During operation, instantaneous high voltages (surges) in LED switching power supplies act like invisible “current assassins,” potentially arising suddenly from lightning strikes, grid switching, motor starts/stops, and similar operations.

Though these surges last only a fraction of a second (typically milliseconds to microseconds), their peak voltages can reach tens or even hundreds of times the normal voltage—sufficient to break down or burn out semiconductor components, causing irreversible damage.

Surge protection serves as the “lifeline” for LED lighting fixtures against grid instability and lightning strikes. Therefore, selecting an appropriate driver power supply is crucial. When necessary, surge protectors should be added to the fixtures.

This article provides a comprehensive analysis of surge protectors, covering technical principles, engineering applications, and installation techniques.

What Is a Surge Protective Device for LED Lights?

What is a surge protector? Simply put, a surge protector “discharges” sudden excessive voltages (surges) in a circuit, preventing damage to the lighting system. It acts like a “safety valve” in the circuit: when voltage exceeds limits, it rapidly conducts to divert current, then resets to its open state once voltage returns to normal, ensuring LED fixtures always operate within safe voltage ranges.

Surge protectors primarily address two typical “voltage surge” scenarios: lightning surges, requiring Type I and Type II SPDs, and switching surges generated by industrial equipment start-ups and shutdowns, necessitating voltage-limiting SPD protection. Both fundamentally intercept voltages exceeding a device’s tolerance range, providing comprehensive protection for electrical equipment.

In summary, surge protectors serve a dual purpose: preventing sudden high voltages from damaging equipment and mitigating frequent minor surges that accelerate aging, thereby providing comprehensive protection for LED lighting systems.

For more information on surge protection devices in LED lighting applications, read the blog: “Surge Protective Devices (SPD) for LED Lighting: Complete Guide for Indoor & Outdoor Applications.”

What types of surge protection devices are there?

Classified by operating principle:

a) Voltage-switching SPDs

High impedance during normal operation; abruptly shifts to low impedance during voltage surges, allowing high current flow. Also known as “short-circuit switch type SPD.” Typically employs discharge gaps, gas discharge tubes, thyristors, or silicon-controlled rectifiers as components. These surge protectors are also referred to as “Croba-type” due to their discontinuous voltage-current characteristics.

b) Voltage-Limiting SPD

Exhibits high impedance in the absence of surges. Impedance continuously decreases as surge current and voltage increase. Components typically include varistors and suppression diodes. Also known as “clamping-type” surge protectors. Characterized by continuous voltage-current characteristics.

C) Combined SPD

A surge protector combining voltage-switching and voltage-limiting components. Its characteristics may manifest as voltage-switching, voltage-limiting, or both, depending on the applied voltage profile.

Composite surge protectors can suppress surge voltages exceeding 6kV to below twice the system’s maximum operating voltage in a single operation. Three-phase units can suppress to 800V, while single-phase units can suppress to below 600V. In contrast, modular surge arresters require three levels of protection (Class B, C, and D) to achieve suppression around 1000V.

Classification by Application:

Based on application, SPDs can be categorized into two types: power line SPDs and signal line SPDs.

