If you work with commercial lighting long enough, you eventually ask yourself a simple question: Why do constant-voltage LED strips always look good on paper but rarely behave well in real projects?

The answer is familiar to anyone who has dealt with long-run installations: voltage drop, uneven brightness, unpredictable color shifts, and the endless trouble of maintaining non-standard components.

So the real question becomes—is there a smarter way to build a lighting system that stays stable, looks clean, and doesn’t need constant babysitting?

This is exactly where linear LED modules come in.

These aren’t just “another type of LED modules.” They’re built for professional spaces that expect more than simple illumination. Whether it’s an SMD module LED board, a compact LED light module, or a fully modular LED lighting setup, the idea is the same: deliver consistent light, simplify maintenance, and make long-term upgrades possible.

And here’s the part facility managers appreciate most: when a section fails, a replaceable LED module means you swap one small piece—not the entire fixture, not the entire run, and definitely not the whole ceiling.

Modular linear LED lighting gives you stable performance, neater lines, cleaner ceilings, and a system that won’t feel outdated the moment new technology comes along.

Linear LED Modules vs. Constant-Voltage Strips

When planning a linear lighting project, engineers and designers face a fundamental technical choice: use common constant-voltage LED strips or adopt professional linear LED module systems. The two approaches differ significantly in design philosophy, performance, and suitable applications.

Electrical Architecture: Constant Current vs Constant Voltage

Constant-voltage LED strips operate at a fixed DC voltage (usually 12V or 24V) and adjust brightness via series resistors or simple linear current chips. This design has an inherent limitation: voltage drop. Over long runs or high currents, the end voltage decreases, causing perceptible differences in brightness and color temperature. Multi-point power injection is often required to address this issue.

Linear LED modules, designed to work with constant-current drivers, deliver precise and uniform current to all LEDs regardless of module quantity. This eliminates distance-related brightness inconsistencies and ensures optical continuity from start to finish, forming the foundation for high-end commercial lighting and meticulous lighting designs.

Optical Quality & Visual Comfort

Constant-voltage LED strips are typically bare LEDs with simple silicone sleeves for protection and light diffusion. The wide, irregular beam angles can cause glare, point-source visibility, and harsh light quality.

Linear LED modules, as complete lighting devices, integrate secondary optics:

- Precise beam control: Batwing distribution for wall washing or narrow beams for accent lighting.

- Smooth light mixing: Eliminates the “pixelated” look of individual LEDs, creating a visually continuous surface.

- Glare management: Lenses direct light to desired areas, improving visual comfort.

Reliability, Heat Management & Long-Term Stability

Flexible PCBs in constant-voltage strips offer limited heat dissipation. Simplified driving can push LEDs to work in suboptimal conditions, causing accelerated lumen depreciation and color shift under long-term high temperatures.

Linear LED modules, usually built on metal-core PCBs (e.g., aluminum), provide superior thermal pathways. Combined with efficient constant-current drivers, junction temperature is kept lower, enhancing reliability and maintaining light output and color stability throughout rated life (e.g., L90B50), meeting strict requirements of commercial projects.

Installation & Maintenance: Engineering-Level Differences

Constant-voltage LED strips are mostly installed with adhesive backing, requiring on-site soldering or connector use. Their flexibility can make long runs hard to keep straight, and maintenance or segment replacement can be difficult.

Linear LED modules reflect an engineered approach:

- Standardized connections: Foolproof quick connectors for both mechanical and electrical connections.

- Rigid structure: Ensures straight, stable installation in pre-mounted profiles.

- Serviceability: Modular design supports front-end maintenance; faulty modules can be replaced individually without disassembling the system, reducing downtime and maintenance costs.

Scenario-Based Guidance

| Consideration | Recommended: Constant-Voltage LED Strips | Recommended: Linear LED Modules |

| Project Type | DIY, low-cost, decorative | Professional commercial, retail, office, public buildings |

| Core Requirements | Flexibility, low initial cost | Optical quality, brightness consistency, long-term reliability |

| Lighting Role | Accent, ambiance, indirect | Primary, accent, functional |

| Maintenance Expectation | Low or one-time use | Easy maintenance, modular replacement |

This comparison demonstrates that choosing between the two is not simply a product decision, but a strategic technical choice based on project goals, performance requirements, and total lifecycle cost.

