Amidst the wave of smart technology and continuous advancements in lighting, the Zhaga Consortium plays a pivotal role in the lighting industry. It not only promotes the circular economy of LED lighting but also illuminates a new era of simpler, smarter, and more personalized lighting solutions.

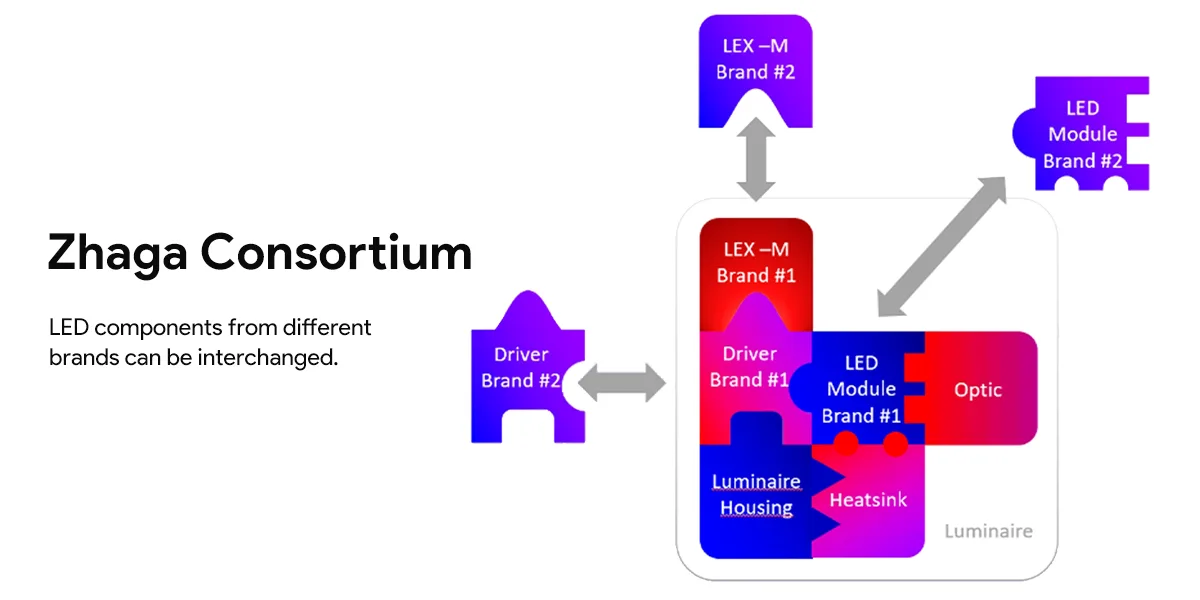

The Zhaga Consortium establishes global standards for LED lighting components and provides certification for related products. It enables interoperability and interchangeability between LED components from different manufacturers, regardless of brand.

This article will take you on an in-depth exploration of the Zhaga Consortium. As the content is extensive, we recommend bookmarking it for future reference.

What Is the Zhaga Standard?

The Zhaga Consortium is an international standardization alliance established in 2010 by global LED manufacturers, including Osram and Philips. Headquartered in Europe, it currently has over 300 member companies worldwide.

The alliance’s core mission is to establish light engine interface specifications. By unifying five key interface standards—mechanical, electrical, optical, thermal, and communication—it ensures compatibility and interchangeability among LED light sources from different manufacturers. This reduces luminaire development costs and fosters market competition. Standardized interface specifications prevent incompatibility issues in light engine products, providing luminaire manufacturers with a stable design platform that lowers development costs and drives market growth.

By 2025, Zhaga had over 330 member companies, including lighting giants like Philips and Osram alongside emerging manufacturers. It has published 26 “Zhaga Books” detailing standards ranging from foundational definitions to specific applications (e.g., outdoor IoT lighting, linear modules). Its certification system is administered by authorized laboratories such as DEKRA and TÜV.

Zhaga has published its specifications in a series called “Books,” with each volume detailing specific aspects of standardized LED components. These books cover the standardization of drivers, LED modules, sensors, and connectors for manufacturers to follow during development.

Standardization reduces supply chain complexity and accelerates the adoption of LED technology. Products support rapid assembly, maintenance, and upgrades of luminaires, minimizing resource waste. Standardization reduces supply chain complexity and accelerates the adoption of LED technology.

Why Should Manufacturers Adopt the Zhaga Standard?

