Surge Protective Devices (SPDs) are classified as Type 1, Type 2, and Type 3 to reflect where they operate within an electrical system and how they manage surge energy at that location. These types are not interchangeable. Each is engineered for a specific surge environment and protection function, and they only perform correctly when applied as part of a coordinated system.

This article is a comparative technical guide. It does not reintroduce surge protection fundamentals. Instead, it focuses on how Type 1, Type 2, and Type 3 SPDs differ in role, capability, and system interaction, and how engineers determine correct placement in real electrical installations.

Comparison Framework: How SPD Types Are Differentiated

SPD classification is not based on product size, price, or perceived robustness. It is based on installation position and expected surge exposure.

As surge energy travels through an electrical system, its characteristics change:

- Surge current magnitude decreases

- Waveform shape evolves

- Residual voltage remains hazardous to sensitive equipment

Because of this behavior, surge protection is divided into zones. Each SPD type is designed to operate within a specific zone, where it can manage surge stress without being overstressed or underperforming.

The comparison between Type 1, Type 2, and Type 3 SPDs should always consider:

- Installation location

- Expected surge energy level

- Primary protection function

- Dependency on other SPD types

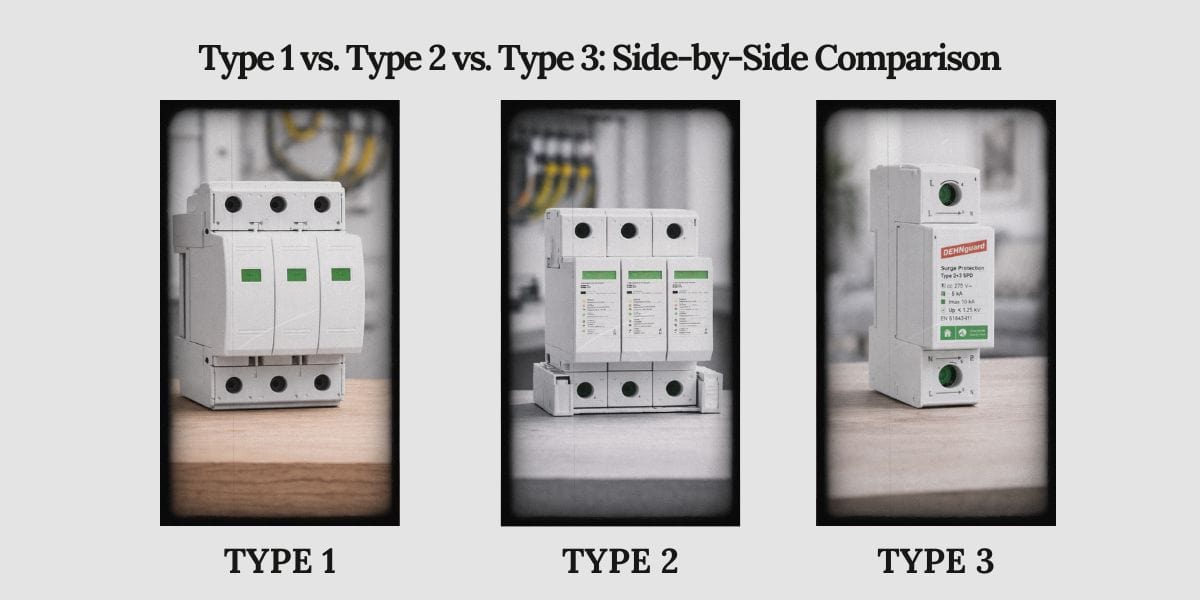

Type 1 vs. Type 2 vs. Type 3: Side-by-Side Comparison

| Parameter | Type 1 SPD | Type 2 SPD | Type 3 SPD |

| Typical installation location | Service entrance, line side of main disconnect | Distribution panels, load side of disconnect | Near sensitive equipment |

| Surge exposure level | Very high | Medium to high | Low |

| Primary function | Divert incoming surge current | Clamp residual and switching surges | Fine voltage limitation |

| Surge current handling | Very high | Moderate to high | Low |

| Voltage clamping precision | Low | Medium | High |

| Standalone suitability | No | Limited | No |

| Dependency on other SPDs | Requires Type 2 downstream | Often paired with Type 1 and Type 3 | Requires upstream Type 1 or Type 2 |

| Typical risk if misapplied | Inadequate equipment protection | Overstress and reduced lifespan | Catastrophic failure |

This comparison highlights a key principle: SPD types are defined by function and placement, not by performance ranking.

