In 2026, RoHS compliance has become a core manufacturing requirement for LED PCBs rather than a post-production checklist. Regulatory enforcement is tighter, documentation expectations are higher, and supply chain accountability is expanding across borders. LED PCBs face greater scrutiny than standard boards because of their material complexity, thermal demands, and long operational lifespans, making compliance directly tied to reliability, market access, and manufacturing risk.

What RoHS Compliance Means for LED PCB Manufacturing in 2026

RoHS compliance in 2026 is no longer limited to confirming that restricted substances are absent from a finished product. For manufacturers involved in custom pcb manufacturing, it now applies across the entire production workflow, from raw material sourcing to final assembly records.

At a practical level, RoHS governs how materials are selected, how processes are controlled, and how compliance evidence is maintained. For LED PCBs, this scope is broader because LEDs combine electrical, thermal, and optical functions on a single board.

Why LED PCBs Are More Affected Than Standard Boards

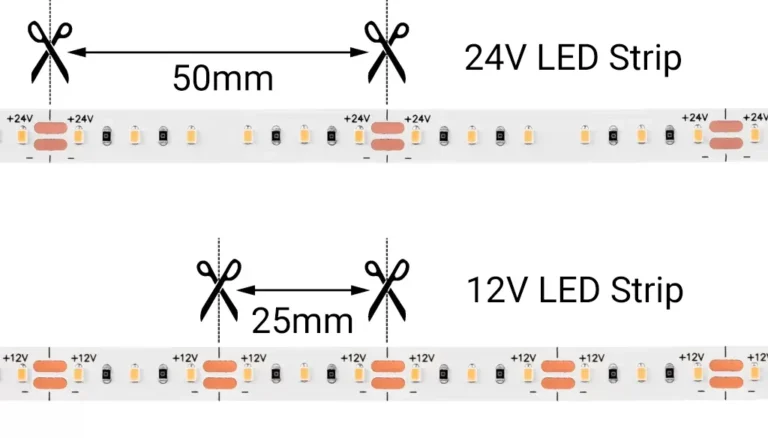

LED PCBs operate under higher thermal stress and longer duty cycles than many conventional electronics. This increases sensitivity to material changes imposed by RoHS restrictions. Small deviations in solder alloys, surface finishes, or dielectric materials can affect heat dissipation and LED lifespan.

Key reasons LED PCBs face higher impact include:

- Higher junction temperatures that amplify material weaknesses

- Dense component layouts that stress solder joints

- Long service life expectations where minor defects accumulate over time

Because of this, RoHS compliance failures in LED applications tend to surface as reliability issues rather than immediate functional failures.

Restricted Substances and LED Sensitivity

RoHS restricts substances such as lead, mercury, cadmium, hexavalent chromium, and certain brominated flame retardants. While these substances were historically used to improve solderability, durability, or flame resistance, their removal changes manufacturing behavior.

LED assemblies are particularly sensitive because:

- Lead-free solders have higher melting points, increasing thermal exposure

- Alternative flame retardants can alter thermal conductivity

- Material substitutions may affect optical stability or color consistency

Component Compliance vs Process Compliance

A common misunderstanding in pcb board custom production is assuming that compliant components automatically result in a compliant product. In 2026, this assumption creates risk.

- Component compliance means each part meets substance restrictions.

- Process compliance means manufacturing steps do not reintroduce restricted substances or compromise material integrity.

Both are required. A compliant LED package can still fail RoHS expectations if soldering materials, flux residues, or rework processes are not controlled.

Key Regulatory Updates Affecting LED PCB Manufacturing in 2026

Regulatory enforcement in 2026 emphasizes verification rather than declarations. Authorities increasingly expect manufacturers to demonstrate how compliance is achieved and maintained.

EU RoHS Enforcement Tightening

EU market surveillance has shifted toward deeper audits of technical documentation. Manufacturers exporting LED products must be prepared to show:

- Clear material traceability

- Supplier declarations linked to specific batches

- Process controls that prevent contamination

Random sampling and post-market checks are becoming more common, particularly for lighting products used in public infrastructure and commercial environments.

Supply Chain Accountability

Responsibility for compliance no longer stops at component sourcing. Manufacturers involved in custom pcb fabrication are expected to understand upstream material origins and downstream assembly risks.

This includes:

- Verifying laminate, solder mask, and surface finish suppliers

- Tracking changes in component formulations

- Managing compliance across subcontracted processes

A weak link anywhere in the supply chain can compromise market access.

Documentation and Traceability Expectations

In 2026, compliance documentation is expected to be structured, searchable, and current. Static declarations updated infrequently are viewed as insufficient.