As the Zhaga Consortium is a global standard, certified lightweight components can be easily replaced with parts adhering to the same specifications. This enables alternative suppliers supporting compatible LED components to minimize supply bottlenecks.

With a fixed standard, manufacturers can produce luminaires featuring similar and compatible components. This reduces the need for new designs for LED components, thereby minimizing production lead times. Consequently, the Zhaga Consortium increases output while minimizing production and development costs for lighting.

Manufacturers adhering to the Zhaga Alliance can produce various LED light variants without significant R&D investment. They can simply follow Zhaga standards to introduce variations in color temperature, lumen output, and color rendering index, thereby enriching their product portfolio. This allows for portfolio expansion and faster new product launches without additional costs.

Key Technical Specifications of Zhaga Linear Modules

The key technical specifications of Zhaga linear modules primarily revolve around their standardized interface design, electrical performance, optical characteristics, and environmental adaptability. Detailed analysis follows.

Standardized Dimensions (Interface Standardization)

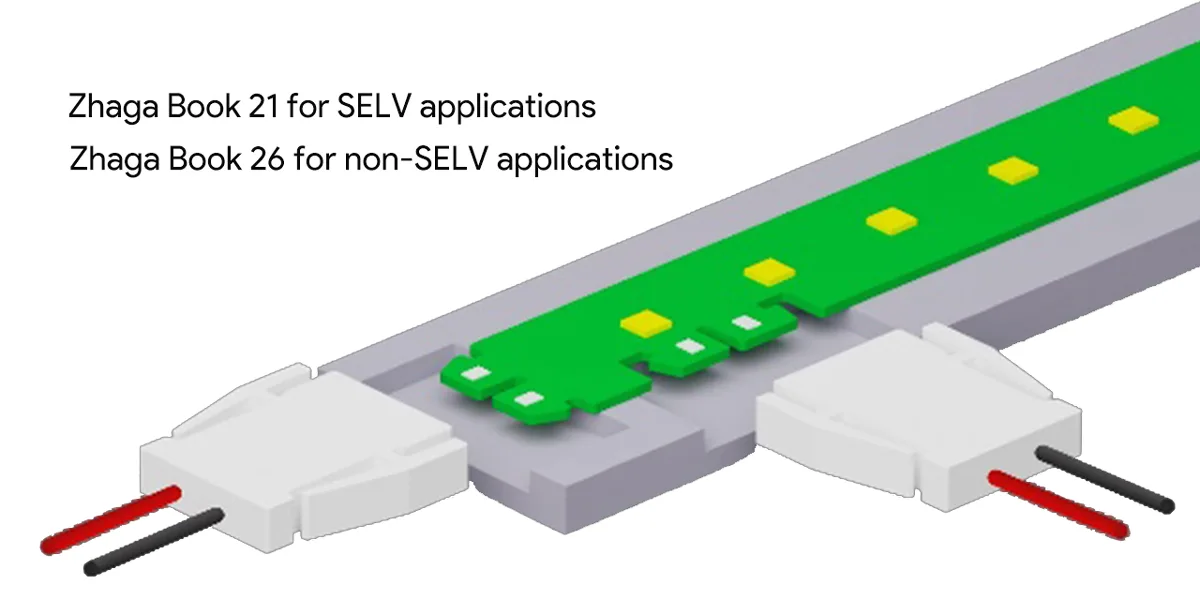

- Zhaga Book 26 and Book 21 define the mechanical interfaces (e.g., mounting holes, connector types) and electrical interfaces for linear modules, ensuring interchangeability between modules from different manufacturers.

