Custom LED PCB Manufacturer

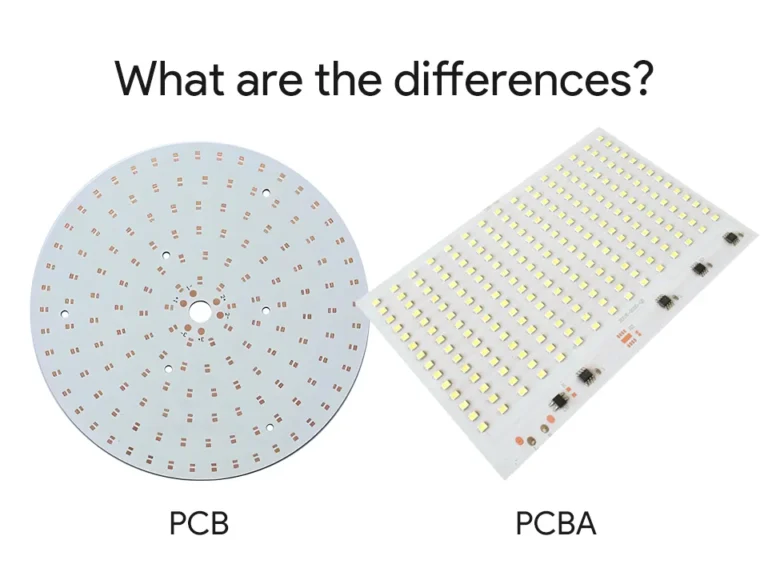

What Is a Custom LED PCB?

A custom LED PCB is a printed circuit board specifically designed for LED lighting applications based on exact electrical, thermal, mechanical, and optical requirements. Unlike standard off-the-shelf boards, custom LED PCBs are optimized for:

- LED power and current requirements

- Heat dissipation and thermal resistance control

- Mechanical size, shape, and mounting constraints

- Application-specific reliability standards

In professional lighting projects, standard PCBs often fail to meet thermal and durability demands. Custom LED PCB manufacturing allows full control over materials, copper thickness, dielectric layers, layout, and assembly processes—ensuring stable performance and long service life.

For projects such as street lighting, horticulture grow lights, automotive modules, and architectural lighting, customization is not optional—it is essential.

Custom LED PCB for Professional Lighting Applications

We design and manufacture custom LED PCBs for a wide range of professional lighting applications. Each solution is engineered around thermal performance, electrical reliability, and long-term operational stability to meet real-world project demands. Each application-specific LED PCB is engineered to meet both performance expectations and compliance requirements, ensuring reliable operation from prototype to mass production.

Outdoor & Street Lighting

Our high-power MCPCB solutions are widely used in street lights, floodlights, tunnel lighting, and industrial outdoor luminaires. These LED PCBs are designed to handle continuous operation, high ambient temperatures, and harsh environmental conditions.

By optimizing aluminum substrates, dielectric layers, and copper thickness, we ensure efficient heat dissipation and stable lumen output over long service lifetimes. Our custom LED PCBs help reduce LED junction temperature, extend product lifespan, and lower maintenance costs for large-scale outdoor lighting projects.

