In demanding environments such as industrial facilities, parking lots, and cold storage warehouses, lighting systems face significant challenges. Conventional fixtures paired with traditional dimming systems often fail to meet the high-performance requirements of these specialized settings, unable to deliver long-term stable operation. For project stakeholders, the lifespan of lighting systems, maintenance costs, intelligent control capabilities, and energy-saving efficiency have become critical factors for project success.

While the combination of standard luminaires and conventional dimming may seem adequate initially, issues like diminished lighting performance, increased energy consumption, and frequent maintenance gradually emerge over time. More critically, traditional dimming methods lack precise control, failing to adapt to changing work environments and lighting demands, resulting in wasted energy efficiency.

Consequently, an increasing number of enterprises are focusing on how to ensure the long-term stability and cost-effectiveness of lighting systems through efficient, intelligent, and energy-saving solutions.

Against this backdrop, LED tri-proof lights integrated with DALI dimming systems are emerging as the mainstream solution for industrial lighting. They not only deliver exceptional durability and reliability but also enable intelligent management, helping enterprises reduce energy consumption, minimize maintenance costs, and extend product lifespans.

What is an LED Tri-proof Light?

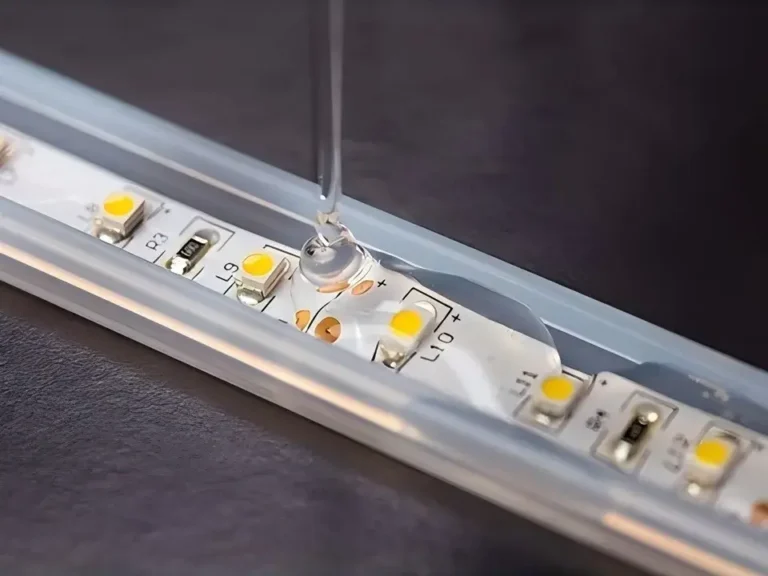

An LED tri-proof light is a specialized lighting solution designed to withstand extreme environmental conditions. The term “tri-proof” refers to three primary protective features: waterproofing, dustproofing, and corrosion resistance. These lights feature rugged construction to ensure reliable operation in challenging environments.

Key Protection Ratings:

- IP Rating: Typically IP65 or IP67, indicating high water and dust resistance. IP65 luminaires withstand powerful water jets and dust accumulation, while IP67 offers greater protection against prolonged exposure to moisture and particulates.

- IK Rating: Typically IK08 or IK10, signifying strong resistance to mechanical impact. IK08 luminaires endure significant physical shocks without structural damage, while IK10 provides the highest level of impact protection.

- Material & Process Corrosion Resistance: True corrosion resistance stems from material selection and meticulous detailing. For instance: – High-strength PC lens instead of standard acrylic to resist UV aging and chemical corrosion – Die-cast aluminum alloy housing with epoxy powder coating – Corrosion-resistant silicone seals at all joints – Internal electronics coated with triple-proof paint These measures collectively withstand chemical corrosion environments like salt spray and acid/alkali vapors.

Typical Application Scenarios:

- Industrial Plants: Suitable for manufacturing workshops with high humidity, dust, or chemical exposure, ensuring stable lighting for equipment and work areas.

- Parking Lots: Suitable for outdoor parking areas, withstanding rain, snow accumulation, and vehicle exhaust to provide enduring, safe illumination.

- Cold Storage & Food Processing Facilities: Maintains hygiene standards and operational efficiency in environments with extreme temperature and humidity fluctuations, such as cold storage and food handling zones.

- Tunnels & Underground Passages: Designed for enclosed spaces with limited ventilation, resisting condensation and structural damage to ensure navigation and safety.

