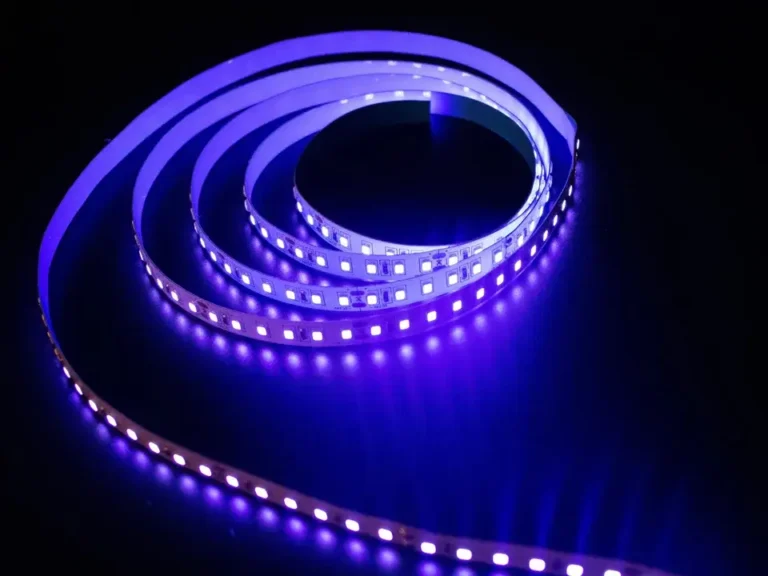

UV LED strip lights are increasingly becoming a key light source in industrial and commercial projects. They are widely used in curing systems, fluorescence detection, anti-counterfeiting identification, stage lighting, aquarium lighting, sterilization, and purification applications.

Among all UV wavelengths, 365nm and 395nm are the two most frequently used wavelengths. Both belong to the UVA (long-wave ultraviolet) range, but they exhibit significant differences in spectral characteristics, excitation effects, and application scenarios. Understanding the distinctions between these two wavelengths enables engineers, procurement personnel, and project integrators to make more precise selections for specific applications.

This article will systematically compare the performance, applications, pricing, and safety of 365nm and 395nm UV LED strip lights, helping you quickly select the appropriate product based on project requirements and recommending suitable solutions.

365nm vs. 395nm LED Strip Lights: Which Is Better?

Although both 365nm and 395nm fall within the UVA spectrum, they exhibit significant differences in their luminous characteristics, excitation capabilities, visual effects, suitable applications, and cost structures in practical applications.

365nm UV light is more commonly used in scientific and industrial applications because of its stronger invisibility, greater penetration, and lack of interference with visible light. 395nm light has a spectrum closer to visible light, making it easier for the human eye to see. While the 395nm wavelength can also be used for various tasks, it is more suitable for applications requiring visible light, such as UV curing or detection.