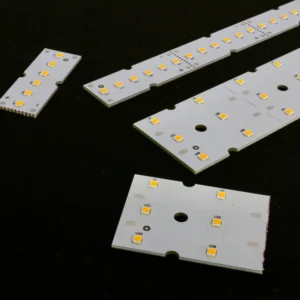

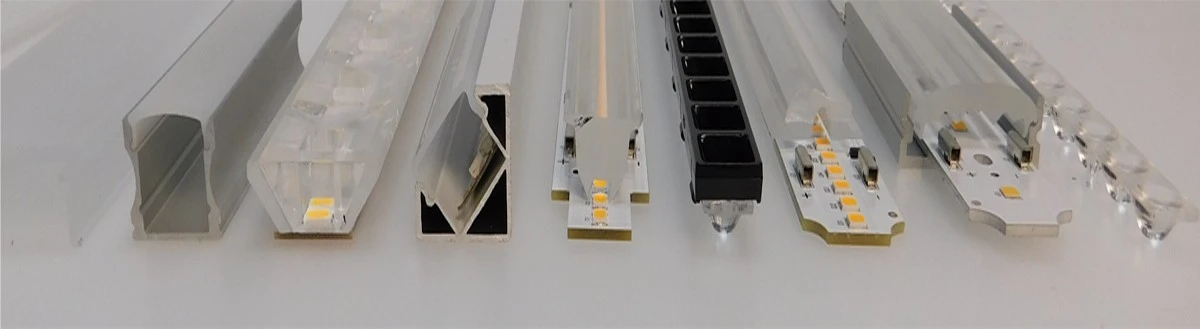

Product Categories: Understanding the Spectrum of Linear LED Modules

Linear LED modules are not a single product but a family of modular lighting solutions designed to meet diverse spatial, functional, and aesthetic requirements. Understanding their classification is essential for precise selection and project design. The main distinctions can be made across size and application, installation method, and optical design.

By Size, Power & Application

| Type | Typical Size/Power | Key Features & Applications |

| Standard Linear Module | Length: 280mm, 560mm, 1120mm, etc. | Most versatile base modules. Can be connected to form continuous light lines. Ideal for office general lighting, corridors, classrooms, supermarkets. Modular design allows easy LED module replacement and maintenance. |

| Power: 10W–30W+/m | ||

| Cabinet Lighting Module | Shorter lengths, lower power (4–12W) | Designed for furniture integration. Small size, low heat generation. Used in kitchen cabinets, wardrobes, bookshelves, or display cases. Provides both functional and accent lighting. |

| Compact size (<20mm width) | ||

| Display Shelf Module | Flexible lengths, medium power | Optimized for retail environments. Typically equipped with lenses for accent lighting to highlight products. Applied in supermarkets, jewelry/cosmetic displays, museums to attract attention and enhance product appeal. |

| High-Power / Industrial Module | High power density (up to 40W+/m) | Built for factories, gymnasiums, warehouses, and high-ceiling spaces. Provides high-brightness, long-range illumination. Often has higher protection ratings and advanced thermal management. |