What is DALI Dimming and Control?

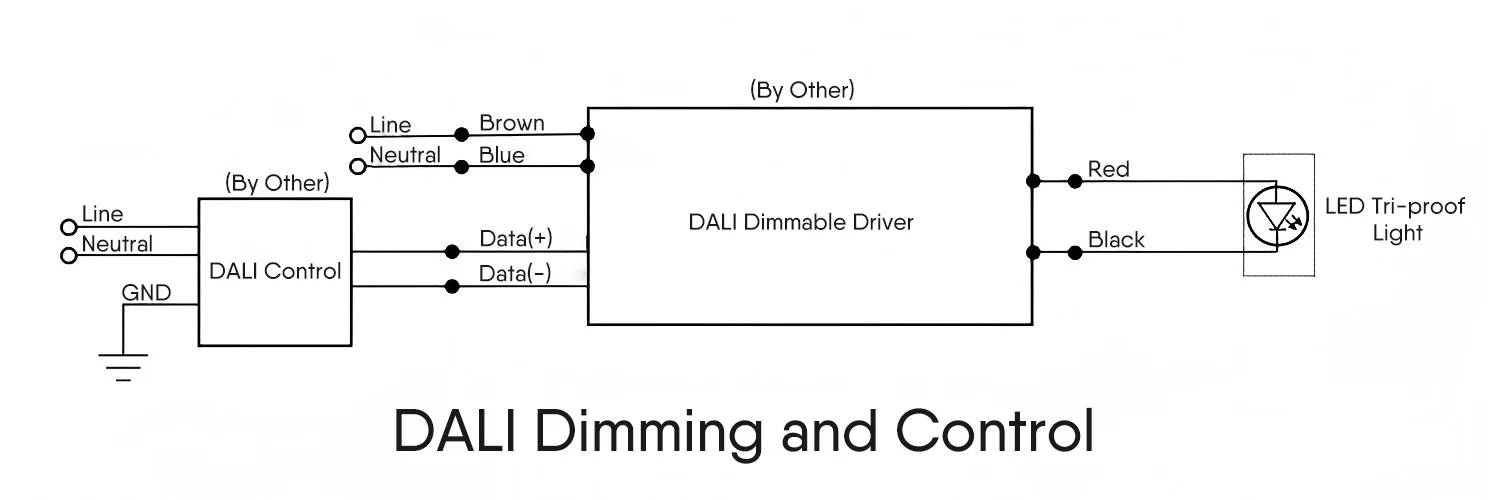

DALI (Digital Addressable Lighting Interface) is an intelligent lighting control protocol that enables more precise dimming and efficient energy management. Compared to traditional 0-10V dimming systems, DALI offers greater control options and enhanced compatibility, allowing luminaires to adjust according to real-time requirements.

Advantages of DALI dimming include:

- Precise light adjustment: DALI systems dynamically adjust luminaire brightness based on ambient light levels to ensure desired illumination.

- Energy efficiency: By precisely controlling brightness, DALI significantly reduces energy consumption and lowers electricity costs.

- Flexible management: DALI supports centralized control and easily integrates with Building Management Systems (BMS) for intelligent control and enhanced management efficiency.

In short, DALI is an “engineering-grade” lighting control solution offering systematic management, diagnostics, and optimization capabilities—beyond mere “brightness adjustment.”

Why Choose LED Tri-Proof Lights + DALI Dimming?

The combination of LED tri-proof lights and DALI dimming represents an optimal pairing—the synergistic effect of rugged hardware and intelligent systems. Integrating DALI into industrial-grade tri-proof lighting creates a synergistic outcome where the whole is greater than the sum of its parts, addressing core pain points in traditional industrial lighting projects.

1. Signal Stability in Harsh Environments

In factory settings with high humidity, dust, and complex electromagnetic interference, traditional analog dimming signals (e.g., 0-10V) are susceptible to line attenuation and electromagnetic interference. This leads to inaccurate dimming, flickering, or even loss of control. DALI employs digital signal transmission with robust interference resistance, ensuring precise and reliable command delivery. This guarantees consistent dimming performance even in harsh electrical environments.

