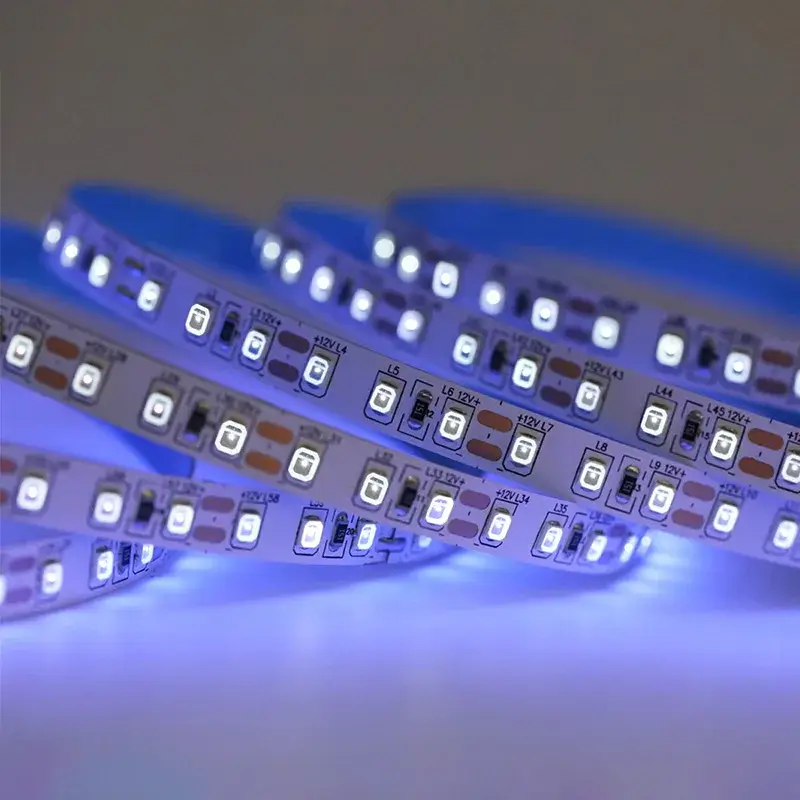

เมื่อเทียบกับหลอดปรอทแบบดั้งเดิมและหลอดฟลูออเรสเซนต์ ไฟ LED แถบ UV กำลังกลายเป็นโซลูชันที่ต้องการสำหรับการใช้งาน UV รุ่นต่อไป เนื่องจากมีขนาดกะทัดรัด ใช้พลังงานต่ำ และอายุการใช้งานยาวนาน ไฟแถบ LED UV ที่ยืดหยุ่นได้มีตัวเลือกความยาวคลื่น กำลัง และความหนาแน่นของแสงที่หลากหลาย

โดยเฉพาะอย่างยิ่งในแถบ UV-A (315–400nm) ความยาวคลื่น 365nm และ 395nm ใช้กันอย่างแพร่หลายในการพิมพ์ UV การบ่มด้วยรังสียูวี โคมไฟเล็บ UV โคมไฟยุง UV การบ่มทางอุตสาหกรรม การแสดงผลและการพิสูจน์ด้วยแสงฟลูออเรสเซนต์และการตรวจสอบทางการแพทย์ รวมถึงอื่นๆ สิ่งเหล่านี้ไม่เพียงแต่ให้เอาต์พุตการฉายรังสี UV ที่เสถียรและควบคุมได้เท่านั้น แต่ยังสามารถปรับให้เข้ากับระบบอุตสาหกรรมหรือเชิงพาณิชย์ที่ซับซ้อนและหลากหลายผ่านโครงสร้างบรรจุภัณฑ์และวิธีการติดตั้งที่แตกต่างกัน

บทความนี้จะเจาะลึกถึงหลักการของแถบแสง UV LED และความแตกต่างระหว่าง UVA, UVB, UVC และแถบความยาวคลื่นหลักสองแถบ (365nm และ 395nm) ช่วยให้ทั้งผู้มาใหม่และผู้เชี่ยวชาญเข้าใจตรรกะการเลือกและเลือกผลิตภัณฑ์แถบแสง UV ที่เหมาะสมที่สุด

ไฟแถบ LED UV คืออะไร?