Input Current: 275mA

Input Watt: 6.1W

Lumens: 1098-1241 lm

Luminous Efficacy: 183-205 lm/W

LED Types: SMD3030/SMD2835

LED Chip: Samsung/Osram/LUMILEDS/Bridgelux/Seoul

LED QTY: 24pcs

Color Temperature: 2700K/3000K/4000K/5000K/6500K

CRI: 80/90

Dimension: 279×23.6×1.6mm

PCB Material: Aluminum/FR-4

Warranty: 5 Years

Input Current: 275mA

Input Watt: 6.1W

Lumens: 1098-1241 lm

Luminous Efficacy: 183-205 lm/W

LED Types: SMD3030/SMD2835

LED Chip: Samsung/Osram/LUMILEDS/Bridgelux/Seoul

LED QTY: 24pcs

Color Temperature: 2700K/3000K/4000K/5000K/6500K

CRI: 80/90

Dimension: 279×23.6×1.6mm

PCB Material: Aluminum/FR-4

Warranty: 5 Years

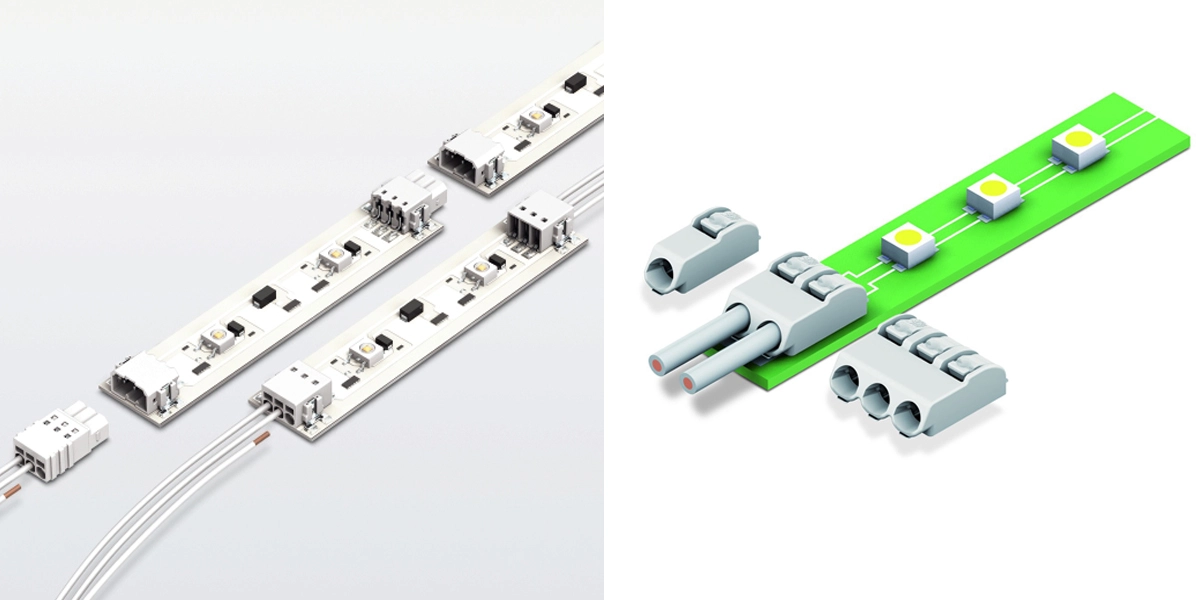

By Installation & Connection Method

Installation method affects construction efficiency, aesthetics, and maintenance convenience, which are critical for professional projects.

Magnetic attachment: Modules have embedded magnets, quickly attach to metal tracks or surfaces. Ideal for temporary displays or adjustable systems. Non-professional personnel can easily install and reposition LED module lights.

Snap-in clips: Secure modules into profiles with built-in clips. Ensures straight alignment and a clean look. Common for recessed lighting, fixed installations, or ceiling systems.

Sliding track: Modules slide along custom tracks and can be fixed after positioning. Provides flexibility for precise optical adjustments, suitable for galleries or high-end retail.

Solder-free Quick Connect: Using WAGO spring terminals or push-in connectors. Strip the wire and insert for safe, reliable electrical connection. Eliminates soldering, speeds up installation, ensures consistent connections, and reduces risk of failure. Widely used in modular LED light strips for professional projects.

By Optics & Light Distribution Design

Optical design directly determines light distribution, quality, and spatial perception. Different types of LED light modules allow designers to achieve precise visual effects:

Standard Diffuser: Milky or frosted PC cover for soft, wide-angle light (>120°). Provides uniform ambient lighting, suitable for offices or hospitals.

Lens Module: Clear PC/PMMA lens redistributes light precisely. Enables professional beam shaping and custom distribution curves.

Wall-Washer Module: Asymmetric lens directs light toward walls, enhances textures, and creates comfortable brightness gradients. Ideal for architectural or wall emphasis lighting.

Narrow Beam Module: Concentrated light (15°–30° or narrower) for accent, task, or product-focused lighting. Highlights objects and creates contrast.

Anti-Glare Grille: Honeycomb, micro-louver, or prism sheet reduces glare (UGR ≤19), improving visual comfort in offices, classrooms, and control rooms.

Lifecycle Analysis: The Long-Term Cost & Reliability Advantage

In professional lighting projects, decisions should be based on total cost of ownership (TCO) rather than the upfront purchase price. Compared with traditional constant-voltage strips or integrated fixtures, linear LED modules deliver significant long-term advantages—lower maintenance expenses, reduced downtime, higher energy efficiency, and a future-proof upgrade path. Many commercial users report 30–50% lower total lifecycle cost within a 3–5-year operation cycle.