2. Precise Centralized Control for Large-Scale Projects

A large parking garage or factory may contain hundreds or thousands of lights. DALI enables control of up to 64 independently addressable devices (each address representing one or more fixtures) via a single two-wire bus, achieving minimal wiring. Administrators can effortlessly implement group control (e.g., by zone or production line), preset scenes (full brightness mode, energy-saving mode, cleaning mode, and night patrol mode), and scheduled tasks from the backend, significantly boosting management efficiency.

3. Revolutionary Reduction in Full Lifecycle Maintenance Costs

In traditional projects, “lights out” incidents require manual, time-consuming troubleshooting. The DALI system remotely locates and reports faulty fixtures (down to the specific address number) while providing predictive alerts (e.g., estimating lifespan based on operating hours). This transforms maintenance from reactive emergency repairs to proactive planning, pinpointing faults precisely and drastically reducing manual inspection costs and downtime.

4. Maximized Energy Savings and Green Certification Advantages

DALI serves as the optimal tool for achieving deep energy savings. Combined with daylight sensors and motion sensors, it enables “on-demand lighting,” delivering energy efficiency far exceeding simple LED retrofits. This granular energy management directly contributes to scoring in green building certifications like LEED, BREEAM, and WELL, fulfilling corporate social responsibility and policy requirements for sustainable development.

DALI Dimming vs. 0-10V Dimming Comparison

For procurement and project decision-makers, how should one choose between DALI and traditional 0-10V systems? The table below clearly contrasts their core differences:

| Feature Dimension | 0–10V Analog Dimming | DALI Digital Dimming | Practical Impact on Lighting Projects |

| Control Method | Analog voltage signal used to control luminaires, typically at circuit or group level | Digital communication protocol with individual or group addressable control | DALI enables advanced scene settings, fine zoning, and single-luminaire control, ideal for complex projects |

| Immunity to Interference | Limited immunity; signal attenuation over long distances and susceptibility to EMI may cause flicker or dimming inconsistency | High immunity; digital signal transmission ensures stable performance over long distances | In industrial environments with heavy electromagnetic interference, DALI offers significantly higher reliability |

| Wiring Complexity | Requires an additional analog control line; topology and distance are relatively constrained | Standard two-wire bus, non-polarized, flexible topology (star, tree, or mixed) | Wiring cost is comparable, but DALI offers greater flexibility and easier on-site installation |

| Maintenance & Diagnostics | No status feedback; fault finding relies on manual inspection | Supports status monitoring, operating hours, and fault code reporting | DALI greatly reduces maintenance time and cost, enabling remote diagnostics and predictive maintenance |

| System Scalability | Limited scalability; fixed functionality and poor integration with smart systems | Excellent scalability; open standard protocol, easy integration with BMS, sensors, and IoT platforms | DALI is future-ready and well suited for smart buildings and smart factory infrastructure |

| Feature Dimension | 0–10V Analog Dimming | DALI Digital Dimming | Practical Impact on Lighting Projects |

Conclusions and Recommendations:

- Choose 0-10V: Suitable for scenarios with extremely limited budgets, simple dimming requirements (only requiring overall dimming), small project scale, and no need for future expansion.

- Prefer DALI: For any medium-to-large industrial, commercial, or public infrastructure project—especially those prioritizing long-term operational costs, management efficiency, system stability, and future scalability—DALI is the indisputably superior investment. Its energy savings and management convenience typically recoup the initial investment difference within a few years.

DALI Dimmable Tri-Proof Lighting Applications and Solutions

The integration of DALI dimming systems with LED tri-proof luminaires not only enhances the intelligence and energy efficiency of lighting systems but is also particularly suited for specific industrial environments. Below are some typical application scenarios:

Food, Beverage, and Pharmaceutical Plants

Requirements: Extremely high hygiene standards (requiring frequent high-temperature, high-pressure washing), corrosion resistance (acidic/alkaline environments), and moisture resistance.

Solution: DALI tri-proof lights with IP66/69K high protection ratings, 304 stainless steel housings, or specialized anti-corrosion coatings. Paired with light sensors to automatically dim during daylight hours using natural light. Combined with scheduled scenes, this enables precise, zoned, and time-based lighting control, meeting HACCP/GMP standards.

Logistics Warehouses & Cold Chain Centers

Requirements: High-bay, high-uniformity lighting; stable operation in low-temperature environments (cold storage); intelligent aisle zone sensing.

