Как много вы знаете о технологии светодиодных водонепроницаемых полосок? Есть простые процессы, такие как аэрозольный клей и капельный клей, а также более сложные, такие как трубки, горшечные экструзии и нанесение покрытия. Каждый из этих процессов имеет свои специфические приложения. Если вам нужна только базовая гидроизоляция, вы можете выбрать аэрозольный клей, капельный клей или процессы нанесения покрытия. Однако, если вам требуется высококлассная гидроизоляция IP68, мы рекомендуем использовать процессы выращивания или экструзии.

Важно отметить, что не все светодиодные ленты подходят для конкретного процесса гидроизоляции. Например, для ленточных фонарей типа RGB использование процесса экструзии для гидроизоляции неуместно, потому что чипы в ленточных лампах хрупки, а процесс экструзии включает высокое давление и температуру, что может легко повредить микросхемы и светодиоды. Однако использование процесса нано-покрытия может идеально решать такие проблемы.

Signliteled уже более десяти лет активно участвует в индустрии светодиодных лент. Благодаря неустанным исследованиям и усилиям мы накопили большой опыт в области водонепроницаемых продуктов. Используя нашу ведущую в отрасли технологию водонепроницаемости, мы гарантируем производительность продукции, помогая вам выбрать правильный процесс гидроизоляции.

Хотя многие могут быть знакомы с первыми пятью процессами гидроизоляции светодиодных лент, гидроизоляция на основе Nano по-прежнему не знакома многим. Ниже я расскажу вам подробное понимание водонепроницаемых светодиодных лент на основе нано-покрытия.

Что такое нано–Светодиодный водонепроницаемый светильник с покрытием

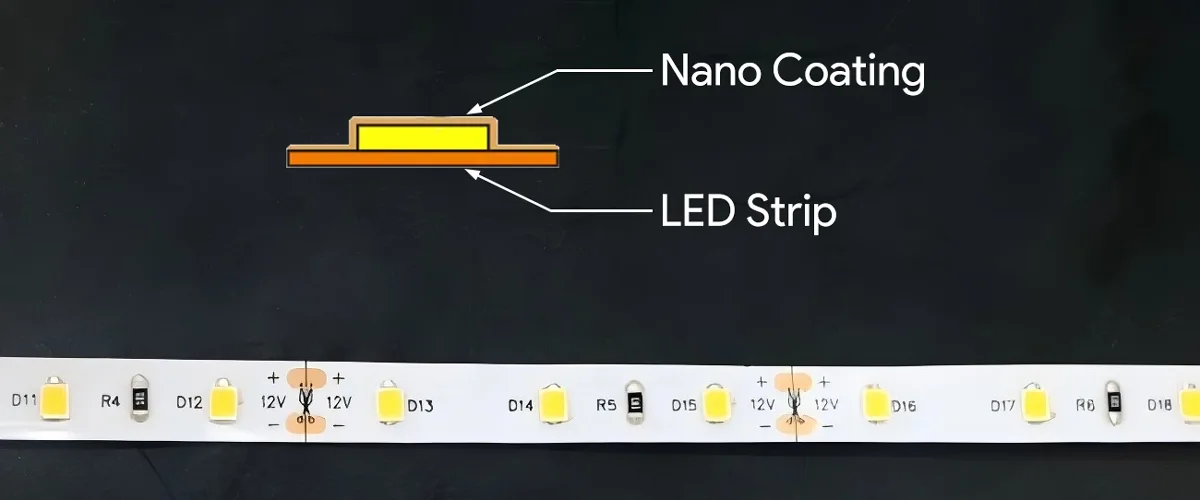

Водонепроницаемая световая полоса с нанопокрытием — это светодиодная лента, которая обеспечивает водонепроницаемость благодаря специальной технологии покрытия поверхности. В основе этой технологии нанесено нанометровое или микрометровое покрытие нанометровой поверхности, обеспечивая тем самым определенную степень гидроизоляции. Нано-изоляция покрытия – это процесс формирования и нанесения тонкопленочных покрытий на материалы подложки. Нанесение тонких пленок различных материалов на подложки является одним из ключевых методов обработки микронано. Тонкие пленки обладают многочисленными различными свойствами, которые можно использовать для изменения или усиления определенных аспектов производительности подложки. Например, они могут быть прозрачными, долговечными и устойчивыми к царапинам, увеличивать или снижать электропроводность или передачу сигнала, а толщина наносов в диапазоне от нанометровых до микрометровых.

