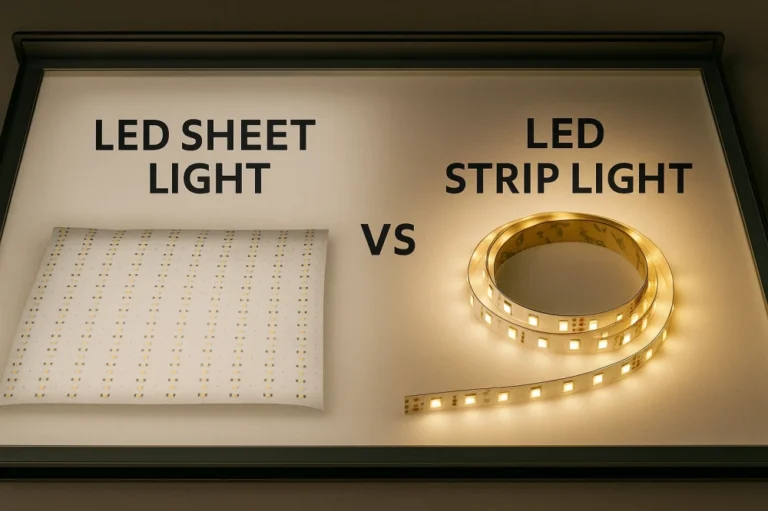

Architectural backlighting has become a hallmark of contemporary design, enriching spaces from hotel lobbies and corporate offices to museum galleries and retail showcases. Among lighting options, LED sheet lights—also referred to as LED light sheets, LED sheet modules, LED light sheet panels, or LED light boards—stand out as an elegant and flexible solution for custom architectural lighting. Unlike conventional LED panel lights, these ultra-thin and flexible LED sheet panels combine high-density layouts with uniform brightness LED sheets, ensuring seamless illumination. Their minimal thickness, cuttable LED sheet lights, and adaptable form empower designers and contractors to realize creative visions—whether illuminating textured walls, backlighting stone or glass, or integrating into signage lighting installations.

What Are LED Sheet Lights and How They Work?

What Are LED Sheet Lights?

