Yes, LED white tape can be used for outdoor lighting if and only if it is a properly rated waterproof COB LED strip designed for environmental exposure. Standard non-waterproof COB LED strip lights, typically rated IP20, are not suitable for outdoor use because they lack protection against moisture, dust, UV radiation, and temperature fluctuations. Outdoor durability depends on three critical factors: appropriate IP rating, effective sealing and encapsulation, and correct installation practices.

This article will explain when LED white tape can safely function outdoors, what protection levels are required, how environmental stress affects performance, and how installation methods determine long-term reliability. It will also clarify the difference between basic moisture resistance and true waterproof construction.

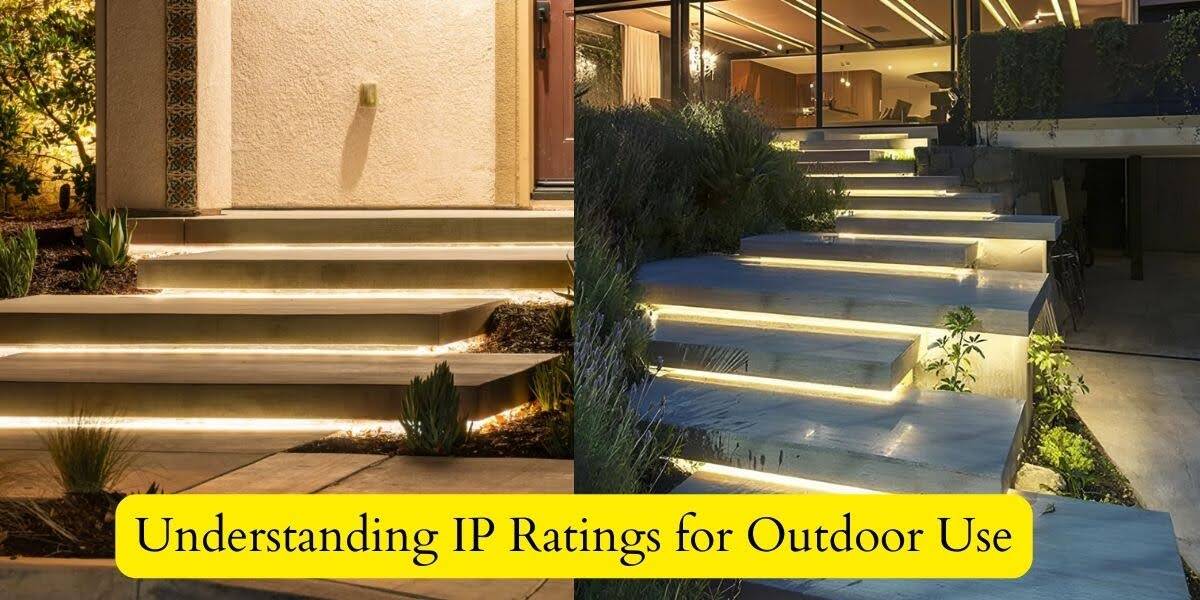

Understanding IP Ratings for Outdoor Use

Outdoor suitability begins with understanding IP (Ingress Protection) ratings. An IP rating defines how well an electrical product resists intrusion from solids and liquids. For any COB LED light strip intended for exterior environments, this rating determines whether it can survive real-world exposure.

An IP20 COB LED strip offers no water protection. It is designed strictly for dry, indoor conditions. Even light humidity or condensation can cause oxidation of exposed copper pads and solder joints. Using IP20 Đèn LED dải COB outdoors will result in rapid degradation and possible short circuits.

IP65 indicates protection against low-pressure water jets from any direction. A waterproof COB LED strip rated IP65 typically features a silicone top coating over the LED surface. This rating makes the strip suitable for areas exposed to rain or splashing, such as under eaves or covered patios. However, IP65 products are not designed for continuous water immersion.

IP67 offers stronger protection. An IP67 waterproof COB LED strip can withstand temporary immersion in water, usually up to 1 meter for a limited duration. These products are typically encased in silicone extrusion tubing or sealed sleeves. This rating is suitable for areas where pooling water or heavy rainfall may occur.