Хотя нано-покрытие имеет толщину только нанометрового уровня и едва видно невооруженным глазом, оно обладает мощными защитными возможностями. Он может обеспечить полное покрытие на поверхности светодиодной ленты. Такой нанослой покрытия образует на поверхности светодиодную полоску супергидрофобный слой, аналогичную эффекту лотоса. Когда вода вступает в контакт с поверхностью Nano Coating, она быстро образует капли, которые скатываются, а не прилипают к светодиодной ленте и проникают внутрь. Используя это гидрофобное свойство и нанося нанопокрытие на поверхность светодиодной световой полосы, световая полоса может легко удовлетворить требования стандартов высокого класса водонепроницаемости, таких как IP65 и даже IP68. Введение в водонепроницаемую светодиодную ленту можно прочитать в блоге: Руководство по рейтингу IP водонепроницаемых светодиодных лент.

Нано-покрытие водонепроницаемо светодиодные ленты

Основная модель: FQW10T120A

Тип светодиода: SMD2835

КОЛИЧЕСТВО СВЕТОДИОДОВ НА МЕТР: 60/72/120/128/140

Ширина печатной платы: 6 мм/8 мм/10 мм

Цветовая температура: 2700K - 6500K/на заказ

ИКР: >80

Входное напряжение: DC12V/DC24V

Мощность на метр: 6W/8W/9.6W/12W/14.4W/19.2W

Водонепроницаемый: Процесс нанопокрытия

Степень защиты IP: IP65/IP67

Гарантия: 5 лет

Преимущества водонепроницаемых светодиодных лент с нанопокрытием

В процессе нанопокрытия используется технология осаждения пара, когда газообразные мономеры разлагаются на свободные радикалы и непосредственно полимеризуются в твердую полимерную пленку на твердой поверхности. В результате покрытие может проникать через любую поверхность, независимо от ее сложности, не оставляя мертвых углов. Нано-водостойкие покрытия, которые являются ультратонкими, обладают отличными тепловыделительными свойствами, безопасны и нетоксичны, широко используются в индустрии светодиодов. В настоящее время они представляют собой одно из самых эффективных гидроизоляционных решений и технологий для светодиодных лент. К их достоинствам относятся:

- Отличная светопередача: Что касается гидроизоляции, нанопокрытие наносим нанометром и микрометром с контролируемой толщиной (1-100 мкм). В соответствии с требованиями к гидроизоляции толщина может быть сделана чрезвычайно тонкой (30 нм), что не влияет на теплоотвод светодиодных чипов. Покрытие тонкое, бесцветное и прозрачное, что не влияет на светопропускание.

- Превосходная водонепро: Покрытие подготавливается с использованием химического осаждения из паровой фазы (CVD). Мономеры, образовавшиеся после разложения, являются наноразмерными, демонстрируя сильную проникающую способность. Они могут проникать во все более узкие зазоры между соединениями паяных пайок LED, образуя непрерывное «бесшовное» барьерное покрытие, эффективно предотвращая повреждающие внешнюю влагу от поврежденных светодиодными продуктами.

- Сохраняет производительность оригинального продукта: Нановодостойкое покрытие имеет превосходную совместимость во время подготовки, что позволяет ему формировать тонкий защитный слой на поверхности изделия в соответствии с его внешним видом без добавления веса и не влияя на сборку. Он даже выглядит так же, как и до нанопокрытия, что является его волшебной особенностью.

- Подходит для суровых условий: В повседневной жизни разъедающиеся вещества, такие как пот, дождевая вода и переносимые по воздуху загрязняющие вещества, могут разрушать поверхность светодиодов или световых полос, в результате чего паяльные площадки ржавеют, а светодиодные компоненты выходят из строя. Технология нанопокрытия создает высокоплотный и стабильный слой-изоляцию на поверхности световой полосы, эффективно предотвращая прямой контакт между коррозионными веществами и подложкой, тем самым препятствуя прогрессированию старения материала и коррозии. В стандартных условиях тестирования соли, светодиодные ленты с нанопокрытием демонстрируют исключительную коррозионную стойкость, сохраняя оптимальную производительность в суровых условиях в течение длительного времени. Покрытие выдерживает температуру до 140°C и ниже -200°C, обеспечивая превосходную стойкость к солевому распылению, напряжению и УФ-излучению.

- высокая плотность: Покрытие может быть нанесено на поверхности различных форм, включая острые края и трещины, предлагая экономичное, чистое, простое, быстрое и высокообъемное решение для обработки.

