If you want truly professional, dot-free linear lighting, using a proper LED channel is not optional — it is essential. An LED channel directly determines heat dissipation, light diffusion, visual comfort, and the long-term reliability of your LED strip lighting system. Without it, even high-quality LED strips can suffer from glare, visible hotspots, and accelerated lumen depreciation caused by poor thermal control.

Many lighting issues blamed on LED strips are actually the result of skipping the aluminum LED channel. When LED tape is installed directly onto wood, drywall, or plastic surfaces, heat builds up quickly and light remains harsh and uneven. A well-designed LED channel system solves these problems by acting as both a heat sink and an optical control housing, turning raw LED strips into refined architectural lighting.

In this guide, you will learn how to choose the right LED channel for different applications, understand critical sizing rules, compare diffuser options, and apply practical buying tips. Whether you are specifying a project or planning to buy LED channel systems for installation, these principles will help you achieve consistent, spotless linear illumination. Inspiration Gallery: Top Applications of LED Aluminum Profiles

What Is an LED Channel and Why Do You Need One?

Technical Definition and Core Function

An LED channel (also called an LED strip channel or aluminum LED profile) is a rigid housing system designed to mount, protect, cool, and visually refine LED strips. It typically consists of an extruded aluminum body, a diffuser cover, and mounting accessories such as clips and end caps.

In professional lighting applications, an LED channel is not an accessory — it is a core system component. It transforms exposed LED tape into a controlled, durable, and architecturally integrated linear lighting solution.

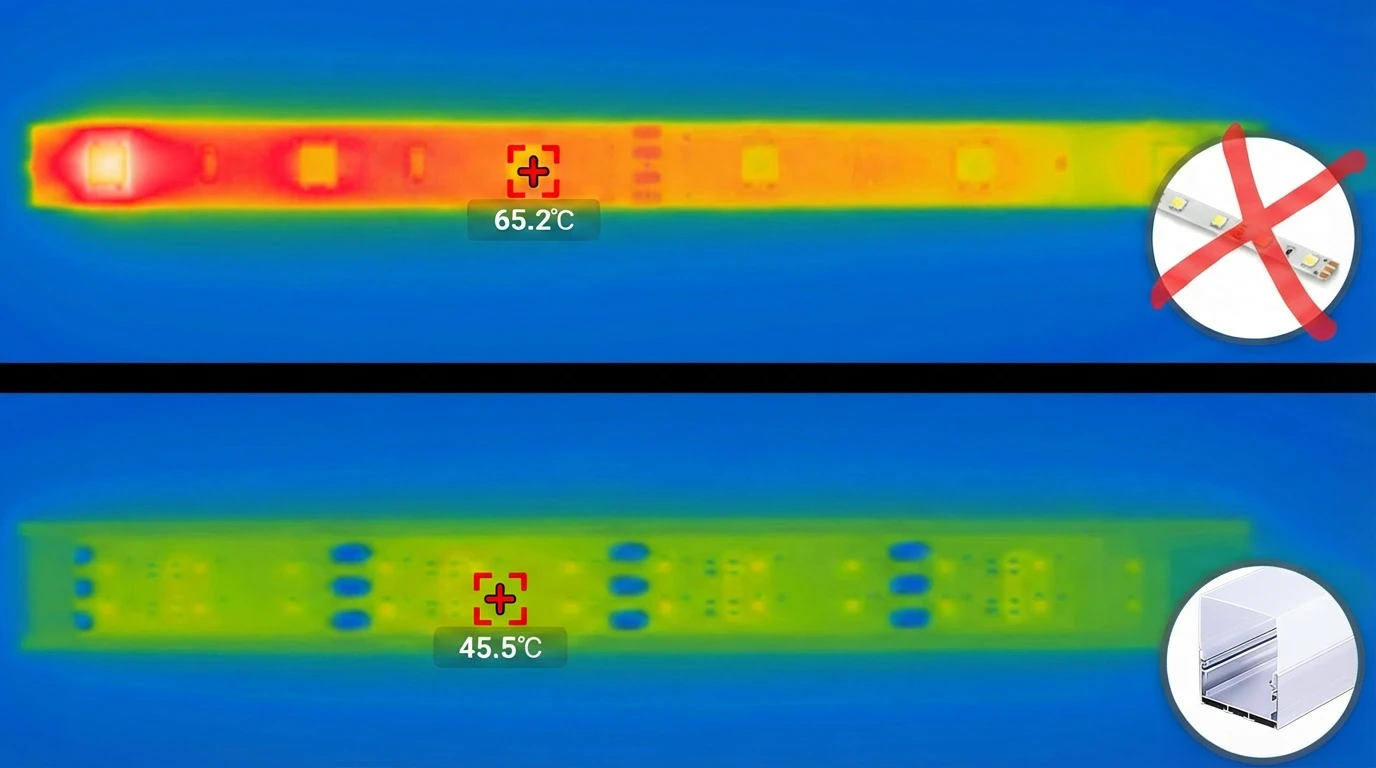

Heat Dissipation: The Foundation of LED Longevity

LED strips generate heat at the PCB level. Without efficient thermal management, junction temperatures rise, leading to faster lumen depreciation and premature failure. An aluminum LED channel addresses this by acting as a passive heat sink. Aluminum has high thermal conductivity (around 205 W/m·K), dramatically outperforming plastic materials.