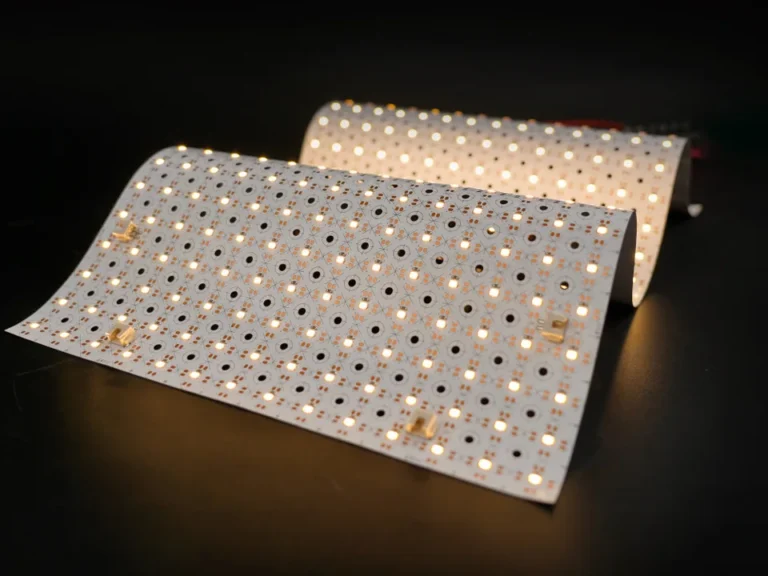

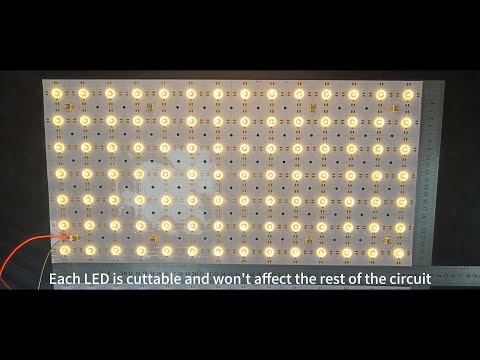

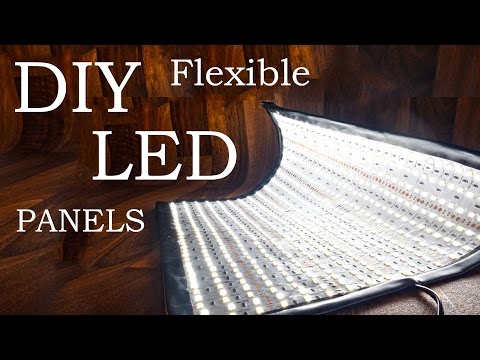

LED sheet lights are ultra-thin LED sheets designed as flexible LED sheet panels with LED chips mounted across a flat PCB board. This configuration ensures they work as high-density LED sheets, delivering uniform brightness LED sheets performance across the entire surface. Each panel can function as cuttable LED sheet lights thanks to marked grid lines, making them ideal for irregular architectural shapes. Whether used as backlit LED sheet panels for signage, LED light boards for glass and stone surfaces, or LED sheet modules in wall features, these products offer architects and designers a versatile backlighting solution.

How Do LED Sheet Lights Work?

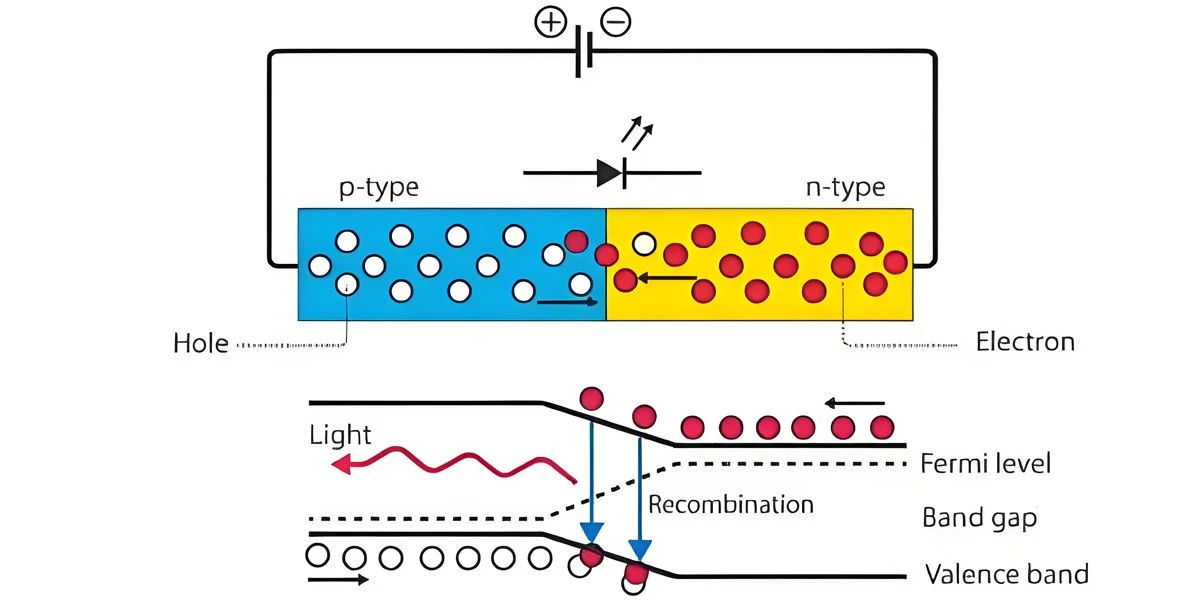

LED sheet lights work on the principle of electroluminescence. Each LED chip is a semiconductor diode made from two layers:

N-type semiconductor (rich in electrons)

P-type semiconductor (rich in positively charged holes)

When current flows through the diode, electrons move from the n-type side toward the p-type side and recombine with holes at the p–n junction. This recombination releases energy in the form of photons — visible light.