- экологически чистый: Прозрачное покрытие не влияет на внешний вид продукта и безвредно для человека.

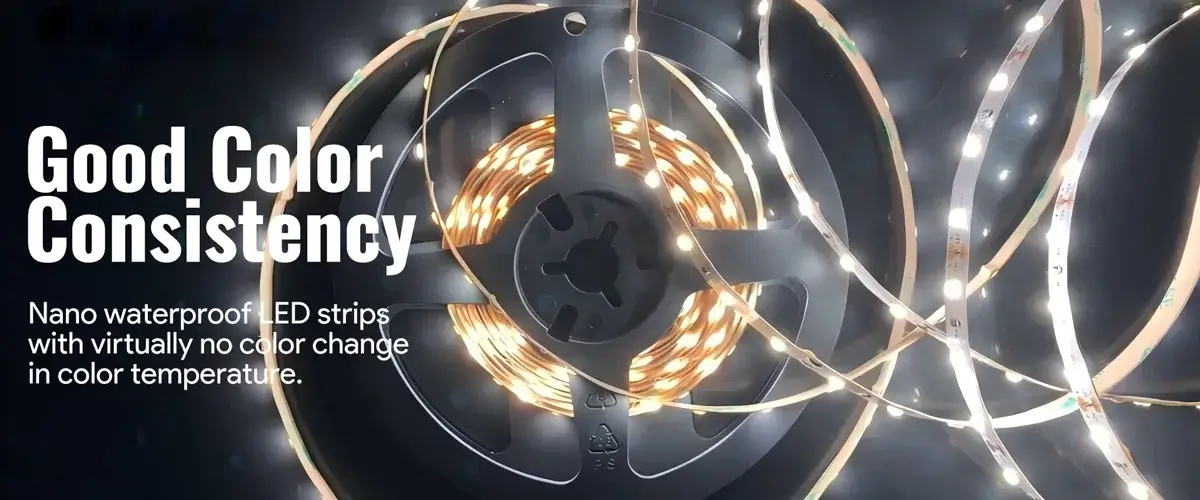

С точки зрения производителей светодиодных лент, технология нанопокрытия предлагает значительные преимущества в стоимости. Это снижает использование уплотнительных материалов, таких как силикон, тем самым снижая общую производственную стоимость продукта. Другие процессы гидроизоляции могут увеличить вес светодиодной ленты и изменить ее цветовые характеристики, такие как горшок.

Например, после заливки влияет свет, проходящий через материал светодиодной температуры 4000K, что приводит к повышению цветовой температуры до 5500K, что создает серьезные проблемы как для производства, так и для пользователей. В процессе нанопокрытия этих проблем нет. Из-за ультратонкой природы световых полос нанопокрытия продукт имеет лучшую теплоотвод, а световой цвет остается практически неизменным, что еще больше повышает надежность продукта. Для сравнения изменений цветовой температуры до и после гидроизоляции между не водонепроницаемыми и водонепроницаемыми светодиодными лентами, пожалуйста, читайте в блоге: Какие бывают типы светодиодных лент?

Какие два процесса используются для гидроизоляции нанопокрытия?

Нано-покрытие в основном использует два различных тонкопленочных процесса нанесения: PECVD (химическое осаждение из плазмы) и парилелен (химическое осаждение из пара).

PECVD покрытие

PECVD покрытие, или технология химического осаждения парового осаждения, усиленная плазмой, играет уникальную роль в повышении водонепроницаемости светостойких полос. Принцип его работы включает использование тлеющего разряда в камере осаждения для ионизации молекул газа, образуя высокореакционно-реактивную смесь молекул газа, ионов высокой энергии, электронов и активных свободных радикалов. Эти частицы подвергаются химическим реакциям на поверхности подложки световой полосы, осаждаясь и вырастая в чрезвычайно тонкое и плотное нанопокрытие (например, диоксид кремния или нитрид кремния).

Технология PECVD нанопокрытия предлагает значительные преимущества по сравнению с традиционными технологиями уплотнения, трехпротекторными и полиимидными защитными пленками. Он не только обеспечивает превосходные защитные характеристики, но и демонстрирует уникальную конкурентоспособность с точки зрения экологичности, стоимости и контроля толщины пленки.

Нанопленки PECVD могут точно контролировать толщину пленки, обеспечивать превосходную производительность пленки, лучшую производительность покрытия, более широкий спектр применений и более высокие показатели текучести, тем самым снижая затраты на техническое обслуживание после продажи. Технология PECVD имеет явное преимущество в стоимости по сравнению с париленом. Это также одна из основных причин, по которой международные технологические гиганты выбирают технологию PECVD для замены оригинальной технологии парилена в своих продуктах следующего поколения.

