LED Tri-Proof Lights—also known as waterproof LED fixtures, vapor-tight lights, dustproof LED lights, or batten light—are widely used in demanding environments such as factories, warehouses, parking garages, and subway stations. Their name “tri-proof” refers to protection against water, dust, and corrosion, making them a reliable choice for industrial and commercial lighting. However, even the most durable fixture can fail if it is not installed correctly. Improper mounting, loose wiring, or poor waterproof sealing may lead to safety hazards, reduced light efficiency, and costly maintenance. That is why following a clear LED Tri-Proof Light installation guide is crucial. In this article, we will walk through step-by-step installation instructions and troubleshooting tips, helping you achieve a safe, long-lasting, and energy-efficient lighting system.

Preparation Before Installation

1. Environment Check

Before installing an LED Tri-Proof Light, carefully inspect the environment. Ensure the surface is stable, dry, and free from excessive dust or oil. Check humidity and temperature levels to confirm they meet the fixture’s specifications, which helps maintain its waterproof and dustproof performance.

2. Materials and Tools Preparation

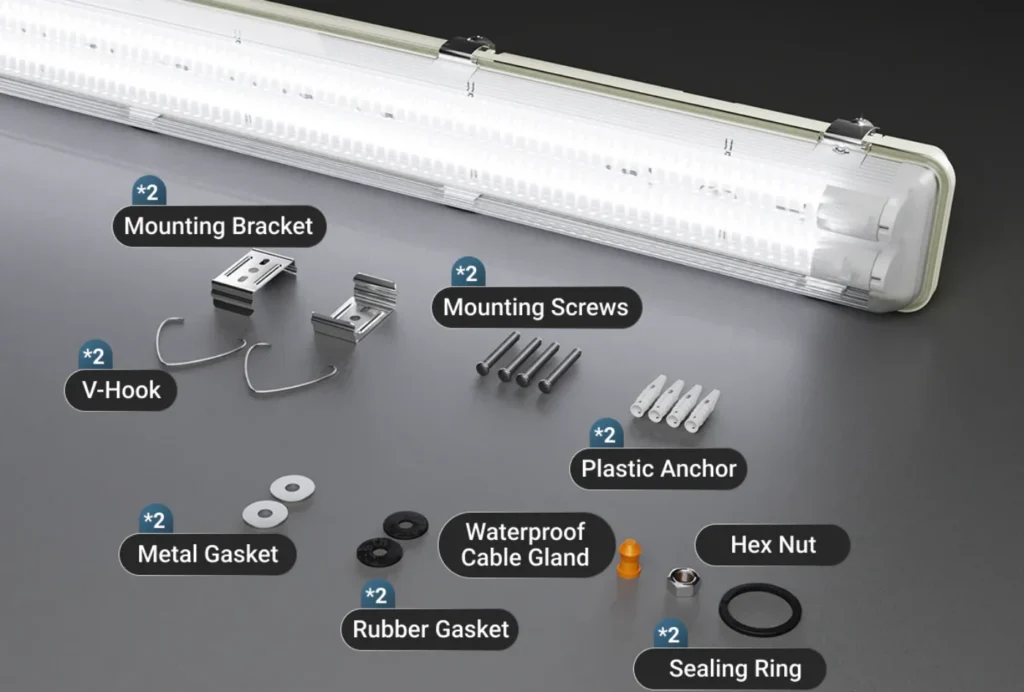

Gather all required items before starting. This includes the LED tri-proof light fixture, mounting brackets, screws, waterproof connectors, and end caps. Essential tools often include a drill, screwdriver, pliers, and insulation tape. Having everything ready ensures a smooth and efficient installation process.

3. Safety Precautions

Always cut off the main power supply before wiring. Use insulated tools and wear protective gloves to prevent accidents. Double-check that all electrical connections comply with local standards. Prioritizing safety at the preparation stage guarantees a reliable and long-lasting LED Tri-Proof Light installation.

Step-by-Step Mounting Methods

Surface-Mounted Installation

- Measure the length of the LED Tri-Proof Light and mark the drilling positions on the ceiling or wall.

- Drill the holes at the marked points, making sure the depth matches the expansion plugs.

- Insert expansion plugs into the drilled holes.

- Fix the metal mounting brackets with screws, tightening them firmly to avoid movement.

- Align the light fixture with the installed brackets.

- Gently press the fixture into the brackets until it clicks securely in place.

- Connect the waterproof power cable according to the wiring diagram.

