When you’re ready to throw an awesome glow party, identify minerals, or create a unique ambiance, a UV blacklight LED strip is an excellent choice.

However, products on the market vary widely in quality, ranging from tens to hundreds of dollars, with equally varied results. Buying the wrong one might leave you with only a faint purple glow, while your beloved fluorescent posters barely light up at all.

So, how can we sharpen our discernment and make a wise choice before purchasing? This article will explore several key considerations for UV LED strips, helping you make the best decision when selecting the blacklight LED strip most suited to your project.

What is a UV LED strip light?

UV LED strip lights, also known as black light LED strips, are flexible lighting fixtures that emit ultraviolet light through semiconductor materials. They consist of multiple UV LED chips arranged sequentially on a flexible printed circuit board (FPC) or rigid circuit board.

UV LED strips are primarily used in industrial applications requiring UV curing and in specialized decorative settings. Unlike standard LED strips, their core function is to emit ultraviolet light at specific wavelengths (typically 365nm or 395nm) to activate the curing reaction of photosensitive materials such as UV adhesives and inks.

What is the wavelength of conventional UV LED strips in nanometers?

Common wavelengths for UV strips primarily fall within the following two bands, with selection determined by specific application scenarios:

365nm (Deep Ultraviolet UVA): Features shorter wavelengths, high photon energy (approximately 3.4 eV), and strong penetration capabilities, making it suitable for deep curing of high-viscosity materials.

Applications: Professional fields such as electronic component encapsulation, thick-layer adhesive curing, and industrial flaw detection.

395nm (Near-UV UVA): Features a longer wavelength, lower photon energy (approximately 3.1 eV), and high luminous efficiency, making it suitable for surface curing or thin-layer processing.

Applications: Everyday scenarios like printing ink curing, nail gel polish curing, and general adhesive curing.

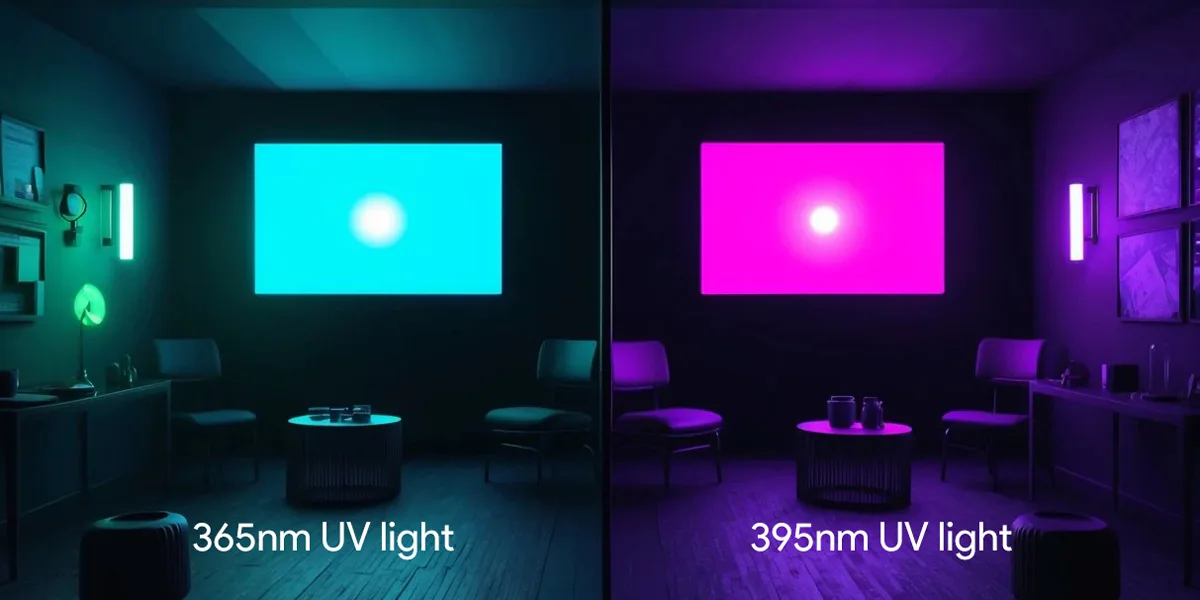

Comparison of 365nm and 395nm UV light

| Item | 365nm UV light | 395nm UV light |

| Color | pale blue-white color | Brighter purple color |

| Effeciency | More powerful fluorescence: Illuminate the tiny particles | Lower fluorescent effect: Illuminate larger |

| Cost | Higher | Lower |

| Application | curing UV glue, UV varnish, surface curing of glue | Curing UV coatings and UV inks, determines the depth of curingt |

395nm near-UV is relatively inexpensive and emits a noticeable pale purple light. It performs adequately in dark environments, though some materials exhibit a weak fluorescence response. 365nm long-wave UVA is more expensive with very low intrinsic light intensity (appearing dark blue), yet it elicits exceptionally intense fluorescence, causing white and specific colors to glow with explosive brightness. It is the preferred choice for professional applications and optimal results.

For a deeper comparison of 365nm and 395nm black light UV LED tape strip lights, read the blog: “Understanding the Difference Between 365nm and 395nm UV LED Strip Lights”.

What brightness level do you require for your UV LED strip lights?

The brightness of UV strip lights is determined by the LED density (number of LEDs per meter) and power rating. 60 LEDs/m and 120 LEDs/m are two common setups. Lower density results in more pronounced light spots, creating a “spotty” effect; higher density produces more uniform and saturated illumination, resembling a continuous light band.

Power (watts/meter): At the same wavelength, higher power typically means stronger UV output and brighter fluorescent effects.

What is the lifespan of UV LED strips?