ไฟแถบ LED UV คือ a ไฟ LED แถบยืดหยุ่น ที่ปล่อยแสงอัลตราไวโอเลต (UV) โดยมีช่วงความยาวคลื่นโดยทั่วไประหว่าง 100nm ถึง 400nm ข้อดีหลักของมันอยู่ที่การรวมขนาดกะทัดรัด การใช้พลังงานต่ำ อายุการใช้งานยาวนาน และคุณลักษณะที่มีความแม่นยำสูงของแหล่งกำเนิดแสงยูวีแบบดั้งเดิม (เช่น หลอดปรอทและหลอดฟลูออเรสเซนต์) ลงในอุปกรณ์เครื่องเดียว ต่างจากไฟ LED ที่มองเห็นได้ทั่วไป ไฟแถบ LED UV ได้รับการออกแบบมาโดยเฉพาะสำหรับงานอุตสาหกรรมหรือการวิจัยบางอย่าง มากกว่าแสงทั่วไป

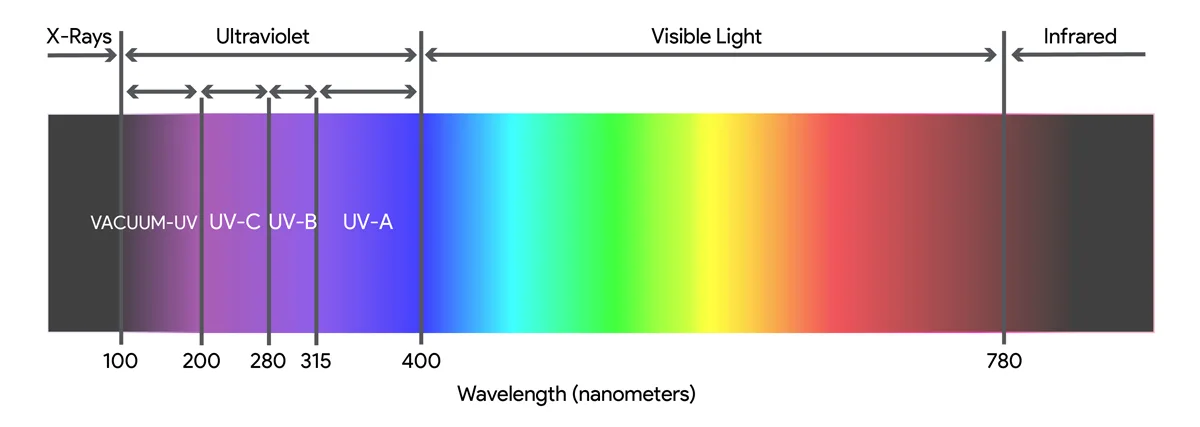

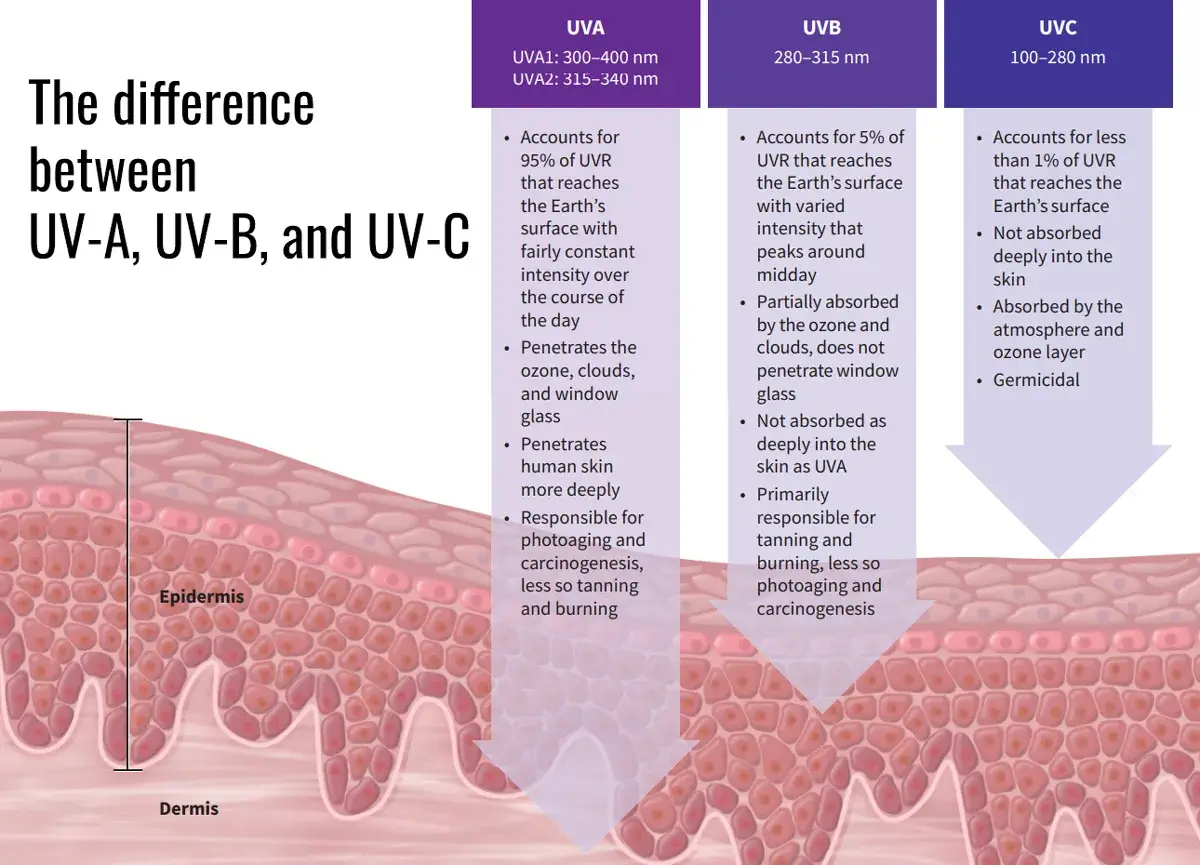

แกนแสงที่เปล่งแสงของไฟแถบ LED UV ใช้ชิป LED UV แสงอัลตราไวโอเลตแบ่งออกเป็นสามประเภท: UV-A, UV-B และ UV-C ขึ้นอยู่กับความยาวคลื่น

- รังสียูวี: 315-400nm แสงยาว/ใกล้แสงอัลตราไวโอเลต ซึมซับบรรยากาศได้อย่างสมบูรณ์ การใช้งานรวมถึงการบ่มทางอุตสาหกรรม (หมึก สี หรือกาว) การตรวจจับสกุลเงิน การระบุคราบเลือด การถ่ายภาพ และการตรวจจับ มันก่อให้เกิดอันตรายน้อยที่สุด

- ยูวี-บี: 280-315nm ความยาวคลื่นปานกลาง ดูดซึมโดยบรรยากาศเป็นหลัก ใช้ในชีววิทยาทางการแพทย์ การพิมพ์หิน การตรวจจับ และการใช้ยาต้านจุลชีพ โดยมีความเสี่ยงที่จะเป็นมะเร็งผิวหนัง

- รังสียูวี: 100-280nm ความยาวคลื่นสั้น ๆ ไม่ถูกดูดซึมโดยบรรยากาศ สามารถทำลาย DNA ของจุลินทรีย์เช่นแบคทีเรียและไวรัสที่ใช้ในการฟอกอากาศ ดับกลิ่น การฆ่าเชื้อในน้ำ การทำให้บริสุทธิ์ และการกรอง