When an LED strip is installed inside an aluminum LED channel, heat spreads along the extrusion and dissipates into the surrounding air. This lowers operating temperature and improves lumen maintenance. Quality LED strips used with properly sized aluminum LED channels can exceed 50,000 hours (L70), while strips mounted directly on wood or plastic surfaces may experience up to 30 percent faster light decay.

Engineering takeaway: an aluminum LED channel is a thermal management device that directly extends LED lifespan and stabilizes system performance.

Dot-Free Performance: Turning Points into Lines

Raw LED strips produce discrete points of light because individual diodes are spaced along the PCB. Without optical control, this creates visible hotspots, especially in shallow or direct-view installations.

An LED channel improves visual uniformity through optical diffusion:

- Channel depth increases the distance between the LED source and the diffuser

- The diffuser spreads and blends the emitted light

- The result is a continuous linear effect instead of visible LED dots

This optical control is critical for applications such as architectural coves, ceiling reveals, wall grazing, and high-end cabinetry lighting.

Without a properly sized LED channel and diffuser combination, achieving truly spotless linear lighting is extremely difficult, even when using high-density LED strips.

Protection and Architectural Integration

Beyond thermal and optical performance, an LED channel provides mechanical protection and supports clean architectural detailing.

实物保护

• Shields LED strips from dust, impact, and accidental contact

• Prevents PCB flexing and solder joint stress

• Extends usable life in commercial and high-traffic environments

Architectural finish

• Creates straight, clean light lines

• Conceals wiring and mounting imperfections

• Enables recessed, trimless, and seamless lighting details

For designers and engineers, the LED channel functions as both a lighting component and a construction element, bridging electrical systems and architectural finishes.

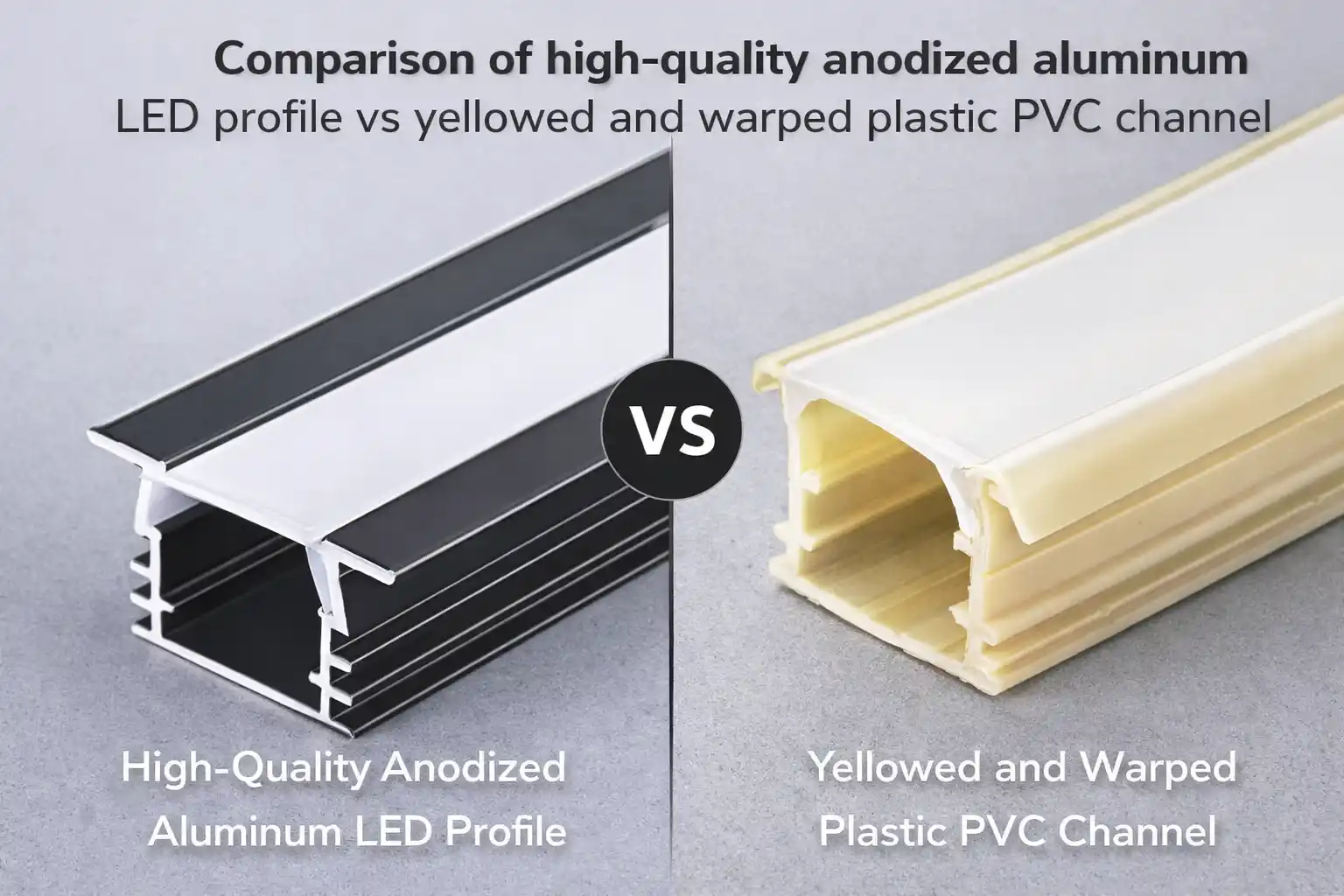

Aluminum vs. Plastic LED Channels (Why Material Matters)