Solution: In standard warehouses, deploy high-efficiency, medium-wide beam angle luminaires paired with DALI motion sensors to achieve “lights on when people approach shelves, lights off when they leave.” In cold storage (-25°C or lower), specialized low-temperature cold storage luminaires are essential. Their drivers and materials are specially engineered to ensure instant start-up at low temperatures and long-term reliability. The DALI system enables remote monitoring of luminaire status within cold storage, preventing energy loss from frequent door openings for inspection due to luminaire failures.

Automotive Manufacturing and Machining Workshops

Requirements: High illuminance, high color rendering (for assembly and quality inspection), oil resistance, vibration resistance, and integration with production systems.

Solution: Employ high -RA value, adjustable-focus luminaires for task lighting along assembly lines and inspection stations. Pre-program “Production Mode,” “Maintenance Mode,” and “Cleaning Mode” via the DALI system. During equipment maintenance, designated areas can be illuminated with a single button press to ensure safety.

Chemical and Hazardous Areas

Requirements: Explosion-proof, corrosion-resistant, high reliability.

Solution: Select DALI-dimmable tri-proof lights with appropriate explosion-proof certifications (e.g., Ex d IIC T6 Gb / Ex tD A21 IP66 T80°C). DALI’s low-voltage signal nature inherently suits hazardous zones, while its status monitoring capabilities significantly enhance safety management.

Typical Application Scenarios: Why Ordinary Tri-Proof Lights Fall Short?

Underground Parking Garages

Requirements: 24/7 lighting with high energy consumption; zone-based energy savings (permanent lane lighting, sensor-activated parking bay lighting); humid environment.

DALI Tri-Proof Light Advantages: During low-traffic nighttime hours, the DALI system uniformly reduces lane base lighting to 50% while triggering 100% illumination in parking bays via motion sensors, achieving over 60% overall energy savings. The system enables remote monitoring of each light’s status, eliminating manual floor-by-floor troubleshooting.

Industrial Manufacturing Workshops

Requirements: High illuminance to ensure production safety and quality; varying lighting needs across workstations (high brightness for assembly areas, dimmable lighting for aisles); presence of vibration and dust.

Advantages of DALI-enabled tri-proof lights: Pre-set “Production,” “Maintenance,” and “Cleaning” scenarios with one-touch switching. Precision assembly lines can be individually boosted for high illumination, while general areas use basic lighting, balancing energy efficiency and functionality. Vibration-resistant design and stable DALI signals ensure flicker-free lighting during large equipment operation.

Tunnels and Underground Corridors

Requirements: 24/7 continuous operation; automatic brightness adjustment at entrances based on external light (“light adaptation” and “dark adaptation”); challenging and costly maintenance.

Advantages of DALI-Controlled LED Lights: Using line-mounted light sensors, the DALI system automatically and smoothly adjusts brightness across tunnel sections, ensuring safe and comfortable driving conditions. Its exceptional reliability reduces maintenance frequency, while remote fault diagnosis enables maintenance teams to arrive at the exact failure point with the correct spare parts, significantly shortening maintenance windows.

These application scenarios demonstrate the adaptability and advantages of LED lights with DALI dimming systems across diverse industrial environments.

Key Considerations for Selecting DALI-Certified Tri-proof Lighting Fixtures

When selecting DALI-certified tri-proof lighting fixtures, it is essential to comprehensively evaluate critical factors such as tri-proof light CE certification, driver compatibility, installation/maintenance, and smart integration to ensure system stability and long-term benefits. The following provides specific selection guidelines:

- Certification and Standards: Verify that the product driver is DALI-2 certified. DALI-2 ensures true interoperability between devices from different brands, eliminating compatibility risks associated with older DALI versions.

- BMS System Compatibility: Verify compatibility with existing Building Management Systems (BMS) to support centralized control and remote monitoring, facilitating future system integration and expansion.

- Simple Installation Design: Opt for modular, easily removable fixtures to reduce installation complexity and costs while enabling straightforward maintenance and upgrades.

- Driver Quality: Drivers are the core executors of DALI systems. Inquire about driver brands. Leading international brands like Tridonic, Osram (LEDVANCE), and Inventronics, or reliable Taiwanese brands such as Mean Well’s DALI series, offer comprehensive assurance in compatibility and reliability.

- Environmental Adaptability Parameters: Operating temperature range is critical, especially for cold storage applications. Clearly specify minimum start-up temperatures for drivers and luminaires (e.g., -40°C). Ensure claimed protection ratings (e.g., IP66) are backed by certification reports from authoritative laboratories.

