with tight deadlines.

Enhancing Sustainability and Environmental Responsibility

Modular LED systems support “on-demand upgrades,” significantly reducing material waste. Instead of discarding the entire lighting system, only the faulty module is replaced, reducing electronic waste. The energy-efficient and long-lasting nature of LED technology, combined with the upgradeability of modular systems, provides a green and sustainable lighting solution for projects.

Cost Effectiveness Analysis: Modular LED Systems vs. Traditional Lighting Systems

The table below illustrates the cost advantages of modular LED systems throughout their lifecycle, providing a clear comparison with traditional lighting systems.

| Cost Type | Traditional Lighting Systems | Modular LED Systems | Savings |

| Initial Installation Cost | High — often requires a full wiring setup, on-site adjustments, and longer commissioning time. | More cost-effective — standardized modules, simplified installation, and shorter deployment time. | 10%–20% |

| Maintenance & Repair Cost | High — failures usually lead to system downtime, and large sections must be repaired or replaced as a whole. | Very low — only the faulty module needs replacement; plug-and-play service reduces labor and downtime. | 50%–70% |

| Upgrade / Retrofit Cost | High — older systems are difficult to update and often need to be scrapped entirely during upgrades. | Low — specific modules can be upgraded individually, enabling an easy upgrade path for new functions or higher efficiency. | 60%–80% |

| Energy Consumption Cost | High — traditional lamps have lower efficacy and waste more power over time. | Low — high-efficiency LED chips, optimized drivers, and improved thermal management help reduce energy use significantly. | 40%–60% |

| Long-Term Value & Sustainability | Poor — rapid technology updates make older systems outdated quickly, increasing long-term costs. | Excellent — modular architecture supports gradual upgrades and ensures long service life, better reliability, and sustainability. | — |

Modules LED: What They Are & How They Work

In modern lighting design, LED modules have replaced traditional bulbs and become the core component for achieving efficient, flexible lighting solutions. Essentially, they are highly integrated “light engine” units.

From Traditional Bulbs to Integrated Light Engines

Unlike traditional light bulbs, which are independent, non-replaceable light sources, LED modules integrate LED chips, driver circuits, optical components (such as lenses or diffusers), and heat sink boards into a compact, all-in-one unit. This “plug-and-play” modular design brings unprecedented flexibility, consistency, and control to lighting applications.

Core Workflow: The Synergy of Light, Power, and Heat

The stable operation of LED modules relies on the efficient synergy of three key elements: light, power, and heat. Their operational workflow can be simplified into the following steps:

- Power Supply & Driving: A dedicated driver converts the incoming AC power to safe and stable low-voltage DC, providing constant current or voltage to the LED chips.

- Electro-Optical Conversion: The electrical current passes through the semiconductor LED chips, exciting the light source and achieving efficient electro-optical conversion.

- Thermal Management: The heat generated during the light emission process is quickly transferred and dissipated through a high-thermal-conductivity aluminum-based PCB, preventing high temperatures from affecting the module’s performance.

- Optical Control: Lenses or diffusers integrated into the module shape the light distribution, control beam angles, and reduce glare to provide the desired lighting effect.

This closed-loop design ensures that LED modules consistently deliver high luminous efficiency, stable light output, and exceptionally long lifespans.

Revolutionary Advantages of Modular Design

The core innovation of LED modules lies in their modular design, which breaks down complex lighting systems into a series of standardized, independent units. This brings three revolutionary advantages:

- Design Flexibility: Just like building blocks, multiple modules can be freely combined to create endless lighting effects and solutions.

- Easy Maintenance: If a module fails, it can be replaced directly without needing to replace the entire fixture, greatly reducing maintenance costs and downtime.

- Future Compatibility: With technological advancements, the system can easily be upgraded by simply replacing modules, without the need for rewiring or complete fixture replacement.

This modular flexibility and efficiency have made LED modules widely applicable in modern lighting projects.

Technical Categories of LED Linear Modules

LED linear modules are engineered to meet diverse lighting requirements, combining modularity, energy efficiency, and precise light control. Below are the main types of linear modules, with key features and advantages highlighted.

