Choosing the right LED light sheet for a commercial lighting project requires evaluating measurable technical criteria rather than relying on general performance claims. Procurement teams should assess lumen output per square meter, CRI levels (typically ≥80 or ≥90 for retail), consistent color temperature (Kelvin stability), voltage compatibility (commonly 24V systems), maximum-to-minimum brightness uniformity, and thermal management structure. Incorrect LED spacing, insufficient heat dissipation, or mismatched driver capacity can result in visible hotspots, voltage drop, premature lumen depreciation, and expensive rework after installation.

Commercial applications also demand predictable integration behind acrylic, fabric, or architectural materials with limited depth. If illumination strength, diffuser distance, or power loading is not calculated properly, the system may fail to achieve uniform brightness across large surfaces.

This article explains how to choose LED light sheets for commercial lighting projects by detailing key technical specifications, performance benchmarks, application-based selection criteria, and supplier evaluation standards required for professional B2B projects.

Key Technical Factors to Consider

Selecting a LED light sheet requires a structured review of measurable performance criteria, not just general brightness or flexibility claims. In commercial projects, specifications such as lumen output per square meter, CRI rating, voltage configuration, thermal limits, and modular connection capacity directly determine whether the system will perform reliably over years of operation.

Brightness Levels

Commercial applications often require significantly higher output than residential settings. A high brightness LED light sheet should typically deliver between 3,000–8,000 lumens per square meter, depending on application depth and diffuser type.

For shallow lightboxes (under 50 mm depth), higher output is required to maintain surface brightness without visible LED points. Storefront displays exposed to daylight may require higher luminance to compete with ambient light levels, while interior architectural features may require controlLED brightness to avoid glare or over-illumination.

Output specifications should always be evaluated after accounting for diffuser light loss, which can reduce visible brightness by 20–40% depending on material thickness.

Uniform Illumination Performance

Uniformity depends on LED spacing density, optical layout, and the reflective characteristics of the mounting cavity. A uniform illumination LED light sheet should achieve a maximum-to-minimum luminance ratio close to 1.2:1 to 1.5:1 for professional display environments.

When evaluating uniformity, assess:

• Maximum-to-minimum luminance ratio across the panel

• Required viewing distance and observer angle

• Compatibility with specific diffuser materials and thickness

• Recommended minimum installation depth from sheet to diffuser

Poor spacing design can result in visible hotspots, especially at shallow depths below 40 mm.

Light Diffusion Quality

Even with sufficient brightness, uneven optical spread can cause shadowing or LED dot visibility. Commercial-grade systems are engineered to perform effectively at defined installation depths (for example, 30–80 mm cavity depth depending on configuration).

Specification sheets should indicate recommended diffuser distance to ensure uniform performance.

CRI and Color Consistency

Color Rendering Index (CRI) directly affects how products, fabrics, and branding graphics appear under illumination. Retail environments typically require CRI ≥80, while premium retail, cosmetics, or art installations often specify CRI ≥90.

Color bin consistency is equally critical. LED sheets used across multiple installations should maintain tight bin control (for example, within 3-step MacAdam ellipse) to prevent visible color variation between batches.

Power Efficiency

Energy efficiency should be evaluated using lumens per watt (lm/W) and system-level driver efficiency. Commercial projects typically target 100–150 lm/W depending on brightness class and configuration.

Driver efficiency, voltage drop over long runs, and power supply compatibility must also be reviewed to prevent uneven brightness across larger installations.