парилен Cкрупный

Парилеленовое покрытие является ветвью химического осаждения из паровой фазы (ССЗ), но не требует плазмы. Парилеленовое сырье – это порошкообразный материал, помещенный в испарную печь оборудования для нанесения покрытия. В вакууме при 150°С твердый сырье испаряется в газообразное состояние. Затем в условиях термического разложения при 650-700°С газообразное сырье расщепляется в реактивные мономеры. Газообразные мономеры откладываются и полимеризуются при скоростях нанометровых градиентов при комнатной температуре, образуя пленку из органического полимера (полипараксилен). Этот процесс осаждения является CVD.

Толщина париленовой защитной пленки составляет около нескольких десятков микрометров, а защитная пленка PECVD еще тоньше, всего в несколько десятков нанометров. При нанесении распыления на поверхность корпуса лампы такое тонкое покрытие практически невидимым невооруженным глазом.

Сравнение парилена Wс Oтам Cкрупный плод

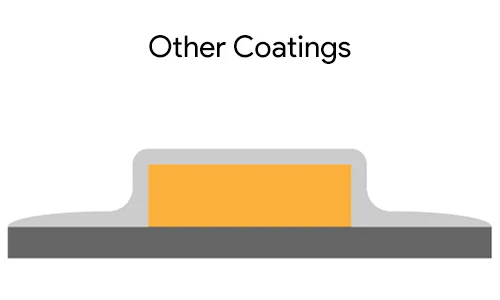

- Толщина пленки однородная, а форма непротиворечива.

- Хорошее покрытие по краям.

- Температура в помещении постоянная, нет давления усадки.

- Толщина пленки неровная, и форма изменилась.

- Покрытие по краям и ступням недостаточно.

- Давление усадки от термоотверждения не выдерживается.

Водонепроницаемые светодиодные световые полосы с нанопокрытием обычно используют парилеленовое нанопокрытие или нанопокрытие PECVD, которое эффективно обеспечивает гидроизоляцию, пыленепроницаемость, стойкость к кислоте и щелочью и продлевает срок службы. Водонепроницаемые светодиодные световые полосы нано-покрытием обеспечивают гидроизоляцию, нанося слой парилена нанопокрытия на поверхность световой полосы или с использованием технологии нанопокрытия PECVD.

Парилеленовые покрытия обладают гидроизоляцией, коррозионной стойкостью, изоляцией и стойкостью к кислоте/щелчаю, что значительно повышает водонепроницаемость и срок службы световых полос. Технология PECVD нанопокрытия формирует плотную нано-масштабную пленку на поверхности световой полосы, эффективно блокируя влагу и пыль, достигая водонепроницаемости IP67. Если приоритеты в экономичности и массовой эффективности производства, выбирайте PECVD; если требуется стойкость к коррозии, погружение в воду или сложные конструкции, выбирайте парилен.

Сравнение производительности процесса между двумя технологиями нанопокрытия

PECVD нанопокрытие использует химическое осаждение из паровой фазы, усиленное плазмой, для образования на поверхности плотной нано- масштабной пленки (толщина 1–100 мкм).

Он обеспечивает гидроизоляцию IP67, устойчивость к солевой распылению и коррозии, а также защиту от ультрафиолетового излучения. Поскольку покрытие наноразмерно, оно не влияет на рассеивание тепла компонента, продлевая срок службы продукта. Он имеет светопереходность более 95%, равномерное покрытие, может проникать в крошечные промежутки и обеспечивает комплексную защиту без слепых зон.

PECVD Nano-покрытие имеет недостаток дорогого оборудования и высоких первоначальных инвестиций, но стоимость единицы снижения с масштабом, требует вакуумной среды, имеет сложный процесс и имеет высокие технические барьеры; подходит для светодиодных световых лент, материнских плат, наружного освещения и т.д.

Слои покрытия парилена микрон-толстой толще, чем покрытия PECVD, имеют чрезвычайно низкую проницаемость молекул воды и обладают отличными изоляционными свойствами при экстремальных температурах (от -200°C до 200°C). Они могут быть применены к сложным конструкциям (таким как паяные соединения печатной платы) с одинаковой толщиной и отсутствием скважин и устойчивы к сильной кислотной и щелочной коррозии, что делает их пригодными для экстремальных условий.