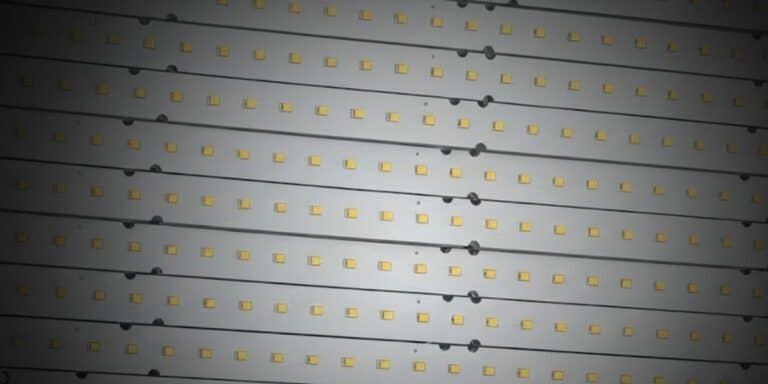

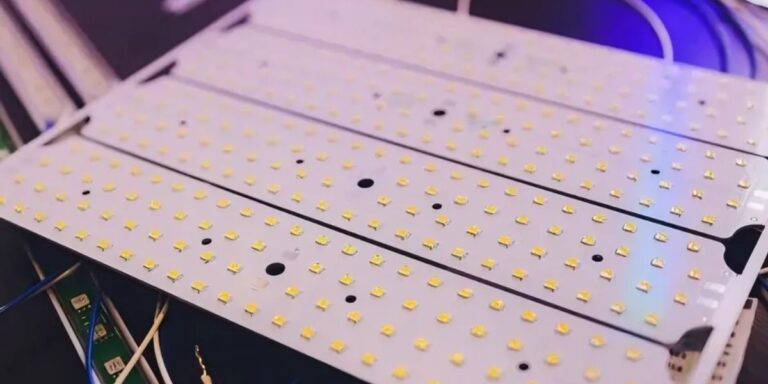

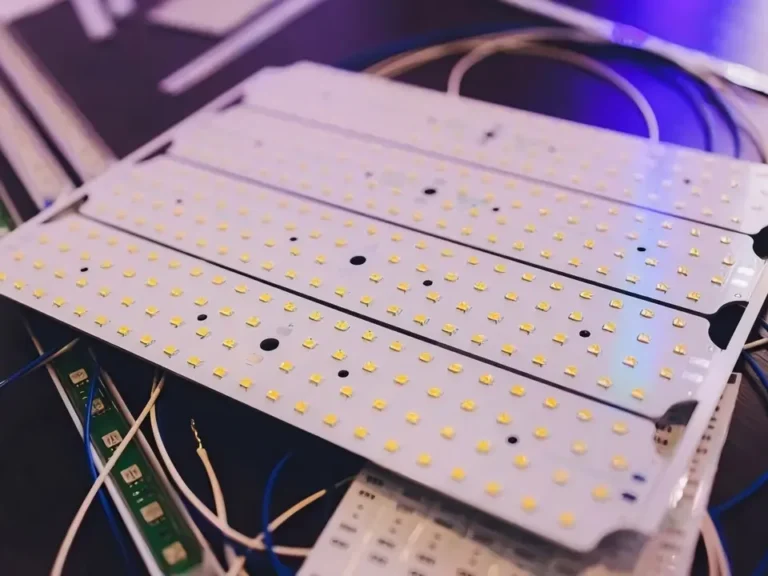

Horticulture & Grow Lighting

We provide custom LED PCB designs for horticulture and plant growth lighting systems, where spectrum accuracy and thermal control are critical. Our solutions support multi-channel layouts, customized LED wavelengths, and high-density LED configurations.

Through precise PCB layout and thermal optimization, we help growers and lighting manufacturers achieve consistent light output, improved energy efficiency, and reliable long-term operation in controlled agricultural environments.

