With the rapid development of LED technology, lighting products are becoming brighter, more efficient, and more widely used in commercial and residential projects. However, high-intensity light sources may also pose potential risks to human eyes and skin. To ensure safety, international standards such as IEC 62471 are used to evaluate the photobiological safety of LED lighting. For manufacturers and importers, understanding and complying with this standard is essential to meet market regulations and protect users from possible light-related hazards.

What Is IEC 62471?

IEC 62471 is an international standard developed by the International Electrotechnical Commission (IEC) that defines the photobiological safety of lamps and lamp systems, including LEDs. It evaluates the potential hazards of optical radiation emitted by light sources.

This standard is often harmonized as EN 62471 in Europe and is a key requirement for CE marking and safety declarations. Essentially, IEC 62471 helps determine whether a lighting product is safe for long-term human exposure, providing a scientific framework for risk classification and safety labeling.

What Does IEC 62471 Evaluate?

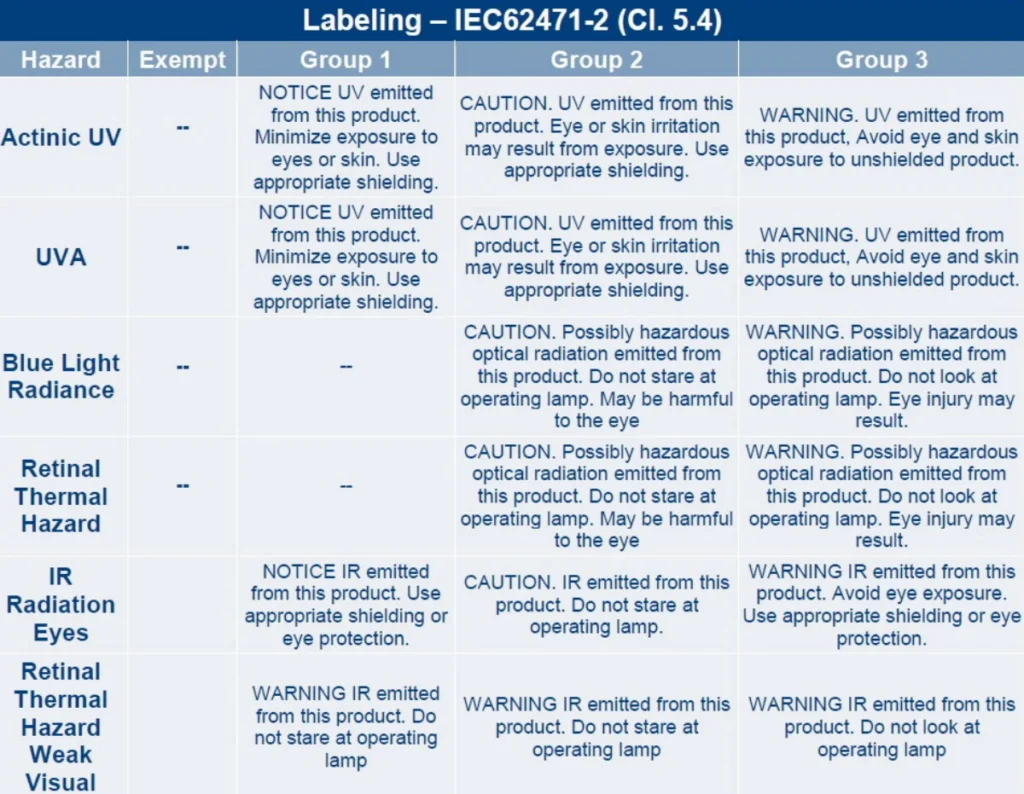

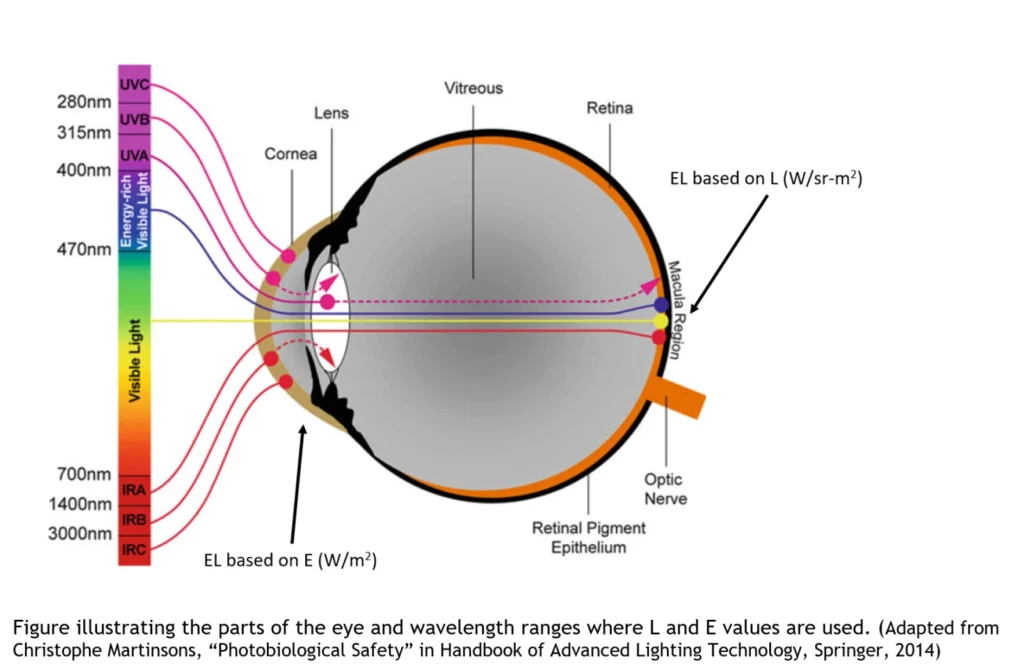

IEC 62471 focuses on the biological effects of optical radiation emitted by LEDs and other LED lighting. The test evaluates exposure to different wavelength regions that may affect the eyes or skin, mainly including:

UV Hazard: Risk of skin burns or eye inflammation caused by ultraviolet radiation.

Blue Light Hazard: Possible damage to the retina due to high-intensity blue light, which is common in white LEDs.

Infrared Hazard: Heat-related damage to the skin or eyes caused by infrared radiation.

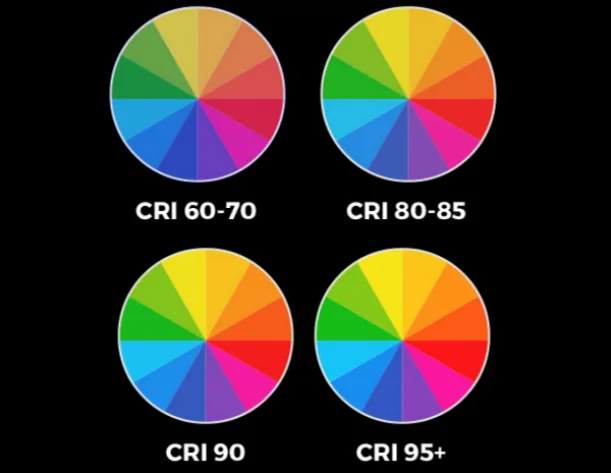

Based on the measurement results, the light source is classified into four risk groups:

Exempt Group (RG0): No photobiological risk.

Risk Group 1 (RG1): Low risk under normal conditions.

Risk Group 2 (RG2): Medium risk; avoid direct eye exposure.

Risk Group 3 (RG3): High risk; safety measures are required.

This classification helps manufacturers label their products accurately and ensure end users apply them safely.

Why Is IEC 62471 Testing Important for LED Lighting?

For LED manufacturers, passing IEC 62471 testing is not only about compliance—it’s about product reliability, brand reputation, and market access.

