In 2025, the demand for COB LED strip lights continues to surge as lighting projects shift toward higher visual comfort, seamless illumination, and improved color accuracy. However, the rapid growth of the COB market has also brought uneven manufacturing quality, inconsistent performance, and unreliable suppliers. Choosing the right Chinese manufacturer is no longer just about getting a good price—it directly affects your project success, long-term maintenance costs, and customer satisfaction. This guide will help you evaluate COB LED strip manufacturers in China with clear, practical criteria, ensuring you build partnerships with suppliers who deliver stable quality and trustworthy support.

What Differentiates a High-Quality COB LED Strip Light

A reliable COB LED strip is not defined by price alone—it is defined by how well each internal component is engineered and how consistently the strip performs under real project conditions. Many manufacturers can produce COB strips, but only a few can maintain long-term stability, uniformity, and performance across large production batches. Below are the key technical factors that separate a truly high-quality COB LED strip from an average one.

Phosphor Coating Uniformity

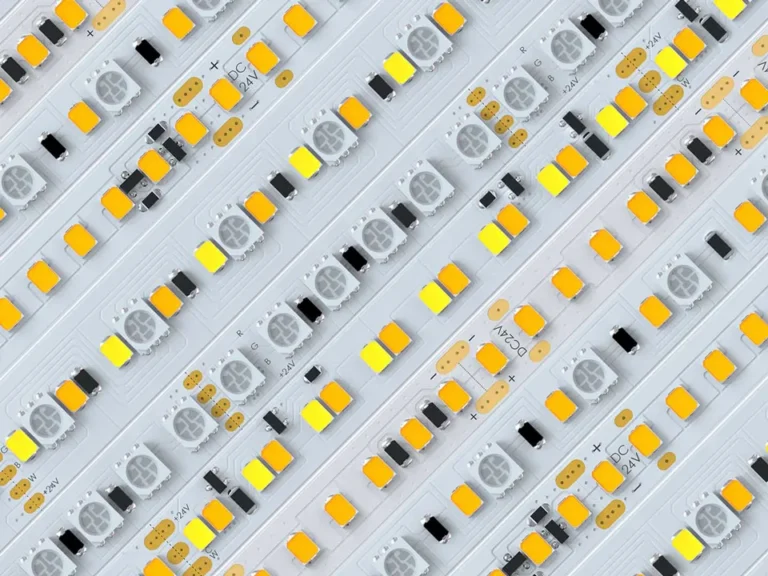

Uniform phosphor coating ensures smooth, dot-free illumination and prevents visible bright or dark patches along the strip. High-end manufacturers use controlled dispensing systems that guarantee consistent coating thickness, which directly affects color accuracy, lumen output, and long-term stability.

CRI Consistency (CRI ≥90 / R9 > 80)

A professional COB strip should not only advertise high CRI—it must maintain CRI consistency across batches. CRI95 with R9 above 80 ensures natural, vibrant color rendering, especially in commercial, retail, and residential applications where visual comfort is essential.

PCB Copper Thickness

The FPC is the backbone of the COB strip. A thicker copper layer (2 oz or 3 oz) reduces voltage drop, improves current stability, and enhances overall durability. Using thin copper (≤1 oz) is a common cost-cutting shortcut that leads to uneven brightness and early failures.

Color Tolerance (≤2–3 SDCM)

Premium COB strips maintain color tolerance within 2–3 SDCM, ensuring excellent CCT uniformity across the entire project area. This prevents visible color deviations between reels, a key requirement for high-end architectural lighting.

Light Efficiency

A high-quality COB strip delivers strong luminous output without excessive energy consumption. Efficient chips and optimized phosphor formulation allow for higher lm/W like 150lm/W while maintaining stable color and CRI.

Heat Management (for 10W–20W High-Power COB Strips)

High-power COB strips require proper thermal design to ensure long-term reliability. This includes thicker copper, better heat-dissipating materials, and stable bonding processes. Good heat management prevents color shift, light decay, and chip degradation over time.

How to Evaluate a Professional COB LED Strip Manufacturer

Selecting a dependable COB LED strip manufacturer in China requires more than checking price lists or sample quality. A truly professional factory demonstrates consistent capability across production, engineering, material control, and after-sales support. Below are the core criteria that determine whether a supplier can meet long-term project demands and deliver stable, repeatable quality.