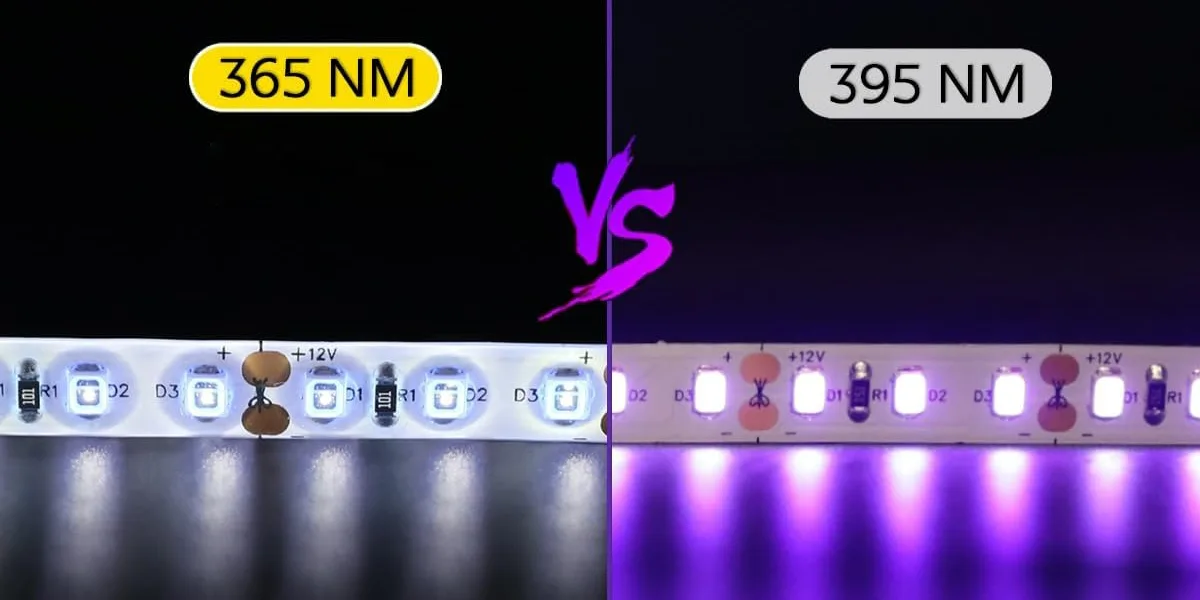

Although both 365nm and 395nm are UVA light and produce black light and curing effects, with only a 30nm difference, 395nm is closer to visible light (purple) than 365nm. Therefore, to the naked eye, 395nm UV light appears purple. 365nm penetrates deeper into the invisible ultraviolet spectrum, contains less visible light, and has a shorter wavelength, so to the naked eye, 365nm ultraviolet light appears as a dim blue-white color.

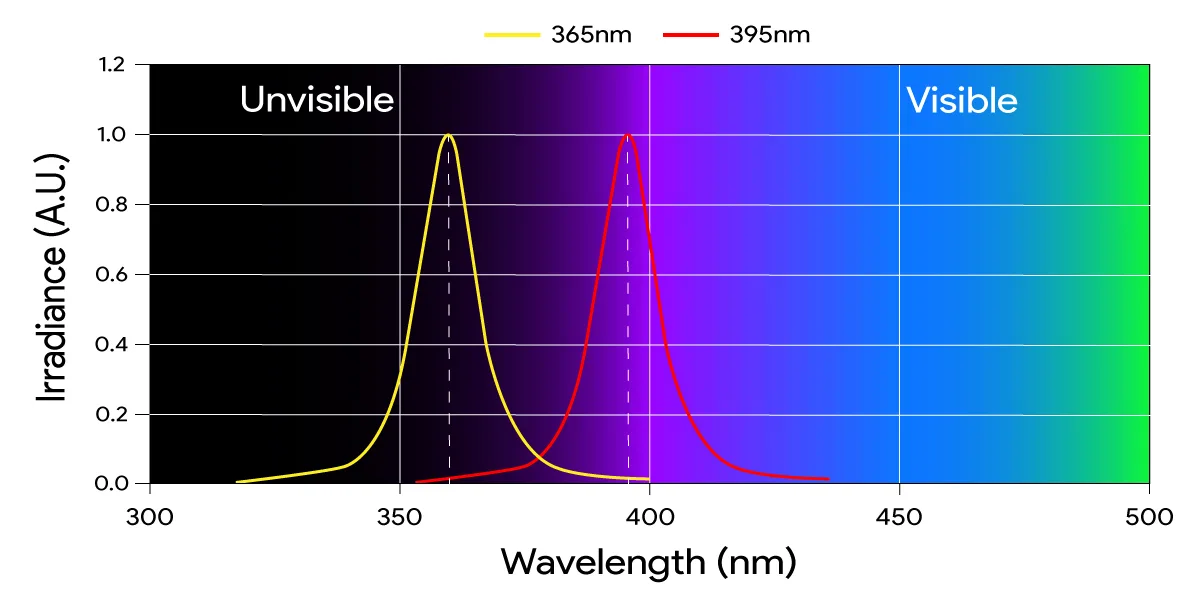

Why is there a difference between 365nm and 395nm? Because 365nm does not only emit light at the 365nm wavelength, and 395nm does not only emit light at the 395nm wavelength. Therefore, when comparing 365nm and 395nm ultraviolet LED lights, it is essential to consider their spectral output and peak wavelengths. As shown in the figure below:

365nm LEDs and 395nm LEDs emit the maximum energy (i.e., peak wavelength) at 365nm and 395nm, respectively, but they also emit significant energy in the adjacent ranges of 350nm to 380nm and 390nm to 410nm. The energy of 365nm and 395nm decreases on either side of the 365nm and 395nm spectral lines.

Compared to 365nm, a larger portion of the 395nm spectral output falls within the visible violet region, providing a more intense visual experience, making it suitable for entertainment venues or decorative lighting. Conversely, the spectral output of 365nm is closer to the visible light threshold of 400nm, resulting in lower energy levels. This difference makes 365nm LEDs the preferred choice for most UV-A applications.

Although the 365nm wavelength is deep within the invisible spectrum, due to limitations in LED design or material properties, 365nm LEDs may emit a small amount of visible “leakage” or radiation beyond the 365nm wavelength. These visible components may fall within the blue or white spectrum range, causing the observed lighting to appear as a dull blue-white hue rather than the desired pure UV output at the 365nm single wavelength.

