In November 2025, a project contractor from the Middle East contacted us while preparing an exterior facade lighting solution for a hotel project. The application required LED lighting products that could withstand outdoor conditions while maintaining stable performance and consistent light output.

What made this project particularly challenging was the delivery timeline. Due to on-site construction scheduling, the client required the products to be delivered within one week, leaving very little margin for production or logistics delays. At the same time, the client emphasized that product quality could not be compromised, as the lighting would be permanently installed on the hotel facade and directly affect the overall visual effect.

As this was the client’s first cooperation with us, they approached the project cautiously. After finding us through a Google search, the client initiated detailed technical discussions to evaluate whether we could meet both the quality standards and the urgent delivery requirement before moving forward.

Client Requirements and Project Challenges

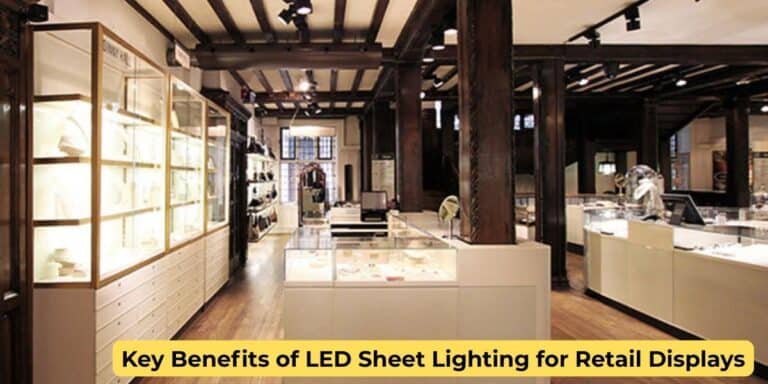

The project involved an exterior lighting installation for a hotel building, where the lighting system was required to deliver dynamic visual effects while maintaining long-term outdoor reliability. The client specified the use of RGBW addressable LED strip lights to achieve full-color effects as well as pure white illumination for architectural accents.

From a technical perspective, the products needed to be fully waterproof and suitable for permanent outdoor installation. To simplify on-site work and reduce installation time, the client requested 6-meter continuous strips, allowing installers to minimize cutting and connection points during mounting. In addition to the hardware requirements, the client also expected comprehensive installation support, including guidance on control software, wiring methods, and strip mounting practices. Lighting effect design support was also required to ensure the final visual result matched the hotel’s architectural layout.

The delivery schedule added another critical layer of complexity. The client required all products to be delivered within a week. This timeline was particularly challenging, as the order was placed in November, traditionally the peak production season due to year-end demand and the Christmas holiday period. During this time, material availability, production capacity, and logistics resources are often under significant pressure.

For our team, the primary challenge was not product design, but execution. Meeting a 7-day delivery requirement during the busiest season demanded precise material planning, fast procurement, and tight coordination between production, quality control, and logistics. Any delay at one stage could have directly affected the overall project schedule.

Communication Process and Technical Coordination

Efficient and structured communication played a critical role in moving this project forward under a highly compressed schedule.

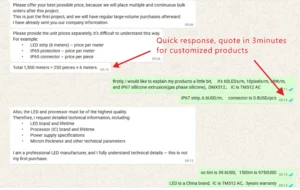

Immediately after receiving the client’s inquiry, our team responded within three minutes with a preliminary technical solution and a complete quotation. This rapid response helped the client quickly assess feasibility and confirmed that the project could proceed within the required timeline.

To address concerns regarding outdoor durability, we provided a detailed explanation of our IP68 silicone extruding RGBW LED strip light manufacturing process. Production images were shared to demonstrate the silicone extrusion structure, sealing method, and internal protection of the LED and PCB. This step was essential in building confidence in the long-term waterproof performance of the product.

For system-level reliability and ease of installation, we recommended the use of IP65 waterproof connectors. This solution ensured stable outdoor connections while allowing the client’s installation team to complete wiring more efficiently on site, reducing both installation time and potential errors.

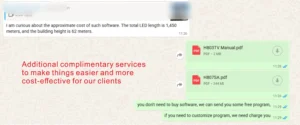

In parallel, we supplied controller specifications and detailed wiring diagrams, ensuring compatibility between the strips and the control system. We also committed to providing lighting effect design support at no additional cost, enabling the client to visualize and program the final RGBW effects before installation.

Due to the tight schedule, the client finalized all technical details late at night and confirmed the order shortly afterward, allowing production to begin immediately.