On the sheet, hundreds of these tiny diodes are arranged in a grid, spreading light evenly across the surface. Combined with a diffuser or reflective layer, this design ensures uniform backlighting without glare, shadows, or uneven brightness — a key requirement for facade lighting, ceiling installations, and logo signage.

How LED sheet lights work: electrons and holes recombine at the p–n junction, releasing energy as light.

Types of LED Sheets

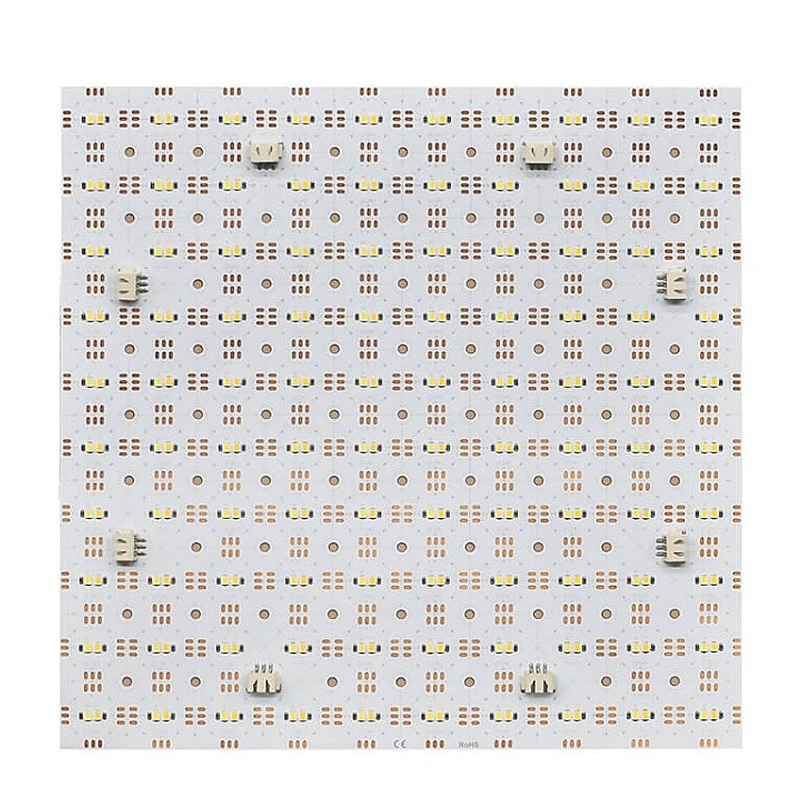

Single Color LED Light Sheets

Available from 2700K warm white to 6500K pure white, these LED sheet modules are common in wall accents, ambient lighting, and logo backlighting. Their high-density layouts (3500+ LEDs/m²) guarantee smooth illumination without hotspots.

Single Color LED Light Sheets

Size( L x W ): 250 mm x 250 mm/ 490 mm x 245 mm

LED type: 2835 SMD

LED quantity: 100PCS/ 242PCS

Working voltage: DC 24V

Power: 12W/ 28W

Colors: 2700K/3000K/4000K/6000K

Luminous flux: 1200lm/m / 2800lm/m

CRI: >80Ra

Minimum cutting length: 25mmx25mm /22.3mmx22.3mm

Dimmable: YES

Beam angle: 120°

Tunable White LED Sheets

These flexible LED sheet panels support adjustable CCT from 2700K to 6500K, aligning with human-centric lighting concepts. Used in offices, hotels, and residential spaces, they adapt mood and time-of-day requirements.