Traceability expectations now include:

- Lot-level BOM records

- Change logs for materials and suppliers

- Alignment between production records and compliance files

Market Access Risks for Non-Compliant Manufacturers

Failure to meet these expectations can result in shipment holds, forced recalls, or exclusion from regulated markets. For LED PCBs, this risk is amplified because lighting products are often subject to additional safety and environmental scrutiny.

Manufacturing Requirements for RoHS-Compliant LED PCBs

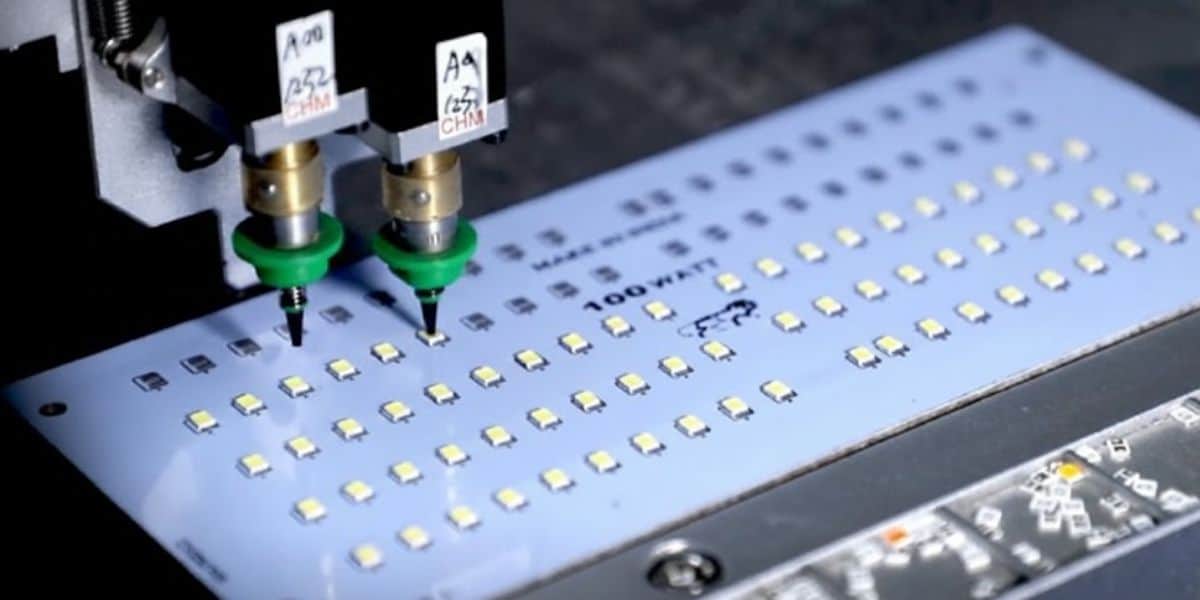

Meeting RoHS requirements in LED PCB manufacturing requires changes at the production level, not just in documentation.

Material Selection Constraints

RoHS limits reduce material choices for laminates, solder masks, and thermal interface materials. Manufacturers must balance compliance with performance, especially in high-power LED designs.

Common considerations include:

- Selecting laminates with compliant flame retardants

- Ensuring solder masks withstand higher lead-free reflow temperatures

- Verifying thermal pads and adhesives meet substance restrictions

Material substitutions often require process requalification.

Soldering and Surface Finish Impact

Lead-free soldering affects both assembly reliability and thermal exposure. Higher reflow temperatures can stress LEDs and PCB materials.

Surface finish choices such as ENIG, immersion silver, or OSP must be evaluated for:

- Compatibility with LED packages

- Long-term stability under thermal cycling

- Interaction with compliant solder alloys

These decisions directly influence yield and field reliability.

Process Control Expectations

Process variability increases compliance risk. In 2026, manufacturers are expected to demonstrate consistent control over:

- Reflow profiles

- Cleaning processes

- Rework and repair methods

Uncontrolled rework is a frequent source of contamination and non-compliance.

Supplier Qualification Importance

Supplier qualification now extends beyond price and capacity. Manufacturers must confirm that suppliers maintain stable, compliant formulations and notify of changes.

This is especially critical for custom pcb board projects where materials may be tailored to specific thermal or mechanical requirements.

Material and Process Challenges Unique to LED PCBs

LED PCBs combine challenges not typically seen in standard electronics, making RoHS compliance more complex.

Thermal Materials vs RoHS Restrictions

High-power LEDs rely on efficient heat transfer. Some historically effective thermal materials contained restricted substances. Compliant alternatives may have different mechanical or aging characteristics.