Constant Current Linear Modules

Constant current linear modules are designed to maintain stable and uniform lumen output across the entire module length. They are commonly used in continuous linear lighting, architectural fixtures, and applications requiring consistent brightness.

Key Features:

- Stable current regulation for consistent brightness

- Deliver up to 210 lm/W high efficacy

- Suitable for long-run linear fixtures

- Supports wide CCT ranges (2700K–4000K)

- High color consistency (≤3 SDCM)

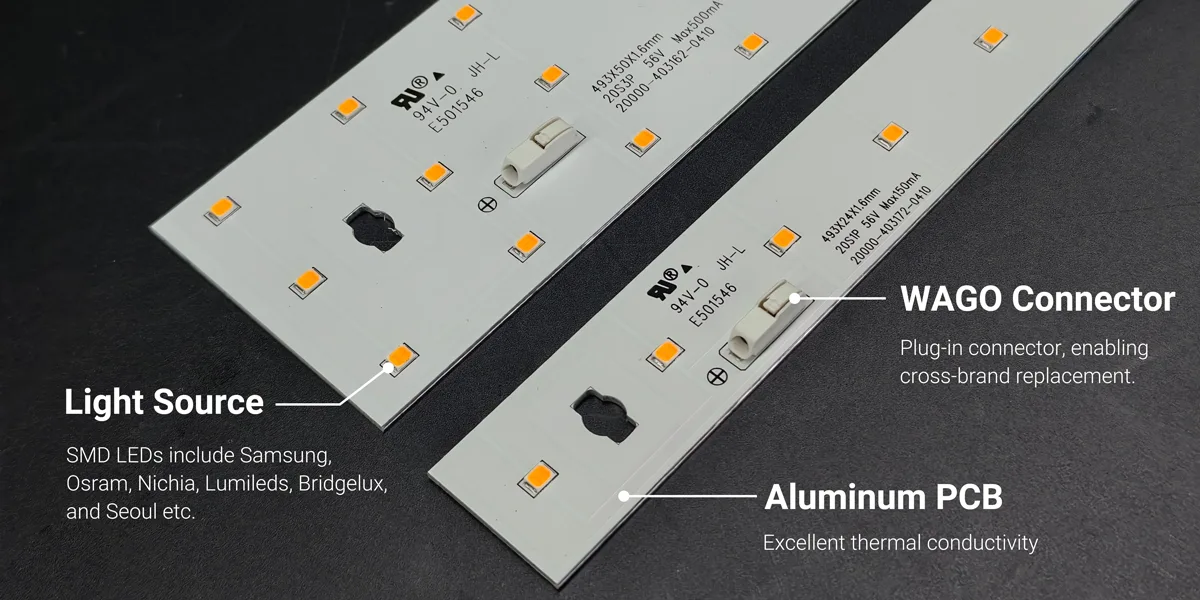

- Equipped with WAGO professional connectors for fast and reliable wiring

- Multiple dimming controls: DALI / 0-10V / PWM

Input Current: 275mA

Input Watt: 6.1W

Lumens: 1098-1241 lm

Luminous Efficacy: 183-205 lm/W

LED Types: SMD3030/SMD2835

LED Chip: Samsung/Osram/LUMILEDS/Bridgelux/Seoul

LED QTY: 24pcs

Color Temperature: 2700K/3000K/4000K/5000K/6500K

CRI: 80/90

Dimension: 279×23.6×1.6mm

PCB Material: Aluminum/FR-4

Warranty: 5 Years

Edge-Lit Linear Modules

Edge-lit modules deliver smooth, uniform illumination along slim profiles, making them ideal for indirect accents, retail displays, and compact architectural fixtures.