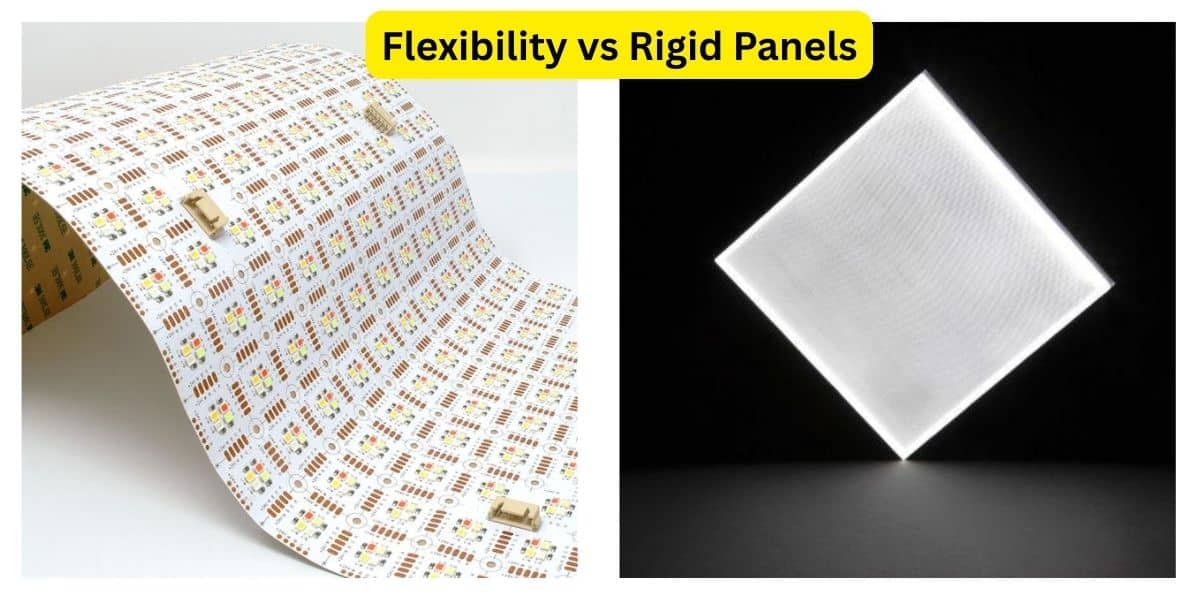

Flexibility vs Rigid Panels

A flexible LED light sheet is suitable for curved surfaces, cylindrical columns, and irregular architectural forms. However, rigid panels may offer better mechanical stability for large flat installations exceeding 1 meter in length.

Selection should consider:

• Mounting surface stability

• Structural support availability

• Required curvature radius

• Long-term mechanical durability

Flexibility should not compromise thermal performance or electrical reliability.

Dimming and Control Compatibility

Commercial projects frequently require integration with 0–10V, PWM, DALI, or other control systems. The LED light sheet must be compatible with constant-voltage drivers matching system voltage (commonly 24V).

Smooth dimming without flicker, particularly below 20% brightness, is critical in hospitality and architectural environments.

Heat Dissipation and Lifespan

Thermal management directly affects lumen maintenance and lifespan. Commercial systems should specify operating temperature range and projected lumen maintenance (for example, L70 at 50,000 hours).

Heat spreading substrates, aluminum backing layers, and proper airflow spacing reduce premature degradation.

Panel Size and Modular Scalability

A LED light sheet panel system should support modular linking without visible brightness variation between sections. Seamless electrical connectors and consistent current distribution are essential for large walls or retail backdrops.

Poor modular design can cause voltage drop, leading to uneven brightness across extended installations.