ด้วยการผสมผสานเทคโนโลยี UV LED เข้ากับแถบแสงที่ยืดหยุ่นได้ ผลิตภัณฑ์เหล่านี้จึงถูกนำมาใช้กันอย่างแพร่หลายในตลาดเฉพาะทาง เช่น การผลิตอัตโนมัติ อุปกรณ์ในห้องปฏิบัติการ การแสดงนิทรรศการ ระบบรักษาความปลอดภัย เครื่องมืออุตสาหกรรมความงาม และการควบคุมทางการเกษตร กลายเป็นโซลูชันที่สำคัญในด้านแสงไฟที่ใช้งานได้ เมื่อเทียบกับแหล่งกำเนิดแสง UV แบบดั้งเดิม (เช่น หลอดปรอทแรงดันสูงและหลอด UV เรืองแสง) ไฟแถบ LED UV มีข้อดีที่สำคัญดังต่อไปนี้:

| ข้อดีและคุณสมบัติ | รูปพรรณ |

| พร้อมใช้งานทันที ไม่ต้องอุ่น | ความสว่างเต็มที่ทันทีที่เปิด ไม่ต้องรอ เหมาะสำหรับสายการประกอบและสถานการณ์การทดสอบอย่างรวดเร็ว |

| ประสิทธิภาพพลังงานสูงใช้พลังงานต่ำ | ประสิทธิภาพการใช้พลังงานสูง ประหยัดพลังงาน มาก ลดต้นทุนการดำเนินงาน |

| ปรับแต่งได้สูง | สามารถปรับแต่งตามความต้องการด้านความยาว กำลังไฟ ระดับ กันน้ำ และพารามิเตอร์อื่น ๆ |

| เอาท์พุทความร้อนต่ำ | สร้างความร้อนได้น้อยกว่าเมื่อเทียบกับหลอด UV แบบดั้งเดิม เหมาะสำหรับใช้กับวัสดุที่ไวต่ออุณหภูมิและในช่องปิด |

| เป็นมิตรกับสิ่งแวดล้อม ปราศจากสารปรอท และอายุการใช้งานยาวนานขึ้น | ปราศจากสารอันตราย ค่าบำรุงรักษาต่ำ เหมาะสำหรับติดตั้งต่อเติมโครงการทดแทนโคมไฟปรอท |

อะไรคือความแตกต่างระหว่าง UV-A, UV-B และ UV-C?

UV-A, UV-B และ UV-C เป็นรังสีอัลตราไวโอเลต (UV) ทุกประเภท โดยจำแนกตามความยาวคลื่น ความยาวคลื่นวัดเป็นนาโนเมตร (นาโนเมตร) และกำหนดชนิดของพลังงานยูวี ดังที่เราได้กล่าวไว้ก่อนหน้านี้ UV-A มีความยาวคลื่นระหว่าง 315 ถึง 400 นาโนเมตร UV-B มีความยาวคลื่นระหว่าง 280 ถึง 315 นาโนเมตร และ UV-C มีความยาวคลื่นระหว่าง 100 ถึง 280 นาโนเมตร

รังสียูวี

UV-A มีความยาวคลื่นที่ยาวที่สุดและพลังงานต่ำสุด มันมีพลังแทรกซึมมากกว่า UV-B และสามารถทำลาย DNA ของจุลินทรีย์ได้ทางอ้อม นอกจากนี้ยังสามารถสร้างชนิดออกซิเจนที่ทำปฏิกิริยาภายในเซลล์ ซึ่งจะช่วยฆ่าเชื้อไวรัสและแบคทีเรีย อย่างไรก็ตาม แสง UV-A เป็นส่วนหนึ่งของสเปกตรัมที่มองเห็นได้และโดยทั่วไปจะปลอดภัยสำหรับมนุษย์