Key Features:

- High efficacy up to 175 lm/W

- Narrow widths (9–20 mm) for slim fixture designs

- Lumen packages from 900–5,460 lm

- Constant-current drive for stable, even output

- Standard or custom lengths with multiple CCT and color options: 2700K, 3000K, 3500K, 4000K, RGB, RGB+W, Tunable White

- Low power consumption (5–24 W) with strong thermal performance

- Equipped with WAGO professional connectors for fast and reliable wiring

- Multiple dimming controls: DALI / 0-10V / PWM

Input Current: 167-533mA

Input Watt: 5-24W

Lumens: 167-800 lm

Luminous Efficacy: 175 lm/W

LED Types: SMD3030/SMD2835

LED Chip: Samsung/Osram/LUMILEDS/Bridgelux/Seoul

LED QTY: 3-12pcs

Color Temperature: 2700K-6500K, RGB, RGB+W, Tunable White

CRI: 80/90

Dimension: 280-600mm Length*20-9mm Width

PCB Material: Aluminum/FR-4

Warranty: 5 Years

Cuttable Linear Modules

Cuttable linear modules allow length adjustments without impacting performance, making them suitable for tight spaces, irregular layouts, and quick on-site customization.

Key Features:

- Up to 180 lm/W high-efficiency output

- Cuttable design for adjustable lengths (every 2″)

- CRI 80 / 90 options with consistent 3 SDCM color quality

- Multiple CCT options: 2700K / 3000K / 3500K / 4000K

- Equipped with WAGO professional connectors for fast and reliable wiring

- Multiple dimming controls: DALI / 0-10V / PWM

Input Current: 507mA

Input Watt: 18.3W

Lumens: 3300 lm

Luminous Efficacy: 180 lm/W

LED Types: SMD3030/SMD2835

LED Chip: Samsung/Osram/LUMILEDS/Bridgelux/Seoul

LED QTY: 72pcs

Color Temperature: 2700K/ 3000K/ 4000K/ 6500K

CRI: 80/90

Dimension: 23.9*19mm

PCB Material: Aluminum/FR-4

Warranty: 5 Years

Tunable & RGBW Linear Modules

Tunable and RGBW linear modules deliver adjustable white tones or full-color effects for dynamic lighting scenes. They offer smooth transitions, stable performance with aluminum PCB thermal design, and support both constant current and constant voltage setups.

Key Features:

- Tunable White, RGB, and RGBW options

- Smooth color transitions and precise dimming

- Constant current or constant voltage versions

- CRI 90+ available

- Customizable lengths and multiple CCT ranges

- Equipped with WAGO professional connectors for fast and reliable wiring

- Multiple dimming controls: DALI / 0-10V / PWM

Input Current: 167-800mA

Input Watt: 5-24W

Lumens: 900-5460 lm

Luminous Efficacy: 175 lm/W

LED Types: SMD3030/SMD2835/ SMD 5630

LED Chip: Samsung/Osram/LUMILEDS/Bridgelux/Seoul

LED QTY: 3-12pcs

Color Temperature: 2700K/ 3000K/ 4000K/ 6500K

CRI: 80/90

Dimension: 280-600mm Length* 9-20mm Width

PCB Material: Aluminum/FR-4

Warranty: 5 Years

Core Specifications of LED Modules

The performance and lifespan of LED modules are directly determined by their core specifications. The following technical parameters serve as the basis for designers and engineers when making selection decisions.

LED Chips & Packaging

The LED chip is the source of luminous efficacy and color, and its packaging method directly impacts performance.

| Specification | Description | Selection Guide |

| Main Packaging | SMD (Surface-Mounted Device): The dominant packaging type for linear LED modules, offering excellent thermal performance, high efficacy, and full compatibility with automated production. | The preferred choice for all linear LED module designs. |

| Common Models | 2835: High efficacy and balanced performance, widely used for general lighting. | Use 2835 for general lighting; choose 5050/5630 for high-brightness or RGBW applications. |

| 5050: Larger chip size with higher per-LED lumen output, commonly used for high-flux and RGBW modules. | ||

| 5630: Similar to 5050 but certain models offer even higher efficiency. | ||

| Chip Quality | Chips with the same package size can vary significantly depending on brand (e.g., Epistar, Samsung, Seoul Semiconductor) and BIN selection. Differences appear in efficacy, lifespan, and color consistency. | For long-term stability and premium performance, specify well-known brands and require tight BIN control. |

LED Module PCB Material & Quality

The PCB is the structural foundation, circuit carrier, and thermal core of the module, and its material choice is critical.