Reduced Maintenance Cost & Operational Downtime

Traditional LED strips and integrated fixtures often require full replacement when a fault occurs. This results in high labor cost, excessive spare-parts inventory, and prolonged downtime—especially in retail chains, airports, or office buildings.

Why linear LED modules save 50–70% maintenance cost:

- Modular replacement – Only the faulty LED module is replaced, not the entire fixture

- Front-access servicing enables 2–5 minute repairs instead of 30–60 minutes

- Lower spare-parts inventory because standardized modules fit multiple fixtures

This dramatically reduces operational disruptions and allows facilities to maintain consistent lighting levels with minimal downtime.

Energy Efficiency & Stable Light Output

Energy efficiency influences both electricity cost and long-term performance.

How linear modules achieve 10–20% energy savings:

- Precision constant-current driving keeps each LED at optimal efficiency

- No brightness drop across long runs ensures uniform light from start to end

- DALI / 0–10V dimming compatibility allows flicker-free low-power operation

For users with long operating hours—such as supermarkets, hotels, and office towers—the accumulated energy savings are substantial.

Engineering for Longevity: Thermal & Structural Reliability

A rated lifespan such as L90B50 50,000 hours is achieved only through sound engineering and robust materials.

Why linear modules last 1.5–2× longer:

- Metal-core PCBs efficiently dissipate heat and lower LED junction temperature

- Industrial-grade LEDs, drivers, optics reduce long-term failure rates

- Predictive maintenance allows planned servicing instead of emergency repair

Lower junction temperature can extend LED lifespan by 100% (per Arrhenius law), providing truly stable long-term operation.

Long-Term Asset Value & Upgrade Path

Linear modules turn lighting systems from a consumable into an upgradeable asset.

Key long-term advantages:

- Upgrade-ready: adopt new LED efficiency or smart features without replacing fixtures

- Supports circular economy: removable parts greatly reduce waste

- Superior ROI within 3–5 years: lower bills, fewer repairs, less downtime

Lifecycle Cost Comparison Table

| Cost Category | Traditional Lighting | Linear LED Modules | Savings |

| Initial Cost | ⭐ Medium | ⭐⭐ Slightly Higher | — |

| Installation Labor | High | Medium | 20–40% ↓ |

| Maintenance Frequency | High (full fixture replacement) | Low (replace only failed module) | 50–70% ↓ |

| Maintenance Time (per incident) | 30–60 minutes | 2–5 minutes | 80%+ ↓ |

| Energy Consumption | Standard | Higher efficiency | 10–20% ↓ |

| System Downtime Cost | High | Very low | 80%+ ↓ |

| Spare Parts Inventory | Many SKUs required | Standardized, fewer SKUs | 60–90% ↓ |

| Expected Lifespan | 20,000–30,000 hours | 40,000–60,000 hours | 1.5–2× ↑ |

| Upgrade Cost | High | Low | 70–90% ↓ |

Long-Run Performance & Thermal Engineering

For commercial lighting projects requiring continuous, long-run installations—such as supermarket aisles, office corridors, and airport halls—LED linear module systems must deliver consistent performance and thermal reliability. Achieving this goes beyond simple driver selection; it relies on careful material engineering and thermal design.

Challenges in Long-Run Linear Lighting Systems

Long-run installations test both electrical stability and physical integrity.

Physical alignment: Flexible or insufficiently rigid modules may sag or bend due to their own weight or thermal expansion, compromising the straightness and visual consistency of the light line.

Thermal accumulation: A long strip acts as a continuous heat source. Poor heat dissipation leads to higher mid-strip temperatures, causing uneven brightness, color shift, and accelerated lumen depreciation.

PCB, Copper Weight & Circuit Design

The PCB acts as the “skeleton and circulatory system” of the module. Its quality determines both electrical stability and heat dissipation.

- Thick copper layers: Professional modules often use 1oz–2oz (35–70μm) copper instead of 0.5oz (18μm) in standard strips. This reduces resistance, lowers self-heating, and provides a stable path for high-current, long-run operation.

- Metal-core PCB (MCPCB): Aluminum substrates efficiently spread heat away from LED chips, preventing hotspots.

- Robust circuit layout: Precision wiring minimizes electrical noise, enhances anti-interference performance, and ensures stable operation even in complex power environments.

System-Level Thermal Engineering

Effective thermal management is a system-level design, combining materials, structure, and installation environment.

- Low thermal resistance path: Ensures heat flows efficiently from LED chips to the environment.

