What causes the installed light strip to come loose?

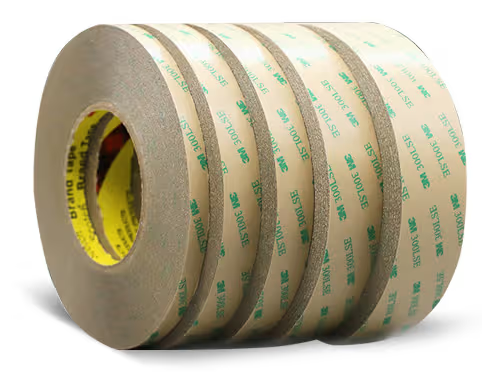

1.Inadequate strip fixing: When installing LED strip lights, if the 3M adhesive is left in place for an extended period of time due to wind and rain, the viscosity of the glue will decrease, turning off the LED strip lights.

2.Paste position and material issues: LED strip lights will also come off quickly if the paste location of the material does not satisfy the requirements, such as if the wall is not smooth enough or if there is a slagging occurrence. Old lime walls and other non-compliant surfaces will cause LED strip lights to easily come off; LED strip light adhesive backing requirements paste site such as walls, glass, stone, and other objects surface is smooth;

3.Cleaning before installation is not standardised: the installation is not cleaned profile surface dust, oil, dirt or other foreign objects, no use of fixtures, etc., will lead to the fall of the light strip.

4.Failure to choose high-quality waterproof light strip: when purchasing the light strip did not require waterproof and the use of adhesive high-quality 3M adhesive.

How to solve the problem of low voltage strip light falling off?

1. Replace the fixing method or light strip: If the light strip falls off because the backing is not strong, you can re-apply a layer of double-sided tape on the profile, or replace the light strip (choose the quality of the light strip as well as the 3M adhesive stronger products)

2. level the surface of the profile: before loading the light strip, make sure that the surface of the profile is flat, if the surface is uneven, you can use abrasive paper and other clean up the surface to increase the adhesion between the light strip and the profile.

3. Clean the pasting position and profile as required: When installing, you should first clean the profile surface of oil, dirt, etc., to avoid dust affecting the fixing effect and to ensure the cleanliness of the pasting position. The light strip should be slowly pasted on the profile and compacted. If you feel that it is not firmly affixed, you can use the fixing sheet to fix the light strip.

4. Outdoor installation should purchase waterproof light strip or often use the slot fixing method, in order to avoid the problem of falling off due to the reduction of the viscosity of 3M adhesive.

Recommended light strips to buy:

What are the Precautions for LED Strip Light Installation?

1. Waterproof profiles should be used for the installation of light strips to avoid moisture affecting the use of the effect.

2. The surface of the profile should be clean and flat.

3. The light strip should be fixed well and cannot be shaken.

4. low LED non-waterproof light strip can not be used in high temperature or humid environment for a long time.

5. When installing the light strip, you can choose a professional installer to ensure the installation effect and quality.

In short, low voltage light strip falling is a problem that many people have encountered. Careful inspection during installation to determine the standard installation method should be able to effectively avoid the occurrence of falling. At the same time, when using LED light strip should also pay attention to moisture and high temperature, to ensure its service life and safety.