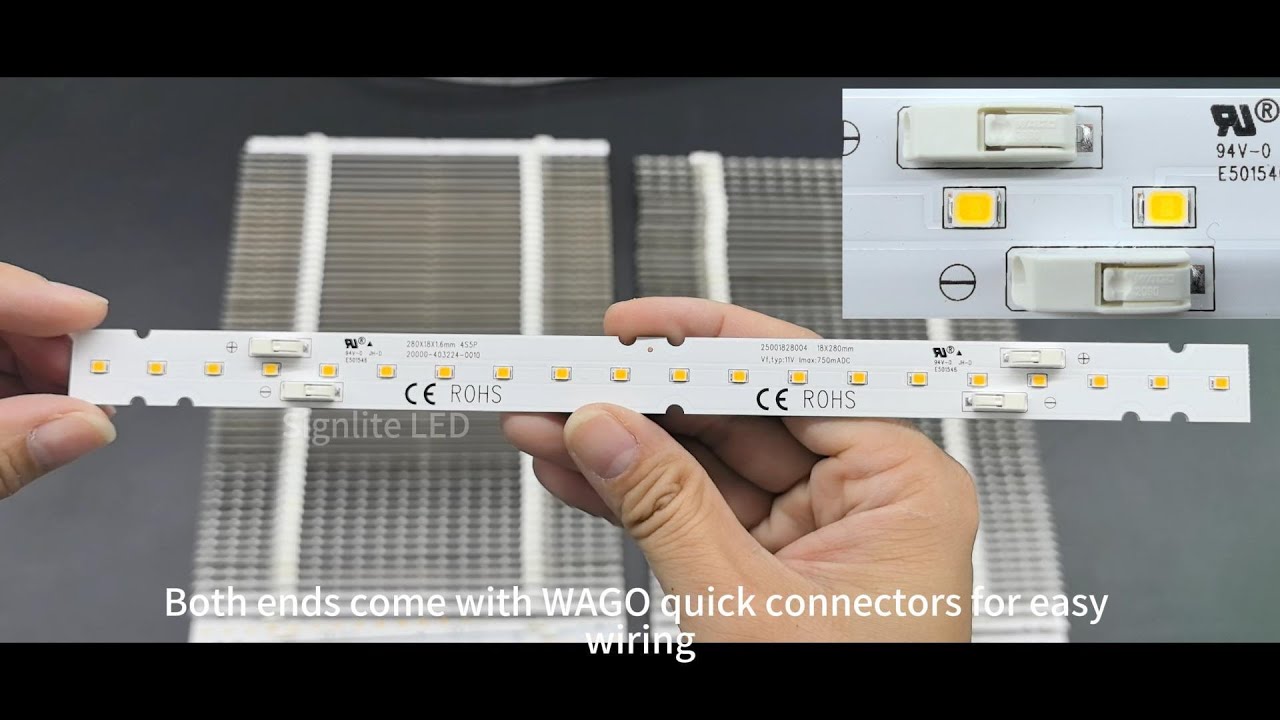

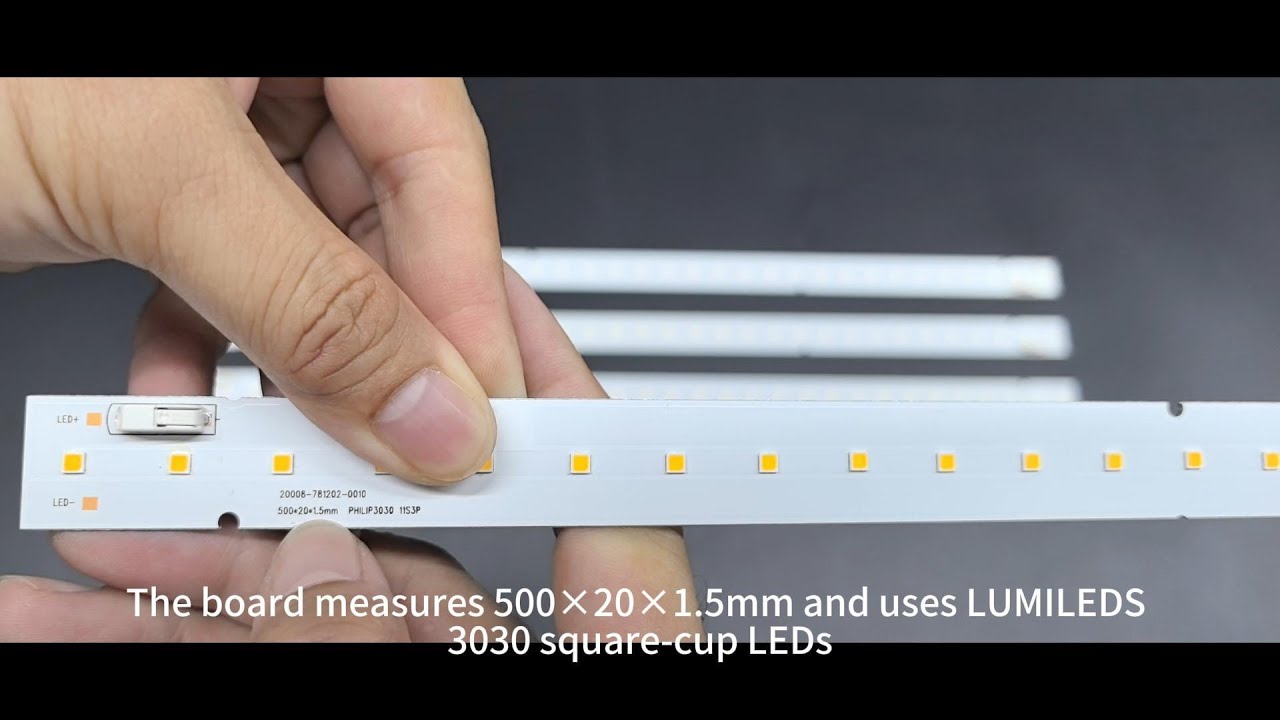

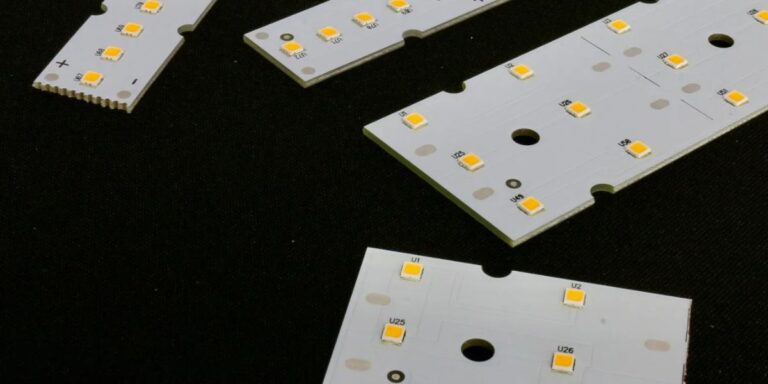

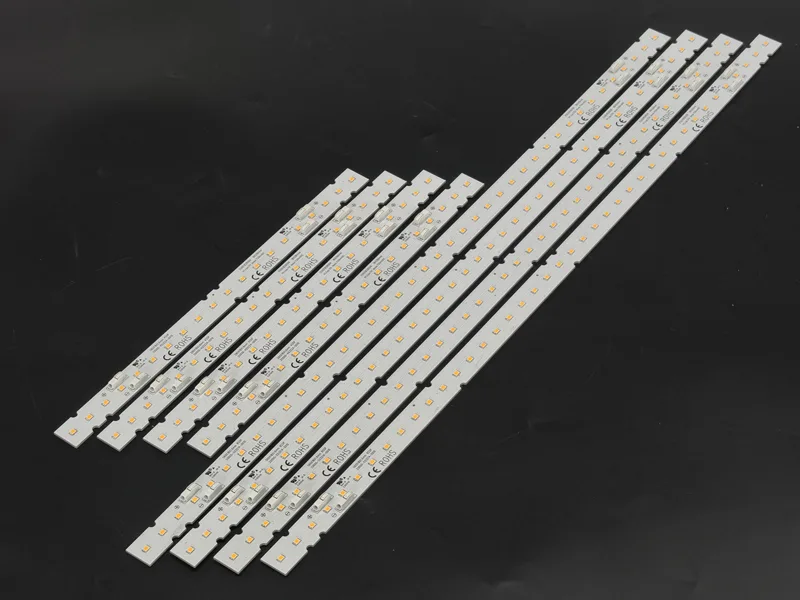

Architectural & Linear Lighting

For architectural and linear lighting applications, we develop slim and uniform LED PCB solutions that fit seamlessly into aluminum profiles and compact luminaires. Our designs focus on even light distribution, minimal thermal hotspots, and consistent color performance.

These custom LED PCBs are ideal for decorative lighting, façade illumination, and modern linear lighting systems where aesthetics, reliability, and thermal stability must work together.

Industrial & High-Bay Lighting

Our industrial and high-bay LED PCBs are engineered for warehouses, factories, logistics centers, and high-ceiling commercial facilities. These applications demand high power density, excellent thermal performance, and stable operation under long daily operating hours.

We design aluminum-based MCPCBs that provide strong mechanical support and efficient heat spreading, ensuring reliable performance for high-lumen industrial luminaires. Custom board sizes, mounting options, and power configurations are available to meet different fixture designs and installation requirements.