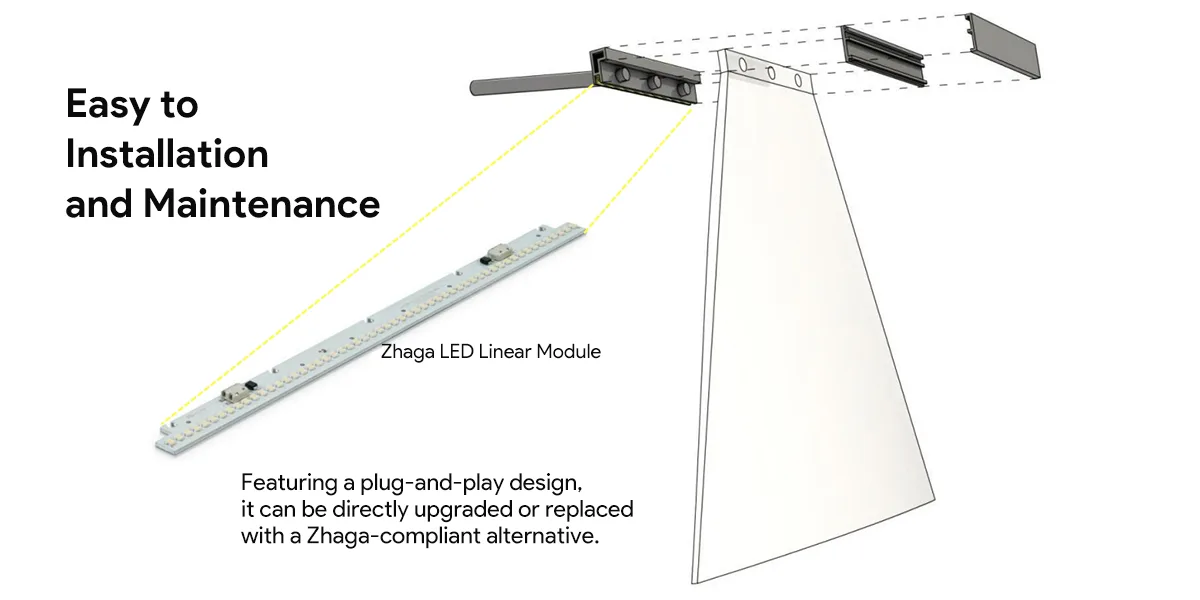

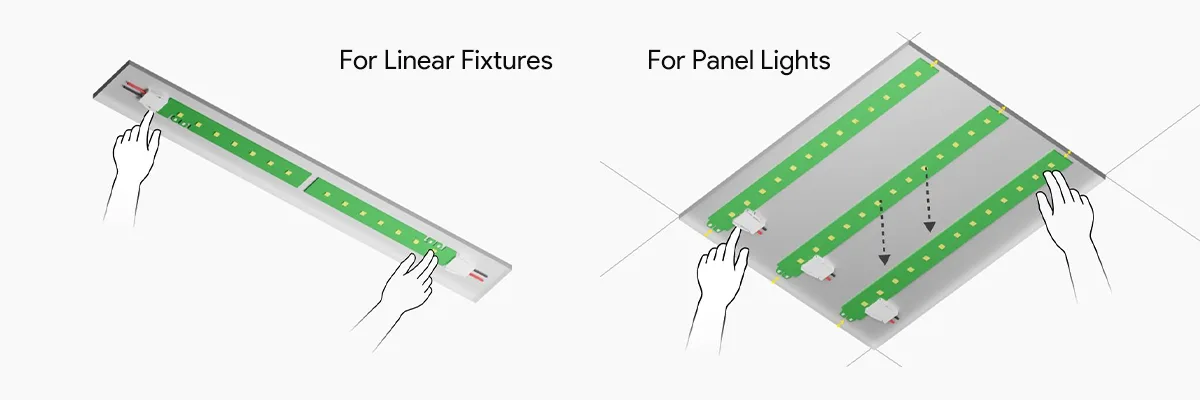

- Modules offer flexible lengths from 1 to 5 feet, suitable for applications like ceilings and cable trays. Additionally, they enable rapid replacement of modules with different shapes (e.g., circular, linear) for compatibility with downlights, panel lights, etc. Featuring a plug-and-play design, they support parallel module expansion to meet varying lumen output requirements, with tool-free installation for luminaires.

Through these technical specifications, Zhaga linear modules deliver design flexibility, maintenance convenience, and long-term sustainability, driving the lighting industry’s transition toward modularity and a circular economy.

Electrical Interface

The Zhaga Alliance’s electrical interface standard is one of its core specifications, establishing the standards manufacturers follow when producing components to ensure interoperability and compatibility among LED lighting assemblies.

- Connector Types: Zhaga standards (e.g., Book 13, Book 22) specify the electrical connector types (e.g., 2-pin or 4-pin configurations) between LED modules and drivers, along with pin definitions (e.g., power, signal, ground).

- Current and Voltage: Book 21 specifies module current ranges from 175 – 1750mA based on length and category; Book 26 covers non-SELV scenarios for SELV (Safety Extra-Low Voltage < 60V) applications.

