The client is a professional linear lighting designer and manufacturer based in Eastern Europe, serving a broad range of customers across the European market. Their core business focuses on customized linear lighting solutions for office and commercial applications, offering a complete one-stop service that covers lighting design, luminaire manufacturing, and installation support.

Unlike manufacturers that rely primarily on standard components, this client develops linear luminaires tailored to each project’s architectural layout and lighting requirements. As a result, their product portfolio spans multiple fixture dimensions, optical configurations, and electrical specifications across different projects.

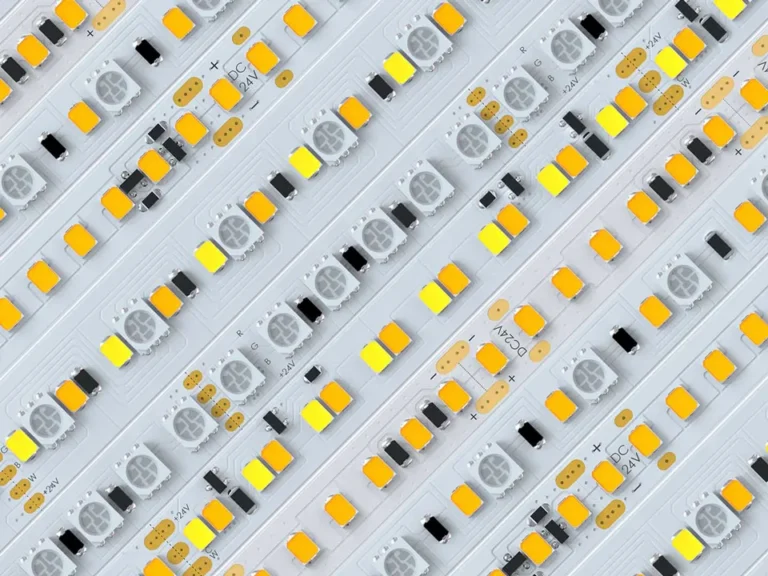

To support this flexible and scalable business model, the client requires customized LED linear modules that can be consistently adapted to various luminaire designs while maintaining stable performance, high efficiency, and compliance with professional lighting standards.

Client Requirements & Challenges

Although several standard linear modules were jointly developed during the early stage of cooperation, the client’s ongoing projects frequently require non-standard LED linear modules due to diverse architectural designs and lighting expectations. Differences in luminaire length, mounting structure, power distribution, and lighting performance often make off-the-shelf solutions impractical for their applications.

In most cases, cooperation begins with relatively high-level input rather than finalized technical drawings. The client typically provides approximate module dimensions, basic electrical parameters, and target power or lumen output. Based on this preliminary information, our engineering team develops the complete module solution, including PCB layout, LED configuration, circuit design, connector selection, and interconnection methods. Achieving alignment between the module design, luminaire structure, and installation constraints often requires close technical communication and multiple design iterations.

Another recurring challenge comes from end-client expectations, which can sometimes be technically ambitious or cost-sensitive. In one case, a project initially targeted a CRI of 95 while requiring an efficacy of 200 lm/W. While technically achievable, such specifications would significantly increase system cost. Through technical evaluation and detailed explanation, the solution was optimized over several revisions, ultimately achieving 180 lm/W at CRI 95—balancing performance, cost, and project feasibility.

These challenges highlight the importance of a flexible development process, sound technical judgment, and practical decision-making to support a wide range of customized lighting projects.

Our Customized LED Linear Module Solution

At the initial stage of developing the standard linear modules, the client provided specifications from a well-known brand as a reference, requesting modules with similar dimensions and performance. Rather than directly duplicating the reference design, we reviewed the client’s luminaire structures, aluminum extrusion profiles, and installation methods in detail. Based on this evaluation, several targeted optimizations were proposed to better support their product range and long-term project needs.

