Aşırı gerilim koruyucu cihazlar (SPD'ler), bir elektrik sistemi içinde nerede çalıştıklarını ve o konumdaki dalgalanma enerjisini nasıl yönettiklerini yansıtmak için tip 1, tip 2 ve tip 3 olarak sınıflandırılır. Bu türler birbiriyle değiştirilemez. Her biri belirli bir dalgalanma ortamı ve koruma işlevi için tasarlanmıştır ve yalnızca koordineli bir sistemin parçası olarak uygulandığında doğru şekilde çalışırlar.

Bu makale karşılaştırmalı bir teknik kılavuzdur. Aşırı gerilim koruma temellerini yeniden sunmaz. Bunun yerine, Tip 1, Tip 2 ve Tip 3 SPD'lerin rol, yetenek ve sistem etkileşiminde nasıl farklılaştığına ve mühendislerin gerçek elektrik tesisatlarında doğru yerleşimi nasıl belirlediklerine odaklanır.

Karşılaştırma çerçevesi: SPD türleri nasıl farklılaşır?

SPD sınıflandırması, ürün büyüklüğüne, fiyatına veya algılanan sağlamlığa dayalı değildir. Kurulum pozisyonuna ve beklenen aşırı gerilime maruz kalmaya dayanır.

Dalgalanma enerjisi bir elektrik sisteminden geçerken özellikleri değişir:

- Dalgalanma akımı büyüklükleri azalır

- Dalga formu şekli gelişir

- Kalan voltaj hassas ekipman için tehlikeli kalır

Bu davranış nedeniyle, aşırı gerilim koruma bölgelere ayrılmıştır. Her SPD tipi, aşırı stres veya düşük performans göstermeden dalgalanma stresini yönetebileceği belirli bir bölge içinde çalışacak şekilde tasarlanmıştır.

Tip 1, Tip 2 ve Tip 3 SPD'ler arasındaki karşılaştırma her zaman dikkate alınmalıdır:

- Kurulum Yeri

- Beklenen dalgalanma enerji seviyesi

- Birincil koruma fonksiyonu

- Diğer SPD türlerine bağımlılık

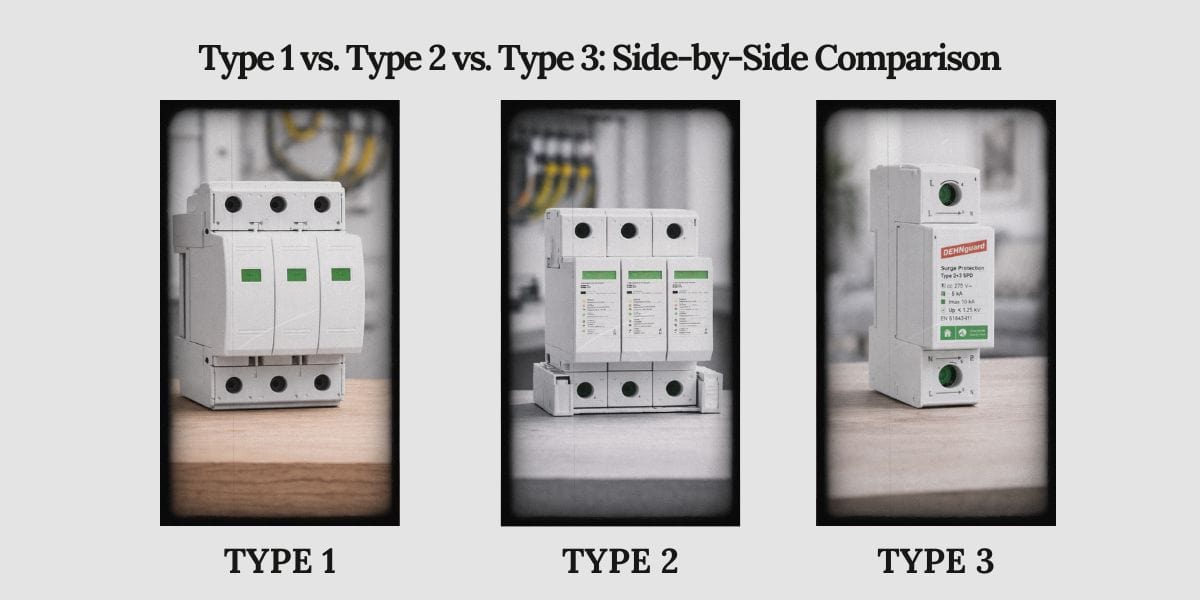

Tip 1 ve Tip 2 ve Tip 3: Yan yana karşılaştırma

| Parametre | Tip 1 SPD | Tip 2 SPD | 3 SPD yazın |

| Tipik kurulum yeri | Servis girişi, ana bağlantı kesme hattı tarafı | Dağıtım panelleri, bağlantı kesmenin yük tarafı | Yakın hassas ekipman |