| Material Type | Quality Level | Layers | Thickness | Copper Thickness | Thermal Conductivity | Applicable Scenarios |

| FR-4 | Economy | 1 | 1.0 mm | 1 oz | — | Cost-sensitive, low-power applications |

| FR-4 | Best Value | 2 | 1.6 mm | 1 oz | — | General commercial lighting |

| FR-4 | Premium | 2 | 1.6 mm | 1.6 oz | — | High-current, complex circuit applications |

| Aluminum | Economy | 1 | 1.6 mm | 1 oz | 2.0 W/mK | Medium/high power modules with basic thermal needs |

| Aluminum | Best Value | 1 | 1.6 mm | 1 oz | 3.0 W/mK | Mainstream high flux modules, balancing thermal and cost |

| Aluminum | Premium | 1 | 1.6 mm | 1 oz | ≥5.0 W/mK | High power density modules, focusing on longevity and stability |

| Aluminum | Premium | 1 | 1.6 mm | 1 oz | ≥5.0 W/mK | High power density modules, focusing on longevity and stability |

Standard PCB Process Characteristics

- Solder Pads: White solder mask, black silkscreen.

- Surface Treatment: HAL lead-free hot-dip tin.

- Minimum Trace Spacing: 0.2 mm.

- Minimum Hole Size: 0.3 mm (Aluminum boards usually ≥ 1.5mm due to process limitations).

- Minimum Component Spacing: 0.5 mm.

Electrical Characteristics

The electrical parameters determine the driving method and system design of the module.

- Operating Voltage: 12V DC, 24V DC, 48V DC. Low voltage (12/24V) is safer and easier to install; high voltage (48V) reduces voltage drop loss over long distances and offers higher overall efficiency.

- Driving Current: Typical range from 175mA to 700mA. Higher currents usually mean higher brightness but also impose stricter requirements on chip quality and thermal management design.

- Drive Type:

Constant Current Driver: Ensures constant current through all LEDs, making it the best choice for uniform brightness and preventing flicker due to voltage fluctuations.

Constant Voltage Driver: Provides constant voltage to the module, with internal resistors or simple ICs limiting the current. Common in cuttable modules and low-voltage RGBW modules, facilitating parallel connections and length customization.

Luminous Performance & Optical Components

This section defines the quality and form of light.

- Luminous Flux: Unit: Lumens. Typically measured in lumens per meter, ranging from 120 lm/m to 500+ lm/m or higher, depending on LED density, chip type, and driving current.

- Color Temperature: Ranges from 1800K (warm candlelight) to 6500K (pure white). 2700K-3000K (warm white) creates a cozy atmosphere; 4000K (neutral white) improves concentration; 5000K+ (cool white) is suitable for spaces that require high alertness.

- Color Rendering Index (CRI): Measures the ability of a light source to reveal the true colors of objects. Ra ≥ 80 is the basic requirement; Ra ≥ 90 is for high color rendering, suitable for retail, museums, medical spaces, and other areas where color discrimination is critical.

- Optical Components: Provide precise beam control such as 15°, 30°, 45°. Ideal for accent lighting, wall washing, façade lighting, and directional illumination.

Thermal Management & Reliability

Thermal design directly impacts the light degradation rate and lifespan of LED modules.

- Core of Thermal Design:

The core of thermal design involves using aluminum substrates or optimized FR-4 layouts to maintain the junction temperature of the LED chip below its rated value. - Reliability Indicators:

- Lifetime: Typically expressed as L70 or L90, which indicates the number of hours required for the luminous flux to decrease to 70% or 90% of its initial value. For example, L70 > 50,000 hours.

- Luminous Decay: Effective thermal management significantly slows down the luminous decay, ensuring the LED module maintains stable brightness and color temperature throughout its entire lifespan.

- Compact Design Benefits:

Optimized SMD layouts not only save space but also effectively prevent localized overheating (hot spots), allowing the module to operate stably at higher currents.

Application Guide of LED Modules

Selecting the right LED module hinges on understanding how its technical characteristics solve specific lighting challenges. The following guide translates technical advantages into practical project value.