Tunable White LED Sheets

Size ( LxH ): 250mmx 250mm/ 490mmx245mm

LED type: 2835 SMD

LED quantity: 200PCS/484PCS

Working voltage: DC 24V

Power: 16W / 40W

Color temperature adjustable range: 2700K – 6500K

Luminous flux:1600lm/m/3800lm/m

Color rendering index: >90Ra

Minimum cutting length: 25mmx25 mm/22.3 mm x22.3mm

Dimmable: YES

Beam angle: 120°

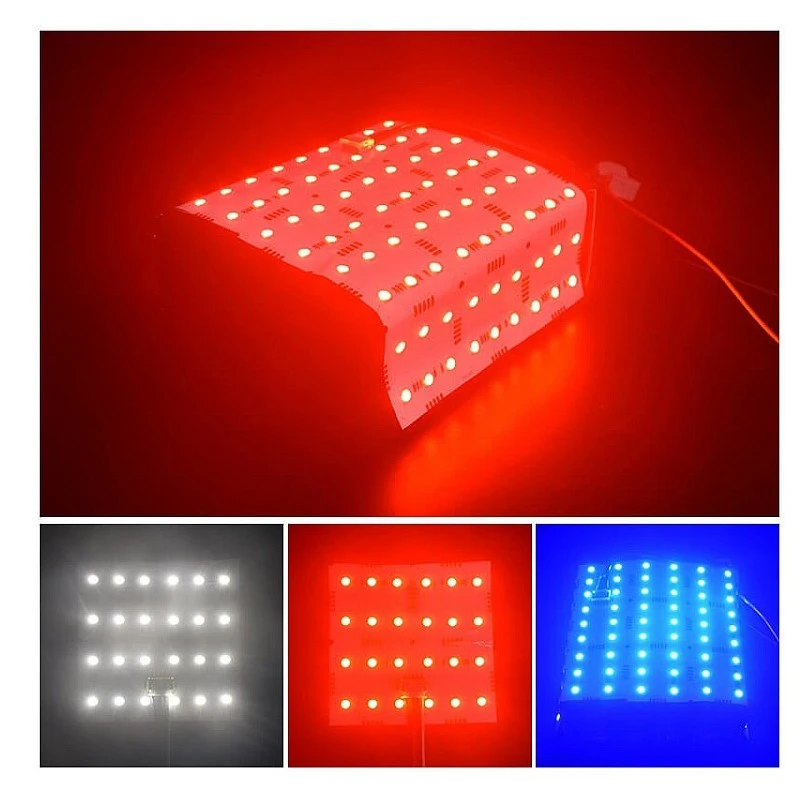

RGBW LED sheet lights

Combining RGB color mixing with a dedicated white channel, these LED sheet lights deliver both decorative effects and functional white lighting. They are widely applied in exhibitions, entertainment venues, and festival lighting projects.

RGBW LED sheet lights

Size(LxW): 250mmx250mm/490mmx250mm

LED type: 5050 RGBW 4 In 1 SMD LEDs

LED quantity: 150LEDs/288LEDs

Working voltage: DC 24V

Power: 24 W/48W

Emitting color: RGB + warm white ( 3000K ), RGB + natural white ( 4000K ), RGB + cool white ( 6000K )

Light Efficiency: 90LM/W

Minimum cutting length: 50mmx50mm/20.4mm x122.5mm

Beam angle: 120°

Dimmable: YES

Addressable LED Sheets

Featuring pixel control, these cuttable LED sheet lights allow designers to program animations and patterns. Integrated with DMX512 or SPI controllers, they are ideal for media walls, themed facades, and interactive signage projects.

Addressable LED Sheets

Size(LxW): 250mmx250mm

LEDs: 100 pieces 5050 SMD

IC type: Built-in WS2812

IC quantity: 100 pieces

Color: RGBIC

Working voltage: DC 12V

Current: 1.08A

Power: 13W

Luminous flux: 20lm/LED

Wavelength: 620-625nm(red), 520-525nm(Green), 465-470nm(Blue)

Beam angle: 120°

Key Features for Architectural Backlighting

When designing architectural backlighting projects, LED sheet lights offer key advantages:

- Ultra-thin LED sheets for discreet installation in tight architectural spaces.

- Cuttable LED sheet lights provide on-site flexibility for irregular shapes.

- Uniform brightness LED sheets ensure a seamless glow with no hotspots.

- Energy-efficient design with a long lifespan (≥50,000 hours).

- Multiple options available, including tunable white, RGBW, and single-color LED sheet panels.

These traits make flexible LED sheet panels a high-impact solution for both interior and exterior architectural backlighting projects.