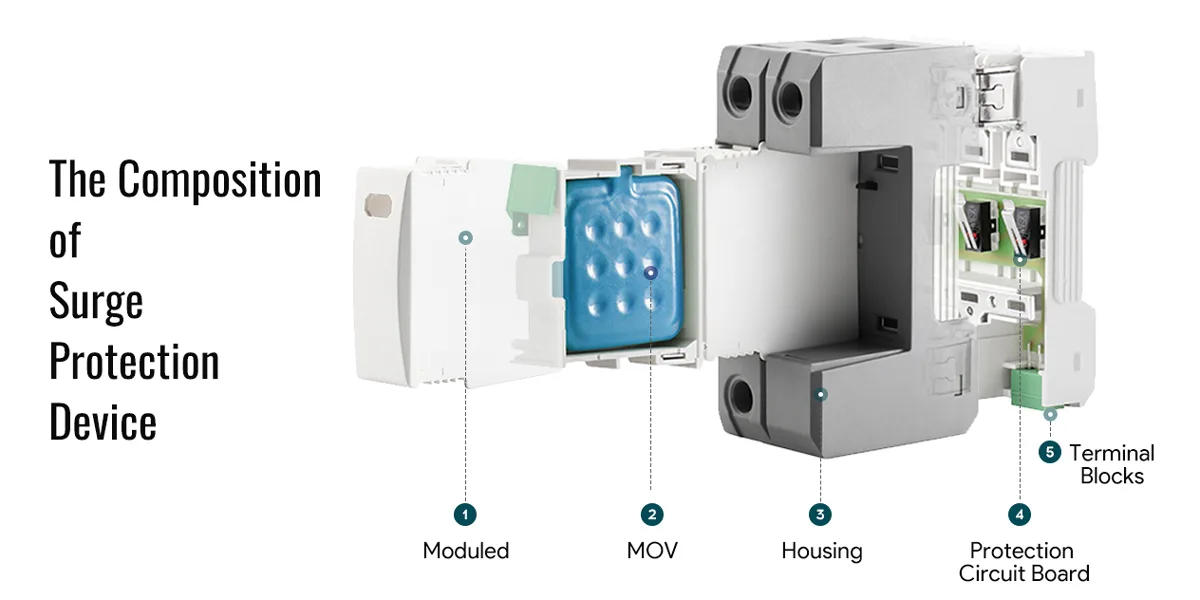

The Composition of the Surge Protection Device

The surge protector structure primarily consists of the following components:

- Metal Oxide Varistor (MOV): The core component of the surge protector, made from materials such as zinc oxide. When overvoltage occurs in the circuit, the MOV rapidly transitions to a conductive state, absorbing the overvoltage energy and diverting it to ground.

- Protection Circuit Board: Located inside the surge protector, it controls and monitors current and voltage changes. Typically composed of integrated circuits, it enables automatic switching and reset functions for the surge protector.

- Terminal Blocks: Connect the surge protector to the circuit, usually featuring two terminals—one for input power and another for output power.

- Housing: Protects the internal components of the surge protector, typically made of insulating material to prevent electric shock and other hazards.

Differences Between SPDs and Ordinary Fuses and Filter Circuits

Differences Between SPDs and Fuses

SPD: Specifically designed to dissipate transient surge currents (e.g., lightning strikes, grid switching). It channels high-voltage surges to ground via components like metal oxide varistors (MOV) or gas discharge tubes (GDT), safeguarding equipment from instantaneous high-voltage damage.

Fuses: Only address sustained overloads or short-circuit currents by interrupting the circuit through melting. They cannot handle nanosecond-level surges.

SPD response time ranges from nanoseconds to microseconds (e.g., nanoseconds for MOVs, microseconds for GDTs), whereas fuses require milliseconds to blow, failing to protect sensitive equipment in time. Degraded SPDs may leak current or short-circuit, necessitating use with fuses (not circuit breakers) to prevent follow-current hazards; blown fuses require replacement but pose no subsequent current issues.

Differences Between SPDs and Filter Circuits

SPD: Protects against transient high voltages (kV level), such as lightning strikes or power surges.

Filter circuits: Remove persistent high-frequency noise (kHz-MHz), such as electromagnetic interference in power supplies.

SPDs function by discharging or clamping voltage (e.g., MOVs conduct above 600V); filter circuits utilize inductors and capacitors to form low-pass networks, attenuating noise progressively. SPDs protect against lightning strikes and utility grid surges; filter circuits serve applications demanding high power purity, like medical equipment and communication systems.

Summary Comparison Table

| Feature | SPD | Fuse | Filter Circuit |

| Core Function | Discharge transient surges | Overload/short-circuit protection | Filter high-frequency noise |

| Response Time | Nanosecond–microsecond range | Millisecond range | Continuous operation |

| Typical Components | MOV, GDT, TVS2 | Metal fuse | Inductors, capacitors |

| Failure Risks | Potential leakage or short circuit | Requires replacement | Performance degradation |

As demonstrated by the above comparison, SPDs, fuses, and filter circuits each serve distinct roles within power systems. Their coordinated use is essential to achieve comprehensive protection.