Constant Current Linear Modules: Ultimate Uniformity & Stability for Commercial Spaces

- Pain Point::

Environments like offices, retail stores, and classrooms require uniformly distributed, flicker-free lighting without brightness variations. Poor lighting over time leads to visual fatigue. - Solution:

Constant current linear modules maintain a consistent electrical current throughout the entire strip, eliminating brightness fluctuations at the source. - Technical Advantages in Practice:

Consistent Brightness creates a uniform, flicker-free light field, ensuring visual comfort and enhancing productivity and the shopping experience.

Long-Term Stability guarantees consistent light output over years, significantly reducing maintenance headaches caused by uneven lumen depreciation. - Typical Applications:

Office troffers, supermarket fresh food lighting, classroom blackboard lights, hospital corridors.

High Flux Linear Modules: Powerful Illumination for Large, High Spaces

- Pain Point::

In high-ceiling spaces like warehouses, factories, and large supermarkets, conventional lighting is often insufficient, requiring numerous fixtures. This leads to high energy consumption and difficult maintenance. - Solution:

High flux modules use high-power chips in a dense layout on aluminum PCBs for effective heat dissipation, delivering superior luminous output per meter. - Technical Advantages in Practice:

High Luminous Output penetrates deep spaces, ensuring required illuminance levels on work surfaces.

Excellent Thermal Management ensures stable performance under full load, meeting the reliability demands of 24/7 operation. - Typical Applications:

High-bay lights in industrial warehouses, stadium lighting, general lighting in large exhibition halls.

Edge-Lit Linear Modules: Creating Uniform Light in Slim Profiles

- Pain Point::

Modern minimalist interiors and high-end displays require concealed lighting effects. However, traditional light sources in narrow slots often create unsightly hotspots and uneven spots. - Solution:

Edge-lit modules use light guides or specialized lenses to channel light from the side and emit it evenly across the front face. - Technical Advantages in Practice:

Uniform & Glare-Free output creates soft, even light strips within ultra-slim profiles, perfectly outlining architectural features.

Slim Form Factor allows discreet integration into minimal spaces, enabling seamless architectural cove lighting. - Typical Applications:

Ceiling coves, mirror lights, display case lighting, wall-washing in ambient lighting designs.

Cuttable Linear Modules: Ultimate Flexibility for Custom Installations

- Pain Point::

Non-standard applications like cabinet lighting, curved structures, and custom signage can’t use standard-length strips. Field-cutting often renders sections inoperative. - Solution:

Cuttable modules can be trimmed at designated cut points (e.g., every 3 LEDs), and the remaining segments will function normally. - Technical Advantages in Practice:

Customizable Length enables “tailor-made” installations, eliminating dead spots and dark zones.

Independent Segment Control simplifies wiring and enables zoned dynamic lighting for creative displays. - Typical Applications:

Under-cabinet lighting, shelf lighting, automotive interior lighting, custom signage letters.

Tunable White & RGBW Linear Modules: Defining Ambiance and Rhythm with Light

- Pain Point::

Spaces like restaurants, hotels, and showrooms need adaptable lighting atmospheres that change based on time of day, event, or theme. A single static color temperature is insufficient. - Solution:

Tunable White modules adjust CCT (2700K-6500K), while RGBW modules mix full color and pure white, all controllable via smart systems.. - Technical Advantages in Practice:

Dynamic CCT/Color allows lighting to align with circadian rhythms or brand themes, shifting from energizing to relaxing scenes instantly.

Precise Dimming & Color Mixing creates rich, scene-specific lighting, enhancing spatial appeal and user experience. - Typical Applications:

Hotel lobbies, branded retail stores, restaurant ambience zones, and dynamic architectural façade lighting.

FAQ

Modular LED systems offer customization and scalability by using independent module units. Each module can be operated and replaced individually, allowing you to adjust the system easily without a major redesign as requirements change. This provides greater flexibility for lighting projects to adapt to new design needs or technological changes.

Thermal management is a crucial factor in the performance of LED modules. A good thermal design not only extends the lifespan of the LED module but also ensures the stability of the system. When choosing LED modules, consider the PCB material, thermal design (such as aluminum substrates), and whether heat sinks or other cooling components are included. These designs help reduce the temperature of the modules and ensure stable long-term operation under high loads..