Regulatory Requirement: Many regions, including the EU, require IEC/EN 62471 compliance for lighting products before they can be sold.

User Safety: It ensures the LED light does not emit harmful radiation levels that could cause visual or skin damage.

Market Advantage: Products with verified safety performance gain higher trust among distributors, project designers, and end customers.

Risk Management: It minimizes liability risks for manufacturers and importers in case of health-related complaints.

Simply put, IEC 62471 certification proves that your lighting products are safe, responsible, and professionally designed for global markets.

How to Ensure Your LED Fixtures Pass IEC 62471 Test

Achieving IEC 62471 compliance starts with good optical design and material selection. Here are several practical recommendations:

Optimize the Light Source Design: Reduce excessive blue light peaks by adjusting LED chips and color temperature, usually CCT under 4000K is more easier to pass the test.

Use Diffusers or Lenses: Adding diffusers helps distribute light evenly and lower irradiance levels.

Control the Distance and Beam Angle: Design fixtures so that users are not directly exposed to intense beams.

Pre-Test During Development: Perform preliminary photobiological assessments early in R&D to identify potential risks before mass production.

Work With Accredited Laboratories: Certified testing labs such as TUV, SGS, or Intertek can provide accurate IEC 62471 reports and professional guidance.

Following these steps greatly increases your chances of passing the test smoothly and ensures your products meet international safety standards.

Conclusion

As LED lighting continues to evolve, photobiological safety has become a key aspect of product compliance and market competitiveness. Understanding IEC 62471 and designing with safety in mind will help manufacturers create lighting products that are both efficient and safe for human use.

At SignliteLED, we design and manufacture high-quality LED fixtures that meet international standards including IEC 62471. Our engineering team focuses on optical safety and compliance to ensure your lighting projects can enter global markets with confidence.

If you are developing or sourcing LED products and want to ensure they pass IEC 62471 testing, feel free to contact SignliteLED for professional support and customized LED lighting solutions.