| 特点 | 铝质 LED 通道 | Plastic / PVC Channels |

| 热管理 | Excellent heat dissipation, stabilizes LED temperature | Poor heat transfer, traps heat |

| 耐用性 | Rigid, impact-resistant, heat-resistant | Can warp, crack, or discolor over time |

| 流明维护 | Supports long-term brightness stability | Heat buildup accelerates lumen loss |

| 审美品质 | Architectural, professional finish | Often looks temporary or low-end |

Plastic LED channels may be acceptable for short-term or decorative use, but aluminum LED channels are the industry standard for architectural, commercial, and high-output lighting where performance and longevity are critical.

Types of LED Channels (By Installation Method)

Selecting the right LED channel depends on how it will be integrated into the space. The installation method directly affects thermal performance, light diffusion, glare control, and construction complexity. The three primary categories are surface mounted, recessed (including trimless), and corner or angled LED channels.

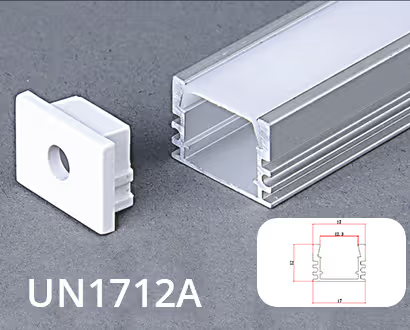

Surface Mounted LED Strip Channels

Surface mounted LED channels are the most versatile and widely used. Installed directly onto finished surfaces such as wood, cabinetry, metal, or masonry, they are ideal for retrofit projects and furniture-integrated lighting. Typical applications include under-cabinet lighting, shelving illumination, and task lighting.

A key technical factor is channel height, which influences optical blending and dot visibility.

| Channel Height | Typical Range | Optical Effect | 推荐使用 |

| Low Profile | 7–10 mm | Minimal LED-to-diffuser distance; higher risk of visible dots | Decorative accents, low-output strips |

| Standard Profile | 12–15 mm | Improved light blending and glare control | General task and architectural lighting |

| Deep Surface Profile | 16–20+ mm | Superior diffusion and reduced hotspot visibility | High-density or COB LED strips |

Deeper LED channels provide better light spread and more uniform output, which is critical for reducing visible LED points in direct-view installations.

Recessed and Trimless LED Strip Channels

Recessed LED channels are installed flush with surrounding building materials, producing a clean, integrated lighting effect. Trimless, also called plaster-in LED channels, eliminate visible edges entirely and create a seamless “light slot,” making them ideal for high-end architectural projects. These channels are typically embedded into drywall ceilings or wall assemblies.

| 特点 | Recessed Channel | Trimless / Plaster-in Channel |

| Installation Stage | After surface cut-out | Before final plaster and finishing |

| Visible Frame | Thin trim edge visible | No visible trim after finishing |

| Aesthetic Result | Clean but defined opening | Seamless “light slot” effect |

| Skill Requirement | 中度 | High (requires drywall finishing precision) |

| 典型应用 | Ceilings, wall slots, cabinetry | Luxury residential, hotels, galleries |

Deeper recessed LED channels are often paired with high-density LED strips to improve optical mixing and achieve spotless linear lighting.

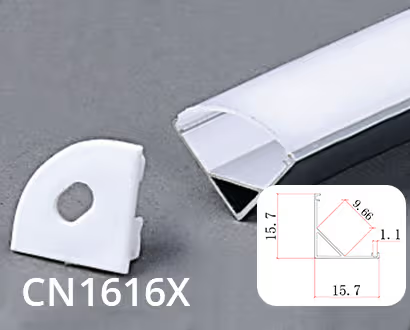

Corner and 45° LED Strip Channels

Corner and 45-degree LED channels are designed to project light diagonally, making them ideal for indirect lighting where vertical and horizontal surfaces meet. By shifting the beam angle, they reduce glare and improve light distribution across adjacent surfaces. Common uses include cabinet corners, stair details, display shelving, and cove transitions.

| 安装地点 | Lighting Purpose | Performance Advantage |

| Under cabinets (rear corner) | Countertop task lighting | Directs light outward, reduces backsplash shadows |

| Ceiling-to-wall junction | Indirect ambient lighting | Creates soft wall wash effect |

| Shelf front corners | 显示灯光 | Evenly illuminates vertical objects |

| Step and stair corners | Safety and accent lighting | Improves visibility without direct glare |

Corner LED channels enhance perceived brightness and visual comfort without increasing wattage, making them efficient for layered lighting design. Installation Guide: Mastering 45° Corner LED Aluminum Profiles.