- Recheck the stability and alignment before moving to the next step.

Suspended Installation

- Mark two suspension points on the ceiling, ensuring they match the fixture’s length.

- Drill holes and insert expansion plugs at the marked positions.

- Screw in the suspension hooks or install steel wire anchors firmly.

- Adjust the length of the hanging chains or steel cables to the desired installation height.

- Attach both ends of the suspension kit to the fixture’s mounting clips.

- Secure the light to prevent swaying or uneven balance.

- Test the stability by gently pulling the fixture before powering on.

- Connect the waterproof wiring carefully, making sure the sealing rings are properly tightened.

Installation Tips

Keep the fixture level during installation to ensure even lighting.

Avoid overtightening screws or brackets to prevent damage to the housing.

Do not place fixtures directly under strong water jets unless rated IP66 or higher.

Always confirm that all connectors and seals are fully locked to maintain waterproof protection.

| Installation Type | Key Steps | Typical Application |

| Surface-Mounted | Drill → Fix brackets → Snap in light → Connect wiring | Parking garages, corridors |

| Suspended | Drill → Install hooks → Adjust chains → Hang fixture → Connect wiring | Warehouses, factories, halls |

Wiring & Waterproof Connections

Wiring Methods

When installing an LED Tri-Proof Light, wiring can be done through single-end input or double-end input depending on project requirements. Single-end input is common in smaller installations, while double-end input is suitable for longer runs or daisy-chain connections. Always verify the fixture’s voltage rating, whether AC220V, AC277V, or higher industrial standards such as AC347V or AC480V, to avoid mismatched power supply issues.

Waterproof Connections

A key factor in maintaining IP65 or IP66 protection lies in the connectors. Use high-quality waterproof cable glands and ensure that sealing rings are correctly tightened. Applying insulation tape or a silicone ring around vulnerable areas can provide secondary protection. Proper grounding is also necessary to ensure electrical safety and stability.

Common Wiring Concerns

Loose connections are the most common cause of failures such as flickering, short circuits, or even water ingress. To prevent these issues, always double-check that wires are stripped to the right length, inserted fully, and securely fastened. Taking extra care at this stage guarantees a reliable and long-lasting LED Tri-Proof Light installation.

Checking and Testing & Troubleshooting

Checking

Before powering on, conduct a careful inspection to ensure a safe and secure installation. Confirm that all electrical wires are connected firmly and that insulation is properly applied to prevent short circuits. Check that the LED Tri-Proof Light has been fixed tightly onto brackets or suspension kits, with no loose fittings. For suspended installations, verify that the hanging height is even to maintain uniform lighting. Finally, make sure the PC diffuser cover is fully locked into place to guarantee waterproof and dustproof performance.

Testing

After inspection, switch on the power to test the fixture. Confirm that the LED Tri-Proof Light turns on immediately and delivers consistent brightness. Observe closely for any flickering, dimming, or unusual sounds from the driver. This step ensures that both electrical and mechanical connections are correct before the lights are put into daily use.

Troubleshooting

If issues occur during testing, consider the following common cases:

Light not turning on → Check if wiring is connected properly or if the power supply is faulty.

Flickering issue → Inspect whether the driver has poor contact with the LED board, or confirm that the driver’s output voltage matches the LED module requirements.

Condensation or moisture inside → Ensure that the diffuser cover is tightly locked and that the cable entry is fully sealed with waterproof connectors.

Proper checking, testing, and troubleshooting will maximize the safety and lifespan of your LED Tri-Proof Light installation.

Conclusion

Proper installation, careful wiring, and thorough testing are the keys to ensuring that LED Tri-Proof Lights deliver reliable performance in demanding environments. By following the recommended steps and applying troubleshooting methods when needed, users can avoid common issues such as flickering, power failure, or water ingress. A well-installed system not only enhances safety but also reduces long-term maintenance costs.

At SignliteLED, every tri-proof light we produce undergoes strict inspection and testing to ensure there are no power failures or waterproofing problems. Our products are designed with flexibility in mind — they support daisy-chain connections for large-scale projects and can also be paired with emergency power supply solutions for added safety. Whether you need durable fixtures for factories, warehouses, or parking garages, SignliteLED provides professional, reliable, and customizable LED Tri-Proof Lighting to meet your project requirements. If you have your private tri-proof light fixture, you can also get customized LED linear module from us, Contact us today for bulk supply and tailored technical support.