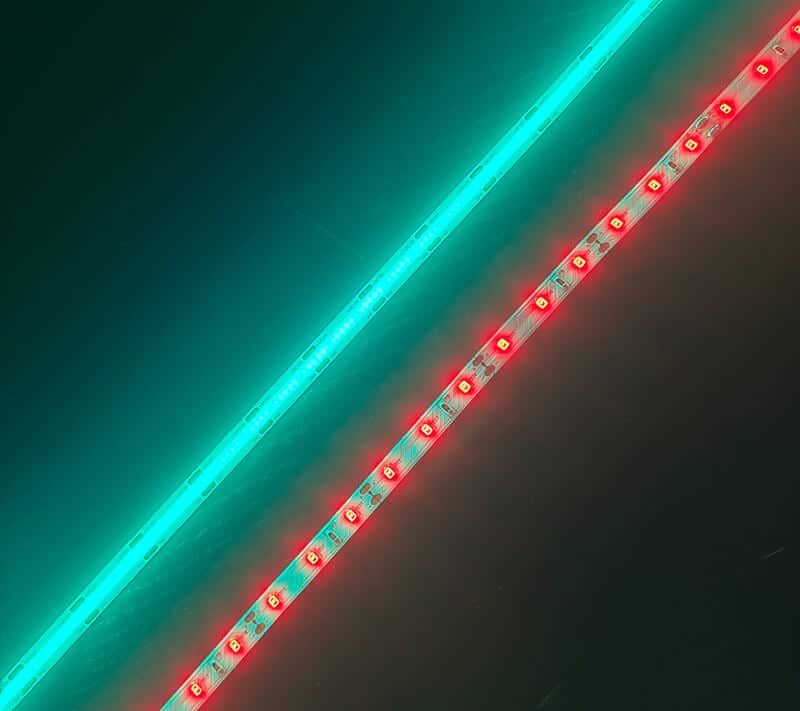

There are two main technologies used in LED strip lighting: COB and SMD (Surface Mount Diode). Brightness levels, among other things, are distinct advantages and disadvantages of each of these lighting sources. We will examine the distinctions between COB and SMD strip lighting in this article and provide you all the details you need to choose the choice that is brighter.

What is COB LED strip lighting?

As was already said, COB LED strip lighting makes use of the most recent LED technology. “Chip on Board” refers to an array of LED chips that is tightly packed and is put directly onto a circuit board. Compared to other SMD LEDs, this design produces light with a higher concentration and brightness.

Compared to SMD LED strips, COB LED strips have a number of advantages that make them more well-liked by consumers. They are a great choice for many lighting applications because of their compact size, potent output, and outstanding energy economy.

What is SMD LED strip lighting?

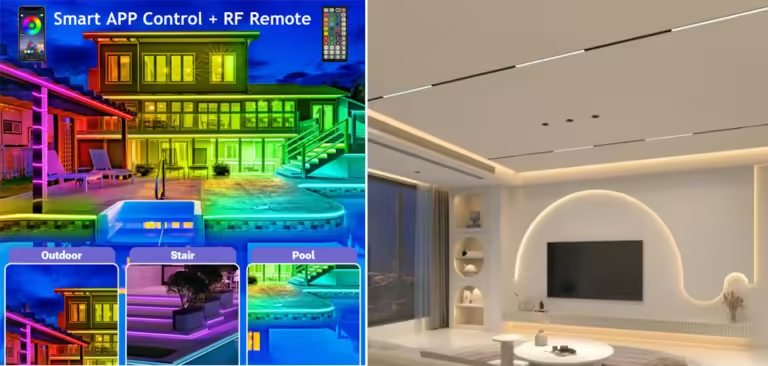

Another sort of LED technology utilized in strip lights is SMD technology. Surface Mount Diodes, or SMDs, are tiny diodes that are grouped together and mounted to a flexible circuit board. SMD LED strip lights typically range in width from 8 to 10 mm and available in a variety of colors.

Compared to conventional LEDs, SMD LED strips offer a brighter and more even light. They are perfect for providing general lighting for both indoor and outdoor use. They have a wider variety of colors, better heat dissipation, and are also more aesthetically pleasing than conventional LED lights.

LED strip lamp comparison between COB and SMD

We examine their traits more closely to compare the brightness levels of COB and SMD LED strip lights:

1. LED Density: COB LED strip lights offer more LEDs per square inch than SMD LED strip lights, which results in a brighter light output.

2. Heat Dissipation: Compared to SMD LED strip lights, COB LED strips have better thermal control. As a result, they can run for longer stretches of time without overheating or breaking.

3. Power Efficiency: Compared to SMD LED strip lights, COB LED strips are more energy-efficient. They may produce more lumens per watt of power used because to their design.

4. Color Rendering: SMD LED strip lights render colors more accurately than COB LED strip lights. They are excellent for accent lighting and setting a particular mood or ambiance since they may produce a larger, more colorful light spectrum.

Which LED strip lighting type, COB or SMD, is brighter?

COB LED strip lighting often produces a brighter, more concentrated light than SMD LED strips in terms of brightness. They are perfect for locations that require powerful illumination due to the higher density of LEDs they include.

SMD LED strips offer a lighter spectrum that is more even and complete, but they often do not emit as much light as COB LED strips. Because of this, COB LED strips are the best option for lighting applications requiring high output brightness.

Conclusion

The brightness levels of COB and SMD LED strip lighting each have advantages and disadvantages. COB LED strips are substantially brighter and have better thermal management, whilst SMD LED strips offer a more natural light spectrum and greater color representation.

Your particular lighting requirements will ultimately determine whether you choose COB LED strip lighting or SMD LED strip lighting. COB strips should be your first choice if you need high-intensity illumination, such as for commercial lighting. SMD strips should be your choice, however, if you need illumination that is more even and natural.