Installation Type Comparison Overview

The installation method of an LED channel influences both construction requirements and optical performance. The summary below helps simplify specification decisions.

| 通道类型 | 安装方法 | Visual Style | Typical Depth | 最适合 | 安装复杂性 |

| 表面安装 | Fixed onto finished surface | Visible linear fixture | Shallow to deep | Cabinets, shelves, retrofits | 低 |

| 隐秘 | Installed into cut-out slot | Flush, integrated | Medium to deep | Ceilings, walls, millwork | 中型 |

| Trimless / Plaster-in | Embedded before finishing | Seamless architectural slot | Medium to deep | Luxury architectural projects | 高 |

| Corner / 45° | Mounted at inside angles | Indirect, angled light | Shallow to medium | Under cabinets, coves, displays | Low to medium |

Choosing the appropriate LED channel type ensures the lighting system aligns with both construction constraints and the desired visual effect.

LED Channel Sizes: Width, Depth, and Length Explained

LED channel size is a critical factor in linear lighting design. Choosing the wrong dimensions can lead to visible hotspots, overheating, and reduced lighting performance. Proper sizing ensures mechanical fit, stable thermal behavior, and smooth optical diffusion.

This section explains how to select the correct width, depth, and length for a professional LED channel installation.

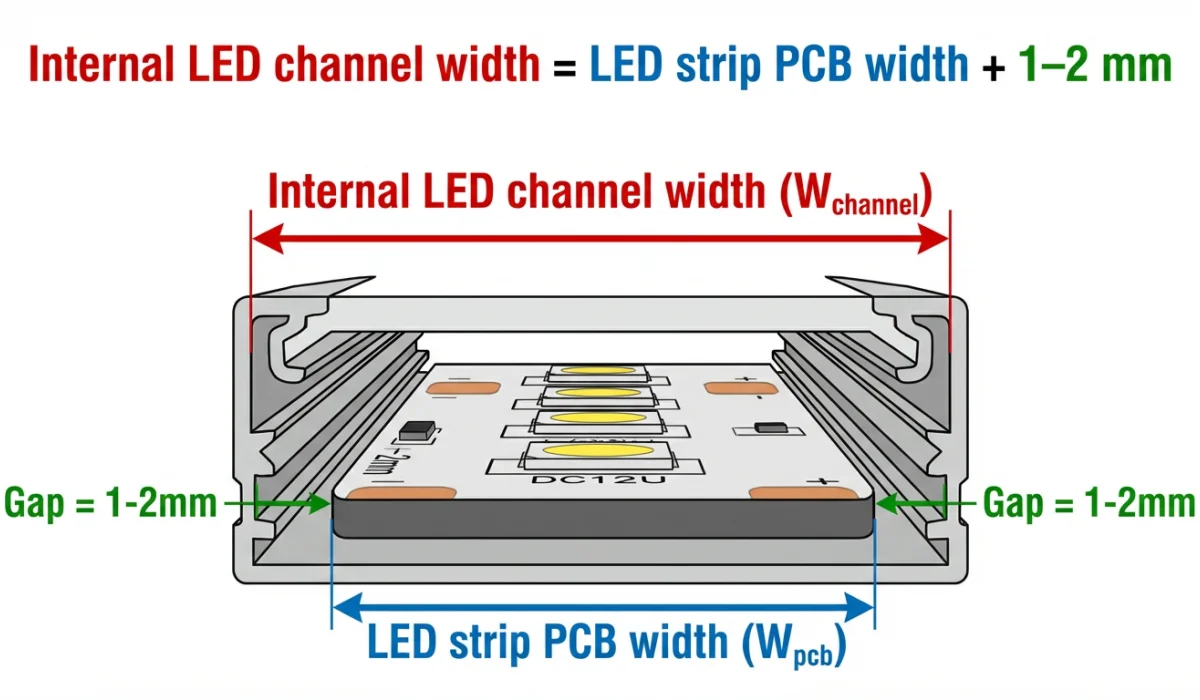

The Internal Width Rule

When specifying an LED channel, the most important dimension is the internal usable width, not the external profile size. This determines whether the LED strip fits correctly and whether there is adequate room for wiring, solder joints, and connectors.

A practical engineering rule is to allow clearance on both sides of the LED strip.

Recommended guideline:

Internal LED channel width = LED strip PCB width + 1–2 mm

This added space prevents compression, reduces stress on solder pads, and simplifies installation.

| LED Strip PCB Width | Minimum Internal Channel Width | 札记 |

| 8 毫米 | 10 mm | Suitable for single-row SMD strips |

| 10 mm | 12 毫米 | Common for high-density 2835 or 5050 strips |

| 12 毫米 | 14 mm | Recommended for RGB or higher-power strips |

| 16 mm | 18–20 mm | Needed for wide COB or dual-row strips |

Undersized LED channels restrict airflow and trap heat, reducing long-term reliability.