- Optical and Mechanical Customization: Professional suppliers should offer multiple beam angles (narrow, medium, and wide) to accommodate varying installation heights and illuminance requirements. Flexible customization capabilities must be available for special requirements like specific lengths, power ratings, and color temperatures (e.g., adjustable 3000K-5000K).

- System Support Capabilities: Can the supplier provide a complete solution—from DALI system architecture design and control device selection (controllers, sensors) to commissioning support? This is often critical for successful project implementation.

As experts specializing in industrial lighting, SignliteLED not only offers a full range of rigorously tested DALI-2-compliant tri-proof luminaires but also maintains a complete product portfolio—from -40°C cold storage-specific fixtures to explosion-proof DALI solutions. Based on your project floor plans and requirements, we provide professional DIALux lighting simulation calculations, system design planning, and customized product development to ensure flawless execution from blueprint to final implementation.

TB Series – Tubular LED Tri-proof Light

Model No: TRC06X20F/TRC12X40F/TRC15X50F

Dimension: φ76600mm/φ761200mm/φ76*1500mm

Input Voltage: 100-277VAC, 50/60Hz

Watts: 20W/40W/50W

Efficacy: 130lm/W

CCT: 3000K/4000K/6500K

CRI: >80

Beam Angle: 120°

IP Rating: IP67

Dimming: 0-10V, Triac, DALI, PWM optional

Certification: CE, RoHS

Lifespan: 50,000hrs

Warranty: 5years

Future Development Trends of DALI and LED Tri-Proof Luminaires

With continuous technological advancements, LED lighting and smart control technologies will increasingly be applied in various industrial lighting projects. The integration of DALI dimming systems with LED tri-proof luminaires will exhibit the following future development trends:

- Enhanced Intelligence: Future DALI dimming systems will support more intelligent functions, such as automatically adjusting brightness to suit different environments and dynamically regulating light intensity based on sensor-monitored human activity. This will make lighting systems more flexible and efficient.

- Enhanced Energy Efficiency: As lighting equipment and control systems undergo continuous optimization, the energy efficiency of LED tri-proof luminaires will steadily improve. DALI dimming systems will further reduce energy consumption, delivering more energy-efficient and environmentally friendly lighting solutions.

- Integration and Modularity: The integration and modularity of DALI dimming systems will simplify installation and maintenance. Future systems will integrate more easily with existing building management systems, security systems, and other infrastructure, providing unified smart solutions.

Conclusion: Advancing Toward Intelligent, Sustainable Industrial Lighting Environments

Against the dual backdrop of Industry 4.0 and carbon neutrality, lighting has transcended its singular function of “illuminating spaces,” evolving into a critical energy management asset and productivity tool. Choosing LED tri-proof luminaires means choosing reliability; integrating DALI dimming systems means choosing manageability, high efficiency, and future-oriented intelligence.

Every industrial project presents unique challenges and requirements—there is no one-size-fits-all solution. We recommend considering lighting as a systemic issue from the earliest stages of project planning. SignliteLED’s engineering team stands ready to provide professional technical consultation, customized solution design, and reliable project implementation support, helping you build a truly robust, intelligent, and efficient industrial lighting environment.

FAQs

A: The ROI primarily comes from two areas: energy savings (achieved through intelligent dimming and sensing, typically yielding an additional 30%-70% reduction in electricity costs) and reduced maintenance (remote diagnostics significantly lower troubleshooting and repair expenses). In medium- to large-scale projects, the additional investment is usually recouped within 1-3 years.

A: No. Its core is a two-wire control bus connecting all devices in a daisy chain configuration, making wiring simpler than traditional multi-circuit control. Commissioning requires professionals, but daily operation is straightforward.

A: No. The DALI bus design features high robustness, isolating single-point failures. Additionally, the system precisely reports the specific address of the faulty device, facilitating rapid maintenance.

A: Yes. Two cost-effective approaches exist: 1) Replacing only the internal driver with a DALI dimming driver; 2) Implementing retrofits by zone or in phases. Professional engineers should evaluate specific solutions.

A: They combine hardware durability with intelligent management. Tri-proof lights withstand harsh environments, while DALI provides precise control and energy management, jointly ensuring long-term stable operation and minimal operating costs.

A: Focus on three core aspects: certification (preferably DALI-2), compatibility (matching existing systems), and adaptability (IP rating, operating temperature, etc., must suit actual environments).