Working Principle of Surge Protection Devices

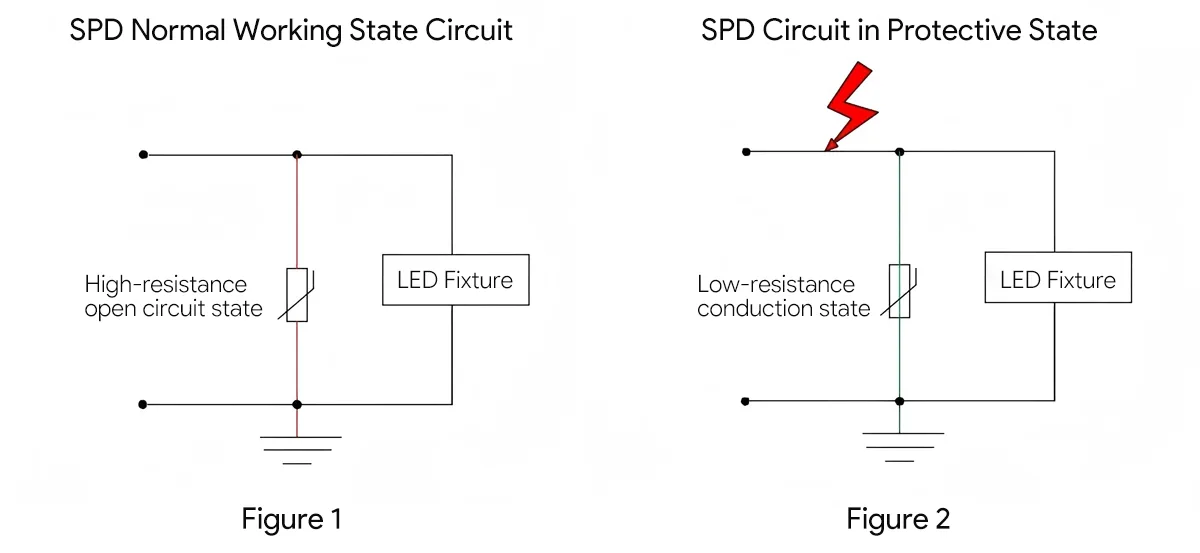

Under normal conditions, the surge protector presents an open-circuit state to ground in the circuit, meaning a high-resistance state. This high-resistance characteristic minimizes its impact on the circuit. It functions like a switch, remaining open when not needed to ensure normal circuit operation without interference. As shown in Figure 1 below.

When a transient high voltage occurs in the main circuit—such as during a lightning strike—the surge protector responds instantly. Under this transient overvoltage condition, the surge protector behaves as a low-resistance state. Its internal components (e.g., varistors, gas discharge tubes) rapidly transition from high-resistance to low-resistance states, forming a conductive path. It instantly diverts the surge current and limits the surge voltage to a safe level, thereby protecting the circuit and equipment from damage. As shown in Figure 2.

As shown in Figure 2, the surge protector plays a critical protective role during transient overvoltage events. It acts as a barrier, shielding the power supply and lighting fixtures from the impact of overvoltage.

Why Surge Protection Matters for LED Lighting Systems?

Surge protection is critical for LED lighting systems for the following primary reasons:

1. LED Sensitivity to Surges

As semiconductor devices, LEDs have forward voltages of only a few volts and exhibit extremely poor surge resistance, particularly weak reverse voltage tolerance. Transient overvoltages (reaching thousands of volts) from lightning strikes or grid switching can directly damage LED chips or drivers, causing immediate failure or latent damage.

2. Diverse Surge Sources

- Lightning Induction: Lightning current discharge causes sudden ground potential surges, entering luminaires via power/signal lines.

- Grid Operations: Switchgear, short-circuit faults, etc., generate transient overvoltages.

- Electrostatic Interference: Static electricity (>10kV) accumulated on metal casings may break down driver circuits.

3. Consequences of Surge Damage

Surge events not only accelerate LED light source aging (reduced luminous efficacy) but may also trigger cascading failures: A single LED short-circuit transfers its voltage drop to adjacent LEDs, accelerating the burnout of entire lamp strings. High maintenance costs for outdoor lighting systems mean inadequate protection significantly increases upkeep expenses.

In one city, 30% of main road lighting drivers failed after a thunderstorm season due to lack of surge protection, incurring over 500,000 yuan in repairs. Inspection revealed that multiple surge impacts had aged and degraded the metal oxide varistors (MOVs), allowing subsequent lightning strikes to directly damage the LED modules.

Surge protection is a critical measure for ensuring the longevity and reliability of LED lighting fixtures, particularly indispensable in high-risk environments like outdoor and industrial settings. LED fixtures equipped with surge protection exhibit enhanced reliability. Installing SPDs compliant with testing standards such as IEC 61000-4-5 substantially reduces maintenance costs, making it vital for LED lighting systems.