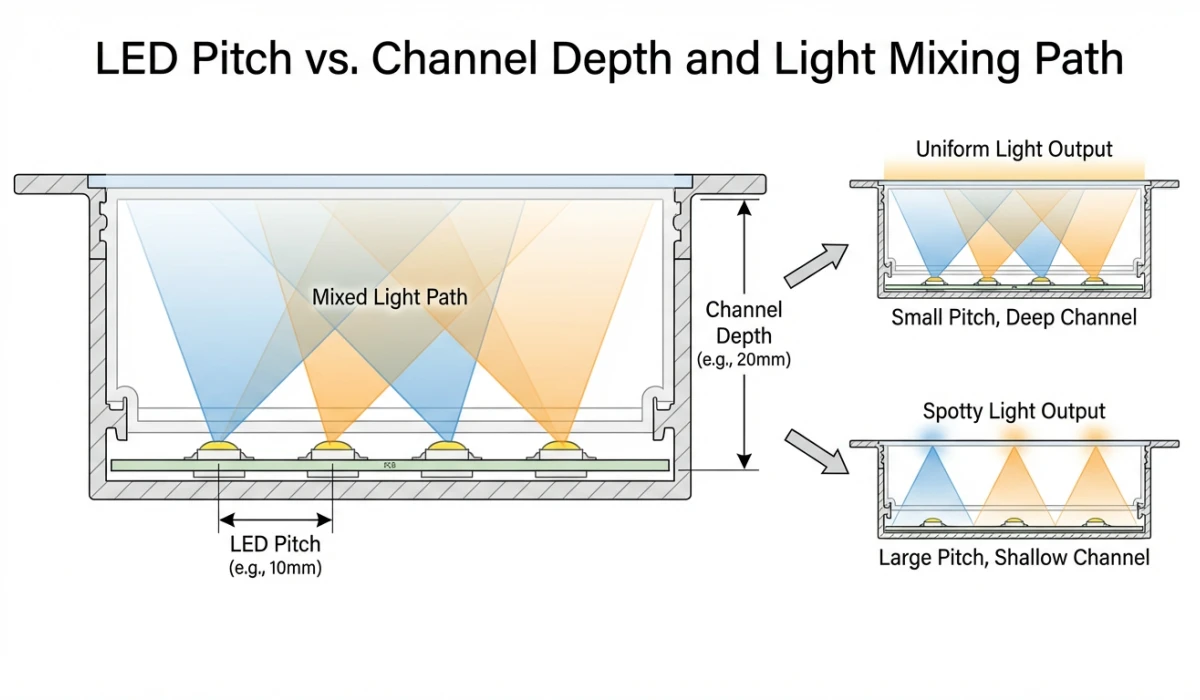

Depth vs. LED Pitch: The Spotless Lighting Formula

LED channel depth is a primary factor in light diffusion. Greater depth increases the distance between the LED source and the diffuser, allowing light to blend more effectively. For dot-free performance with a milky diffuser, channel depth should be equal to or greater than the LED pitch.

| LED 密度 | Approx. LED Pitch | Recommended Minimum Channel Depth |

| 60 LED/m | ~16.6 mm | 16 mm or deeper |

| 120 LED/m | ~8.3 mm | 12 mm or deeper |

| 180 LEDs/m | ~5.5 mm | 10 mm or deeper |

| COB LED 灯带 | Continuous phosphor layer | 8–10 mm typically sufficient |

Shallow LED channels increase the risk of visible hotspots, especially with high-density LED strips.

Shallow vs. Deep Channels: Performance Trade-offs

Deeper LED channels improve light uniformity but require more installation space. The choice depends on visual expectations and construction constraints.

| Channel Depth | 优势 | 局限性 | Best Applications |

| Shallow (7–10 mm) | Slim appearance, fits tight spaces | Higher risk of visible dots | Hidden coves, indirect lighting |

| Medium (12–15 mm) | Good diffusion, balanced design | Slightly more visible profile | Cabinets, shelves, general architectural use |

| Deep (16–25+ mm) | Excellent hotspot suppression, reduced glare | Requires more installation depth | Premium architectural lighting, COB strips |

Where the LED channel is directly visible, deeper profiles significantly improve visual comfort and perceived light quality.

Standard Lengths and Engineering Considerations

LED channels are manufactured in standard lengths, and selecting the correct size improves alignment and installation efficiency.

| Standard Length | Common Use | 札记 |

| 1 meter | Retail and DIY projects | Easy handling and shipping |

| 2 meters | Residential and light commercial | Fewer joints, cleaner lines |

| 3 meters | Architectural projects | Reduces connection points |

| 8 ft (94 in) | North American commercial projects | Matches common building module spacing |

Longer LED channels reduce the number of joints, improving visual continuity and mechanical strength. However, installers must consider thermal expansion and leave a small gap between sections.

Width, Depth, and Thermal Performance

LED channel dimensions also influence thermal behavior. Wider and deeper aluminum profiles provide greater surface area for heat dissipation, helping maintain lower junction temperatures and better lumen maintenance. Undersized LED channels can trap heat, accelerating light decay and shortening system lifespan. Proper sizing therefore supports optical performance, glare control, and long-term reliability, turning a simple LED strip into a professional-grade linear lighting system.

Diffusers Matter: Clear vs Milky vs Black Covers

The diffuser is the primary optical control component in an LED channel system. While the aluminum LED channel manages heat and structure, the diffuser determines how light is seen — affecting brightness, glare, softness, and whether LED dots remain visible. Choosing the wrong LED channel diffuser can result in harsh light, visible hotspots, or reduced visual comfort, even when the channel size is correct.

Diffusers are engineered to balance light transmission and diffusion, and each type serves a different lighting goal.

| Diffuser Type | 光传输 | 视觉效果 | 最适合 |

| Clear | ~90–95% | Maximum brightness, LED dots often visible | Indirect lighting, concealed coves, hidden channels |

| Milky (Opal) | ~70–75% | Soft, uniform light, dot-free appearance | Under-cabinet, shelves, wall slots, general architectural lighting |

| Black (Smoke) | ~30–45% | Channel looks dark when off, subtle glow when on | High-end retail, hospitality, cinema, minimalist interiors |

Clear diffusers prioritize output over softness and are best where the LED channel is hidden from direct view. Milky diffusers provide the best balance between efficiency and visual comfort and are the standard choice for visible linear lighting. Black diffusers focus on aesthetics, helping the LED channel visually disappear when off, though with reduced brightness when illuminated.