IP68 represents the highest commonly available protection level. A waterproof COB LED strip with IP68 rating is fully encapsulated and designed for continuous submersion under specified conditions. These are used in fountains, water features, or permanently wet environments. However, IP68 suitability depends on manufacturer specifications, not simply the number.

It is important to distinguish between splash-resistant and submersible products. Splash-resistant strips handle rain and incidental moisture. Submersible strips require complete encapsulation and sealed connections. Selecting the correct rating is the first condition for outdoor viability.

Environmental Stress Factors Outdoors

Outdoor environments expose lighting systems to multiple stress factors that indoor installations never encounter. Even a waterproof COB LED strip must be selected and installed with these risks in mind.

- Water exposure: Rain, irrigation systems, condensation, and humidity can penetrate poorly sealed strips. Water intrusion causes corrosion of copper traces and solder joints, leading to flickering or complete failure.

- UV radiation: Continuous sunlight degrades low-quality silicone coatings. UV exposure can cause yellowing, cracking, or brittleness in encapsulation materials, reducing protection over time.

- Temperature expansion and contraction: Outdoor temperatures fluctuate significantly between day and night. PCB materials and silicone coverings expand and contract at different rates, potentially weakening seals or causing micro-cracks.

- Dust and debris: Wind-driven dust can accumulate on exposed surfaces. Over time, abrasive particles may damage protective coatings or reduce light output.

- Corrosion of connectors: Unsealed connectors and exposed cut points are common failure points. Moisture combined with oxygen accelerates oxidation of metal contacts.

These environmental factors explain why a waterproof COB LED strip requires not just a water-resistant surface but a fully integrated sealing system that includes end caps, connectors, and protected power supplies. Outdoor durability depends on the weakest point in the system.