Dimension Optimization

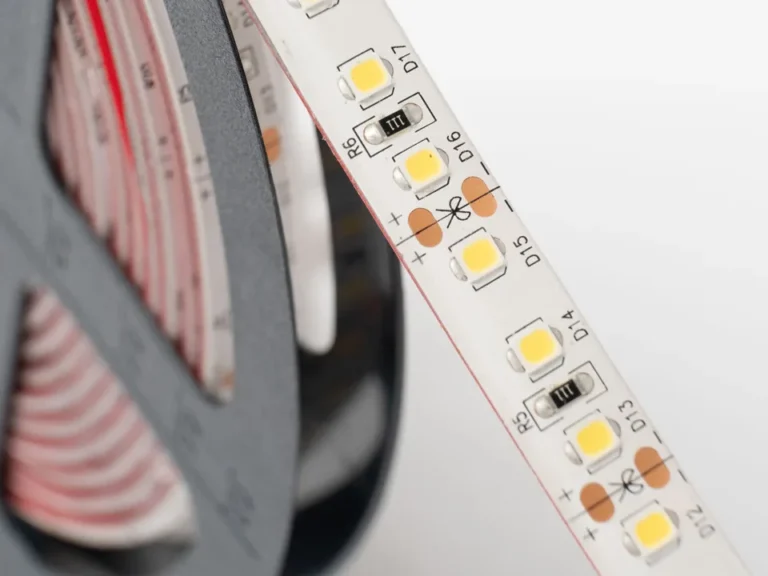

The module width was adjusted to match the internal dimensions of the client’s aluminum profiles more precisely. This improved mechanical compatibility, reduced tolerance gaps, and simplified the luminaire assembly process.

Circuit Design Optimization

The original design used the same number of parallel strings for different module lengths. We reconfigured the circuit to maintain the same number of series-connected LEDs instead. This approach allowed multiple module lengths to share the same LED driver, significantly reducing the number of driver models required and simplifying inventory management.

Connector Optimization

The connector layout was simplified from four connectors to two. This not only reduced material and assembly costs, but also improved wiring efficiency and minimized potential failure points during installation.

PCB Material Upgrade

The PCB material was upgraded from FR4 fiberglass to an aluminum-based PCB. This change enhanced thermal dissipation, improved lumen maintenance, and increased long-term reliability, especially for office and commercial lighting applications.

Mounting Hole Design Improvement

Round mounting holes were replaced with elongated slots, allowing for installation tolerance compensation and reducing alignment issues caused by mechanical deviations. This made on-site installation more efficient and forgiving.

Project Result & Client Feedback

Order Confirmation and Project Outcome

Throughout the development process, the client expressed strong confidence in our technical expertise and responsiveness. Based on the finalized designs, they placed production orders for two customized linear modules, each with an initial quantity of 500 sets, without requesting pre-production samples. The modules were delivered on schedule and quickly integrated into ongoing office and commercial lighting projects.

On-Site Evaluation and Product Feedback

After receiving the products, the client shared direct feedback from on-site installation and real-world use. They noted that “the elongated mounting holes are drilled very well, clean and smooth, with no burrs at all,” which made installation easier and avoided alignment issues.

They also commented on the connector quality, stating that “the WAGO connectors did not turn yellow after reflow soldering, so they must be genuine,” reinforcing their confidence in material selection and overall reliability.

In terms of lighting performance, the client remarked that “the brightness is very high, and I can even consider reducing the power to save electricity costs,” highlighting the efficiency margin provided by the module design.

Ongoing Collaboration and Mutual Value

After each completed project, the client regularly shares installation photos and videos, demonstrating the performance of the modules in real applications. This ongoing feedback not only validates the design approach but also motivates continuous improvement and deeper long-term collaboration.

Conclusion

This case demonstrates how customized LED linear modules can effectively support a wide range of office and commercial lighting projects when flexibility and engineering collaboration are prioritized. Through continuous co-development, technical optimization, and real-world validation, the linear modules evolved into reliable building blocks for diverse luminaire designs. Ultimately, successful linear lighting solutions are defined not by specifications alone, but by how well performance, cost, installation, and long-term reliability are balanced across multiple projects.

Work with an Engineering-Focused LED Linear Module Partner

SignliteLED specializes in the design and manufacturing of customized LED linear modules for architectural and commercial lighting. We work closely with customers to translate project concepts, preliminary dimensions, and performance targets into practical, production-ready solutions. With in-house engineering and manufacturing capabilities, we can turn ideas into physical products in as fast as five days. If you have upcoming linear lighting projects that require flexibility and reliable technical support, we welcome you to discuss your requirements with our team.