Deep Dive: How to Choose the Right LED Channel Diffuser (Clear vs. Milky vs. Black)

Material Matters: PC vs PMMA

LED channel diffusers are typically made from polycarbonate (PC) or acrylic (PMMA), and material choice affects durability and long-term appearance.

Polycarbonate offers high impact resistance and better heat tolerance, making it suitable for high-power LED channel installations. UV-stabilized PC also resists yellowing in outdoor or sun-exposed environments.

PMMA provides excellent optical clarity and smooth diffusion but may yellow faster under prolonged UV exposure unless specially treated. For architectural and commercial projects, material quality is just as important as diffuser color.

Waterproof & Outdoor LED Channels: What to Know

Waterproof and outdoor LED channels are essential for protecting linear lighting systems from moisture, dust, and harsh environmental conditions while maintaining thermal and optical performance. A properly specified LED channel not only shields the LED strip from water ingress but also ensures stable heat dissipation in fluctuating outdoor temperatures. Understanding waterproofing methods, IP ratings, and material durability is critical for long-term reliability.

Structural Waterproofing vs. Strip Waterproofing

Structural waterproofing refers to sealing the entire LED channel system to block water entry. This includes using sealed end caps, gaskets, and neutral silicone sealant at all joints and terminations.

Strip waterproofing refers to the LED strip itself being coated or encased in a water-resistant layer, typically rated IP65 or higher. However, even a waterproof LED strip can fail if installed inside a non-sealed LED channel where water can accumulate.

For outdoor installations, both the LED strip and the LED channel housing must be considered as part of one waterproof system, especially in environments with heavy rain, humidity, or salt exposure.

Choosing the Right IP Rating for Outdoor LED Channels

Ingress Protection (IP) ratings indicate how well an LED channel system resists dust and water. Selecting the correct rating depends on the installation environment.

| IP 等级 | 保护级别 | Suitable For |

| IP65 | Dust-tight and resistant to water jets | Outdoor walls, façades, and areas exposed to rain |

| IP66 | Protected against powerful water jets and dust-tight | Wet environments like fountains and walkways |

| IP67 | Submersible up to 1 meter for 30 minutes | High-humidity zones, near pools or docks |

| IP68 | Suitable for continuous immersion | Pools, water features, underwater architectural lighting |

Installation Techniques for Waterproof LED Channels

Proper installation is critical to maintaining waterproof integrity. Even a high-IP LED channel can fail if incorrectly assembled.

• Use sealed end caps to prevent water entry at channel terminations

• Apply neutral cure silicone sealant along joints and seams

• Route wiring through waterproof junction boxes to avoid exposed connections

Attention to detail during installation ensures the LED channel system maintains its rated protection level over time.