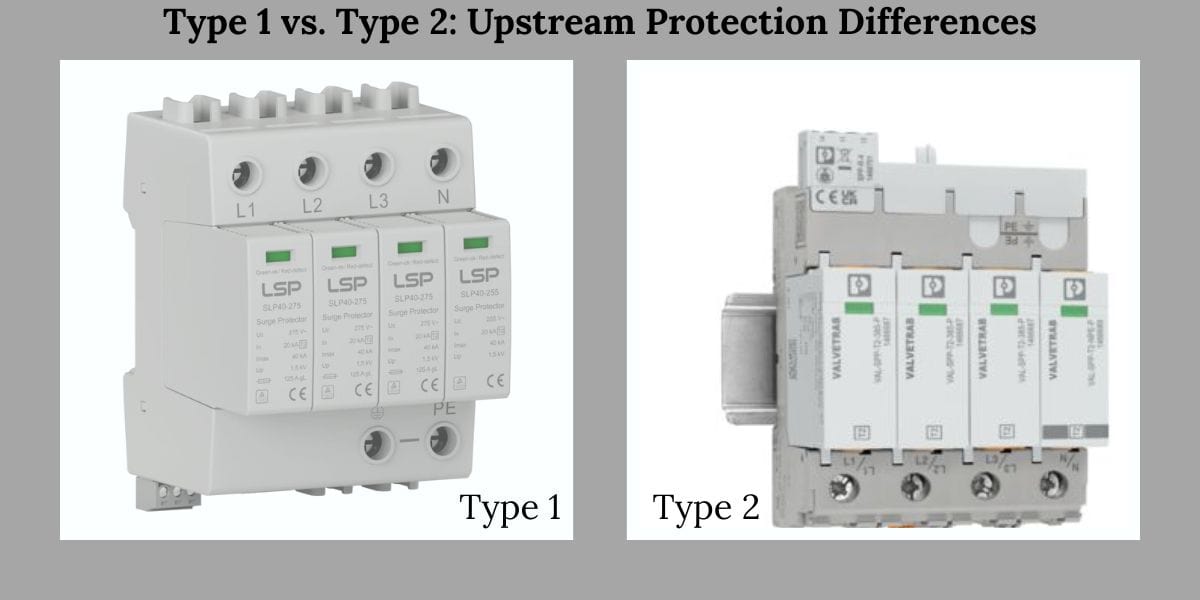

Type 1 vs. Type 2: Upstream Protection Differences

Installation context

Type 1 SPDs are installed at the service entrance, where external surge exposure is highest. Type 2 SPDs are installed downstream, within the internal distribution system.

This positional difference fundamentally changes what each device is expected to handle.

Surge energy profile

- Type 1 SPDs encounter high-energy impulses associated with lightning-related events entering from the utility network.

- Type 2 SPDs encounter residual lightning energy and frequent internally generated switching transients.

Because Type 2 devices are not designed for the highest energy impulses, they cannot replace Type 1 protection at the service entrance.

Functional distinction

- Type 1 focuses on surge current diversion

- Type 2 focuses on voltage limitation and repetitive surge control

Installing only Type 2 protection in high-exposure environments shifts excessive stress onto devices that are not designed for it, leading to premature degradation.

Type 2 vs. Type 3: Distribution vs. Equipment-Level Protection

Installation proximity

Type 2 SPDs protect distribution networks, while Type 3 SPDs protect individual equipment or circuits. The distance between the SPD and the protected load is a critical differentiator.

Residual voltage control

After upstream protection, residual transient voltage can still exceed the impulse withstand capability of sensitive electronics. Type 3 SPDs provide fine voltage refinement at the point of use.

Energy handling limitation

Type 3 SPDs are not designed to absorb surge energy. If exposed directly to high-energy events, they can fail rapidly. This is why they must never be used without upstream protection.

The comparison between Type 2 and Type 3 is not about which is “better,” but about where precision replaces energy handling.

Why No Single SPD Type Is Enough

Surge protection is not additive. Installing multiple devices of the same type does not provide layered protection.

Each SPD type operates optimally only within its intended stress range:

- Type 1 reduces incoming surge energy

- Type 2 manages remaining overvoltage

- Type 3 limits final residual voltage

Attempting to perform all these functions with a single device results in compromised protection, shortened service life, or both.