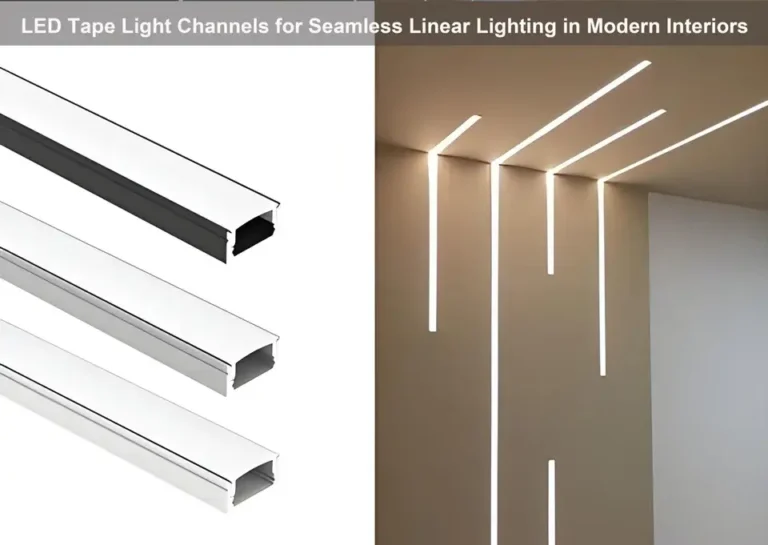

Manufacturing Capability & Facilities

A reliable COB LED strip manufacturer should operate advanced production lines, including automatic phosphor-dispensing machines, high-precision packaging equipment, soldering lines, and 24–48-hour aging systems. These facilities ensure uniform phosphor coating, stable chip packaging, and reduced failure rates. Factories lacking automated equipment typically struggle to maintain consistency across batches, especially for high-volume orders.

R&D Strength and Customization Capability

Strong engineering capability is essential for projects that require unique CCTs, special wattages, extra-long lengths, or customized color rendering. An experienced R&D team can optimize chip selection, develop new phosphor formulas, adjust PCB layouts, and design improved thermal solutions. Manufacturers with in-house R&D can respond quickly to technical challenges and create tailored products that standard suppliers cannot offer.

Quality Control Standards & Certifications

Strict QC systems separate true manufacturers from simple trading companies. Look for suppliers that follow standardized inspection procedures and provide certification reports such as LM-80, CE, RoHS, and ISO9001. These certifications indicate regulated production processes, verified material safety, and documented product reliability. A trustworthy manufacturer should also provide photometric data, IES files, and batch QC records on request.

Raw Material Quality

High-performance COB strips depend heavily on the quality of core materials. Premium suppliers use branded LED chips, 2–3 oz copper PCBs for better heat dissipation, and stable encapsulation materials that resist yellowing. Cutting corners with low-cost chips or thin FPC copper may reduce price temporarily but will quickly lead to issues such as color shift, overheating, or shortened lifespan.

Production Capacity & Lead Time Stability

A capable manufacturer should maintain predictable production capacity, supported by continuous raw-material stocking and efficient scheduling. This ensures stable lead times even during peak seasons. Factories with insufficient capacity may delay orders or compromise QC when overloaded, impacting downstream project timelines.

Supply Chain Reliability

Long-term cooperation requires a supplier with strong purchasing systems and stable upstream partners. Reliable supply chain management helps ensure uniform material batches, reduced risks of shortages, and better overall consistency. Manufacturers relying on unstable component sources often deliver inconsistent quality from reel to reel.

Warranty and Return Policies

A credible manufacturer provides transparent warranty terms, traceable batch identification, and a clear return or replacement procedure. Good suppliers are willing to analyze failure samples and offer technical advice rather than avoiding responsibility. Their after-sales support reflects their confidence in the durability of their products.

Testing Methods to Ensure High-Quality COB LED Strips

A dependable COB LED strip manufacturer must prove product reliability through systematic testing. These tests verify performance, safety, and long-term stability before the products enter the market. Below are the essential testing methods that indicate a professional quality-control system.