| Dalgalanma Pozlama Seviye | çok yüksek | orta ila yüksek | Düşük |

| birincil işlev | Gelen dalgalanma akımını yönlendir | Kelepçe artık ve anahtarlama dalgalanmaları | İnce voltaj sınırlaması |

| Dalgalanma akımı | çok yüksek | Orta ila yüksek | Düşük |

| Voltaj sıkıştırma hassasiyeti | Düşük | Orta | Yüksek |

| Bağımsız uygunluk | Hayır | sınırlı | Hayır |

| Diğer SPD'lere bağımlılık | Tip 2 aşağı akış gerektirir | Genellikle Tip 1 ve Tip 3 ile eşlenir | yukarı akış tipi 1 veya tip 2 gerektirir |

| Yanlış uygulanırsa tipik risk | Yetersiz ekipman koruması | Aşırı stres ve azaltılmış ömrü | felâket başarısızlığı |

Bu karşılaştırma önemli bir ilkeyi vurgulamaktadır: SPD Türleri performans sıralamasına göre değil, işlev ve yerleşime göre tanımlanır.

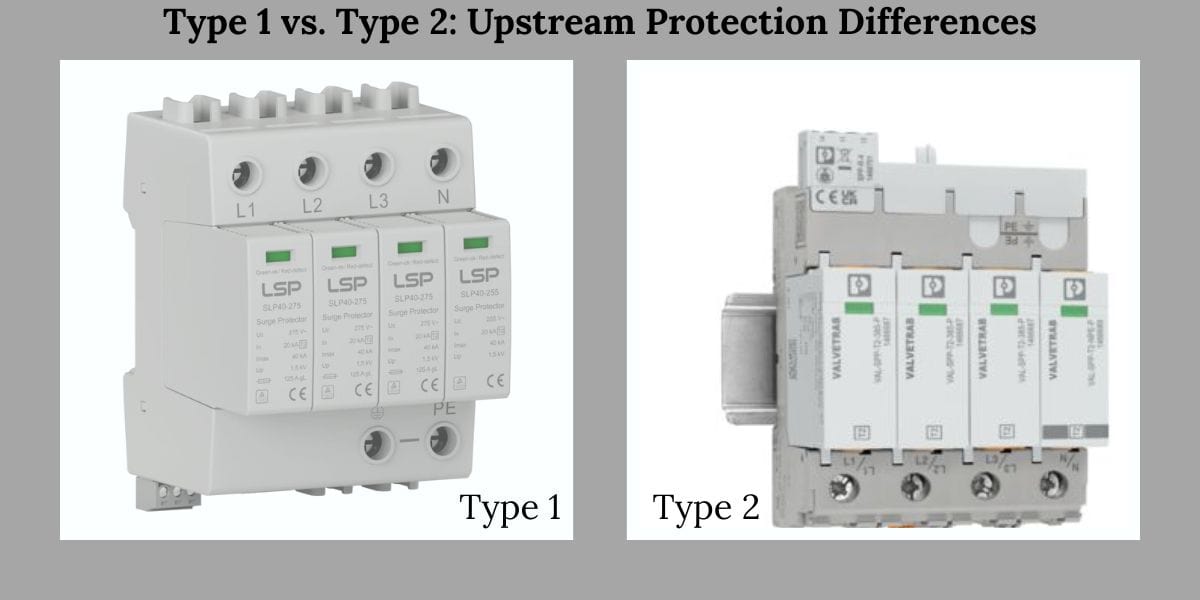

Tip 1 ve Tip 2: Yukarı akış koruması farklılıkları

Kurulum bağlamı

Harici aşırı gerilimin en yüksek olduğu servis girişine Tip 1 SPD'ler kurulur. Tip 2 SPD'ler, dahili dağıtım sistemi içinde aşağı akışa monte edilir.

Bu konumsal fark, her cihazın ele alması beklenen şeyi temelden değiştirir.

Dalgalanma Enerji Profili

- 1 SPD'leri yazın Yardımcı program ağından giren yıldırımla ilgili olaylarla ilişkili yüksek enerjili dürtülerle karşılaşın.

- 2 SPD yazın Artık yıldırım enerjisi ve sık dahili olarak üretilen anahtarlama geçişleri ile karşılaşın.