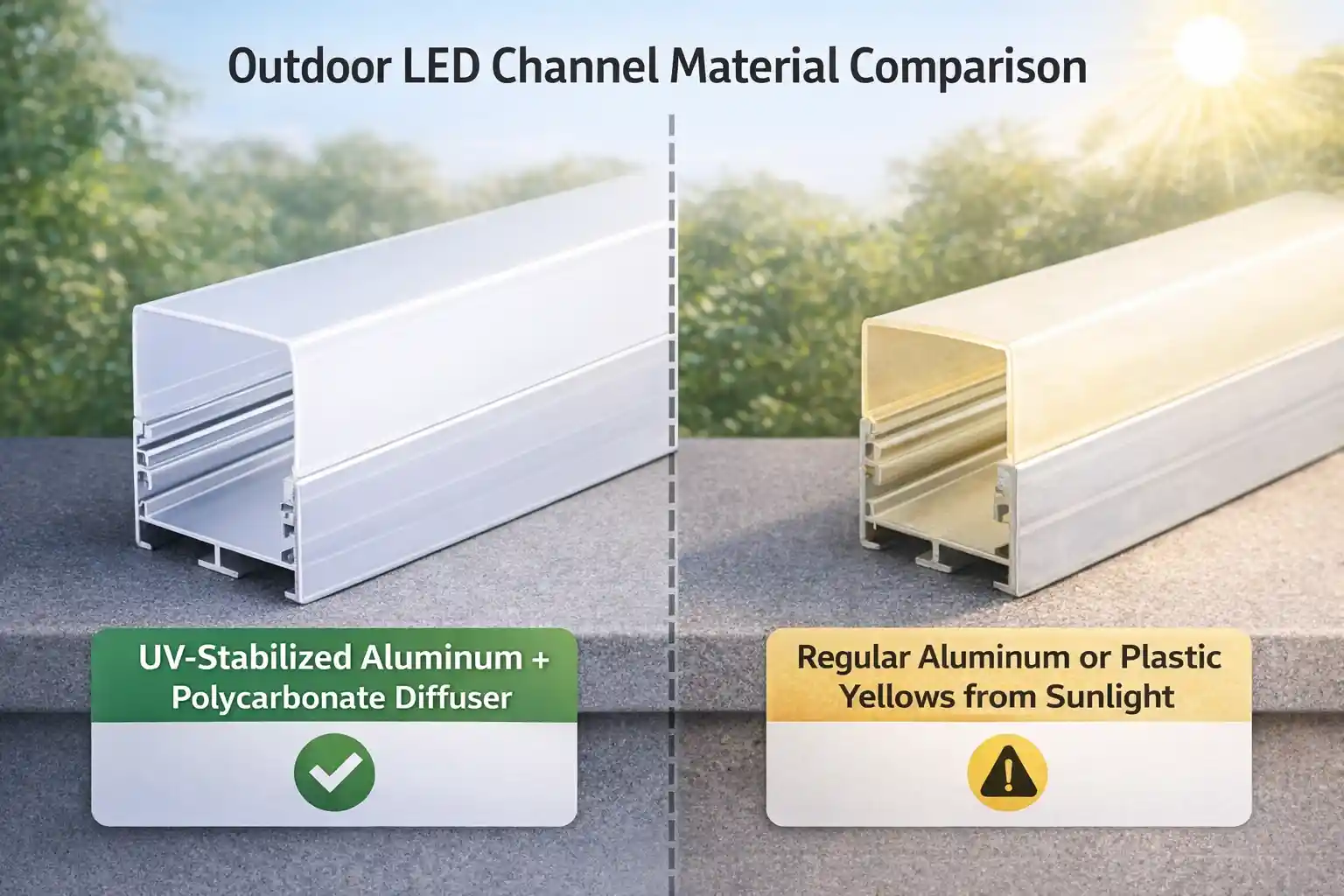

Materials and UV Resistance for Outdoor LED Channels

Aluminum LED channels are ideal for outdoor use due to their strength, corrosion resistance, and excellent heat dissipation. For sun-exposed locations, channels should feature UV-stabilized coatings or anodized finishes to prevent discoloration and surface degradation.

Diffusers used in outdoor LED channels should also be UV-resistant, typically made from UV-stabilized polycarbonate, to prevent yellowing and loss of light transmission over time. Proper material selection ensures both performance and appearance are maintained in demanding outdoor environments.

Common Mistakes When Buying LED Channels

Choosing the right LED channel involves more than selecting a profile that “looks right.” Specification and installation errors can lead to uneven brightness, visible hotspots, overheating, and shortened system lifespan. Avoiding the following mistakes ensures your LED channel system performs reliably and delivers professional lighting results.

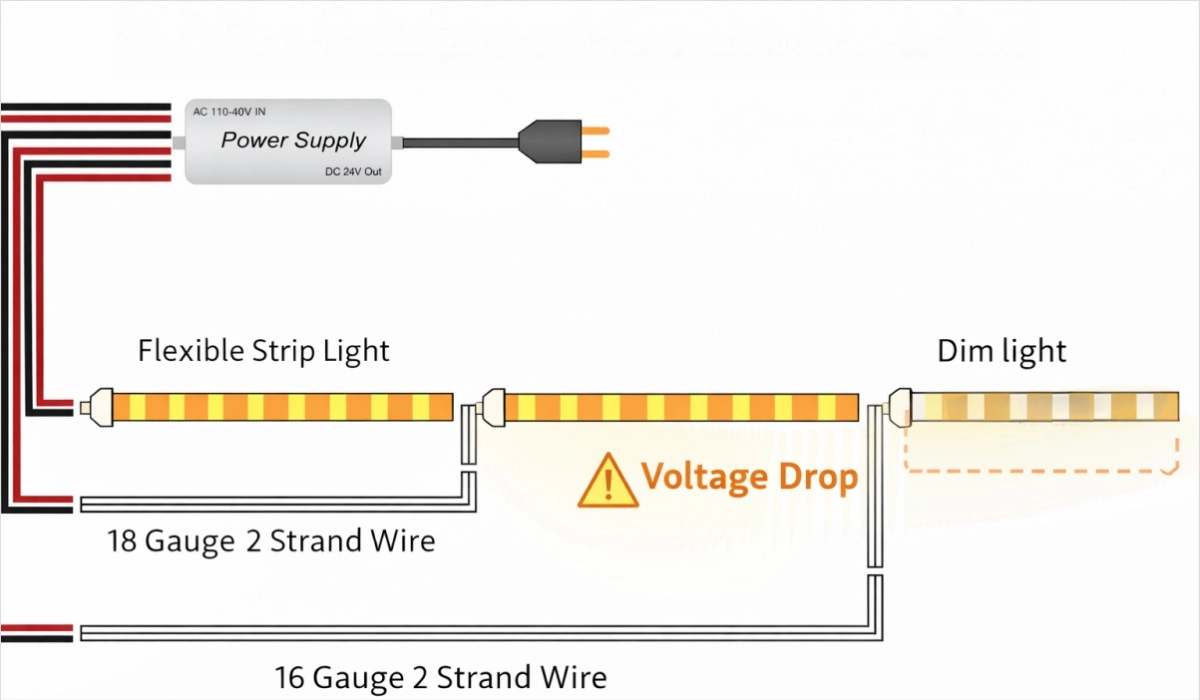

1. Ignoring Voltage Drop

In long LED strip runs (typically over 5–10 meters), voltage drop can cause dimming and inconsistent brightness. Even with a properly sized LED channel, poor power distribution affects overall performance.

