LED strip lights are very popular because they are versatile. One of their great features is the ability to cut them to any length, making them easy to customize. But what if you need to extend them over a larger distance, like tens or even hundreds of feet? This can be a bit tricky and requires careful planning and setup.

When planning longer runs of LED strip lights, there are two main factors to consider for each strip length:

The LED strip light’s max run length specification

The power supply’s maximum capacity specification

Based on your installation, one or more of these factors may play a role in deciding the maximum length of your LED strip sections. We will explain each of these factors in detail below.

The LED Strip Light’s Max Run Length Specification

The maximum run length of an LED strip is the longest length that can be connected to a single power source, as defined by the manufacturer and typically found on the specification sheet.

For Signlite LED strip lights, this maximum length depends on the voltage.

DC 12 volts: 16.4 ft / 5 mtr

DC 24 volts: 32.8 ft / 10 mtr

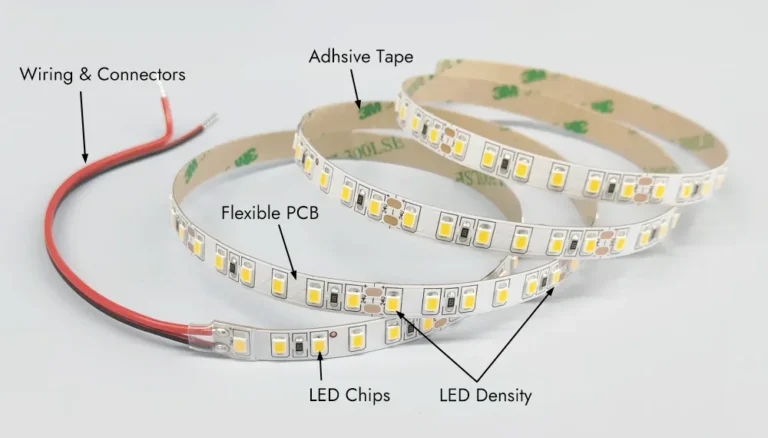

The maximum run length specification is due to the design and configuration of LED strip lights. LED strips are a long and linear circuit boards, so every point must carry enough current for all downstream LEDs. Longer LED strip runs require higher electrical current, especially in the first few inches near the power source.

Do not exceed the maximum run length for LED strips. Longer runs can cause voltage drops and safety issues. Note that wires and connectors do not count towards this maximum length.

What can I do ? if the total LED strip length exceeds the max run length?

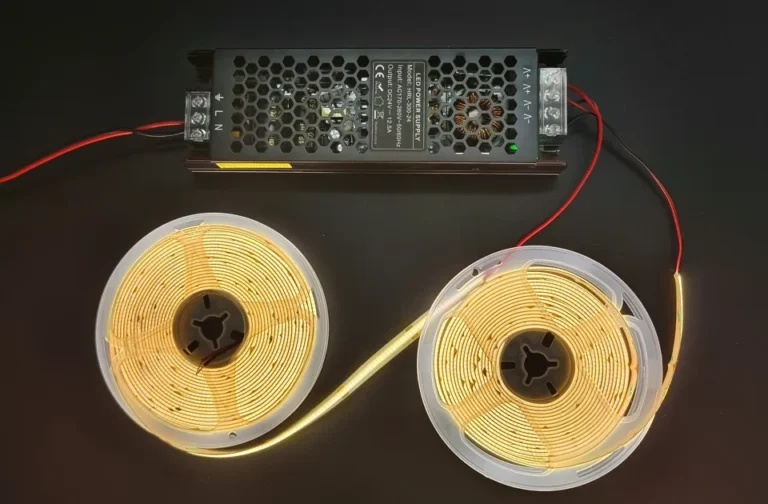

You could connect multiple LED strip runs in parallel, or joint extra power supply by double feed.

Besides, the another constant current led strip can work in one road of DC 24 volt 65.6 ft / 20 mtr, these lights provide a longer length per reel without voltage drop issues. Simply connect the power supply to one end, and the brightness will remain consistent from end to end. However, due to higher production costs, most people still prefer standard constant voltage LED strips.

The Power Supply’s Maximum Capacity Specification

For low voltage DC lighting systems, the power supply unit is a device that converts AC line voltage (e.g. 120 volts) to low voltage DC (e.g. 12 volts). The power supply unit has a maximum capacity that dictates how much electrical current it can convert from AC line voltage to low voltage DC at any given time. This is typically expressed in amps (A) or watts (W). We will use watts (W) in our example here for consistency. A common power capacity may be 120 watts (or expressed as 5 amps at 24 volts).

The primary rule here is that the power supply’s capacity must be higher than the power draw of the LED strip run. Exceeding the capacity of the power supply’s ability to provide power can damage the power supply unit and lead to potential safety issues.

The power supply’s capacity is one of the first things that power supply manufacturers will note on the product datasheet and should be quite straightforward to determine. In some cases, you may need to convert watts to amps, and vice versa using the formula [Power (watts) = Current (amps) x Voltage (volts)]

For example, If led strip lights have a 5.5watt per foot and 24 volt, the 32.8 ft run length above would require 180.4 watts (5.5 watts per foot x 32.8 feet = 180.4 watts).

From there, simply multiply the power draw (in watts per foot) by the run length (feet). For example, the 32.8 ft run length above would require 180.4 watts (5.5 watts per foot x 32.8 feet = 180.4 watts).

This means that at an absolute minimum, the power supply must have a capacity of 180.4 watts or higher, and ideally up to 20% overhead, meaning 216.5 watts would be the recommended minimum capacity for a 32.8 ft run.

If the power supply unit that you have in mind does not have sufficient power capacity for a given LED strip run, you will need to either search for a higher capacity power supply, or reduce the LED strip run length and use multiple power supply units.

In addition, AC 110/220V LED strips are available in a single length 164 ft / 50 mtr. These are excellent for applications where you need long-length strips. You can cover up to 164 ft with a single strip; no need to take the hassle of strip slicing and parallel wiring. Besides, these high-voltage strips provide smooth and even lighting.

To sum up, the length of the LED strip depends on voltage drop. When you increase the size of the LED strip, the resistance inside the strip increases, so the voltage drops. And due to voltage drop, the strip’s brightness is directly affected. That is why the voltage rate is increased with the length. Because as the voltage is increased, it reduces the voltage drop and keeps the brightness of the LED strip constant.

However, if you want a suitable length of LED strips to light your project, go to ask SignliteLED now.