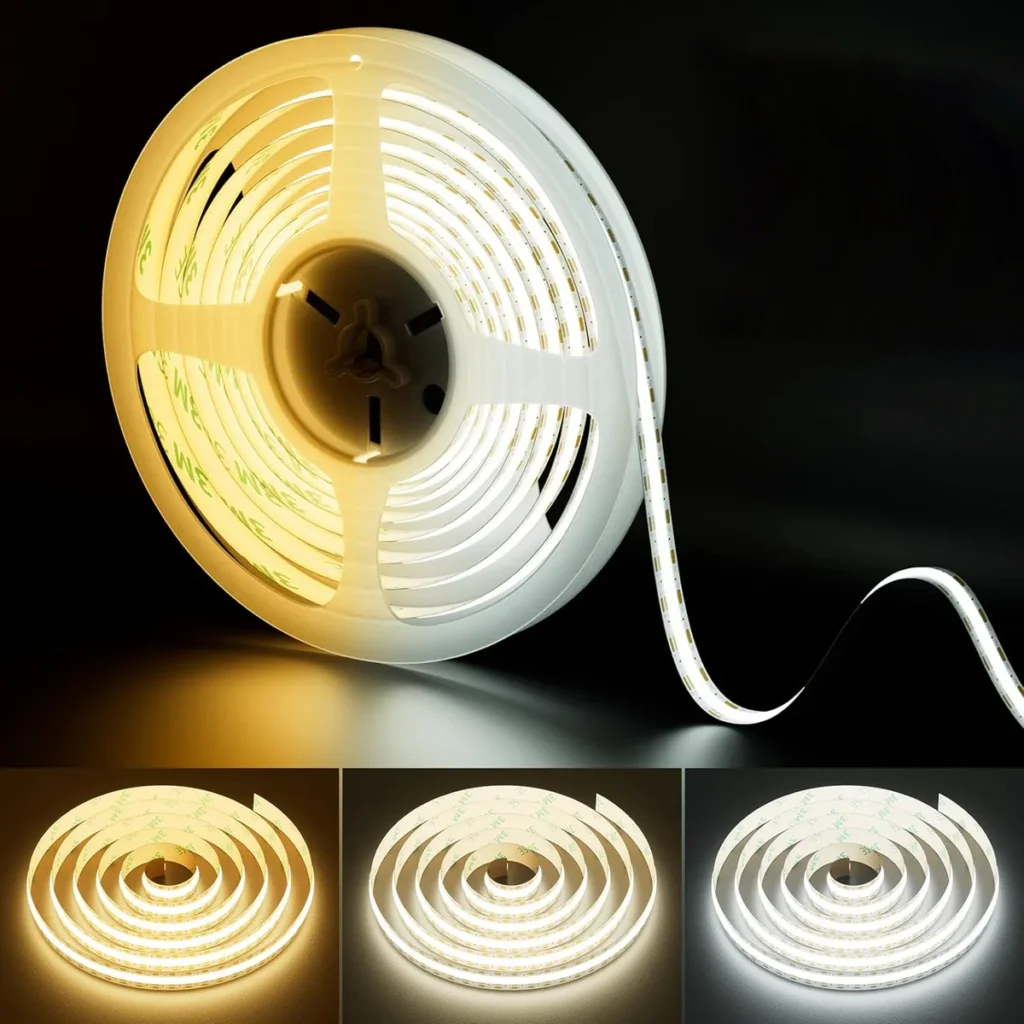

Đèn LED màu trắng có thể điều chỉnh được

- Mô hình chính: FYT10T608C

- Led QTY tùy chọn tùy chọn: 608/640Chips (Sanan)

- Tùy chọn chiều rộng PCB: 10mm

- Tùy chọn màu sắc: 2700K – 6500K tunable

- CRI:> 90

- Điện áp đầu vào: DC12V/DC24V

- Công suất trên mét: 14W / 16W

- Hiệu quả: 90-110 lumen/watt

- Tùy chọn cấp độ IP: IP20/IP54/IP65/IP67/IP68

- Bảo hành: 3 năm

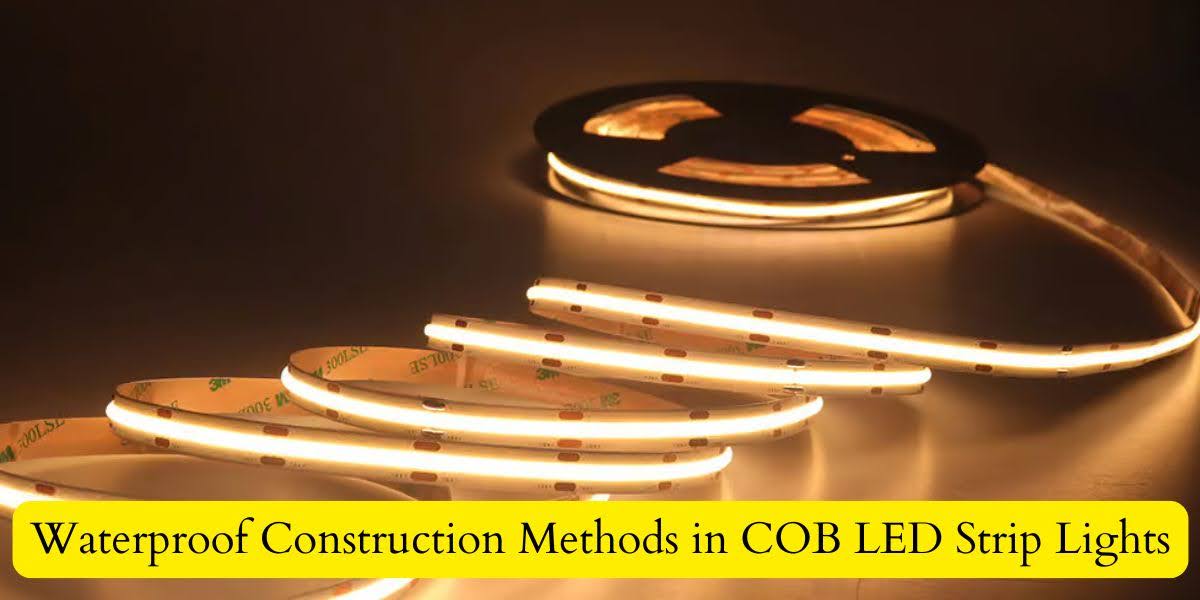

Waterproof Construction Methods in COB LED Strip Lights

- Silicone Top Coating (Surface Sealing)