Use thicker gauge wires for long distances, confirm the power supply can handle the full load, and add power injection points for runs beyond 10 meters to maintain stable illumination.

2. Neglecting Thermal Management

An LED channel is also a thermal management device. Profiles that are too shallow or made from low-quality materials trap heat, accelerating lumen depreciation and reducing LED lifespan.

Always choose aluminum LED channels and match channel depth to strip power and density. Deeper profiles are especially important for high-output LED strips such as COB.

3. Overlooking Channel Depth

Channel depth directly affects optical performance. Shallow LED channels may leave individual LED points visible, creating distracting hotspots.

Low-output strips may work in 7–10 mm profiles, but direct-view or high-density installations typically require 12–16 mm or deeper LED channels to achieve smooth, uniform light.

4. Ignoring Diffuser Type

The LED channel diffuser strongly influences final light quality. Selecting the wrong cover can result in glare or visible LED dots.

| Diffuser Type | 光传输 | 视觉效果 | 最适合 |

| Clear | ~95% | Maximum brightness, visible dots | Concealed or indirect lighting |

| Milky (Opal) | 70–75% | Soft, uniform, dot-free light | Task lighting, visible linear runs |

| Black (Smoke) | 30–45% | Subtle glow, channel blends when off | High-end architectural and retail spaces |

Match the LED channel diffuser to the visual goal and installation environment.

5. Choosing the Wrong Channel Length or Width

Internal width must be 1–2 mm wider than the LED strip PCB to prevent compression and allow wiring space. Channels that are too narrow trap heat and complicate installation.

For long runs, ensure LED channel lengths are planned to minimize joints and maintain visual continuity while still allowing for thermal expansion gaps.

6. Failing to Plan for Expansion

Lighting systems often evolve. Without planning, future upgrades can require dismantling installed LED channels.

Leave extra wiring capacity, accessible power points, and modular channel layouts so additional LED strips or drivers can be added without damaging finished surfaces.

7. Skipping Installation Guidelines

Improper installation can compromise both performance and safety. Always follow the manufacturer’s instructions for mounting, wiring, and sealing.

For waterproof LED channels, use the specified end caps, gaskets, and sealants to maintain the intended IP rating and prevent moisture ingress.

结论 Careful attention to power distribution, thermal design, diffuser selection, and installation practices ensures an LED channel system delivers uniform, efficient, and long-lasting linear lighting. Avoiding these common mistakes protects both performance and visual quality.

Custom & Wholesale LED Strip Channels from Manufacturer

For large-scale lighting projects, custom and wholesale LED channels provide greater flexibility and efficiency compared to off-the-shelf solutions. By working directly with manufacturers like SignliteLED, you can secure tailored solutions that meet your unique design, performance, and cost requirements. Whether you’re an architect, lighting designer, or distributor, understanding the advantages of custom LED channels ensures your lighting projects achieve the desired results.

定制选项

SignliteLED offers a range of customization options to meet specific project requirements. These options are vital for achieving both aesthetic goals and performance needs.

| Customization Option | Available Features | 益处 |

| 长度 | Customizable to project specifications | Fits specific design needs |

| Finish | Anodized, matte, glossy, powder-coated | Matches project aesthetics |

| Diffuser Type | Clear, milky, black, frosted | Controls light diffusion |

| Channel Depth | Shallow to deep | Ensures proper heat management and light diffusion |

| 材料 | Aluminum, stainless steel, custom alloys | Durable and rust-resistant options |

结论

Choosing the right LED channel is essential for both the performance and aesthetic quality of your lighting installation. Whether your goal is to eliminate visible LED spots, improve heat dissipation, or achieve a sleek, architectural finish, the right LED channel can make all the difference. By understanding the various types, sizes, and customization options available, you can make informed decisions that enhance both the functionality and longevity of your LED lighting system. Always consider critical factors such as channel depth, diffuser type, and the installation environment to achieve optimal results. With the right LED channel knowledge, you will create flawless, professional lighting solutions every time.

常见问题

An aluminum LED channel acts as a passive heat sink by dispersing the heat generated by the LED strip. Aluminum has high thermal conductivity, which helps maintain optimal temperatures, preventing lumen depreciation and prolonging the lifespan of the LEDs. Without a channel, the heat buildup can shorten the LED’s life.

The right LED channel size depends on your LED strip’s width and power.

Width: Ensure the internal channel width is 1–2mm wider than the width of your LED strip.

Depth: Deeper channels offer better light diffusion and heat management, especially for high-power strips.

Clear diffusers provide the maximum light output but may show visible LED dots.

Milky diffusers provide a soft, uniform light and are perfect for task lighting or visible installations.

Black (smoke) diffusers are used for aesthetic purposes and reduce visible glare, offering a subdued look when the LEDs are off.

Yes, LED channels are available with various IP ratings for both indoor and outdoor use. Outdoor-rated channels typically have UV-resistant coatings and waterproof seals to protect against harsh environmental conditions like rain, snow, and sun exposure.

If your project requires specific dimensions or finishes, consider custom LED channels. Customizations include length, diffuser type, finish (e.g., anodized or matte), and material. Contacting manufacturers like SignliteLED for custom orders ensures that your channels meet your exact needs for performance and aesthetics.