As LED technology continues to advance, high-power PCB LEDs are now widely used in several applications. It is used in industrial lighting, automotive headlights, street lamps, stadium lighting, and high-bay commercial fixtures. These LEDs deliver superior brightness, energy efficiency, and longevity compared to traditional light sources. They also generate significant heat during operation. In short, managing this heat effectively is one of the most critical challenges in LED PCB system design.

Printed Circuit Boards (PCBs) play a critical role in thermal management for modern electronic systems. In high-power LED light PCB applications, controlling heat dissipation is essential for performance and operational longevity. Among various PCB LED light materials available, aluminum substrates have become the preferred solution worldwide. Round aluminum PCB LED offer superior thermal conductivity, enabling heat transfer away from sensitive LED components.

This article explains

- Fundamentals of LED heat dissipation

- Elimitations of conventional PCB materials

- Why aluminum PCBs are considered the optimal solution for high-power LED systems.

Understanding Heat Generation in High-Power LEDs

Unlike incandescent bulbs, LEDs do not emit heat through infrared radiation. Instead, most of the heat is generated at the LED junction. It is the point where electrical energy is converted into light. In high-power LED PCB board design, only about 30–40% of the input energy becomes visible light. The remaining energy is converted into heat.

If this heat is not removed efficiently, the junction temperature rises rapidly, leading to:

- Reduced luminous efficiency

- Color shift and degraded light quality

- Accelerated material degradation

- Shortened LED lifespan

- Increased risk of premature failure

Therefore, effective thermal management is not optional. It is a fundamental requirement for reliable high-power LED operation.

Role of PCB in LED Thermal Management

The PCB serves two primary functions in an LED system:

- Electrical interconnection: Providing power and signal routing to the LED chips

- Thermal pathway: Conducting heat away from the LED junction to external heat sinks or ambient air

In low-power PCB LED strip applications, standard FR-4 fiberglass PCBs may be sufficient. However, as power density increases, FR-4 quickly becomes a thermal bottleneck due to its poor heat conductivity.

This is where Metal Core PCBs (MCPCBs), particularly aluminum-based PCBs, offer a decisive advantage.

| Feature | Aluminum PCB Advantage | Impact on High-Power LEDs |

| Thermal Conductivity | 200–235 W/m·K | Rapid heat transfer, reduced junction temperature, stable operation |

| Heat Spreading | Aluminum base acts as integrated heat spreader | Even heat distribution, minimizes hot spots |

| LED Performance | Lowers thermal stress on LEDs | Higher luminous efficacy, stable color, longer lifespan |

| Mechanical Strength | Rigid metal core | Resistant to vibration, thermal cycling, and mechanical stress |

| Weight | Lightweight compared to copper | Ideal for automotive, aerospace, and compact designs |

| Cost-Effectiveness | Economical material and processing | Feasible for mass production without compromising performance |

Limitations of Traditional FR-4 PCBs

FR-4 is the most common PCB material in general electronics, but it is not designed for high thermal loads. Its thermal conductivity typically ranges between 0.3 and 0.4 W/m·K, which severely limits its ability to transfer heat.

In high-power PCB LED design, using FR-4 can result in:

- Heat accumulation near the LED junction

- Need for oversized external heat sinks

- Reduced system efficiency

- Higher failure rates under continuous operation

These limitations make FR-4 unsuitable for applications where long-term reliability and thermal stability are essential.

What Is an Aluminum PCB?