Manufacturers must validate:

- Long-term thermal stability

- Adhesion under thermal cycling

- Interaction with solder joints

Surface Finishes and Compliance Balance

Certain finishes perform well electrically but may introduce corrosion or migration risks if not properly controlled. In LED applications, these risks can manifest as gradual lumen depreciation or color shift.

Balancing compliance and performance requires careful process tuning rather than default material selection.

LED Reliability Risks if Compliance Is Mishandled

Improper compliance handling can lead to:

- Early solder joint fatigue

- Delamination due to thermal stress

- Optical degradation from material interactions

These failures often appear months or years after deployment, increasing warranty and reputational risk.

Why Shortcuts Cause Long-Term Failures

Shortcuts such as undocumented material substitutions or incomplete cleaning may not cause immediate defects. However, under continuous thermal load, small inconsistencies accumulate.

In LED systems expected to operate tens of thousands of hours, these shortcuts translate directly into reduced lifespan.

Documentation, Traceability, and Compliance Verification

In 2026, documentation is treated as part of the manufacturing process itself.

Why Documentation Matters in 2026

Documentation is the primary evidence that compliance is systematic rather than accidental. For manufacturers, it provides internal control as much as external proof.

Good documentation helps:

- Identify root causes of failures

- Manage supplier changes

- Respond quickly to audits

BOM Traceability

Each BOM entry should be traceable to a compliant supplier declaration. This includes passive components, connectors, and materials that may seem insignificant but still fall under RoHS scope.

Supplier Declarations

Declarations must be current and specific. Generic statements without material identifiers are increasingly questioned during audits.

Audit Readiness

Audit readiness means being able to demonstrate compliance without disrupting production. This requires alignment between engineering, procurement, and manufacturing records.

Common RoHS Compliance Risks in LED PCB Manufacturing

Understanding common risks helps prevent costly corrections.

Partial Compliance Misunderstandings

Assuming that compliance at one stage covers the entire process leads to gaps. Compliance must be continuous from material receipt to final shipment.

Component Substitution Risks

Last-minute substitutions, even for equivalent parts, can introduce non-compliant materials or untested interactions.

Incomplete Documentation

Missing or outdated records weaken compliance claims, even if the physical product is compliant.

Manufacturing Process Gaps

Uncontrolled cleaning agents, rework solder, or shared equipment can reintroduce restricted substances.

How Compliance Impacts Lead Time, Cost, and Planning

RoHS compliance directly influences manufacturing economics.

Why Compliance Affects Timelines

Additional validation, supplier checks, and documentation extend preparation phases. For custom pcb manufacturing projects, this must be accounted for early.

Cost vs Risk Tradeoffs

Compliant materials and controlled processes may increase unit cost, but they reduce risk of rework, recalls, and market access issues.

Planning Changes for 2026 Manufacturing

Manufacturers are adjusting planning models to include compliance lead time as a standard variable rather than an exception.

Preparing LED PCB Manufacturing for 2026 Compliance Standards

Preparation is about building resilience, not reacting to audits.

Process Readiness

Processes should be designed to prevent non-compliance rather than detect it after the fact.

Design-for-Compliance Mindset

Engineers are increasingly considering compliance constraints during design, reducing downstream adjustments.

Supplier Coordination

Close coordination ensures that changes are communicated early and validated properly.

Long-Term Manufacturing Stability

Stable, compliant processes support consistent quality and predictable delivery, which are critical in LED applications with long service expectations.

RoHS Compliance Impact on LED PCB Manufacturing

| Compliance Area | Manufacturing Impact | Risk If Ignored |

| Material Selection | Limits laminate, solder, and finish options | Thermal failure, audit rejection |

| Soldering Process | Higher reflow temperatures and tighter control | Joint fatigue, LED damage |

| Supplier Control | Requires verified declarations and change tracking | Hidden non-compliance |

| Documentation | Ongoing record maintenance | Market access restrictions |

| Process Traceability | Lot-level tracking and audits | Recall and liability exposure |

Conclusion

RoHS compliance in LED PCB manufacturing is a disciplined production approach, not a paperwork exercise. In 2026, compliance affects material choices, process control, documentation, and long-term reliability. Manufacturers that treat compliance as an integrated manufacturing function are better positioned to manage risk, maintain market access, and deliver stable LED performance over extended lifecycles.

FAQs

Because LED PCBs operate under continuous thermal stress, small compliance errors can lead to long-term reliability failures.

Indirectly, yes. Material and process changes required for compliance can influence thermal management and solder joint reliability.

Partial compliance is not sufficient. Both components and manufacturing processes must meet RoHS requirements.

Compliance adds validation and documentation steps, which must be planned into production schedules.

Manufacturers may face shipment delays, recalls, or loss of access to regulated markets.