Elevator Interiors

In elevator interiors, space is limited and glare is a common issue. Ultra-thin LED sheets can be installed directly behind glass or stainless-steel panels without reducing cabin space. Their uniform brightness LED panels eliminate shadows, giving elevators in hotels and office towers a modern and refined look while saving energy.

Hotel & Office Lobbies

Hotel and office lobbies demand large-scale, seamless illumination. Flexible LED sheet panels backlit behind marble walls, frosted glass, or ceiling features create consistent brightness across expansive areas. For hotels, this delivers luxury and warmth; for corporate offices, it reinforces professionalism and brand image.

Glass & Stone Surfaces

Backlighting translucent marble, onyx, or frosted glass with cuttable LED sheet lights enhances depth and elegance. Unlike rigid modules, these high-density LED sheet boards ensure even brightness across large surfaces, making them ideal for luxury retail, hotel bars, and residential feature walls.

Signage & Logos

For brand signage and logos, LED light sheets provide sharp, uniform backlighting without hotspots. Their flexible LED sheet modules fit irregular shapes, making them the preferred choice for retail stores, airports, and corporate branding projects.

Installation & Best Practices for LED Sheet Lights

Surface Preparation & Cutting

Before mounting, always clean glass, metal, or acrylic panels thoroughly to remove dust and oil, ensuring strong adhesion for LED sheet modules. When trimming, use precision tools to cut only along the designated cut lines of cuttable LED sheet lights, protecting circuit integrity and preventing edge damage.

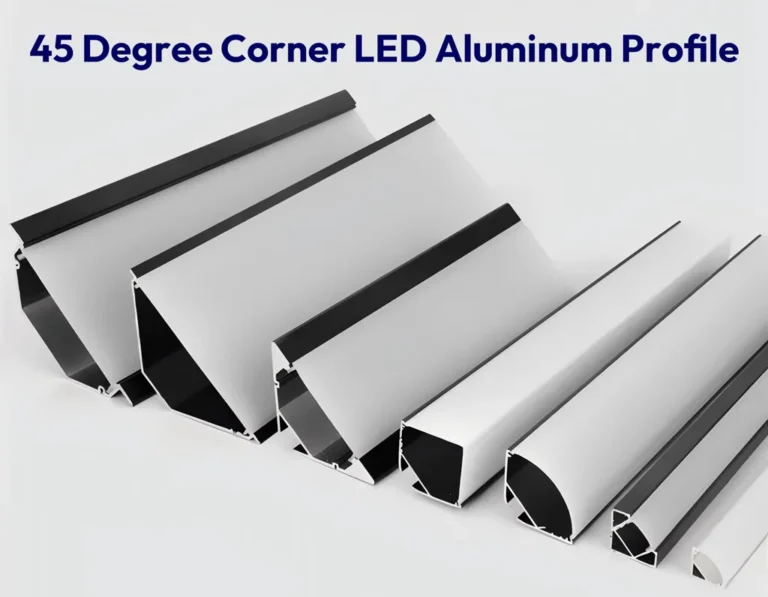

Mounting Methods (Adhesive, Screws, Magnets)

Most flexible LED sheet panels come with industrial-grade adhesive backing (e.g., 3M VHB) for quick “peel-and-stick” installation. For permanent or structural applications, reinforce with screws; for removable systems, magnetic mounting is an option. Always ensure the mounting surface allows slight expansion to maintain stability.

Power Connection & Wiring

For small projects, solderless connectors enable fast plug-and-play integration. For customized installations, soldering wires to copper pads ensures a reliable setup. Always match your driver to the voltage (12V or 24V DC) and wattage requirements of the LED light boards, leaving at least 20% power headroom.

For long runs, use parallel connections or additional power supplies to avoid voltage drop and maintain consistent brightness across multiple LED sheet lights.

System Testing Before Final Installation

Always prototype first: connect LED sheet panels, controllers, and power supplies, then check for even brightness and correct color. Verify compatibility with dimmers or DMX systems before fixing the panels permanently.

Troubleshooting Common Issues

- Overheating: Ensure ventilation and correct voltage.

- Incomplete Lighting: Check polarity and connector stability.