A thin silicone layer is applied over the LED phosphor surface. This method typically supports IP65 protection and guards against splashes and light rain. However, the underside PCB may remain partially exposed, making it unsuitable for immersion. - Silicone Extrusion (Sleeve Encapsulation)

The COB LED strip is inserted into a continuous silicone tube or sleeve. Both ends are sealed using molded caps or injected silicone. This construction usually achieves IP67 protection and offers improved resistance against temporary water immersion. - Epoxy Encapsulation

The entire COB LED light strip is embedded in a hardened resin compound. This provides strong mechanical and moisture protection but reduces flexibility. It is used where structural rigidity is acceptable. - Full Injection-Molded Sealing (IP68 Systems)

In high-grade waterproof COB LED strip lights, sealing includes molded entry points, integrated cable glands, and sealed connectors. This prevents capillary water migration along the PCB and supports continuous submersion ratings. - PCB Protective Layers

High-quality COB LED strip products include corrosion-resistant copper layers, protective solder masks, and anti-oxidation coatings. These internal protections prevent moisture-induced degradation even if external sealing is stressed. - Sealed End Caps and Cable Entry Points

End caps must be bonded using silicone adhesive or overmolding techniques. Poorly sealed ends are the most common failure point in outdoor installations. - Limitations of Adhesive Backing Outdoors

Standard pressure-sensitive adhesive degrades under moisture and temperature cycling. Waterproof COB LED strip lights intended for exterior use should not rely solely on adhesive for structural support.

The following demonstration shows how IP65 waterproof sealing is practically applied to a COB LED strip.

Installation Requirements for Outdoor Use

Even the highest-rated waterproof COB LED strip will fail if installed incorrectly. Proper installation ensures that environmental protection is maintained.

- Seal all cut points: When a COB LED strip is cut to length, exposed copper pads must be resealed using waterproof end caps or silicone sealant. Leaving cut points exposed defeats the IP rating.

- Use waterproof connectors: Standard snap connectors are not suitable outdoors. Only connectors rated equal to or higher than the strip’s IP rating should be used.

- Install within aluminum profiles: Aluminum channels provide mechanical protection, improve heat dissipation, and shield the strip from direct UV exposure.

- Use mounting clips instead of relying only on adhesive: Outdoor temperature changes weaken adhesive backing. Supplemental clips prevent sagging and detachment.

- Protect the power supply: Drivers must be installed in waterproof enclosures or rated for outdoor use. Exposed drivers are a common failure point.

- Ensure drainage and ventilation: Avoid sealing strips in areas where water can accumulate. Proper drainage prevents prolonged water exposure.

Outdoor reliability depends as much on installation discipline as on product rating.

Outdoor Applications Where White COB LED Strip Works Best

trong trắng dải đèn LED lights perform particularly well in controlled exterior environments where direct immersion is not required. Under-eave lighting is a common example. Installed beneath roof overhangs, a waterproof COB LED strip provides uniform illumination for pathways and building facades while remaining shielded from direct rainfall.

Pergolas and patio structures also benefit from COB LED strip installation. When mounted inside aluminum channels and protected from standing water, the continuous light output enhances visibility without exposed LED dots.

Architectural accent lighting is another suitable application. A waterproof COB LED strip can highlight building lines, columns, or textured surfaces, provided that it is installed within rated housings.

Garden pathway lighting works effectively when the strip is installed in protective channels slightly above ground level. Direct soil contact should be avoided unless the product is IP68 rated.