Modern modular LED systems are typically compatible with smart lighting control systems, supporting protocols like DMX512, DALI, and Zigbee. Users can control and adjust lighting remotely through smart platforms. Whether it’s dimming, tunable white, or scheduling, modular LED systems can be easily integrated into smart buildings and automation systems, offering greater efficiency and convenience in management and control.

The ZHAGA standard ensures that LED light sources and drivers from different manufacturers are interchangeable. By standardizing interfaces, sizes, and electrical characteristics, ZHAGA allows LED modules to be easily swapped in various projects and systems. Choosing LED modules that meet the ZHAGA standard ensures compatibility and provides support for future upgrades and expansions.

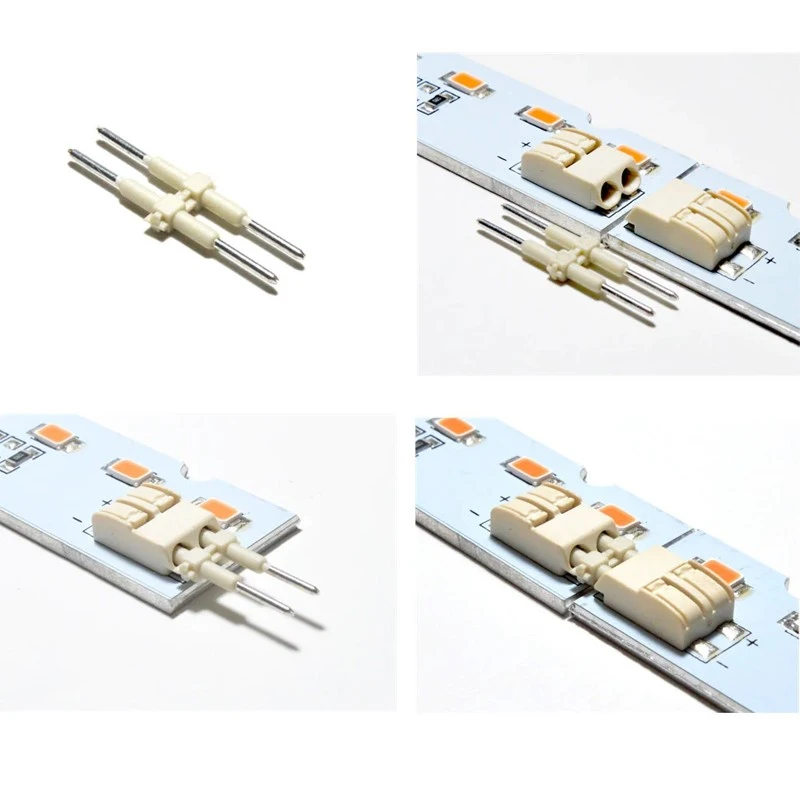

WAGO connector technology simplifies the connection between LED modules and other electrical systems. Using high-quality connectors, WAGO ensures more stable and reliable connections between modules, reducing potential contact issues during installation. Additionally, WAGO connectors support quick wiring and easy maintenance, ensuring that the LED lighting system operates efficiently and reliably over time.

Conclusion

Modular LED solutions by SignliteLED provide outstanding flexibility, cost-effectiveness, and long-term sustainability for modern lighting projects. By enabling easy installation, customization, and scalability, modular LED systems from SignliteLED are the ideal choice for a wide range of applications—whether for commercial, residential, or architectural lighting. With the ability to replace and expand individual modules, these systems offer future-proof solutions that evolve with your needs, minimizing maintenance costs and providing superior energy efficiency.

Interested in exploring our high-quality LED modules?

Click here to view SignliteLED’s full product range or check out these helpful articles:

- How to Choose the Right LED Driver for Linear LED Modules?

- LED Linear Module Complete Guide: Structure, Drivers, and Applications

- What Is the Zhaga Standard for LED Linear Modules? And Why Does It Matter?

- High-performance LED Linear Modules for Lighting Applications – WAGO Connector & Zhaga Standard

- Linear LED Module Series