More Custom LED PCB Applications

Beyond the core lighting sectors above, we support a wide range of custom LED PCB applications across different industries and project requirements.

Start Your Custom LED PCB Project

Whether you already have design files or are still in the planning stage, you’re welcome to contact us.

Share your lighting application details, performance requirements, or reference designs. If available, you may upload drawings or Gerber files for review. Our engineering team supports custom LED PCB projects from concept to mass production.

*All project information will be kept confidential.

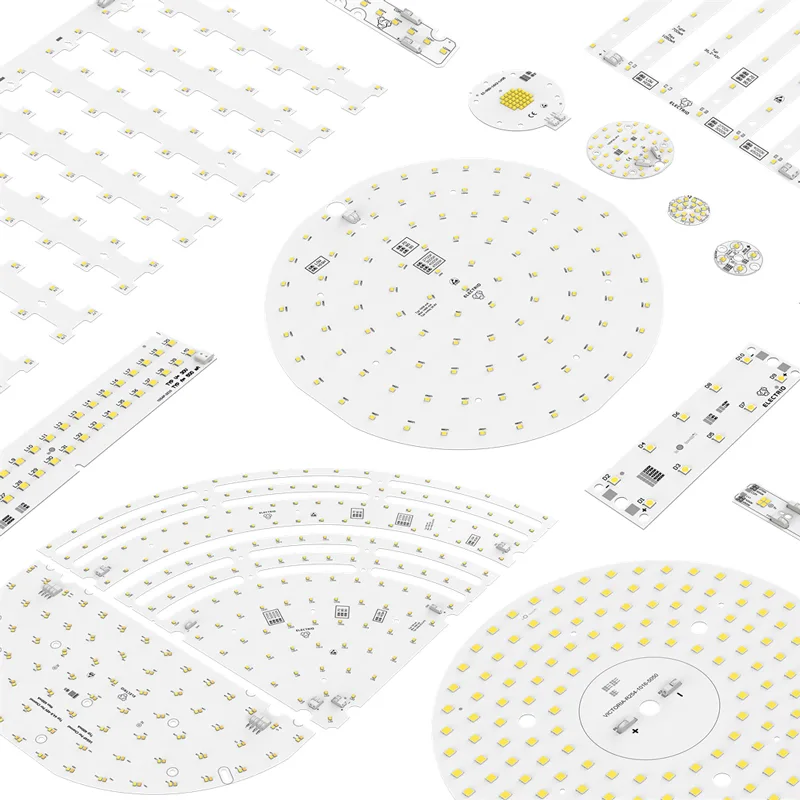

Custom LED PCB Solutions for Your Lighting Application

SignliteLED's Custom LED PCB Manufacturing Capabilities

As a one-stop full-service custom LED PCB manufacturer, we provide end-to-end solutions covering engineering support, material selection, precision manufacturing, and stable mass production. Our capabilities are built to support project-based customization, OEM/ODM cooperation, and long-term supply requirements for professional lighting applications.