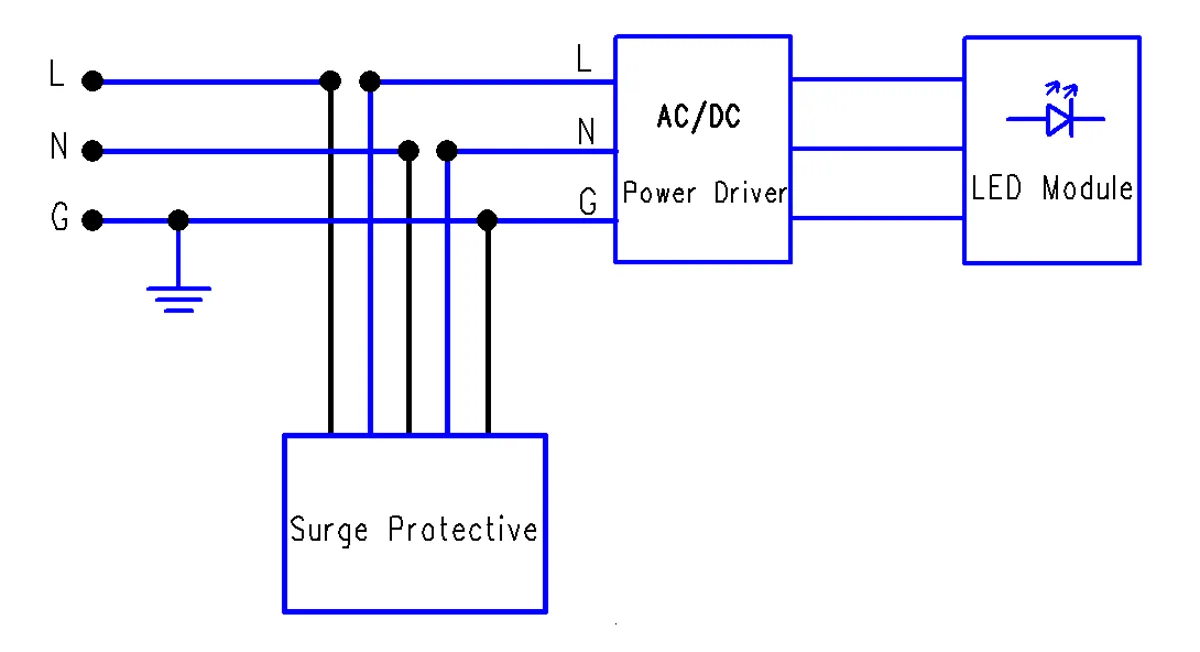

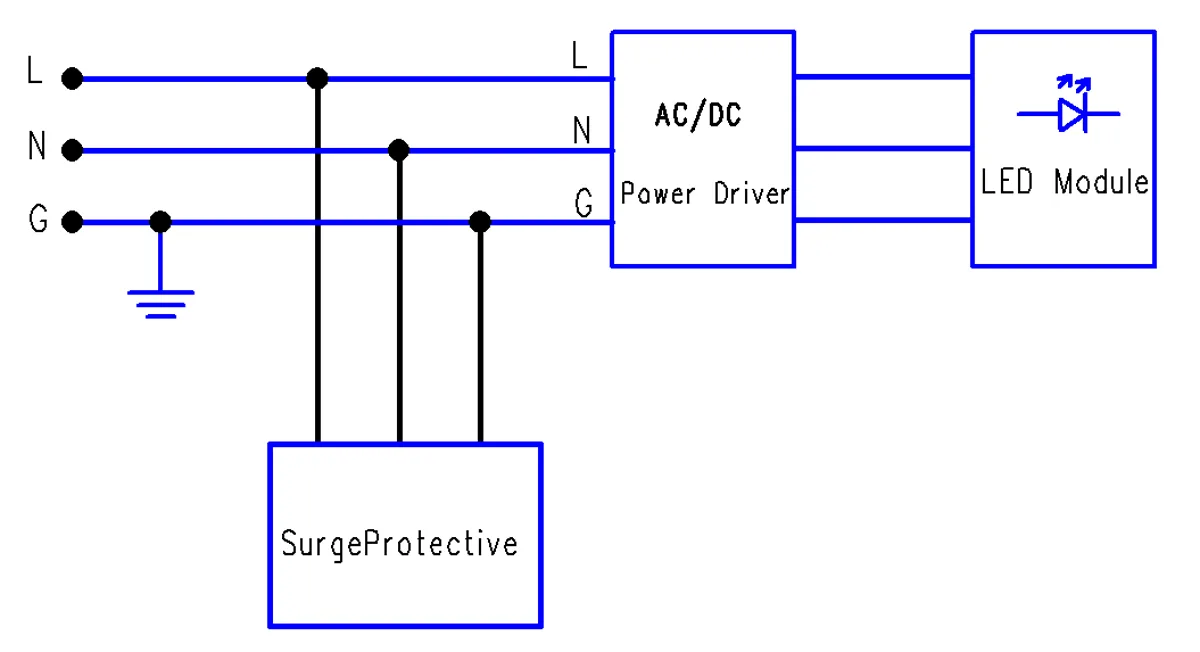

Connection Methods for Surge Protectors in LED Fixtures

The most common approach for connecting surge protectors to LED fixtures involves installing them in series or parallel at the input or output terminals. Based on different installation locations and methods, these can be categorized as follows:

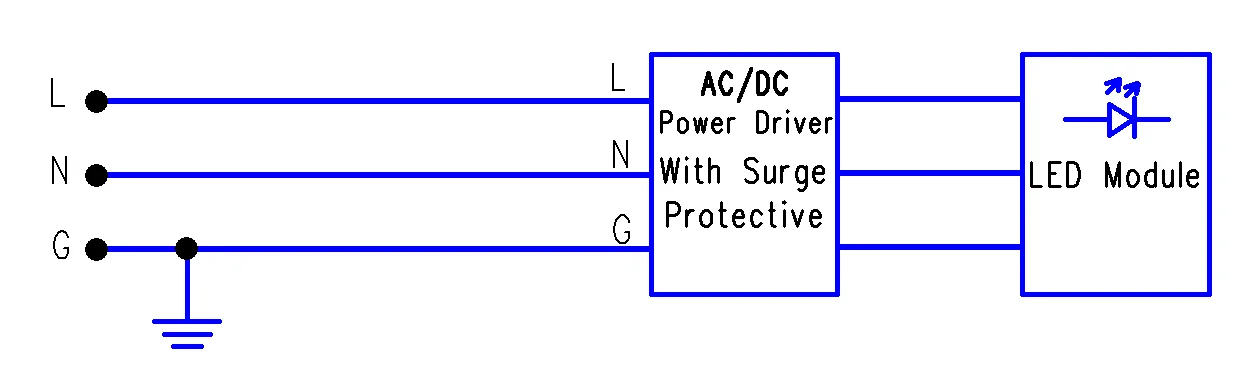

1. Surge Protectors Integrated into Drivers

Built-in surge protectors mitigate the impact of transient overvoltages caused by lightning strikes, switching operations, or electrostatic discharge on the system. They maintain power supply stability and ensure continuous operation of the lighting system. By rapidly responding to and suppressing transient overvoltages, surge protectors reduce damage to LED driver modules and light-emitting modules caused by abnormal voltages, thereby extending the overall lifespan of the equipment.