Consistency Testing

Manufacturers should test color temperature, brightness uniformity, and wavelength accuracy for each production batch. Proper consistency testing ensures that large project installations remain visually uniform, avoiding noticeable color shifts between reels.

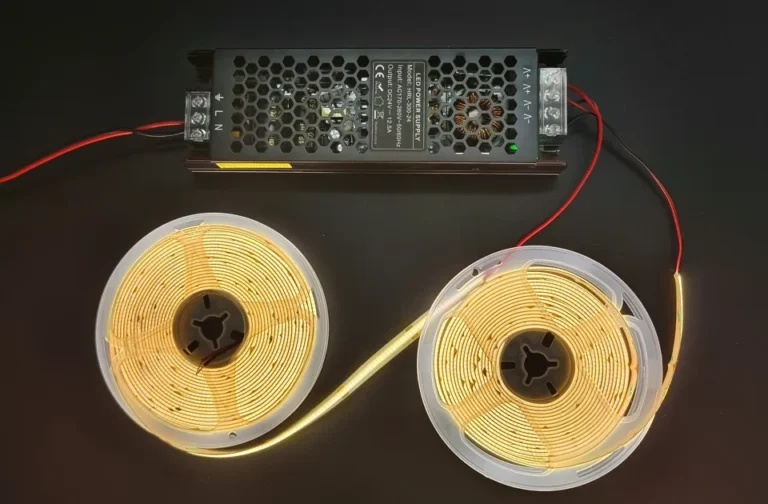

Reliability Testing

Aging tests—typically 24 to 48 hours under rated voltage—help identify early failures. Additional tests like high/low voltage fluctuation, bending endurance, and solder joint strength ensure long-term performance, especially for installations requiring frequent handling or long runs.

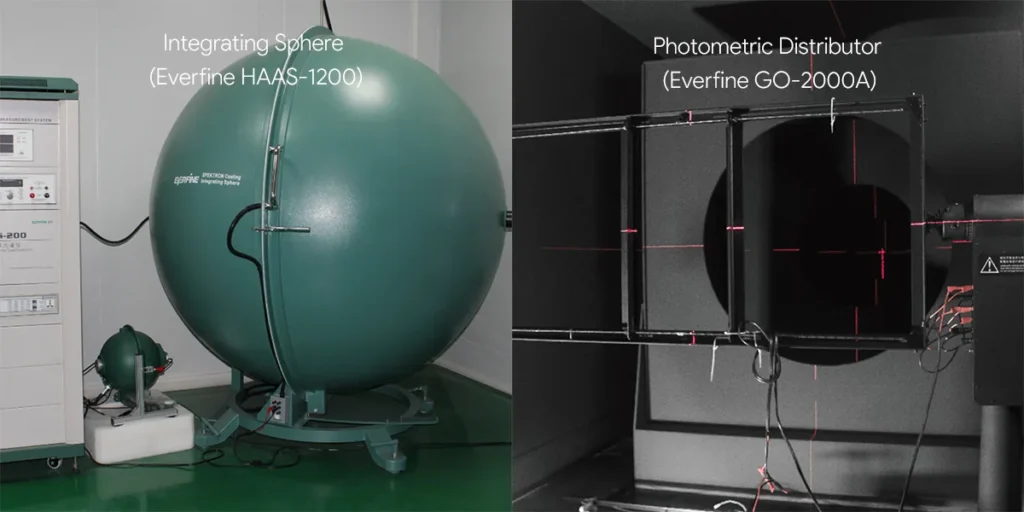

Optical Performance Testing

High-quality COB strips must undergo CRI, R9, and luminous efficacy testing. Photometric equipment and integrating spheres measure key parameters to confirm that the strip meets design specifications and provides accurate, comfortable illumination.

Environmental Testing

For indoor and outdoor applications, COB strips should be validated for IP rating, moisture resistance, UV stability, and temperature tolerance. These tests identify how well the strip withstands real-world conditions such as humidity or heat buildup.

Electrical Safety Testing

Professional factories conduct insulation resistance, Hi-Pot testing, and certification compliance checks (CE, UL, RoHS). These ensure the products are electrically safe and suitable for global markets.