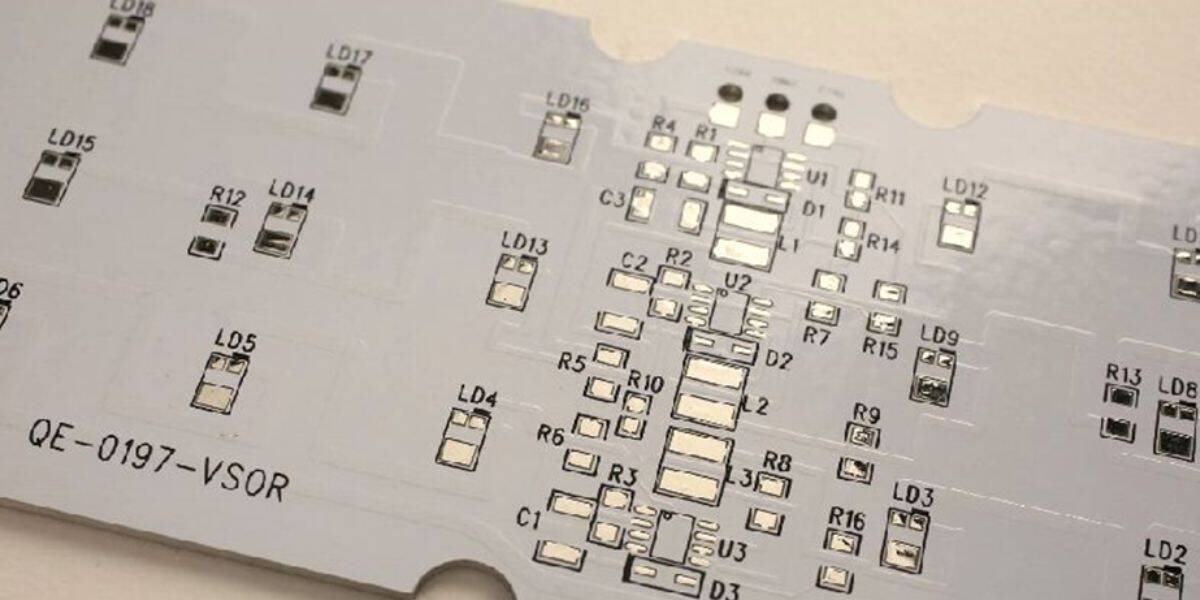

An aluminum PCB is a type of Metal Core PCB consisting of three primary layers:

- Copper Circuit Layer: Conducts electrical signals and power

- Dielectric (Insulating) Layer: Electrically isolates the copper from the metal base while allowing heat transfer

- Aluminum Base Layer: Acts as a heat spreader and structural support

The aluminum base is the key differentiator. It provides a direct thermal path from the LED junction to the heat sink or surrounding environment.

Why Aluminum Is Best for High-Power LED Heat Dissipation?

1: Superior Thermal Conductivity

Aluminum has a thermal conductivity of approximately 200–235 W/m·K, which is dramatically higher than FR-4 and significantly better than most composite PCB materials.

This high conductivity allows heat to spread rapidly across the PCB and away from the LED junction, reducing localized hot spots and maintaining a stable operating temperature.