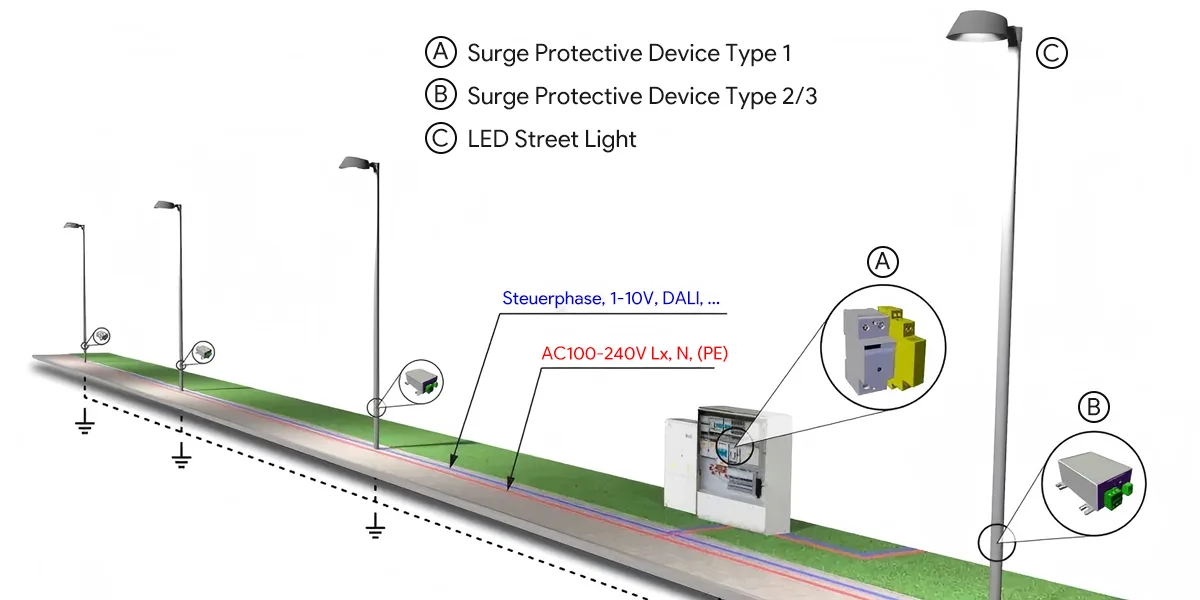

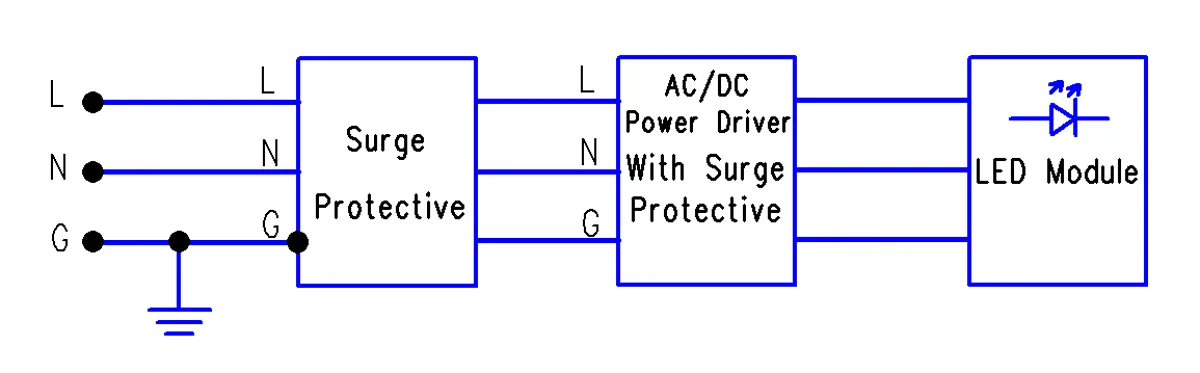

2. Surge Protector Installed at Driver Front End

This approach is primarily suited for areas with frequent lightning strikes and high environmental humidity. Installing a surge protector at the front end of streetlights, for example, provides enhanced protection against electrical damage from lightning strikes and electromagnetic interference, serving as a dual safeguard. It also facilitates easier maintenance later on. However, it is essential to ensure that the newly added SPD is compatible and matched with the existing system’s grounding method.

3. Series Connection at Input

Connect the surge protector in series with the input of the LED driver power supply. When a surge occurs at the input, the surge protector interrupts the current flow, thereby protecting the LED lamp.

4. Parallel Connection at Input

Connect the surge protector in parallel with the input of the LED driver. When a surge occurs at the input, the surge protector conducts the current, diverting excess current away.

Different surge protector types have distinct advantages and disadvantages, requiring selection based on specific conditions.

Generally, series surge protectors offer fast response times, strong protection, and minimal impact on normal operation, but present drawbacks such as complex installation, space requirements, and susceptibility to damage.

Parallel surge protectors feature simple installation, a compact footprint, and ease of replacement, yet suffer from slower response times, weaker protection, and potential interference with normal operation.

What type of SPD is used in LED lighting?

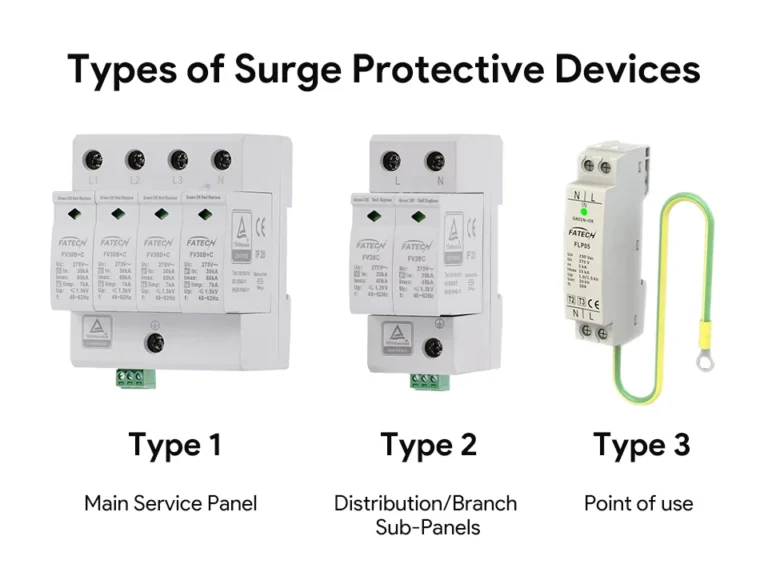

Surge protection devices (SPDs) are primarily classified based on their protection capability, installation location, and waveform tolerance characteristics. International standards typically categorize them into three types, as follows:

Type 1 SPD

Designed for direct lightning strikes or high-energy surges, installed at the main distribution panel or power entry point of a building. Features a higher voltage protection level (Up) ranging from 1.5kV to 4kV, with a nominal discharge current (In) typically between 12.5kA and 200kA.

Typical Applications: High-risk locations prone to direct lightning strikes, such as industrial plants and communication base stations.