Additionally, from a cost perspective, 365nm LEDs are typically expensive. Due to the complex manufacturing process of LED diodes, 365nm wavelength chips are inefficient and costly. The specific price difference depends on the product type, but 365nm LEDs are generally more expensive. Therefore, if you prefer a brighter, wider beam and do not need to illuminate any minor imperfections or spots, then a 395nm LED light strip would be more suitable for you.

The following is a system comparison table to help you quickly understand the core differences between the two:

| Item | 365nm UV LED strip light | 395nm UV LED strip light |

| Wavelength range | 360–370nm (peak at 365nm) | 390–400nm (peak at 395nm) |

| Visible light characteristics | Blue-white | Purple |

| Excitation capability | Extremely strong, capable of exciting various fluorescent powders, UV inks, and UV adhesives | Strong, but with limited excitation effects on certain materials |

| Typical application scenarios | UV adhesive/ink curing, PCB inspection, laboratory UV imaging, passport/anti-counterfeiting identification, industrial fluorescent detection | Stage lighting, blacklight parties, aquarium lighting, fluorescent art displays, blacklight ambiance in entertainment venues |

| Human visual comfort | Not suitable for direct viewing with the naked eye, no photic sensation (high safety but not suitable for prolonged exposure) | Perceives ultraviolet light, minimal light pollution, suitable for decorative purposes |

| Power density options | Common systems are 12V/24V, supporting high power (10–30W/m) | Common systems are 12V/24V, with flexible power options, supporting a range of 3–20W/m |

| Lighting effects | Emphasizes excitation/penetration/reaction efficiency rather than visual appeal | Emphasizes visual effects and atmospheric rendering |

| Fluorescent dye compatibility | Can excite most commercial fluorescent dyes and coatings | Can excite some fluorescent dyes, but with relatively weaker excitation intensity |

| Price and Availability | Higher unit cost (due to high-power/imported chip driver costs) | Lower cost, offering better cost-effectiveness for bulk use |

| Suitability for curing applications | Highly suitable, with precise wavelength and strong light energy | Generally not recommended, only suitable for mild reaction excitation |

| Suitability for atmosphere creation | Not suitable, visually invisible | Suitable, commonly used for commercial decoration and stage effects |

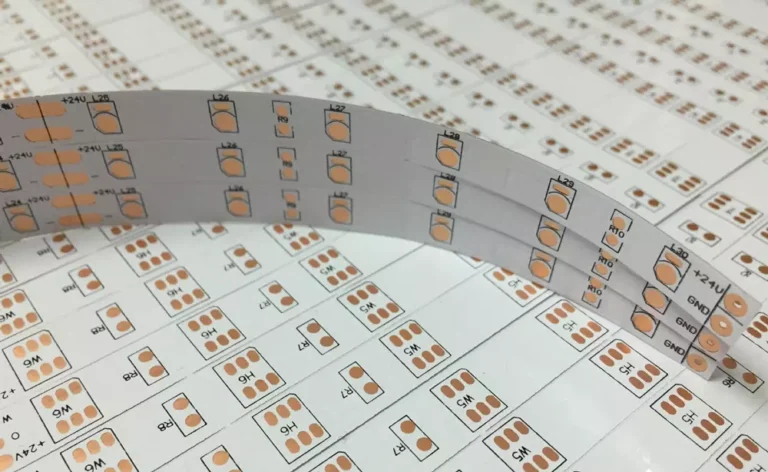

| Recommended packaging | 3535 high-power ceramic packaging / 2835, 5050 high-density packaging | 2835 / 5050 packaging, suitable for flexible LED strip applications |

In summary, the choice between 365nm and 395nm depends on the specific application and personal preference. Each wavelength has its own advantages, so it is essential to consider the advantages of each wavelength when determining which UV light is most suitable for your needs. Additionally, while 395nm is more cost-effective, it cannot replace 365nm for industrial-grade UV curing or precise detection. Conversely, 365nm, due to its invisible light characteristics, often fails to achieve the desired visual effects when used for commercial lighting.

For more information about UV LED strip lights, please read the blog: Guide to UV LED Strip Lights.

Product Recommendations: High-Performance 365nm and 395nm UV LED Strips

To meet the diverse needs for UV light strips across different wavelength bands in industrial curing and commercial lighting applications, SignliteLED has carefully selected and launched the following two flagship products, each focusing on high-precision UV curing and blacklight ambiance lighting. These products support large-scale OEM customization, international shipping, and integration with project contractors.