Submersion in pools, fountains, or water features requires an IP68 waterproof COB LED strip specifically designed for continuous immersion. Standard IP65 or IP67 products are not sufficient for permanent underwater exposure.

The key principle is matching the product rating to the environmental demand.

Đèn LED dải đèn LED

- Mô hình chính: FYX08T480C

- LED QTY per Meter Option: 320/384/480/528chips (Sanan)

- PCB Width Option: 8mm/10mm

- Tùy chọn màu sắc: 2700K / 3000K / 4000K / 6500K / Đỏ / Xanh lá / Xanh / Tùy chỉnh

- CRI:>90

- Điện áp đầu vào: DC12V/DC24V

- Power per Meter:8W/10W/11W/14w

- Efficiency: 90-110 lumen/watt

- Tùy chọn cấp IP: IP20/IP54/IP65/IP67/IP68

- Warranty:3 years

Indoor vs Waterproof COB LED Strip Performance

| mẫu | Indoor COB LED Strip | Waterproof COB LED Strip |

| Cấp bảo vệ | IP20 (no water protection) | IP65, IP67, or IP68 |

| Suitable Environments | Dry indoor spaces only | Outdoor areas exposed to rain, moisture, or dust |

| Lifespan Outdoors | Very short; prone to failure | Long-term durability when properly installed |

| Yêu cầu cài đặt | Adhesive mounting only | Sealed ends, waterproof connectors, mechanical support |

Những sai lầm phổ biến cần tránh

One of the most common mistakes is installing IP20 COB LED strip lights outdoors under the assumption that a covered area eliminates risk. Even covered spaces experience humidity and condensation. Without waterproof protection, corrosion begins quickly.

Another frequent error is failing to reseal cut ends. When a COB LED strip is shortened for custom length, the exposed copper pads create a direct path for water intrusion. Even a small amount of moisture can migrate along the PCB.

Exposing drivers and power supplies to weather is another critical oversight. A waterproof COB LED strip does not compensate for a non-rated power supply. The entire electrical system must match the environmental rating.

Ignoring thermal expansion can also reduce lifespan. Installing strips tightly in rigid channels without allowing for slight movement may stress encapsulation layers over time.

Finally, relying solely on adhesive backing leads to detachment in outdoor conditions. Mechanical reinforcement is essential for secure, long-term installation.

Phần kết luận

LED white tape can be used for outdoor lighting only when it is a properly rated waterproof COB LED strip designed for environmental exposure. Standard indoor COB LED strip lights are not suitable for outdoor conditions due to their lack of moisture and UV protection.

IP rating, sealing integrity, encapsulation method, and installation quality collectively determine performance and lifespan. Selecting the correct waterproof COB LED strip and installing it using proper sealing, housing, and environmental protection practices ensures safe and durable outdoor operation.

Outdoor success depends on correct product selection and correct installation, not simply on the presence of LEDs.

hỏi Ẩn

Yes, a waterproof COB LED strip rated IP65 or higher can withstand heavy rain when properly installed. However, all connectors and power supplies must also meet the same protection rating to prevent failure.

COB LED strip lights can be used near pools if they are rated IP67 or IP68. For direct submersion in pool water, only an IP68 waterproof COB LED strip specifically designed for immersion should be used.

For covered patios, IP65 is generally sufficient. For exposed patios where water pooling may occur, IP67 provides additional safety.

Yes, prolonged UV exposure can degrade silicone coatings on lower-quality products. A high-quality waterproof COB LED strip should use UV-resistant materials to maintain durability.

Lifespan depends on environmental severity and installation quality. Properly installed waterproof COB LED strip lights can operate reliably for many years, provided sealing remains intact.

Yes, but only if the cut ends are properly resealed with waterproof end caps or silicone sealant. Failing to reseal compromises the IP rating.

Aluminum profiles are strongly recommended. They provide heat dissipation, mechanical protection, and improved structural stability for outdoor COB LED strip installations.

IP65 is sufficient for rain and splashing water but not for submersion. For environments with standing water or potential immersion, IP67 or IP68 is required.