High-quality UV LED strips typically last between 20,000 and 50,000 hours (approximately 5.7 years based on 24-hour daily operation), though environmental factors may shorten actual lifespan. Per the L70 standard—where light intensity reaches 70% of initial output—most products achieve this benchmark between 20,000 and 30,000 hours.

Factors affecting lifespan:

- Heat dissipation design: High temperatures accelerate light decay; ensure adequate heat dissipation (e.g., metal substrates, ventilated structures).

- Operating environment: Avoid high temperatures, humidity, or frequent vibrations; extreme conditions may halve lifespan.

- Power Stability: Constant-current drivers minimize current fluctuations, extending lifespan.

Methods to Extend Lifespan:

- Regular Cleaning: Dust accumulation impairs heat dissipation; wipe the strip surface with a soft cloth.

- Avoid Overloading: Keep operating current below 80% of the rated value.

- Monitor Lumen Depreciation: If brightness significantly decreases after 2 years of use, inspect heat dissipation or power supply.

For more discussion on LED strip light lifespan, read the blog post “LED Strip Light Lifespan: How Long Do They Last and Why?“

The waterproof rating of UV LED strip lights

Selecting UV strip lights requires careful consideration of the intended environment. The IP rating indicates dust and water resistance, directly impacting safety and longevity. Choosing the appropriate IP rating ensures optimal performance and extended product lifespan.

- IP20/IP33: No waterproofing capability; suitable only for dry indoor environments.

- IP65: Dustproof and resistant to low-pressure water jets; suitable for kitchens, bathrooms, balconies, or cleaning walls.

- IP67/IP68: Fully dustproof and capable of short-term or prolonged submersion; suitable for pools, outdoor surfaces, or environments directly exposed to rain or immersion.

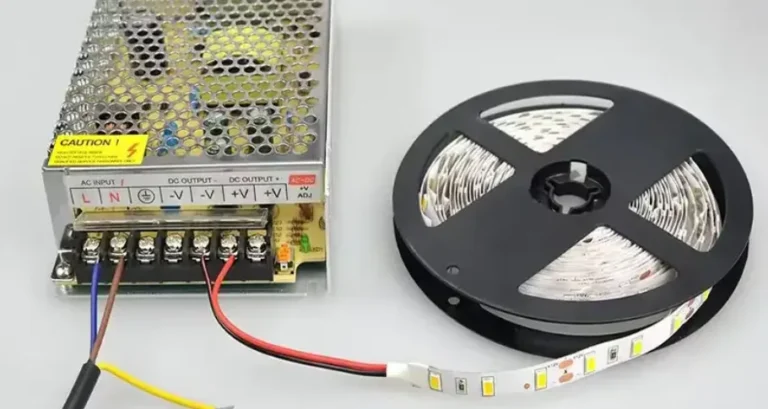

Selecting Electrical Parameters for UV Light Strips

What voltage does the light strip operate at? What power rating of power supply and controller is required? UV light strips require dedicated power supplies; incorrect matching may damage the strip or cause hazards. Common voltages are 12V or 24V—ensure the power adapter voltage matches precisely.

Adequate Power: The total power supply capacity should exceed the strip’s total power consumption (watts/meter × total length in meters) by at least 20% to prevent overload.

Controller: No controller is needed for constant-on operation. For dimming or synchronization with other lights, purchase a compatible controller.

Installation and Maintenance of UV Light Strips

Is the selected strip easy to install? How is the adhesive backing quality? Can it be easily cut and connected? A smooth installation experience makes the job twice as simple.

First, confirm the presence of strong 3M double-sided adhesive tape on the back for secure attachment. Second, check the cutting intervals marked on the strip (typically indicated by scissors symbols) to ensure cuts along these lines won’t compromise the remaining sections. Finally, examine the connector options—determine whether soldered connections or solderless connectors are needed to join different sections of the strip.

Safety and Protection When Using UV Light Strips

Although 395nm emits lower levels of ultraviolet radiation, high-intensity 365nm sources still present safety risks that must be managed. According to the IEC 62471 photobiological safety standard, powerful UV-A LED lamps are classified as Risk Group 3 devices (the highest hazard category)—meaning even momentary direct exposure can be harmful to the eyes or skin.

Therefore, in UV curing environments, workers must wear appropriate personal protective equipment (PPE) when operating or maintaining UV curing equipment. This includes wearing UV-blocking glasses and protective clothing.

FAQ

A: While 365nm UV LEDs are generally safe, direct skin contact and prolonged eye exposure should be avoided, as UV radiation can cause skin burns and eye damage. Always use protective gear when working under UV light.

A: 365nm and 395nm UV LEDs are ideal for curing inks, adhesives, and coatings.

A: Compared to 395nm, 365nm UV light typically offers greater curing efficiency for materials. The 365nm wavelength produces stronger black light and curing effects, making it more suitable for industrial and professional applications.

A: Like standard LED strips, UV LED strips produce some heat while emitting light. However, they are generally more efficient than traditional UV lamps and generate less heat. When using high-intensity UV LEDs, adequate ventilation is recommended.

A: Most UV LED strips function on 12V or 24V DC power supplies. Ensure your power source meets these specifications to prevent damage to the LED strip.

Summary

Selecting a satisfactory UV black light LED strip involves more than just price. Keep this decision path in mind:

First, determine the wavelength:

- For optimal fluorescent effects, prioritize 365nm;

- For budget-conscious applications with lower demands, 395nm is suitable.

Next, consider density and power: Choose LED density based on required uniformity and ensure sufficient power supply capacity.

Finally, evaluate the usage environment: Confirm the IP protection rating based on installation location (indoor, outdoor, underwater).

By addressing these key factors, you can systematically assess products, avoid common purchasing pitfalls, and ultimately select a UV blacklight LED strip that truly meets your needs—delivering stunning effects while remaining safe and durable.