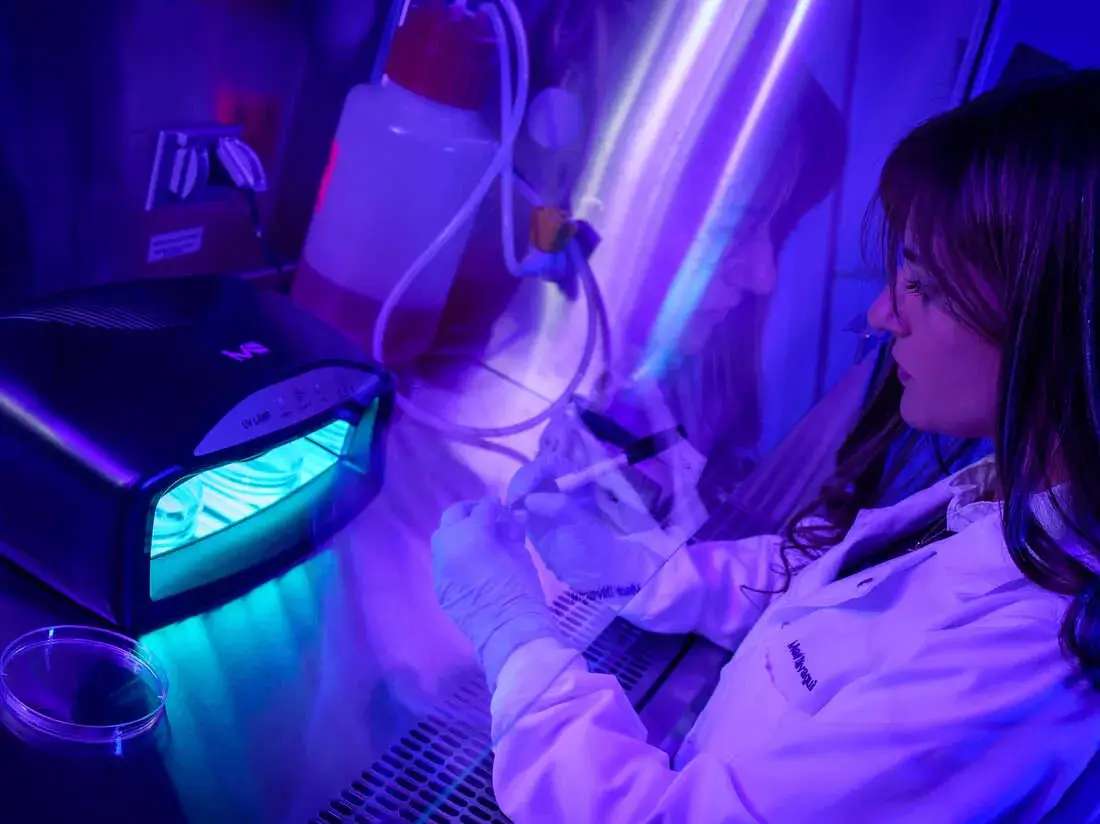

แอปพลิเคชัน LED UV-A ส่วนใหญ่สามารถแบ่งออกเป็นแอปพลิเคชันเรืองแสงหรือบ่ม การใช้งานเรืองแสงไม่ได้จำกัดเฉพาะสาขาวิทยาศาสตร์ เช่น นิติวิทยาศาสตร์ ชีววิทยาระดับโมเลกุล และธรณีวิทยา นอกจากนี้ยังสามารถใช้เพื่อสร้างเอฟเฟกต์ภาพที่น่าทึ่งต่างๆ และนำไปใช้ได้ในการถ่ายภาพเรืองแสงและงานศิลปะจากแสงสีดำ UV-A ที่ใช้ในการบ่มสามารถทำให้เกิดการเปลี่ยนแปลงทางเคมีและโครงสร้างในวัสดุต่างๆ เช่น การบ่มสีลาเท็กซ์ในการพิมพ์สกรีนและการบ่มอีพอกซีเรซินและยาทาเล็บในงานอุตสาหกรรม โดยทั่วไปแล้ว การบ่มต้องใช้ความเข้มของรังสียูวีที่สูงขึ้นอย่างมาก แต่สามารถใช้ความยาวคลื่น UV-A เท่ากันได้ เช่นเดียวกับการเรืองแสง 365nm เป็นความยาวคลื่นการบ่มที่ใช้กันทั่วไป

ยูวี-บี

UV-B มีความยาวคลื่นที่ยาวที่สุดเป็นอันดับสองในบรรดารังสียูวีโดยมีระดับพลังงานสูงกว่า UV-A มันสามารถทำลาย DNA ของจุลินทรีย์ได้โดยตรงและการเปิดรับแสงมากเกินไปอาจทำให้ถูกแดดเผาล่าช้า อันที่จริง แสง UV-B ที่เกิดขึ้นตามธรรมชาติส่วนใหญ่จะถูกดูดซับโดยชั้นโอโซน ดังนั้นมีเพียงปริมาณเล็กน้อยเท่านั้นที่ไปถึงโลก อย่างไรก็ตาม แสง UV-B นั้นสัมพันธ์กับความเสี่ยงสูงที่จะเป็นมะเร็งผิวหนัง ดังนั้นจึงถือว่าไม่ปลอดภัยสำหรับมนุษย์