Solution & Product Selection

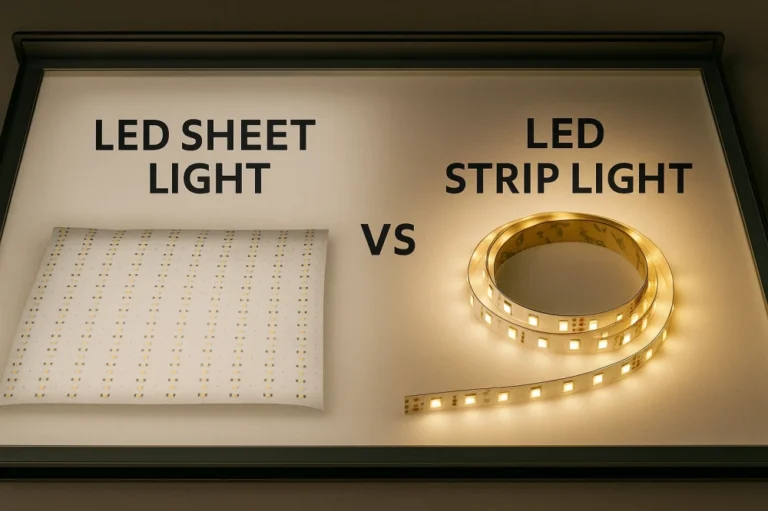

Based on the project requirements, two technical solutions were proposed to the client: an addressable neon light system and an addressable LED strip light system. Both options were capable of delivering RGBW dynamic lighting effects and were suitable for outdoor architectural applications.

After reviewing the installation conditions and overall project budget, the client selected the IP68 DMX512 RGBW LED strip light (EAA12T060C) as the final solution. For outdoor use, the IP68 protection level provided a higher level of resistance against water exposure, making it more suitable for long-term exterior installation.

From a control perspective, the DMX512 protocol offered greater signal stability compared to SPI-based solutions, particularly in outdoor environments with longer cable runs and multiple connection points. This ensured consistent color performance and reliable control during operation, aligning well with the project’s technical and environmental requirements.

DMX512 Addressable RGBW Facade LED Strip Light

Model No.: EAA12T060C

Input Voltage: DC24V

Watt: 18W/m

LED QTY: SMD5050 60LEDs/m

Color : RGBW (6000K)

CRI: Ra90

IC: DMX512, TM512AC

Pixels: 10pixels/m

Cuttable Length: 100mm

IP Grade: IP68

Length: 5m/reel

Warranty: 3years

Order Execution and On-Site Support

Once the client confirmed the order details by email, production was arranged immediately to minimize lead time. To help the project stay on schedule, manufacturing was initiated before payment was fully received, reducing the waiting period between order confirmation and material preparation.

Given the tight delivery requirement, our team coordinated closely with the production department to prioritize this order within the overall manufacturing schedule. Key processes were adjusted to ensure accelerated production without compromising quality, allowing the project to move forward during the peak season.

While production was in progress, we continued to support the client on installation planning. Detailed wiring diagrams were provided and further optimized based on feedback from the client’s installation team, helping to ensure compatibility with the actual site conditions.

During on-site installation, it was discovered that the wiring had not been executed strictly according to the original diagram. Upon receiving this information, we promptly updated the connection instructions and revised the control program files to match the actual wiring layout, preventing delays in system commissioning.

Due to the time difference, the client encountered technical issues outside of regular working hours. Our team provided remote assistance late at night, supporting software installation, controller configuration, and program debugging to ensure the lighting system operated as intended.

Project Outcome and Client Feedback

Despite the language barrier, as the client did not communicate in English and relied mainly on Google Translate, the project progressed smoothly from production to on-site commissioning. Clear technical documentation, timely responses, and step-by-step support ensured that communication remained effective throughout the entire process.

The lighting system was successfully installed and put into operation as planned. The RGBW lighting effects met the visual expectations for the hotel exterior, and the products performed reliably under outdoor conditions. Both the product quality and the execution process received positive feedback from the client.

After project completion, the client shared the following comment:

“Your LED strips are really great. I truly appreciate how proactive you were in pushing this project forward. For the next project, I will continue to purchase from you — the order will be around 1,800 meters of LED strips.”

This feedback confirmed not only the performance of the products, but also the value of consistent technical and project-level support.

Conclusion

This project demonstrated our ability to deliver reliable outdoor lighting solutions under tight timelines and challenging seasonal conditions. From rapid technical response and solution selection to accelerated production and continuous on-site support, each stage was handled with a strong focus on execution and coordination. The successful completion of this first cooperation also laid a solid foundation for future projects, proving that clear communication, engineering-driven decision-making, and proactive service can significantly reduce project risk and ensure consistent results in exterior lighting applications.