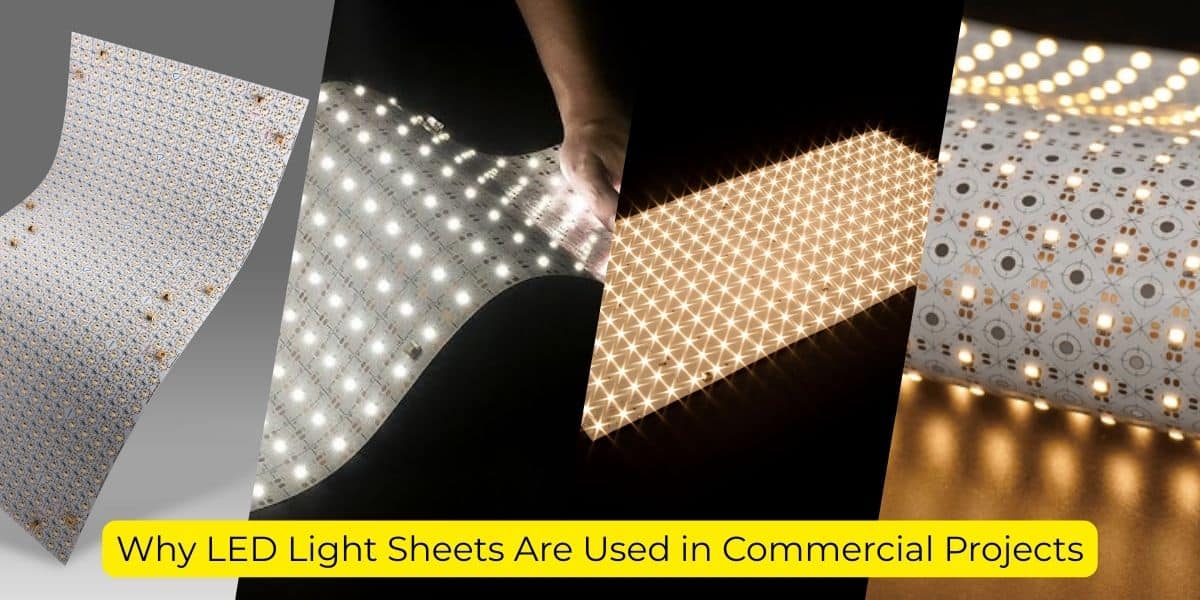

Why LED Light Sheets Are Used in Commercial Projects

In commercial lighting projects, LED light sheets are selected not for aesthetics alone, but for measurable performance advantages in controlLED backlighting environments. Their use is driven by three operational requirements: uniform luminance distribution, reduced installation depth, and long-term thermal stability.

Uniform Illumination Performance

Uniformity is a technical requirement in retail, signage, and architectural backlighting. Inconsistent light distribution results in visible hotspots, shadow bands, and color distortion behind acrylic or fabric diffusers. A properly engineered uniform illumination LED light sheet maintains tight luminance variation across the surface, typically targeting a max-to-min brightness ratio within 1.3:1 to 1.5:1 depending on viewing distance and diffuser thickness.

In commercial signage and display systems, this directly affects brand color accuracy and visual consistency. Even minor luminance imbalance becomes visible when backlighting translucent graphics, particularly in large-format installations.

Slim Construction and Integration Depth

Commercial installations often operate under strict depth constraints. Traditional fluorescent lightboxes or framed LED panels may require 50–100 mm installation depth. In contrast, a LED light sheet panel can operate effectively within significantly shallower cavities, often under 30 mm depending on brightness level and diffuser type.

This reduced depth allows:

• Thinner display cabinets

• Lighter aluminum framing systems

• Reduced material consumption

• Greater architectural flexibility

Depth efficiency becomes especially critical in retail shelving, window displays, and wall-integrated branding systems.