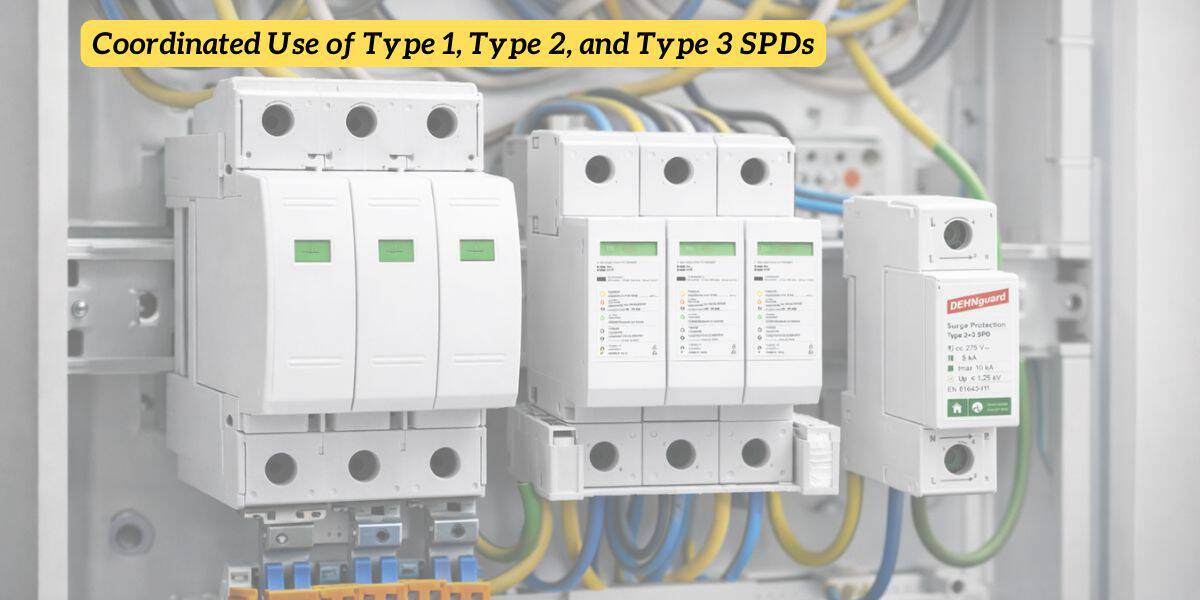

Coordinated Use of Type 1, Type 2, and Type 3 SPDs

How coordination works

A coordinated surge protection system mirrors the way surge energy propagates:

- Type 1 diverts high-energy impulses at system entry

- Type 2 clamps remaining surges within the distribution system

- Type 3 protects sensitive loads from residual voltage

Each stage reduces stress on the next.

Why coordination matters more than quantity

Improper coordination can cause:

- Uneven energy sharing

- Localized overheating

- Unpredictable failure behavior

Correct placement and impedance separation matter more than installing additional devices.

Application-Based Comparison Scenarios

Service entrance with external exposure

Facilities with overhead utility lines or outdoor electrical infrastructure require Type 1 protection at the service entrance, followed by Type 2 protection downstream.

Commercial and industrial distribution systems

Switching operations dominate surge activity. Type 2 SPDs provide the primary protection role, often coordinated with upstream Type 1 devices.

Sensitive electronic systems

Automation controllers, instrumentation, and communication interfaces require Type 3 protection, but only when upstream surge energy has already been reduced.

Single-phase vs. three-phase systems

A 3 phase surge protective device must manage phase-to-phase and phase-to-ground transients consistently. SPD type selection must align with system configuration, not just voltage rating.

Common Comparison Mistakes Engineers Make

- Assuming Type 3 devices can operate standalone

- Oversizing one SPD instead of coordinating multiple types

- Installing multiple Type 2 devices without considering impedance

- Treating SPD types as performance tiers rather than functional roles

These errors reduce protection effectiveness and increase maintenance risk.

Standards Context

Standards such as UL 1449 and IEC 61643 define test conditions and classification criteria for SPD types. They support consistent comparison, but they do not replace system-level engineering judgment regarding placement and coordination.

Conclusion

Type 1, Type 2, and Type 3 surge protective devices serve distinct and complementary roles within an electrical system. Their differences are defined by installation location, surge exposure, and protection function, not by product class or marketing position.

Effective surge protection depends on coordination, not oversizing or redundancy. When each SPD type is applied where it performs best, surge energy is progressively controlled, equipment stress is reduced, and long-term system reliability improves.

FAQs

No. Type 2 devices are not designed for the highest surge exposure levels present at system entry.

Only indirectly, and only when upstream protection has already reduced surge energy.

In low-exposure environments it may be acceptable, but risk increases significantly without upstream protection.

Because incorrect placement can overstress devices regardless of rating.

Not always, but most modern installations benefit from at least Type 1 and Type 2 coordination.