Model.No.: FV30B+C/4-275S

SPD protection conforms to IEC 61643-11/EN 61643-11: Type1+2

SPD installation type conforms to IEC 61643-11/EN 61643-11: Class I+Il

Protection level conforms to DIN VDE0675-6: B+C

Type of Network: TT, TN

Protection mode: L1, L2, L3, N-PE

Nominal Voltage Un: 220/380 Vac/50(60)Hz

Maximum continuous operating voltage Uc: 275 Vac/50(60)Hz

Maximum discharge current (8/20μs) Imax: 60 kA

Nominal discharge current (8/20μs) In: 30 kA

Continuous operating current Ic: <20 μA

Standby power consumption Pc: ≤25 mVA

Voltage protection level Up: ≤1.5 kV

Response time ta: ≤25 ns

Mounting type: 35mm DIN rail acc.to EN 60715

Degree of protection: IP20

Housing material: UL94V-0

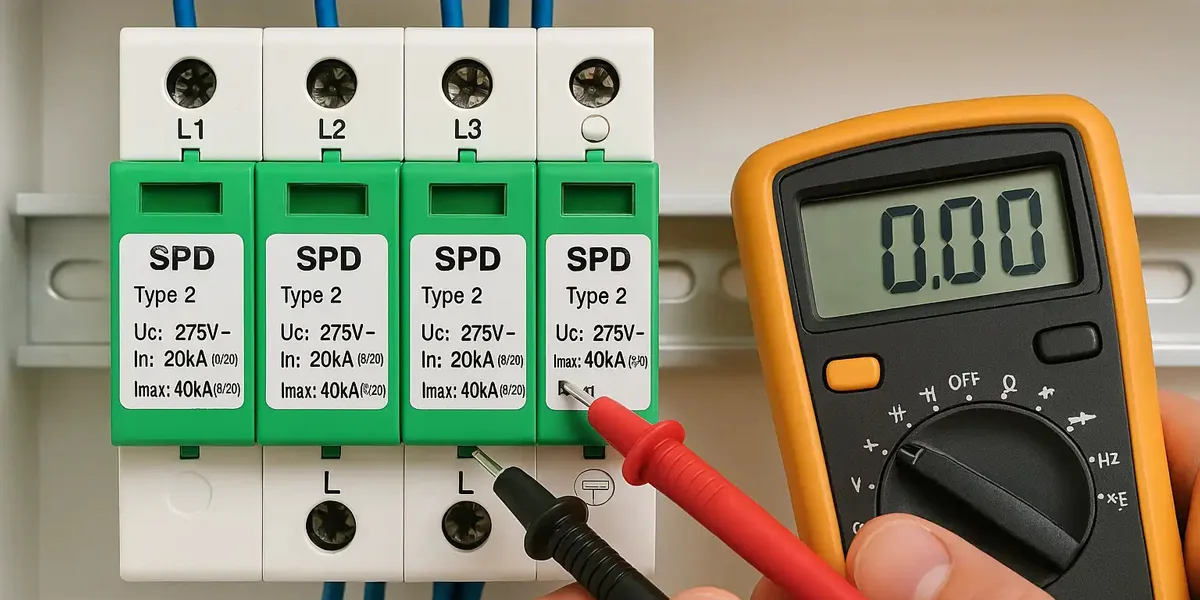

Type 2 SPD

Suitable for indirect lightning strikes or power grid disturbances, installed in distribution panels or floor-level distribution cabinets. In is generally 5kA to 20kA, and Up is typically 1.5kV to 2.5kV.

Typical Applications: Outdoor and commercial LED lighting applications and LED signage and traffic light manufacturers, including road lighting, parking lot lighting, wall-washing lighting, traffic lighting, flood lighting, digital signage, street flash lighting, and tunnel lighting.

Model.No.: FV20C/2-275S

SPD protection conforms to IEC 61643-11/EN 61643-11: Type 2

SPD installation type conforms to IEC 61643-11/EN 61643-11: Class Il

Protection level conforms to DIN VDE0675-6: C

Type of Network: TT, TN

Protection mode: L→PE, N→PE

Nominal Voltage Un: 230 Vac/50(60)Hz

Maximum continuous operating voltage Uc: 275 Vac/50(60)Hz

Short-circuit withstand capability Isccr: 20 kA

Maximum discharge current (8/20μs) Imax: 40 kA

Nominal discharge current (8/20μs) In: 20 kA

Continuous operating current Ic: <20 μA

Standby power consumption Pc: ≤25 mVA

Voltage protection level Up: ≤1.3 kV

Response time ta: ≤25 ns

Mounting type: 35mm DIN rail acc.to EN 60715

Degree of protection: IP20

Housing material: UL94V-0

Type 3 SPF

Suitable for end-device protection, installed at the front end of equipment or outlets. Typically in ≤10kA. Provides fine protection (up to ≤1 kV) with faster response times (nanosecond level).

Typical Applications: Often integrated into LED drivers for local voltage protection.