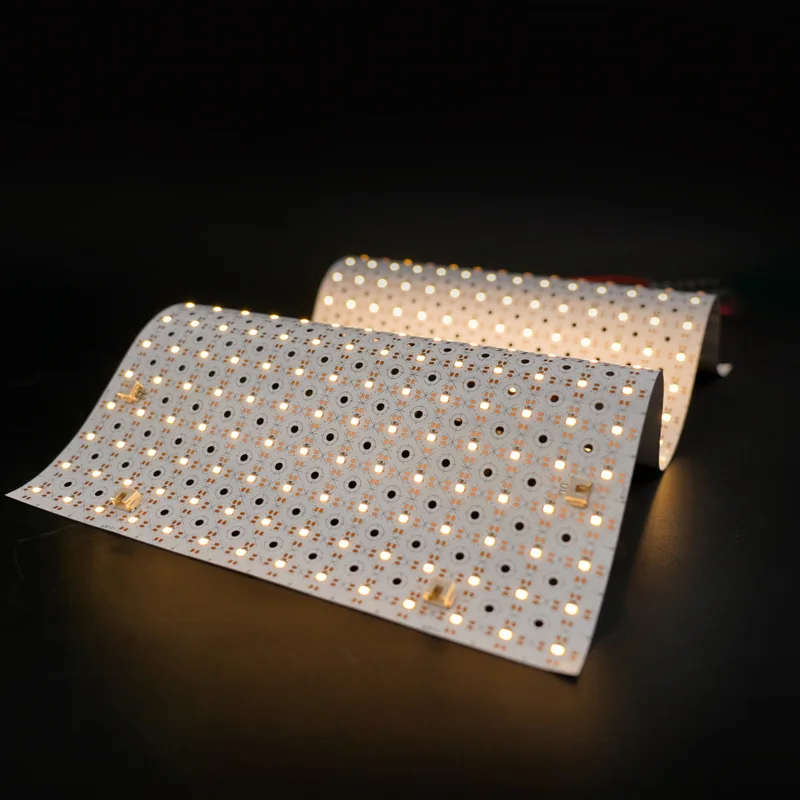

Thermal Management and Operational Reliability

Heat accumulation is one of the primary causes of LED lumen depreciation and premature failure. Commercial LED light sheet panels are engineered with distributed LED spacing and conductive substrate layers to reduce localized thermal concentration.

Proper thermal distribution supports:

• Stable lumen maintenance over extended operating hours

• Reduced color shift over time

• Lower driver stress

• Extended service intervals

In high-duty commercial environments where systems may operate 10–14 hours daily, thermal stability directly influences lifecycle cost and maintenance planning.

Functional Differences from Standard LED Panels

Standard LED ceiling panels are typically manufactured in fixed dimensions and optimized for grid-based ceiling installation. They are not designed for precision backlighting applications where:

• Custom cut dimensions are required

• Irregular shapes must be illuminated

• Installation depth is limited

• Light must be evenly distributed across signage surfaces

By contrast, LED lighting sheet panels are engineered for modular expansion, cut-to-size adaptability, and controlLED backlighting performance in commercial environments.

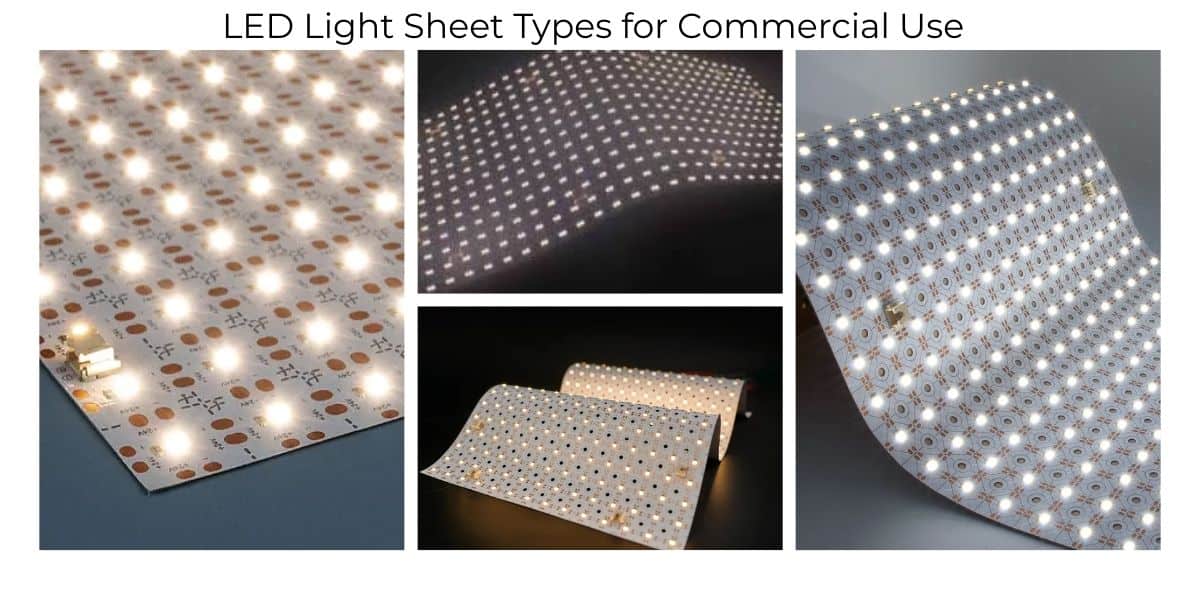

LED Light Sheet Types for Commercial Use

Different LED sheet light types serve different performance goals in commercial environments. Selecting the correct type depends on application requirements, control needs, and branding objectives.