Tip 2 cihazlar en yüksek enerji darbeleri için tasarlanmadığından, servis girişinde Tip 1 korumanın yerini alamazlar.

işlevsel ayrım

- Tip 1, aşırı akım saptırmalarına odaklanır

- Tip 2, voltaj sınırlaması ve tekrarlayan dalgalanma kontrolüne odaklanır

Yalnızca Tip 2 korumanın yüksek pozlama ortamlarında kurulması, aşırı stresi kendisi için tasarlanmamış cihazlara kaydırarak erken bozulmaya yol açar.

Tip 2 ve Tip 3: Dağıtım ve Ekipman Seviyesi Koruması

Kurulum Yakınlığı

Tip 2 SPD'ler dağıtım ağlarını korurken, Tip 3 SPD'ler bireysel ekipmanı veya devreleri korur. SPD ile korunan yük arasındaki mesafe kritik bir farklılaştırıcıdır.

Kalan Gerilim Kontrolü

Yukarı akış korumasından sonra, artık geçici voltaj, hassas elektroniklerin impuls dayanma kapasitesini aşabilir. Tip 3 SPD'ler, kullanım noktasında ince voltaj iyileştirme sağlar.

Enerji İşleme Sınırlaması

Tip 3 SPD'ler, dalgalanma enerjisini emmek için tasarlanmamıştır. Doğrudan yüksek enerjili olaylara maruz kalırlarsa, hızla başarısız olabilirler. Bu nedenle, yukarı akış koruması olmadan asla kullanılmamalıdırlar.

Tip 2 ve Tip 3 arasındaki karşılaştırma, hangisinin "daha iyi" olduğu değil, hassasiyetin enerji işlemenin yerini nereden aldığıyla ilgilidir.

Neden tek bir SPD türü yeterli değildir?

Dalgalanma koruması katkı maddesi değildir. Aynı türden birden fazla cihazın yüklenmesi katmanlı koruma sağlamaz.

Her SPD tipi, yalnızca amaçlanan stres aralığında en iyi şekilde çalışır:

- Tip 1, gelen dalgalanma enerjisini azaltır

- Tip 2 kalan aşırı gerilimi yönetir

- Tip 3 Limitler Son Kalıntı Gerilimi

Tüm bu işlevleri tek bir cihazla gerçekleştirmeye çalışmak, korumanın zayıf olmasına, hizmet ömrünün kısaltılmasına veya her ikisine birden neden olur.

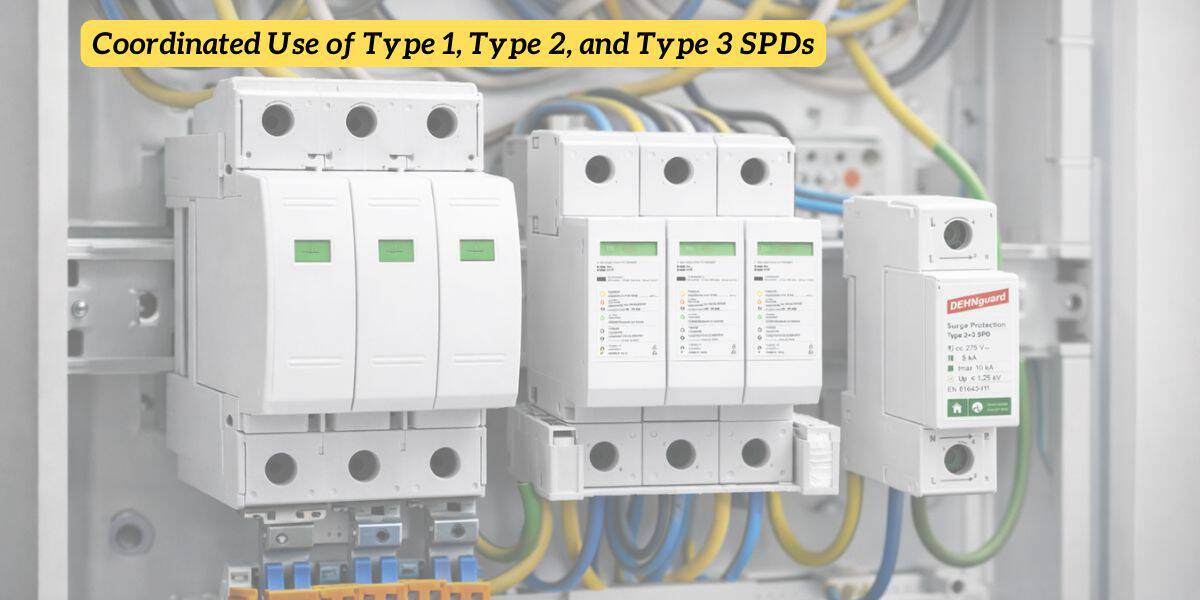

Tip 1, Tip 2 ve Tip 3 SPD'lerin koordineli kullanımı

Koordinasyon Nasıl Çalışır?