FAU10T60A-365NM—DC12V 365nm UV LED Curing Strip Light (Industrial Grade)

This 365nm UV LED strip light is specifically designed for UV adhesive curing, fluorescent detection, and precision lighting applications, utilizing high-intensity UV SMD5050/SMD2835 light sources with exceptional excitation efficiency and structural stability.

Main Model: FAU10T60A-365NM

LED Type: UV SMD5050/SMD2835

LED QTY per Meter: 60/120

PCB Width: 10mm

Wavelength: 365-370nm

Input Voltage: DC12V

Power per Meter: 14W

IP Grade: IP20/IP65/IP67

Warranty: 5 years

Above the function supports customization.

FAU10T60A-395NM—DC12V 395nm Black Light UV LED Strip Light (Visual Decoration)

Specifically designed for creating commercial atmospheres and enhancing visual effects, the 395nm wavelength emits visible violet light. When paired with fluorescent coatings or reflective materials, it can create rich interactive experiences and visual impact.

Main Model: FAU10T60A-395NM

LED Type: UV SMD5050/SMD2835

LED QTY per Meter: 60/120

PCB Width: 10mm

Wavelength: 395-400nm

Input Voltage: DC12V

Power per Meter: 14W

IP Grade: IP20/IP65/IP67

Warranty: 5 years

Above the function supports customization.

Why are 365nm and 395nm the mainstream wavelengths for UV LED lighting?

365nm and 395nm refer to wavelengths in the ultraviolet spectrum. These wavelengths fall within the UVA range and are commonly referred to as “black light” because they can cause certain materials to emit fluorescence or visible light.

The wavelength range of commercially available UVA light sources typically spans from 365nm to 405nm, with 365nm and 395nm being the more commonly chosen options. In UV blacklight and fluorescence detection applications, selecting between 365nm and 395nm is a common consideration.

These two wavelength bands have become industry standards primarily because they achieve an optimal balance between performance and cost-effectiveness in terms of excitation efficiency, material compatibility, safety of use, and cost control. The following analysis explores why these two wavelength bands dominate the market from four key perspectives:

1. Strong spectral excitation capability, suitable for diverse applications

Both 365nm and 395nm are located in the UVA (315–400nm) long-wavelength ultraviolet region, exhibiting excellent fluorescence excitation capabilities and capable of activating a wide range of ultraviolet-reactive materials.

365nm: Nearly invisible, pure UV wavelength, effectively excites fluorescent powders, UV inks, UV adhesives, etc., widely used in high-demand applications such as curing, industrial inspection, and laboratory lighting.

395nm: Features a slight purple hue, offering more noticeable visual effects, making it ideal for decorative or interactive applications such as stage lighting effects, art displays, and aquarium lighting.

Whether for technical applications (e.g., PCB fluorescence inspection) or visual experience-oriented applications (e.g., blacklight party lighting), suitable solutions can be found within these two wavelength bands.

2. Moderate safety rating, suitable for long-term commercial/industrial use

Compared to the UVB (280–315nm) and UVC (100–280nm) bands, the 365nm and 395nm bands pose a lower potential risk to human health. Their radiation energy has minimal impact on operators and surrounding personnel when not directly exposed to the eyes or skin, making them widely used in public areas and open environments.

- Indoor display light boxes

- Inspection workshop lighting

- Educational/laboratory equipment

- Smart home UV functional lighting

For project developers, this means fewer safety restrictions, higher project compliance, and greater flexibility in application.

3. Mature supply chain, easy to integrate in bulk

Whether 365nm or 395nm, their LED chips, optical packaging, and driver solutions have achieved large-scale production globally, with good technical maturity and channel stability.

- Chip brands: CREE, OSRAM, LG, SEOUL, Sanan, etc., all provide a stable supply.

- Packaging formats: Mainstream packaging formats such as 2835, 3535, and 5050 are all customizable.

- Voltage support: 12V/24V constant voltage design, compatible with mainstream LED strip driver systems

This significantly enhances product integration efficiency and post-sales controllability for OEM manufacturers, engineering project contractors, and international buyers.

4. Cost-effective, suitable for various budget levels

- 395nm LED strips, due to their simple structure and low material costs, are commonly used in medium- to low-power applications and are the preferred choice for budget-sensitive projects.

- 365nm LED strips, with their stronger excitation effects and technical added value, offer higher cost-effectiveness in professional-grade testing/curing projects despite their slightly higher unit price.

Customers can flexibly choose between the two based on project budget and functional requirements to achieve the optimal balance between performance and cost.