- Dimming Compatibility: Supports mainstream protocols like DALI and 0-10V, simplifying compatibility through standardized interfaces. Book 24 defines NFC communication interfaces for parameter configuration and smart control.

- Luminance Standards: Recommended lumen outputs correspond to different module lengths, ensuring luminance consistency and enabling seamless module replacement. Contact specifications between LED board areas and luminaire housings guarantee thermal efficiency.

- Standardized Interfaces: Zhaga Book 12 standards prioritize interchangeability between luminaires. These cover LED module dimensions, configurations, and interfaces. Standardized interfaces enable tool-free installation, reducing maintenance costs.

Zhaga electrical interface standards drive the lighting industry toward sustainability and intelligence through unified specifications.

Optical Interface

The Zhaga Consortium’s standardization of optical interfaces is primarily achieved through the following technologies, combined with its core specifications such as Book 3, Book 7, and industry application requirements.

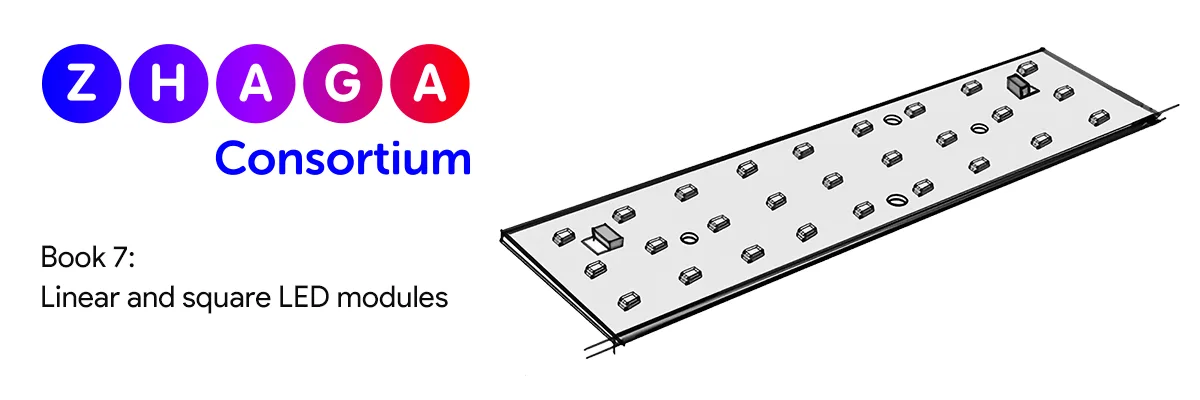

Zhaga Book 7 defines a series of linear and square LED modules typically used for indoor lighting applications. Within Book 7, there are 18 LED module categories defined by the overall maximum dimensions of the LED module. The maximum dimensions of an LED module also indicate the size of the retention area within the luminaire. Book 7 LED modules require professional installation and replacement.

- Standardized Lenses and Reflectors: Zhaga defines the dimensions, mounting positions, and optical path design of LED module optical components (e.g., lenses and reflector cups). This ensures consistent beam angles and luminous intensity distributions across modules from different manufacturers when installed in the same luminaire.

- Luminous Flux Matching: By specifying luminous flux ranges for modules (e.g., circular modules in Book 7), brightness compatibility is achieved, preventing luminous efficacy variations caused by module replacement.

- Beam Angle Standardization: Zhaga mandates modules provide explicit beam angles (e.g., 15°, 30°, 60°) and validates their luminous intensity distribution curves through testing, ensuring consistent illumination when modules are replaced.

- Light Mixing Design: For multi-module applications (e.g., linear lighting), Zhaga specifies optical spacing between modules to minimize light spot overlap or dark zone issues.

Testing & Certification

- Products must undergo third-party laboratory testing (e.g., DEKRA) for color temperature, color rendering index (CRI), and luminous flux to ensure compliance with Zhaga standards.

- Zhaga-D4i Certification: Collaborates with the DALI Alliance to ensure compatibility of smart lighting systems. Zhaga verifies interoperability through third-party laboratory testing (e.g., DEKRA, UL).

Authentication steps:

- Zhaga-D4i certification of luminaire-mounted control devices is a two-step process (Table 1).