IEC 62471 Photobiological Safety Testing

A high-quality COB LED strip should pass IEC 62471 testing, which evaluates blue-light hazard and photobiological safety. This ensures the strip is safe for prolonged human exposure, especially important for indoor ambient lighting and close-proximity installations. Manufacturers that can provide IEC 62471 reports demonstrate a higher level of technical competence and quality assurance.

Common Red Flags When Choosing a COB LED Strip Supplier

Even though many suppliers claim to produce high-quality COB LED strips, not all of them meet professional standards. Identifying red flags early can help you avoid inconsistent performance, project delays, and long-term maintenance issues. Below are the most common warning signs to watch for when evaluating a COB LED strip manufacturer in China.

Claiming to Be a Factory but Lacking Real Production Facilities

Some suppliers present themselves as manufacturers but operate only as trading companies. If they cannot provide factory photos, production-line videos, or allow virtual audits, this is a clear indication that they do not control the actual manufacturing quality.

Suspiciously Low Pricing

Extremely cheap COB strips often use low-cost chips, recycled phosphor materials, or 1-oz FPC copper. These shortcuts lead to color shifts, overheating, and early failures. A price that seems “too good to be true” almost always signals compromised materials.

Inconsistent Batches and Visible Color Differences

If the supplier cannot maintain 2–3 SDCM color tolerance, you may receive reels with noticeable variations in CCT or brightness. This inconsistency makes large-scale installations impossible to match visually.

Lack of Aging Tests or QC Documentation

Professional factories provide aging records, IES files, test reports, and batch tracking labels. Suppliers who avoid sharing QC documents or ship products without proper aging tests often have high failure rates.

Unclear Warranty Terms or Poor After-Sales Support

When a supplier cannot explain their warranty policy or delays responding to quality issues, it reflects poor responsibility. Reliable manufacturers offer structured after-sales procedures, failure analysis, and clear replacement terms.

How to Perform a Practical Supplier Evaluation in 2025

Evaluating a COB LED strip manufacturer is not just about reviewing samples—it requires a structured and practical approach to verify the supplier’s true capability. By following the steps below, you can minimize risks, identify reliable partners, and build long-term cooperation with confidence.

Conduct a Factory Audit (Online or On-Site)

A real manufacturer should be open to factory audits. Whether through a video tour or an in-person visit, check for automated dispensing machines, chip packaging lines, SMT equipment, aging racks, and testing laboratories. A supplier unwilling to provide transparency is often hiding limited production capability.

Request Multiple Samples from Different Batches

One sample is never enough. Ask for samples produced weeks apart to evaluate batch consistency in CCT, CRI, brightness, and phosphor uniformity. Stable manufacturers can maintain uniform performance across different production cycles.

Review QC Reports and Technical Documentation

Professional suppliers provide IES files, LM-80 data, IEC 62471 reports, RoHS/CE certificates, batch tracking labels, and aging test logs. These documents reveal their quality management level and their commitment to traceable production.

Place a Small Trial Order Before Scaling Up

A pilot order is essential to test packaging quality, shipping reliability, lead-time accuracy, and overall product stability. This step helps verify whether the manufacturer can support real project demands instead of only sample-level quality.

Evaluate Communication Efficiency and After-Sales Support

A reliable supplier responds quickly, provides technical guidance, and handles issues professionally. Consistent communication and timely after-sales support signal strong internal systems and long-term reliability.

Conclusion

Choosing a reliable COB LED strip manufacturer in China requires more than comparing prices—it demands a clear evaluation of production capability, material quality, testing standards, and long-term support. By examining consistency testing, certifications, engineering strength, and supply-chain stability, you can confidently select partners who deliver dependable performance for every project.

SignliteLED operates a 3,000 m² COB LED strip production workshop, equipped with professional manufacturing and testing systems including die-bonding machines, automatic phosphor-dispensing machines, integrating spheres, IES test instruments, and salt-spray testing equipment. These facilities ensure strict quality control from materials to final inspection.

Our R&D team supports full customization, allowing us to tailor wattage, CCT, PCB design, and more to meet project requirements. We maintain regular stock for standard models to enable immediate shipping, while customized items are typically delivered within 15 days, ensuring fast and reliable supply for your business needs.