- High-performance thermal interface: Thermal pads or paste connect PCB to heat sinks.

- Integrated heat dissipation structures: Enclosures may include fins or increased surface area to release heat into the air.

- Environmental synergy: Aluminum channels or mounting rails act as additional heat sinks.

- Temperature monitoring & protection: Some advanced drivers use NTC sensors to reduce output current if temperatures rise, protecting LEDs until normal conditions return.

Performance Results: Lower Tj & Lower Light Decay

These engineering measures yield measurable, verifiable performance:

- Lower LED junction temperature (Tj): Professional modules maintain chip temperatures 15–30°C lower than standard products, potentially doubling lifespan for every 10°C reduction.

- Excellent lumen maintenance (Lp): High-grade modules easily achieve L90B50 (≥90% lumen retention after 50,000 hours), sometimes reaching L90B100.

- Suitable for harsh commercial use: This robust thermal reliability allows 24/7 operation in convenience stores, hospitals, data centers, high-temperature kitchens, or outdoor facades.

System Compatibility & Standardized Architecture: Building a Future-Ready Linear Lighting System

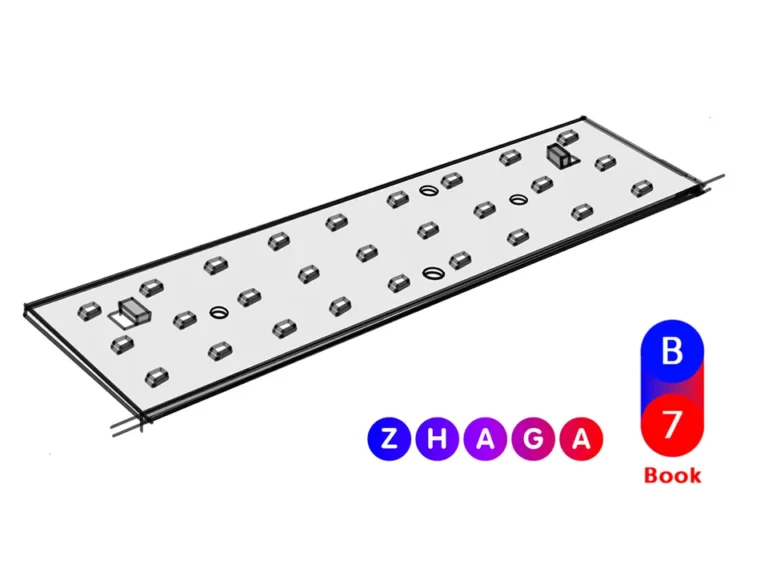

Mechanical & Electrical Standardization: The Value of Zhaga Interface

Choosing linear LED modules is not just about selecting a light source—it defines the system’s flexibility, maintainability, and upgrade potential over the next decade.

Standards such as Zhaga Book 7 (linear modules) and Book 18 (light engine interface) ensure that modules and fixtures from different brands can operate together seamlessly.

This standardized mechanical and electrical interface reduces SKU complexity, simplifies installation, and guarantees long-term consistency in thermal and structural performance.

With a Zhaga-ready modular system, facility owners avoid vendor lock-in, reduce spare-part inventory, and build lighting infrastructure that remains compatible with future generations of LED modules.

Digital Intelligence & Control: DALI-2 and D4i for Modern Smart Lighting

Digital control is now a core requirement in modern commercial lighting, and DALI-2 remains the most widely adopted universal protocol for stable, flicker-free dimming. It supports grouping, scene programming, daylight sensing, and occupancy-based automation, making large lighting systems more efficient and responsive.

D4i extends the DALI-2 ecosystem by adding local data storage and plug-and-play identification, enabling fixtures to act as smart, addressable nodes in an IoT-ready building network. Together, DALI-2 and D4i allow lighting systems to integrate sensors, collect diagnostic data, and maintain consistent control behavior across different brands and components.

Upgradeability & Future-Proofing: Long-Term Investment Protection

A modular and standards-based LED system ensures that upgrades can be performed without changing fixtures or rewiring. When next-generation LED linear modules achieve higher efficacy, improved color rendering, or enhanced optical performance, they can be installed directly onto the existing Zhaga infrastructure. Similarly, tunable-white, RGBW, or specialized optics can be adopted without altering the building’s ceiling layout. This protects the initial investment and significantly extends the useful life of lighting infrastructure in offices, retail stores, airports, and public buildings.