- D4i certification (step 1) is required before proceeding to Zhaga-D4i certification (step 2).

| Step | Name | Provider | Requirements | Requirements |

| 1 | D4i certification | DALI Alliance (DiiA) | DALI Alliance membership | DiiA Specification Part 351 |

| 2 | Zhaga-D4i certification | Zhaga Consortium | Zhaga membership | Zhaga Book 18 or Zhaga Book 20 |

Advantages of Zhaga-Compliant LED Linear Modules

Zhaga-compliant LED linear modules offer the following core advantages.

1. Standardization

Unified electrical connections and mechanical interfaces defined by standards such as Zhaga Book 26 ensure full compatibility between modules, connectors, and luminaires from different manufacturers.

For example, IEC 63356-2 (based on Zhaga Book 7) specifies dimensions and mounting hole positions for 18 linear module types, establishing interchangeability. Support for multiple lengths (up to 5 feet) and connector options accommodates applications like ceiling fixtures and cable tray systems. The certification system also enables future module upgrades, extending luminaire lifecycles and simplifying installation and maintenance.

As shown below:The three LED modules used, though manufactured by different vendors, all meet the specifications outlined in Zhaga Book 3. Consequently, these optical modules are compatible with the same spotlight fixture.

2. Installation and Maintenance

Features a plug-and-play design enabling tool-free installation. For instance, TE’s Zhaga-D4i interface solution simplifies streetlight architecture for efficient integration. Using standardized modules reduces design costs, facilitates future replacements, and lowers overall expenses.

Should any specific optical component require attention, you can upgrade or replace it with a Zhaga-compatible alternative instead of replacing the entire finished luminaire.

3. Reliability

Certified by independent testing centers to ensure high luminous efficacy, low blue light, and other characteristics. Some products also hold LM80 certification (e.g., TYF’s PCBA series). Surface-mount module technology further optimizes heat dissipation and dynamic display effects.

4. Efficient Innovation

Zhaga focuses on enhancing lighting performance by integrating advanced and cutting-edge technologies. This ensures long-term compatibility for luminaires, making Zhaga-certified lighting future-proof.

When upgrading any luminaire, manufacturers need not redesign it from scratch. They can adhere to Zhaga standards for core lighting components while modifying specific sections. Modular design facilitates partial replacements, reducing overall maintenance costs. This saves R&D expenses and accelerates new product launches.

Applications of Zhaga Linear Modules

Zhaga Linear Modules are standardized interface components in the LED lighting industry, primarily used to achieve modular connections between LED light sources and driver circuits.

1. Standardized Interfaces and Modular Design

Zhaga Linear Modules simplify LED luminaire assembly and maintenance through unified mechanical and electrical interfaces (e.g., dimensions, pin definitions). For example, the HUB75 interface (16/32-channel scan driver) and TM1628 driver IC both adopt similar standardized designs, supporting matrix control of multi-row LEDs. This design is widely applied in smart home devices (e.g., air conditioner and microwave display panels) and industrial equipment (e.g., electronic scales).

2. High-Precision Drive & Energy Efficiency Optimization

- PWM Dimming: Controls LED brightness via duty cycle adjustment (e.g., breathing light effects). Typical applications include the TIM output comparator module in STM32.

- Switching Regulators: For current >500mA scenarios, Zhaga modules can integrate switch drivers (e.g., DC-DC conversion) to enhance energy efficiency and support full-color displays.

3. Full-Color Display and Complex Control

- Multi-Channel Data Input: Interfaces like HUB75 support RGB color data (R1/R2/G1/G2/B1/B2), enabling synchronized control of 32 LED rows via time-division multiplexing.

- Dynamic Scanning Technology: 1/16 or 1/32 scanning modes reduce power consumption while meeting high-resolution display requirements.

4. Cross-Domain Application Expansion

- Integrated with mesoporous materials like MOFs/COFs, Zhaga modules can be incorporated into smart lighting systems for temperature and humidity regulation in museum display cases.

- Biosensing: The standardized design approach of protein THR (Threonine Helix Repeat) modules aligns with Zhaga’s modular philosophy, potentially enabling future exploration of bio-electronic hybrid systems.

Current technological trends indicate that Zhaga linear modules are evolving from traditional lighting toward intelligent and multifunctional applications. Examples include integrating machine learning to optimize energy material performance or enhancing electrochemical energy storage efficiency through two-dimensional materials like MXene.