Monochrome LED Sheets

- Main Models: PQx4925T242C

- LED Iype: SMD2835

- LED QIY: 242pcs/plece

- Input Voltage: DC24V

- Power: 28W/plece

- Coiors:2700K/3000K/4000K/6000K

- Lumens: 2800Im/plece

- CRl:80/90

- Size(Lx W):490 mmx245 mm

- Minimum Cutting Unit: 22.3 mm x 22.3 mm

- Dimmable: Yes

- Beam angle:120°

- IP Rating: IP20/IP54

- Lifespan:50,000 hours

- Warranty: 3years

- Certification: CE, RoHS

- The back has SM double-sided adhesive tape

Monochrome LED sheets emit a single fixed color temperature (for example, 3000K, 4000K, or 6500K). These are commonly used in retail shelving, display cabinets, and lightboxes where consistent white illumination is required.

They are typically:

• More cost-efficient

• Easier to control

• Suitable for large-scale rollouts

Monochrome systems are ideal when color consistency and budget control are priorities.

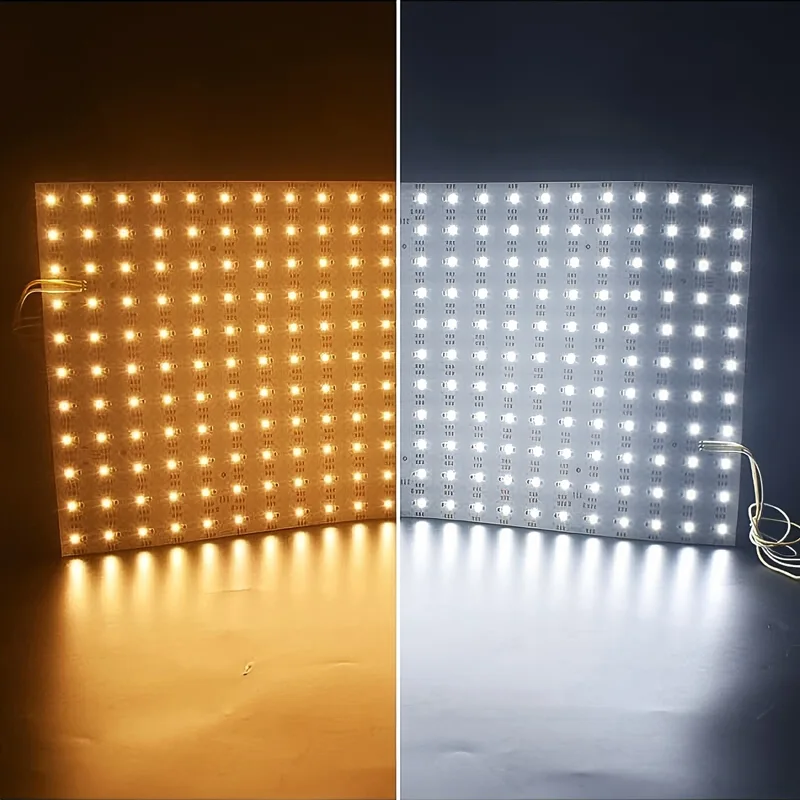

Tunable White LED Sheets

- Size( L x W ): 250mmx250 mm/ 490mmx245mm

- LED type: 2835 SMD

- LED quantity: 200PCS/484PCS

- Working voltage: DC 24V

- Power: 16W/40W

- Color temperature adjustable range: 2700K-6500K

- Luminous flux: 1600lm/3800lm

- CRI: >90Ra

- Minimum cutting length: 25mmx25mm/ 22.3mmx22.3mm

- Dimmable: YES

- Beam angle: 120°

- Waterproof level: IP20 non-waterproof, IP54 waterproof

- Warranty: 3 years

Tunable white LED sheets allow adjustment between warm and cool white tones. This flexibility supports environments where lighting atmosphere must adapt throughout the day.

They are commonly used in:

• Showrooms

• Hospitality spaces

• Premium retail environments

Tunable systems increase project cost but provide greater environmental control and user experience customization.