Koordineli bir aşırı gerilim koruma sistemi, aşırı gerilim enerjisinin yayılma şeklini yansıtır:

- 1. yazın Sistem girişinde yüksek enerjili impulsları yönlendirir

- 2. Tip Dağıtım sisteminde kalan dalgalanmaları kelepçeler

- 3. yazın Hassas yükleri artık gerilimden korur

Her aşama bir sonraki aşamadaki stresi azaltır.

Koordinasyon Neden Miktardan Daha Önemlidir?

Yanlış koordinasyon şunlara neden olabilir:

- Eşitsiz enerji paylaşımı

- Yerelleştirilmiş aşırı ısınma

- öngörülemeyen başarısızlık davranışı

Doğru yerleştirme ve empedans ayırma, ek cihazların kurulmasından daha fazla önemlidir.

Uygulamaya dayalı karşılaştırma senaryoları

Dış pozlama ile servis girişi

Havai elektrik hatlarına veya dış mekan elektrik altyapısına sahip tesisler, servis girişinde Tip 1 koruma ve ardından aşağı akışta Tip 2 koruma gerektirir.

Ticari ve endüstriyel dağıtım sistemleri

Anahtarlama işlemleri, dalgalanma faaliyetine hakimdir. Tip 2 SPD'ler, genellikle yukarı akış Tip 1 cihazlarla koordine edilen birincil koruma rolünü sağlar.

Hassas elektronik sistemler

Otomasyon kontrolörleri, enstrümantasyon ve iletişim arayüzleri, Tip 3 koruma gerektirir, ancak yalnızca yukarı akış dalgası enerjisi zaten azaltılmışsa.

Tek fazlı ve üç fazlı sistemler

3 fazlı Aşırı gerilim koruyucu cihaz fazdan faza ve fazdan toprağa geçişleri tutarlı bir şekilde yönetmelidir. SPD tipi seçimi, yalnızca voltaj derecesi değil, sistem konfigürasyonu ile uyumlu olmalıdır.

Mühendislerin yaptığı yaygın karşılaştırma hataları

- Tip 3 cihazların bağımsız çalışabileceğini varsayarsak

- Birden çok türü koordine etmek yerine bir SPD'yi büyük ölçüde büyütmek

- Empedans dikkate alınmadan birden fazla Type 2 cihazının yüklenmesi

- SPD türlerini işlevsel rollerden ziyade performans katmanları olarak ele almak

Bu hatalar koruma etkinliğini azaltır ve bakım riskini artırır.

Standartlar bağlamı

UL 1449 ve IEC 61643 gibi standartlar, SPD türleri için test koşullarını ve sınıflandırma kriterlerini tanımlar. Tutarlı karşılaştırmayı desteklerler, ancak yerleştirme ve koordinasyonla ilgili sistem düzeyinde mühendislik yargısının yerini almazlar.

Çözüm

Tip 1, Tip 2 ve Tip 3 aşırı gerilim koruyucu cihazlar, bir elektrik sistemi içinde farklı ve tamamlayıcı rollere hizmet eder. Farklılıkları, ürün sınıfı veya pazarlama pozisyonuna göre değil, kurulum yeri, aşırı gerilim ve koruma işlevi ile tanımlanır.

Etkili aşırı gerilim koruması, aşırı boyutlandırma veya fazlalığa değil, koordinasyona bağlıdır. Her SPD tipi en iyi performansı gösterdiği yerde uygulandığında, dalgalanma enerjisi kademeli olarak kontrol edilir, ekipman stresi azalır ve uzun vadeli sistem güvenilirliği artar.

SSS

hiç . Tip 2 cihazlar, sistem girişinde mevcut olan en yüksek aşırı gerilime maruz kalma seviyeleri için tasarlanmamıştır.

Yalnızca dolaylı olarak ve yalnızca yukarı akış koruması dalgalanma enerjisini zaten azalttığında.

Düşük maruziyetli ortamlarda kabul edilebilir olabilir, ancak yukarı akış koruması olmadan risk önemli ölçüde artar.

Çünkü yanlış yerleştirme, derecelendirmeden bağımsız olarak cihazları aşırı strese sokabilir.

Her zaman değil, ancak çoğu modern kurulum en az tip 1 ve tip 2 koordinasyonundan yararlanır.