Model.No.: FLP05-275i-D

SPD protection conforms to EN 61643-11: Type 2+3

SPD installation type conforms to EN 61643-11: Class Il+III

Protection level conforms to DIN VDE0675-6: C+D

Type of Network: LED light

Protection mode: L-N, N-PE, L-PE

Nominal Voltage Un: 230 Vac/50(60)Hz

Maximum continuous operating voltage Uc: 275 Vac/50(60)Hz

Maximum discharge current (8/20μs) Imax: 15 kA

Nominal discharge current (8/20μs) In: 5 kA

Voltage protection level Up: ≤1.5 kV

Response time ta: ≤25 ns(L-N)

Mounting type: 35mm DIN rail acc.to EN 60715

Degree of protection: IP20

Housing material: UL94V-0

General main distribution panels use Type 1 or Type 2 devices; distribution boxes may use Type 2 and Type 3 devices, with Type 2 and Type 3 also suitable for back-end applications.

For AC supply lines entering buildings, install Type 1 or Type 2 surge protectors as primary protection at the boundary between LPZ0A/LPZOB and LPZ1 zones (e.g., at the main distribution panel).

At the boundaries of subsequent protection zones, such as distribution panels in power distribution lines or electronic equipment rooms, Type 2 surge protectors may be installed as secondary protection. For devices like LED lighting fixtures, Type 2 or Type 3 surge protectors may be installed before the power supply port.

How to choose a surge protector correctly?

In electrical applications, selecting a surge protector is a highly complex issue involving factors such as system grounding configuration, exposure level, lightning protection zones, cable length, inter-level protection, short-circuit current magnitude at protection points, and the number of shunt circuits.

Numerous manufacturers produce surge protectors in the market. Therefore, when selecting surge protection devices, special attention should be paid to the following points:

1. Determine the Uc Value

The selection of the surge protector’s maximum continuous operating voltage (Uc) requires comprehensive consideration of system voltage, equipment withstand voltage, and standard specifications. The minimum Uc value should be 1.15 times the rated voltage.

For example, in a 220V phase voltage system, Uc = 1.15 × 220V = 253V. Since AC grid peak voltages can reach 1.1 times the RMS value (253V × 1.414 = 357V; approx. 350V peak for a 220V system), Uc must exceed this value. However, in practical applications, to avoid frequent activation, selecting a higher value such as 385V is recommended. Simultaneously, the varistor’s activation voltage (U1mA) should match the grid fluctuation range.

2. Selecting Protection Levels

Class I SPDs (e.g., Iimp ≥ 100kA) are used for main distribution, while Class II SPDs (In ≥ 40kA) are used for distribution panels, forming multi-level protection. SPD installation dimensions and types must meet on-site requirements. Selection guidelines are shown below:

| Protection Level | Installation Location | Application Scenario | Key Parameters |

| Type 1 | Main distribution panel | Direct lightning strike protection | ≥100kA(10/350μs) |

| Type 2 | Distribution box | Induced lightning/Operating surge | 40kA(8/20μs) |

| Type 3 | LED driver front end | Precision equipment terminal protection | Up to ≤1.5 kV |

3. Installation Method

Select an SPD that is correctly positioned and easy to install based on the luminaire’s location. Since SPDs are typically concealed in hard-to-reach areas, such as in front of luminaires, they can additionally disconnect the luminaire from the circuit in case of failure, facilitating future replacement and maintenance.

4. Environmental Adaptation

For outdoor lighting, select SPDs with an IP rating of IP54 or higher. In humid or dusty conditions, use SPDs with a higher IP rating of IP67.

5. Grounding Specifications

SPD must be grounded via a dedicated PE terminal, avoiding shared ground paths with outgoing conductors. Ground continuity resistance test ≤0.1Ω.

6. Multi-Level Protection

Beyond safeguarding 230V power supplies, consider protecting control units such as DALI, second (control) phase, 1-10V, or DMX. Combined AC and control SPDs are ideal for these fixtures, typically offering better coordinated protection than two separate SPDs.

7. Certification and Safety

Select SPDs with reliable certifications like TUV or UL, tested to meet IEC 61643-11 and VDE 0100-534 requirements.

Conclusion

Surge protection devices serve as the core barrier for outdoor lighting systems against lightning strikes and grid surges. Through the synergistic action of varistors and gas discharge tubes, they divert high-voltage surges to ground within microseconds while clamping voltages to safe equipment thresholds.

Without adequate protection, LED fixtures and their drivers face risks of irreversible damage, reduced efficiency, and potential complete failure. Surge protection devices significantly enhance the reliability of LED streetlights in harsh grid environments, making them indispensable protective components for smart city lighting systems.