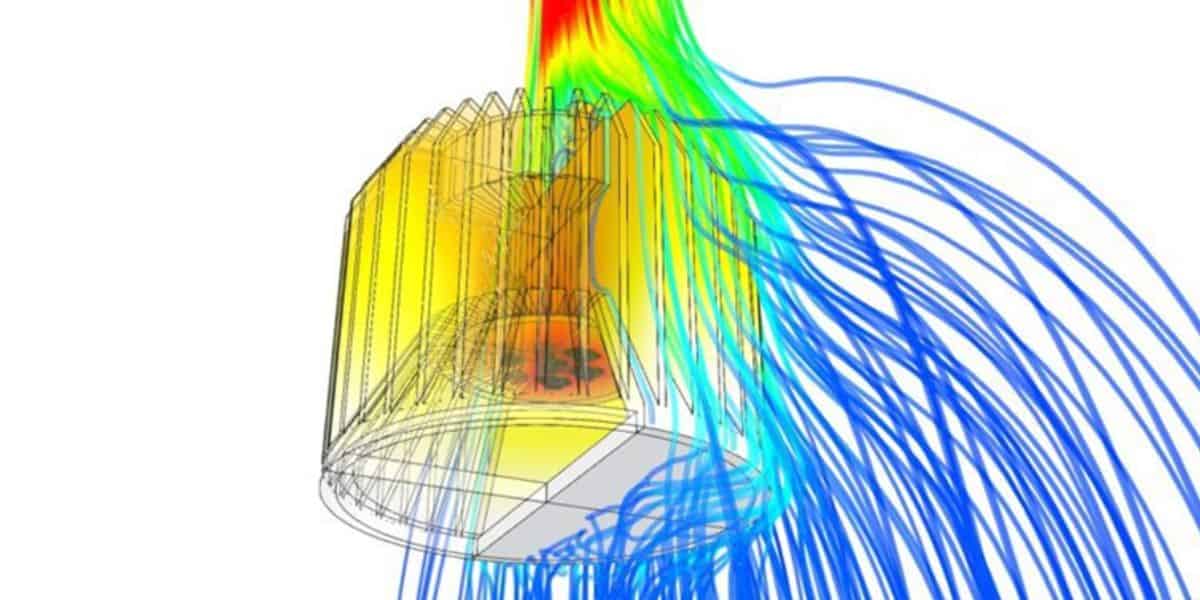

2: Efficient Heat Spreading and Dissipation

The aluminum base layer functions as an integrated heat spreader. Instead of relying solely on external heat sinks, aluminum PCBs distribute heat evenly across a larger surface area, improving overall thermal efficiency.

This is particularly beneficial in compact LED designs where space constraints limit the size of traditional heat sinks.

3: Enhanced LED Performance and Lifespan

Lower junction temperatures directly translate into improved LED performance. Aluminum PCBs help achieve:

- Higher luminous efficacy

- Stable color temperature over time

- Reduced thermal stress on solder joints

- Longer operational lifespan

In many cases, using an aluminum PCB can extend LED life from tens of thousands to well over 50,000 hours under continuous operation.

4: Mechanical Strength and Durability

Aluminum PCBs are engineered for structural reliability in mission-critical applications. The solid metal core enhances board stiffness, minimizes flexing, and protects solder joints from fatigue caused by vibration, repeated thermal cycles, and mechanical load. This durability makes aluminum substrates a preferred choice when designing products that must perform consistently over long service lives.

Where Custom Aluminum PCB Designs Perform Best

- Custom PCB design for automotive: Widely used in automotive lighting systems, power control units, and EV electronics where vibration resistance and thermal stability are mandatory.

- Custom PCB design for medical devices: Supports diagnostic equipment, powered instruments, and imaging systems that require mechanically stable and thermally controlled PCB platforms.

- Industrial and outdoor environments: Ideal for industrial machinery, street lighting, and outdoor installations exposed to shock, temperature variation, and continuous operation.

Value of Professional Design Support

Partnering with a specialized custom PCB design service ensures aluminum PCBs are optimized for mechanical strength, component anchoring, and heat flow. Advanced custom PCB design services further help manufacturers meet industry standards while improving product reliability and lifecycle performance.

5: Lightweight Compared to Other Metal Substrates

While copper PCBs offer even higher thermal conductivity, they are significantly heavier and more expensive. Aluminum strikes a practical balance by offering excellent thermal performance at a fraction of the weight and cost.

This lightweight nature is especially important in applications like automotive and aerospace lighting, where weight reduction is a key design objective.

6: Cost-Effectiveness for Mass Production

Aluminum is abundant, widely available, and easy to machine. Compared to ceramic or copper substrates, aluminum PCBs are more economical for large-scale manufacturing.

For OEMs and custom PCB manufacturing, this cost advantage makes aluminum PCBs the most commercially viable option without compromising performance.

7: Compatibility with Standard Manufacturing Processes

Aluminum PCBs are compatible with conventional PCB fabrication and SMT custom PCB assembly processes. This reduces production complexity and allows manufacturers to integrate aluminum PCBs into existing production lines with minimal changes.

Aluminum PCB vs. Other Thermal Solutions

Aluminum vs. Copper PCBs

- Copper offers higher thermal conductivity but at higher cost and weight

- Aluminum provides sufficient performance for most high-power smd LED PCB at a lower total system cost

Aluminum vs. Ceramic Substrates

- Ceramics offer excellent thermal performance and electrical insulation

- Aluminum PCBs are more impact-resistant, easier to process, and more cost-effective

For the majority of high-power RGB PCB LED applications, aluminum PCBs deliver the best balance of performance, durability, and cost.