Zhaga vs. Non-Standard Linear LED Modules

The application differences between Zhaga standard and non-standard linear LED modules in the lighting industry primarily manifest in compatibility, design flexibility, and sustainability. Below is a comparative analysis:

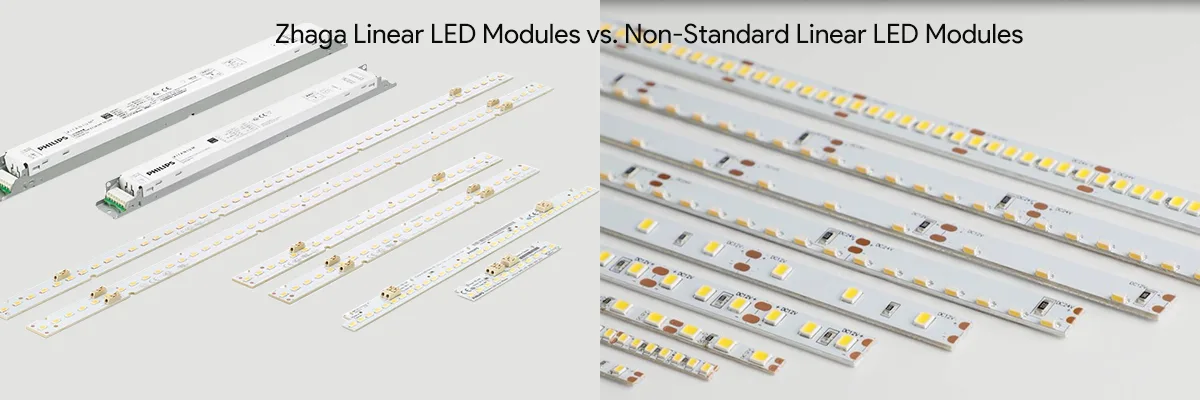

1. Standardization and Compatibility: Zhaga standards ensure interchangeability among modules from different manufacturers through unified mechanical, electrical, and optical interface specifications (e.g., Book 13, Book 26), supporting future upgrades and maintenance. Non-standard modules lack uniform interfaces, often requiring custom drivers or fixture designs, resulting in limited compatibility.

2. Design Flexibility: Zhaga offers multiple module lengths (1-5 feet) and connection methods, supporting parallel designs to adapt to diverse luminaire scenarios. Non-standard modules feature varied electrical parameters but require individually matched drivers, resulting in higher design costs.

3. Sustainability and Maintenance: Zhaga’s modular design enables replacement of individual components, extending luminaire lifespan and aligning with circular economy principles. Non-standard modules typically require complete replacement upon failure, increasing electronic waste and long-term costs.

4. Market Application and Cost: Zhaga-certified products: Commonly found in high-end commercial lighting (e.g., OSRAM S3030 quantum dot modules), offering higher prices but lower maintenance costs.

Non-standard modules: Lower priced but carry compatibility risks.

Zhaga vs. Non-Standard Linear LED Modules

| Type | Zhaga LED Modules | Non-Standard Linear LED Modules |

| Compatibility | Unified interfaces, interchangeable | Lack of standardized interfaces, limited compatibility |

| Flexibility | Standardized modules, easy to connect | Varied dimensions, incompatible, requires custom matching |

| Maintenance | Easy component replacement | Non-replaceable, becomes scrap upon damage |

| Cost | High quality, low maintenance costs | Low price, high maintenance costs |

Zhaga standards suit projects prioritizing long-term sustainability and design flexibility, while non-standard modules better serve low-cost, short-term applications. Selection requires balancing initial investment with long-term maintenance costs.

Conclusion

Zhaga focuses on innovative lighting technologies, driving global standardization of lighting components. By separating light sources from luminaires, Zhaga simplifies replacement, maintenance, and upgrades.

The establishment of Zhaga standards benefits both luminaire manufacturers and LED component producers. It reduces product development costs and shortens R&D cycles. Standardized interfaces also promote division of labor within the supply chain, enabling manufacturers to concentrate on innovation rather than repetitive adaptation, thereby accelerating technological iteration.

Compared to non-standard modules, Zhaga reduces resource waste and compatibility risks. The adaptability of Zhaga standards expands functionality and provides manufacturers with an innovative framework. Integration between different lighting components and technologies becomes significantly easier.

Overall, the Zhaga Consortium plays a crucial role in the future of the lighting industry.