- Uneven Brightness: Caused by voltage drop—resolve with parallel wiring or distributed power.

For a step-by-step installation tutorial—including how to cut LED sheet lights, connect power, and set up flexible LED sheet panels—see our detailed guide: How To Cut, Install, And Set Up LED Sheet Lights.

Buyer Tips for Architectural Projects

Define Project Requirements Clearly

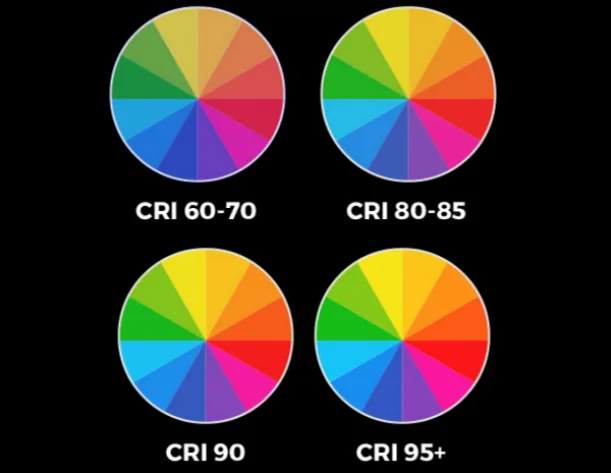

Before selecting LED sheet lights, outline the project’s backlighting objectives: Is the goal decorative ambiance, functional uniformity, or brand logo highlighting? Clarify brightness levels (lumens per watt), color temperature (2700K–6500K), and CRI requirements (≥90 for hospitality and retail projects). Defining these criteria early helps avoid mismatches and ensures smooth integration into architectural lighting projects.

Evaluate Supplier Capabilities

Choose reliable LED sheet light suppliers with proven track records in architectural backlighting. Assess whether they provide:

- Technical datasheets with complete specifications.

- LM-80, CE, RoHS, or UL certifications for safety and quality compliance.

- References from similar large-scale facade or lobby projects.

Suppliers with OEM/ODM capabilities can also offer custom backlighting solutions, such as pre-cut panels or tailored layouts.

Compare Cost vs. Lifecycle Value

While upfront cost matters, long-term value is determined by energy efficiency, warranty, and expected lifespan. A sheet light with 50,000+ hours lifetime and a 3–5 year warranty may cost more initially, but reduces maintenance frequency and downtime in hospitality or commercial projects. Evaluate total cost of ownership (TCO), not just purchase price.

Verify Installation & After-Sales Support

Architectural projects often face complex installation conditions—curved walls, narrow coves, or irregular ceiling designs. Confirm that the supplier provides clear installation manuals, wiring diagrams, and technical support. After-sales services such as quick replacement of faulty sheets or remote troubleshooting can save contractors significant time and ensure project deadlines are met.

Consider Scalability & Customization

For hotel chains, office towers, or shopping malls, scalability is essential. Ensure the supplier can handle bulk orders, consistent batch quality, and custom layouts. Features like cuttable LED sheet panels, modular connections, and uniform brightness across large surfaces are especially valuable in multi-site rollouts.

For a more detailed overview of technical specifications, installation options, and project planning advice, see our LED Sheet Lights Complete Guide for Projects and Buyers.

Conclusion

LED sheet lights have become a transformative solution for architectural backlighting projects, offering unmatched flexibility, consistent illumination, and adaptability to complex surfaces. From hotel lobbies and office ceilings to brand walls and elevator interiors, these ultra-thin panels unlock new creative possibilities for designers and contractors alike.

For project managers and architects, selecting the right LED sheet lights supplier is as important as the product itself. Reliable partners ensure not only technical excellence—high CRI, long lifespan, certifications—but also smooth installation support and long-term value.

If you are planning a large-scale backlighting project and looking for custom LED sheet lighting solutions, SignliteLED is ready to support your vision. Our products are engineered for durability, precision, and energy efficiency, making them a trusted choice for international architectural lighting projects.

Contact SignliteLED today to discuss specifications, customization options, or to request a tailored quotation for your upcoming project.