Sustainability & ESG Benefits: Designed for Low Waste and Circular Value

The modular nature of linear LED systems directly supports sustainability goals. Only the faulty LED module needs replacement, rather than the entire fixture—reducing electronic waste by more than 90% throughout the lifecycle. Zhaga-standard modules are easier to disassemble, categorize, and recycle, improving material recovery rates. This low-waste approach aligns with global environmental regulations and contributes positively to corporate ESG ratings and responsible building practices.

Industry Applications: From Functional Lighting to Spatial Experience

The true value of LED linear modules is realized through their performance across industries. Their modularity, high quality, and controllability make them the preferred tool in modern lighting design, meeting needs from basic illumination to mood creation.

Commercial Spaces & Malls

Core needs: Bright, open, high-end shopping environments; guide customer movement; highlight brand identity.

LED module solutions:

- Continuous, seamless lighting along corridors and atriums to create a modern, clean aesthetic.

- Highlight key areas: reception desks, brand walls, elevator lobbies.

- Dynamic lighting scenes via dimming/color control to match opening, operating, and closing hours while saving energy.

Advantages vs. traditional lighting: Linear light provides uniform, soft illumination, reduces shadows and glare, and enhances overall space quality.

Office Lighting

Core needs: Visual comfort, focus, productivity; meet wellness standards (e.g., WELL); efficient energy management.

LED module solutions:

- Low-UGR grille systems (<19) for glare-free office illumination.

- Human-centric lighting: simulate natural light rhythms via DALI for employee wellbeing.

- Task-specific illumination with sensors: “occupancy-based dimming” reduces energy in open-plan offices.

Advantages vs. traditional lighting: Modular design integrates with ceilings and HVAC systems, maintaining clean aesthetics and flexibility for future office reconfiguration.

Retail Display Lighting

Core needs: Highlight product color, texture, and shape; attract attention; increase conversion.

LED module solutions:

- High-CRI (>95) modules for accurate color rendering of textiles, jewelry, and fresh foods.

- Diverse optical options: narrow-beam modules for spotlighting key items; wall-wash modules for even shelf illumination; ultra-thin modules for cabinet interiors.

- Flexible integration: modules adapt to shelf layout changes.

Advantages vs. traditional spotlights: Provides even, shadow-free illumination, avoids overexposure, and emphasizes texture through light direction.

Architectural & Ambient Lighting

Core needs: Beyond functional lighting, express architectural language; shape space identity and nighttime image.

LED module solutions:

- Architectural outlines: hidden in eaves, handrails, baseboards to define lines and spatial layers.

- Dynamic media façades: RGBW or full-color modules with control systems for color changes and patterns.

- Immersive experiences: guide paths, create dramatic light-shadow effects in hotels, museums, and clubs.

Advantages vs. conventional solutions: Flexible, cuttable, seamless modules fit curves perfectly; IP65/67 ensures long-term outdoor reliability.

Summary Table: Industry Applications & Module Value

| Industry | Core Lighting Goals | Recommended Module Features | Value Created |

| Commercial | Continuity, ambience, guidance | High efficiency, uniformity, dim/color control, seamless | Enhance space quality & brand image |

| Office | Visual comfort, health, smart energy | Low-UGR optics, high CRI, DALI/D4i compatible | Boost employee efficiency, reduce operational costs |

| Retail | Product highlight, true color, attraction | Ultra-high CRI, narrow-beam/wall-wash, precise control | Enhance product appeal, drive sales |

| Architecture | Artistic expression, structure, emotion | High IP, flexible, RGBW, robust | Unique landmarks & immersive experience |

Why Choose SignliteLED

SignliteLED is a trusted partner for high-quality linear lighting modules, offering professional engineering, stable supply, and consistent performance for global B2B lighting projects.

- Reliable Performance: High-efficiency LEDs, low SDCM consistency, long lifetime, and strict QA ensure stable output across every batch.

- Modular System Expertise: We design modules that meet Zhaga, DALI-2, and D4i requirements, ensuring easy maintenance and long-term scalability.

- Strong Manufacturing Capability: Automated SMT lines, optical testing, and aging systems guarantee production accuracy and fast delivery.

- OEM/ODM Support: Customized sizes, optics, PCB layouts, connectors, and CCT options tailored to different brands and project needs.

- Better Lifecycle Cost: Durable components, replaceable modules, and low-failure-rate systems reduce long-term maintenance and operational costs.