In summary, the 365nm and 395nm wavelength bands are not only technically mature, safe, stable, and widely available but also cover a wide range of application scenarios from industrial manufacturing to commercial displays. As a result, they have become the “dual core” of the UV LED light strip market and will continue to lead application trends for years to come.

FAQ

A: We do not recommend using 395nm LED strips for industrial curing applications. Although 395nm falls within the UVA spectrum, its excitation efficiency is significantly lower than that of 365nm, making it unable to meet the curing strength requirements of most UV adhesives and inks. For applications involving bonding, printing, encapsulation, and other industrial curing tasks, we recommend prioritizing 365nm.

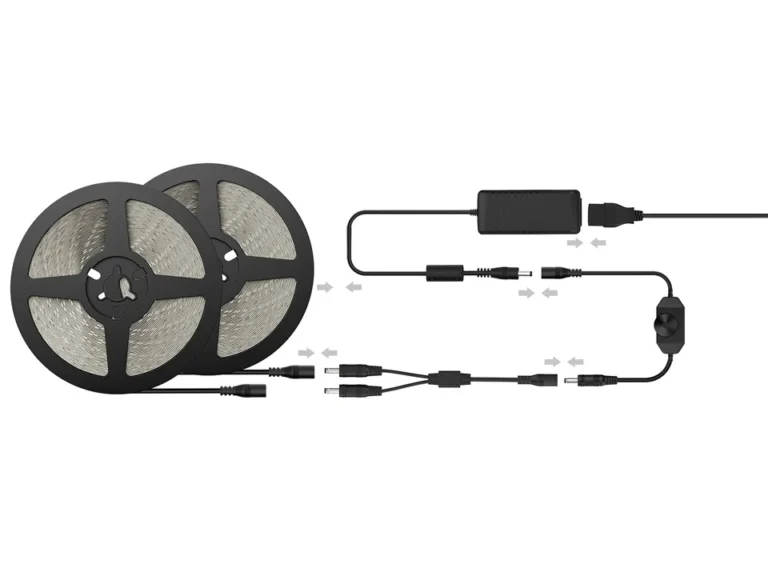

A: Yes. SignliteLED supports customization for multiple input voltages, including DC12V, DC24V, and DC36V, to accommodate varying requirements for circuit integration and power distribution across different projects. The 24V version is more suitable for large-area or long-distance installations to minimize voltage drop effects.

A: Absolutely. We offer comprehensive OEM/ODM customization services, including:

1. LED chip type (2835/5050/3535, etc.)

2. LED strip width (8mm/10mm/12mm)

3. LED quantity (30 LEDs/m to 240 LEDs/m)

4. Power range (5 W/m to 30 W/m)

5. PCB material, segment length, connectors, adhesive backing, and other details

6. Please submit your drawings or specifications, and we can provide sample production services.

A:

1. Standard models in stock: Shipment within 3–5 days;

2. Customized models for sampling: Approximately 7–10 working days;

3. Bulk orders: The production cycle is 10–15 days, depending on order complexity;

4. Shipping methods: Supports DHL, FedEx, and UPS air freight; sea/land freight can also be arranged.

We have extensive experience in handling international orders and support exports to multiple countries and regions, including Europe, the Middle East, Southeast Asia, and Australia.

A: Yes. Our UV LED light strips are compatible with most constant-voltage PWM dimmers, smart lighting systems, infrared/microwave sensors, and other control modules available on the market. If support for industrial-grade protocols such as DMX, 0–10V, or DALI is required, we can also provide corresponding solutions.

A: No. 365nm falls within the pure ultraviolet wavelength range, which is virtually invisible to the human eye, but it is indeed functioning. You can verify its functionality by shining it on white paper or fluorescent materials or using a UV detection card. If the LED chips show no spots or heat, please contact technical support for further confirmation.

Conclusion

Advancements and innovations in the UV LED field have made most applications safer and more effective. UV-A wavelengths and light sources are the most effective, such as 365nm and 395nm. However, the specific wavelength and light source ultimately depend on the user’s requirements.

In today’s highly competitive UV LED lighting market, choosing the right supplier is more important than choosing the right product. SignliteLED, as a professional LED strip lighting manufacturer and solutions provider, has earned the trust of numerous global wholesale customers through its exceptional product performance and comprehensive service system.

Whether you are an LED strip brand manufacturer, lighting engineering company, or global distributor, SignliteLED can be your trusted UV LED lighting partner. Contact us to request samples, project quotes, or customized solutions, and embark on your UV lighting upgrade journey!