Rather than offering one-size-fits-all products, we focus on application-driven LED PCB manufacturing, ensuring that every board meets specific electrical, thermal, mechanical, and reliability targets. Our processes are optimized for consistency and traceability, making us a trusted OEM LED PCB supplier for long-term cooperation.

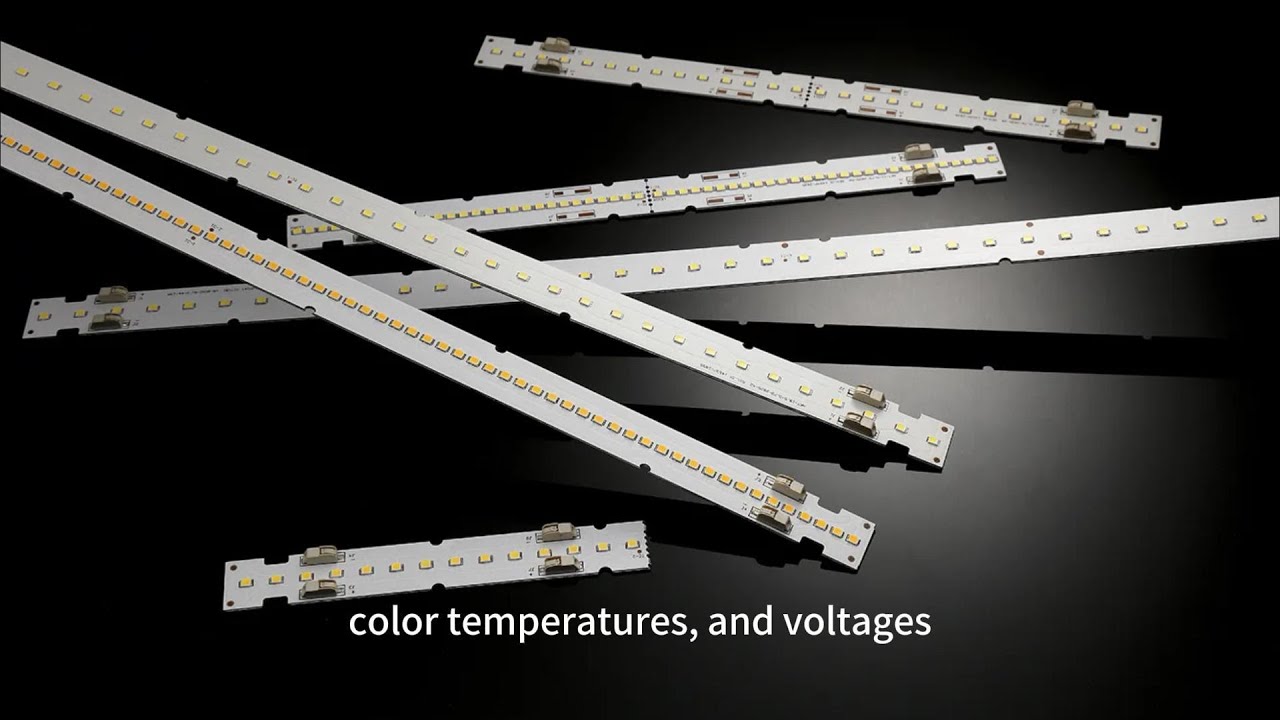

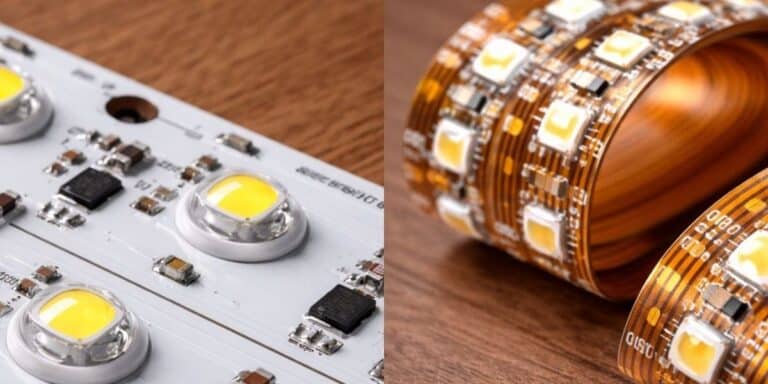

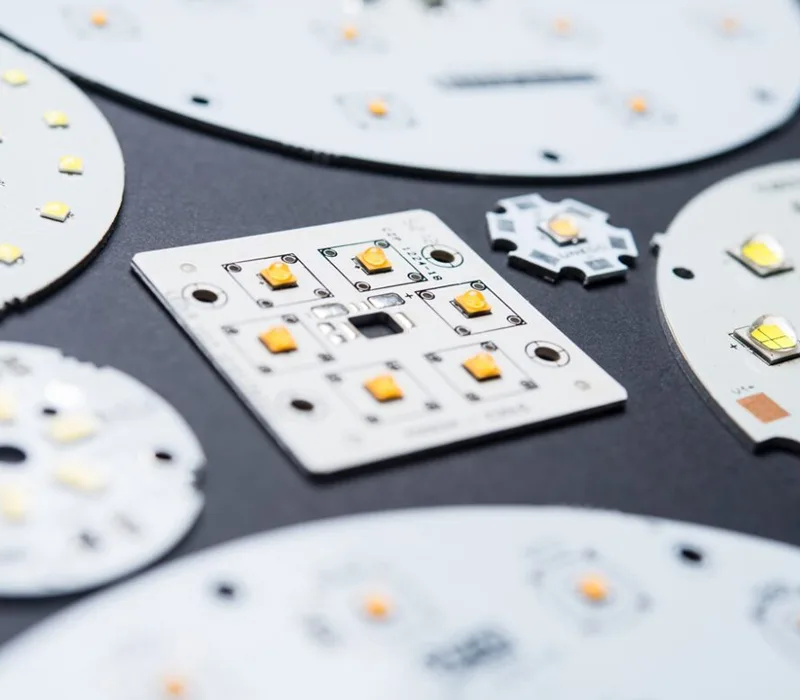

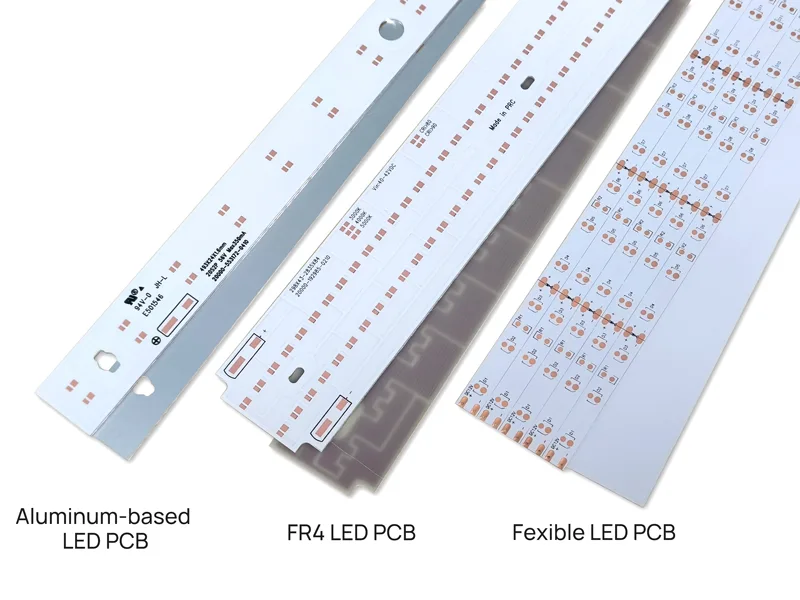

Custom LED PCB Types

We manufacture a wide range of custom LED PCB types to support different power levels, thermal demands, and installation environments:

- Aluminum-based LED PCB (MCPCB): Ideal for high-power and high-lumen lighting applications requiring efficient heat dissipation and mechanical stability.

- FR4 LED PCB (Low & Mid-Power Applications): Cost-effective solutions for lower power density lighting where thermal demands are moderate.

- RFlexible LED PCB: Custom form factors to meet space constraints, curved designs, or integrated lighting structures.

Materials & Technical Options

To support full customization, we offer extensive material and technical options, these options allow precise control over thermal resistance, current carrying capacity, and mechanical performance. Tailored to your project requirements:

- Single-layer and multi-layer LED PCB structures

- Customized board thickness and copper weight for thermal and electrical optimization

- High thermal conductivity dielectric materials

- White, black, or custom solder mask colors for optical and aesthetic requirements

- ENIG, HASL, and OSP surface finishes based on assembly and reliability needs

Manufacturing & Assembly Services

Through controlled processes and strict quality management, our manufacturing capabilities support reliable scaling and repeatable performance. Our manufacturing and assembly services are designed to ensure quality consistency from prototype to mass production:

- Precision PCB fabrication and surface treatment

- SMT LED assembly, including SMD and COB technologies

- Thermal interface optimization to improve heat transfer efficiency

- Electrical testing, functional testing, and aging tests

- Packaging solutions for bulk shipment and long-term supply stability

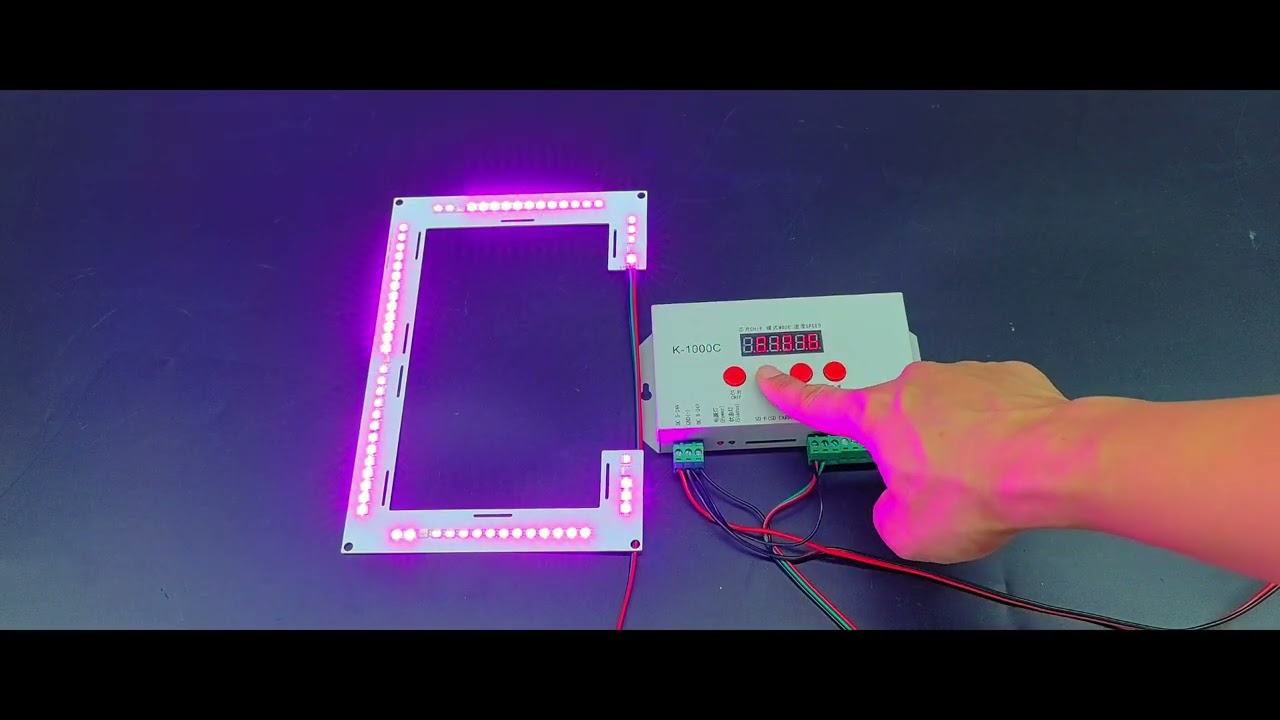

Custom LED PCB Project Video Gallery

Each video highlights a different custom LED PCB project, covering design challenges, material selection, thermal solutions, and final application results.

Playlist

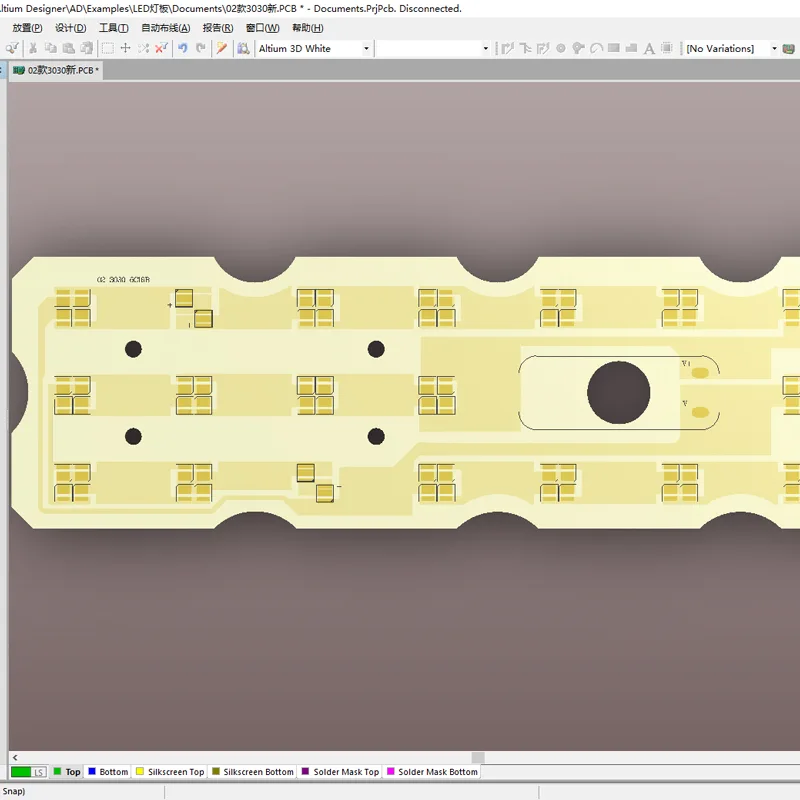

Our Custom LED PCB Development Process

We follow a structured development process to ensure efficiency, quality, and scalability:

- Requirement Analysis

Power, size, application environment, thermal targets, and budget evaluation. - PCB & Thermal Design

Layout optimization, material selection, and DFM review to reduce production risks. - Prototype & Testing

Sample fabrication, electrical testing, and thermal performance validation. - Mass Production

Stable volume manufacturing with strict quality control.

This process allows us to support both rapid prototyping and long-term mass production projects.

Why Choose SignliteLED as Your LED PCB Manufacturer

We specialize in custom LED PCB manufacturing for professional lighting applications, supporting projects from early concept to stable mass production. Our team provides practical engineering and thermal design support, helping customers develop reliable, application-specific LED PCB solutions. With controlled SMT assembly and factory-direct production, we ensure consistent quality, dependable delivery, and long-term manufacturing support.

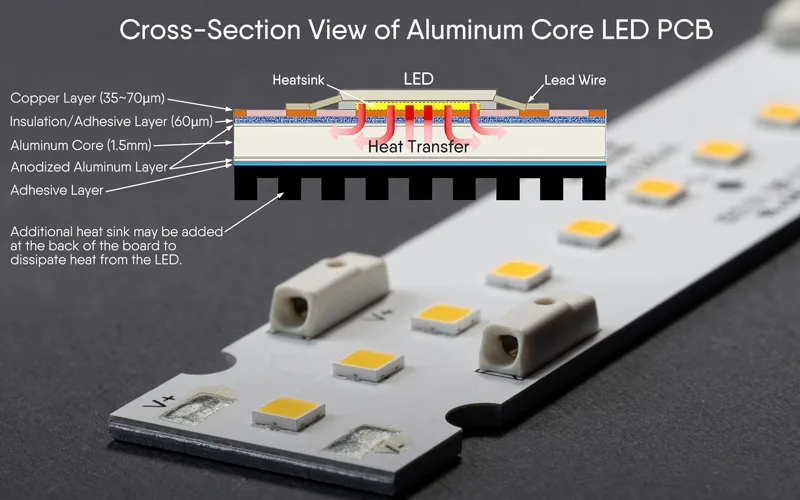

Why Thermal Management Is Critical in LED PCB Design

Heat is the primary factor affecting LED lifespan and performance. Poor thermal design leads to lumen depreciation, color shift, and early failure. As an experienced LED PCB manufacturer, we treat thermal management as the core of every design.

Key thermal considerations include:

- Substrate material selection(aluminum, copper, ceramic)

- Dielectric thickness and thermal conductivity

- Copper weight and heat spreading paths

- LED layout and spacing optimization

Our aluminum-based MCPCB solutions are widely used for high-power LED applications due to their excellent heat dissipation and mechanical stability.

Thermal management in LED PCB design often involves application-specific trade-offs and detailed engineering considerations. For a deeper look into materials, design strategies, and real-world applications, you may find the following articles helpful.

Custom LED PCB Manufacturing FAQ

Looking for answers about custom LED PCB manufacturing, MCPCB materials, or thermal design? Here are some of the most common questions from our customers.

Custom LED PCB manufacturers focus on thermal management, LED layout, and reliability, which are critical for LED performance and lifespan.

We specialize in LED-specific materials, thermal design, and process control to ensure consistent performance from prototype to mass production.

Yes. We support design review, PCB fabrication, SMT assembly, and quality control under one roof.

MCPCB (Metal Core PCB) improves heat dissipation, making it ideal for high-power and long-lifespan LED applications.

Yes. We manufacture aluminum-based MCPCBs with controlled dielectric thickness and thermal conductivity.

Yes. Our engineers recommend materials based on power density, thermal requirements, and application environment.

Thermal management directly affects LED lifespan, light output, and color stability, especially in high-power applications.

Yes. We provide professional thermal and layout optimization based on your LED power and usage conditions.

Yes. We specialize in high-power and high-density LED PCB manufacturing with proven thermal solutions.

Yes. We support both OEM and ODM cooperation for custom LED PCB projects worldwide.

Yes. We support prototypes, pilot runs, and low MOQ orders before mass production.

Lead time depends on complexity and quantity. Prototypes are usually completed within a short timeframe.

Gerber files, BOM, PCB specifications, and application details help us provide accurate quotations.

Yes. You can contact us with basic project information, and our engineers will assist you step by step.