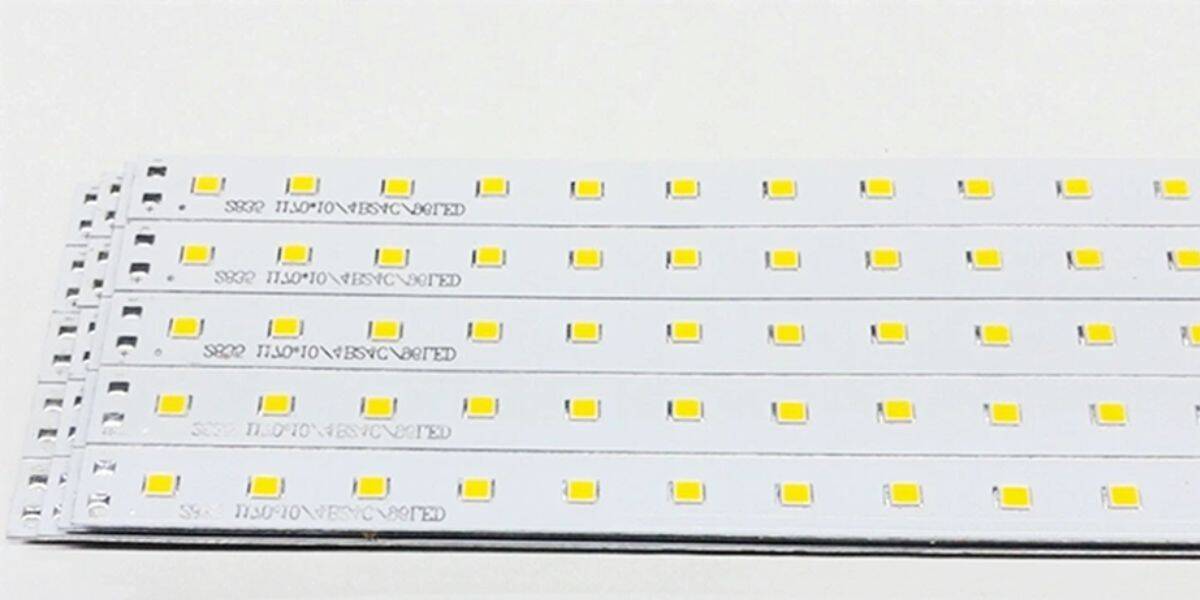

Common Applications of Aluminum PCBs in High-Power LEDs

Due to their superior heat dissipation properties, aluminum smd PCB LED are widely used in:

- LED street lights and floodlights

- High-bay and warehouse lighting

- Automotive headlights and daytime running lights

- Architectural and façade lighting

- Industrial and explosion-proof lighting

- Medical and scientific illumination systems

In all these applications, thermal reliability is directly linked to product quality and brand reputation.

Key Custom PCB Design Considerations for Aluminum LED PCBs

To maximize the benefits of aluminum PCBs, designers should consider:

- Dielectric layer thickness and thermal conductivity

- Copper thickness for current handling

- Thermal interface materials (TIMs)

- Proper mounting to external heat sinks

- Optimized trace layout for heat flow

A well custom pcb design and fabrication services can significantly outperform a poorly designed one, even with the same materials.

Conclusion

Effective heat dissipation forms the foundation of reliable high power LED light PCB design performance. As LED power densities rise, PCB materials fail to meet thermal demands. Aluminum PCBs deliver optimal performance through high thermal conductivity and mechanical properties. By transferring heat from LED junctions, PCBs stabilize temperatures and extend lifespan. For B2B buyers, SignliteLED is best LED PCB manufacturer in China.

There are many LED PCB board manufacturers in China. For superior high-power LED performance, choose aluminum PCBs from SignliteLED. Our solutions ensure efficient heat dissipation, enhanced reliability, and longer lifespan. Contact SignliteLED today to discuss customized PCB options for your next high-power LED project.

FAQs

Effective heat dissipation prevents LED junction overheating, ensuring stable light output and extended product lifespan.

Aluminum PCBs provide significantly higher thermal conductivity, allowing faster heat transfer from LED chips.

Its metal core and dielectric layer efficiently conduct heat from LEDs to external heat sinks.

Yes, aluminum PCBs maintain thermal stability under continuous high-current and high-temperature operating conditions.

By reducing thermal stress, aluminum PCBs enhance LED reliability, brightness consistency, and overall system efficiency.