RGB LED Sheets

- Size( L x W ): 490mmx245 mm

- LED type: 5050 SMD

- LED quantity: 128pcs

- Working voltage: DC24V

- Power: 45W

- Color: RGB

- Dimmable: YES

- Cut length: 39.6 mm

- Beam angle: 120°

- Waterproof level: IP20 non-waterproof, IP54 waterproof

- Lifespan: >35,000 hours

- Warranty: 3 years

RGB LED sheets enable dynamic color changes for branding and decorative applications. They are often selected for experiential retail, signage, and architectural features where color variation is required.

However, RGB systems:

• Require advanced drivers

• Need proper control integration

• Demand more precise installation planning

They are not typically used for standard white backlighting projects.

Pixel LED Sheets

- Size( L x W ): 250mmx250mm

- LED Type: 5050 SMD

- LED quantity: 100pcs

- IC type: Built-in WS2812

- IC quantity: 100pcs

- Color: RGBIC

- Working voltage: DC 12V

- Current: 1.08A

- Power: 13W

- Luminous flux: 20lm/LED

- Beam angle: 120°

- Waterproof Level: IP20 non-waterproof, IP54 waterproof

- Lifespan: >35,000 hours

- Warranty: 3 years

Pixel LED sheets allow individual LED control for animations or dynamic effects. These are used in digital display walls, interactive installations, and advanced branding applications.

Pixel systems require:

• Dedicated controllers

• Programming support

• Higher technical integration

They are selected when visual impact is more important than basic illumination.

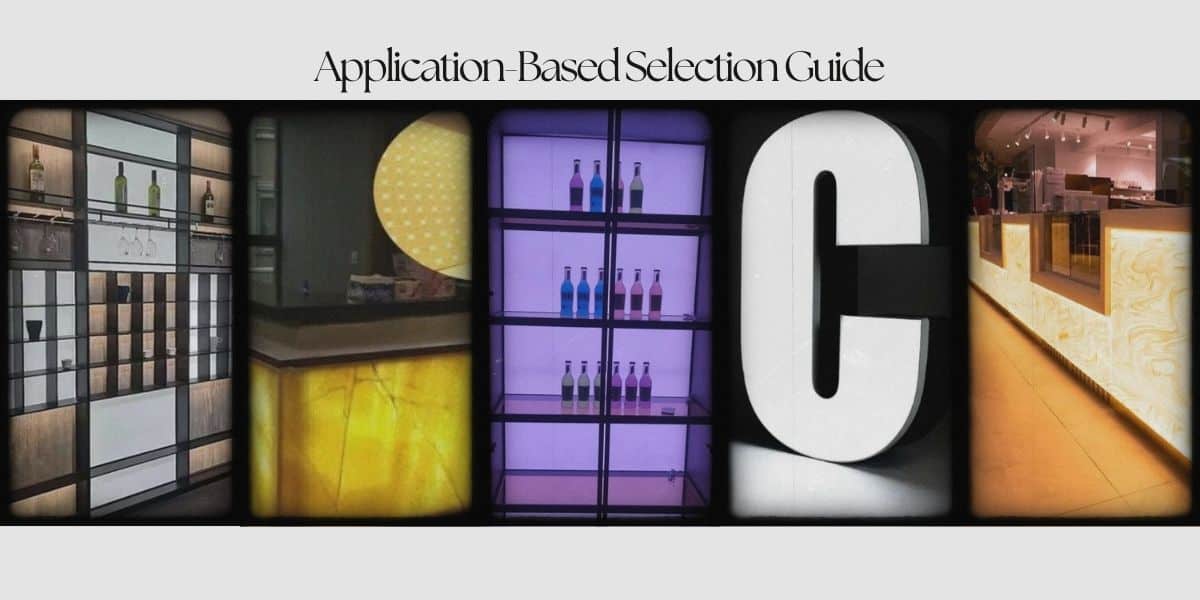

Application-Based Selection Guide

Lighting requirements vary by application. A standardized specification rarely suits all environments.

Retail Displays

Retail environments prioritize high brightness and excellent color rendering. A high brightness LED light sheet ensures product visibility under ambient lighting. Uniformity is critical to avoid shadowing across shelves.