К недостаткам покрытия париленом микрон является дорогое сырье и оборудование, низкие скорости осаждения, необходимость полного удаления старого покрытия при ремонте, что предполагает сложный процесс. Покрытие также хрупкое и имеет слабое сопротивление физическому воздействию. Он также подходит для светодиодных лент, военной техники и медицинских изделий высокого класса.

Сравнение характеристик двух процессов нанопокрытия

| специальный | pecvd | парилен |

| Тип материала | Неорганические (оксиды, нитриды и т. | органический полимер |

| толщина | Нано до микронного уровня | 0,1–100 мкм (может точно контролировать) |

| равномерность | Высокая плоскостность, немного слабее покрытие сложных конструкций | Полное покрытие с превосходным проникновением в острые углы/щели |

| гидроизоляция | Плотная влагостойкая, но для тонкой пленки множественные слои | Сверхнизкая проницаемость водяного пара (<0,1 г/м²/сутки) |

| Изолирование | Высокая диэлектрическая прочность | Отличная изоляция (стабильная диэлектрическая проницаемость) |

| Температурная устойчивость | Обычно ≤400°C | Тип HT устойчив к 200°C, склонен к низкой температуре хрупкость |

Сравнение основных характеристик между двумя нанопокрытиями

| пункт оценки | pecvd | парилен |

| Водонепроницаемый рейтинг | IP65-IP67 | IP65-IP68 |

| Толщина пленки и теплоотдача | Наноразмерный (10 нм-1 мкм), практически не влияет на рассеивание тепла | Микронная шкала (0,1-100 мкм), оказывает небольшое влияние на теплоотвод чипов высокой мощности |

| Экологическое сопротивление | Соляная устойчивость к туману, устойчивость к УФ-излучению, коррозионная устойчивость | Чрезвычайно коррозионно-стойкая (кислотная и щелостой, устойчивая к погружению в морскую воду) |

| Покрытие процессов | Подходит для плоских поверхностей, ограниченное покрытие для сложных конструкций | Полное покрытие без слепых зон, проникает в пайки/зазоры |

| Оптические свойства | Высокое светопропускание (>98%), бесцветный и прозрачный | Слегка более низкое пропускание света (влияние на толщину пленки), но равномерное и без бликов |

| Массовое производство CСТ | Высокие инвестиции в оборудование, но низкие затраты на единицу продукции (высокоскоростное осаждение) | Высокие затраты на сырье и оборудование, низкая скорость осаждения (приблизительно 1 мкм/ч) |

Для производства PECVD требуется вакуумная среда и плазменный генератор с температурой подложки ≤500°C и достаточно быстрыми скоростями осаждения, что делает его пригодным для полупроводниковых устройств. Оптические пленки и гидроизоляция бытовой электроники могут производиться серийно; париленовое покрытие не требует плазменного генератора, с температурой разложения до 650°C, нанесением подложки при комнатной температуре, но стоимость оборудования относительно высокая, а скорость осаждения составляет примерно 1 мкм/ч, что делает его пригодным для гидроизоляции сложных компонентов в военной электронике и аэрокосмическом оборудовании. PECVD покрытие обычно имеет IP65-IP67 IP67 для световых полосок, для световых полосок с рейтингом IP68 рекомендуется париленовое покрытие.

Для получения информации о процессе производства и выбора водонепроницаемых светодиодных лент, пожалуйста, читайте в блоге: Какие процессы гидроизоляции используются в светодиодных лентах?

Краткое содержание

В открытом ландшафтном освещении, Светодиодные водонепроницаемые световые пользуются большим спросом за свою гибкость и декоративную привлекательность. Светодиодные полоски наружного освещения, использующие технологию нанопокрытия, идеально решают эту проблему. Эти легкие полосы не только обеспечивают исключительную водонепроницаемость, сохраняя стабильную подсветку в различных суровых погодных условиях, но и их ультратонкое покрытие также не ставит под угрозу декоративный эффект световых полос.

Технология водонепроницаемости покрытия нано-покрытия предлагает инновационные решения для проблем гидроизоляции и теплоотдачи, с которыми сталкиваются светодиодные световые полосы. По мере того, как технологии продолжают развиваться и дальнейшие затраты снижаются, нанопокрытие готово к более широкому применению и внедрению в светодиодной отрасли. Забегая вперед, с появлением новых материалов и процессов, технологии гидроизоляции и теплоотдачи для светодиодных светопропускающих полосок, чтобы раскрыть еще больший потенциал для развития.