Shop Windows

Shop windows face daylight competition. Higher output and glare control are essential. Thermal stability is also important due to direct sun exposure.

Display Cabinets

Display cabinets require moderate brightness and excellent uniformity. Limited internal space makes slim LED sheet lighting solutions advantageous.

Signage and Branding

Signage applications demand consistent brightness across graphic surfaces. A uniform illumination LED light sheet prevents hotspots that distort branding elements.

Architectural Feature Lighting

Architectural applications may require curved integration, making a flexible LED light sheet more appropriate. Aesthetic continuity and dimming control become primary concerns.

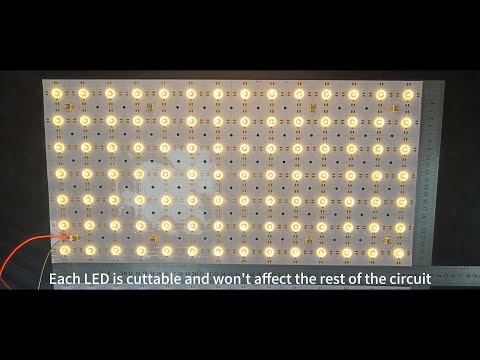

For a clearer understanding of spacing, cutting zones, and placement depth in real installations, the following video example demonstrates how LED light sheets are arranged behind translucent panels in commercial backlighting projects

How to Evaluate LED Light Sheet Quality

Quality assessment extends beyond brightness.

Material quality affects durability and heat conduction. Substrate stability prevents warping over time.

LED chip consistency determines color uniformity. Poor bin management can create visible variation across multiple LED light sheet panels.

Diffuser compatibility influences perceived uniformity. Testing should include real-world installation depth conditions.

Long-term reliability testing should simulate extended operational hours. Thermal stress testing and lumen maintenance evaluation provide insight into lifespan.

Production consistency ensures that repeat orders match initial samples, which is essential for multi-phase commercial projects.

Supplier Evaluation for Commercial Projects

Choosing a supplier involves structured evaluation.

Sample testing allows assessment of brightness, uniformity, and dimming behavior. Real installation mock-ups provide accurate insight.

Batch consistency must be verified through documented quality control processes. Variation between shipments can disrupt brand consistency.

Customization capability matters for non-standard dimensions or brightness tuning. A supplier should demonstrate engineering support for adapting LED sheet lighting to project needs.

Production scalability ensures capacity for large commercial rollouts without compromising quality.

Technical documentation, including photometric data and thermal performance reports, supports compliance and design validation.

When Customization Matters

Customization becomes necessary when:

- Installation depth is limited

- Shapes are irregular

- Brightness must be tuned to specific branding requirements

- Integration with architectural elements demands precise sizing

A tailored LED light sheet panel configuration ensures alignment with structural constraints and design intent. For curved or complex shapes, a flexible LED light sheet may be essential to achieve seamless integration.

Conclusion

Selecting the right LED light sheet requires balancing brightness, uniformity, energy efficiency, thermal management, flexibility, and scalability. Commercial projects demand predictable performance over extended operational lifecycles.

Decision-making should follow a structured evaluation process: define application needs, assess technical specifications, validate uniformity and brightness, confirm compatibility with control systems, and review supplier consistency.

A properly specified solution enhances visual quality, reduces maintenance risk, and supports long-term project performance. In commercial environments where lighting directly influences brand perception and operational efficiency, careful selection is not optional. It is foundational.

FAQs

Brightness depends on application. Retail windows may require higher lumen output to compete with daylight, while interior feature lighting may require moderate levels to prevent glare. Always account for diffuser losses and ambient lighting conditions.

They are not universally better but offer greater flexibility, thinner profiles, and customization options. For signage and architectural backlighting, they are often more suitable than fixed-size panels.

Choose flexibility when integrating lighting into curved surfaces, irregular shapes, or architectural elements that cannot accommodate rigid panels.

LED spacing, optical design, diffuser compatibility, and installation depth all influence uniformity. Poor bin consistency can also create visible variation.

Lifespan depends on thermal design, driver quality, and operating conditions. Commercial-grade systems are typically designed for extended operational hours with gradual lumen maintenance rather than abrupt failure.