ไฟ LED UV-B สามารถใช้สำหรับการรักษาทางการแพทย์ การเพาะปลูกพืช และการทดสอบวัสดุ ในด้านการแพทย์ พวกมันถูกนำไปใช้มากขึ้นเพื่อรักษาสภาพผิว เช่น โรคสะเก็ดเงินและโรคด่างขาว เช่นเดียวกับการสังเคราะห์วิตามินดี นอกจากนี้ หลอด excimer หรือเลเซอร์ที่มีความยาวคลื่น 308nm ยังถูกนำมาใช้ในโรคผิวหนังเป็นเวลาหลายปี ไฟ LED UV-B ยังสามารถใช้ในการเพาะพันธุ์พืช เนื่องจากแสง UV-B ส่งผลต่อการเจริญเติบโตของพืช เวลาออกดอก และสารทุติยภูมิ การเปิดรับแสง UVB สามารถเพิ่มผลผลิตของส่วนประกอบพืชบางชนิด เช่น วิตามิน กลิ่นหอม และเม็ดสี

รังสียูวี

UV-C มีความยาวคลื่นที่สั้นที่สุดและพลังงานสูงสุด อย่างไรก็ตาม เนื่องจากความยาวคลื่นสั้น รังสี UV-C ที่เกิดขึ้นตามธรรมชาติส่วนใหญ่จึงถูกดูดซับโดยชั้นโอโซนอย่างสมบูรณ์ นอกจากนี้ แสง UV-C ยังเป็นแสงที่ฆ่าเชื้อโรคที่มีศักยภาพมากที่สุดในธรรมชาติ มันสามารถทำลายพันธะเคมีในจุลินทรีย์และเชื้อโรคและทำลายพวกมันได้ ดังนั้นจึงเป็นวิธีที่เหมาะอย่างยิ่งสำหรับการฆ่าเชื้อที่พื้นผิว

UV-C เป็นวิธีที่มีประสิทธิภาพในการยับยั้งเชื้อโรค เช่น ไวรัส แบคทีเรีย เชื้อรา และเชื้อรา เป็นผลให้ไฟ LED UV-C ใช้กันอย่างแพร่หลายในการฆ่าเชื้อโรค, การฆ่าเชื้อระบบน้ำบริสุทธิ์, การฆ่าเชื้อด้วยรังสียูวีและการฆ่าเชื้อที่พื้นผิว ความสามารถในการฆ่าจุลินทรีย์ที่ทรงพลังมีบทบาทสำคัญในการรักษามาตรฐานด้านสุขอนามัย หนึ่งในการใช้งานที่โดดเด่นที่สุดของ UV-C คือการฆ่าเชื้อน้ำ พื้นผิว และอากาศ เนื่องจากสามารถทำลาย DNA หรือ RNA ของพวกมันได้ ซึ่งจะช่วยป้องกันไม่ให้เกิดการสืบพันธุ์

การทำความเข้าใจความแตกต่างที่สำคัญระหว่าง LED UV-A, UV-B และ UV-C สามารถช่วยให้คุณเลือกประเภทแถบ LED ที่เหมาะสมตามความต้องการของคุณ

| รังสียูวี ประเภทแสง | ความยาวคลื่น | แอปพลิเคชัน | อันตรายที่อาจเกิดขึ้น |

| รังสียูวี | 315-400Nm | การบ่มทางอุตสาหกรรม (หมึก สารเคลือบ หรือกาว) การตรวจจับธนบัตร การระบุคราบเลือด การถ่ายภาพ และการตรวจจับ | อันตรายน้อยที่สุด |

| ยูวี-บี | 280-315nm | ชีววิทยาทางการแพทย์ การพิมพ์หิน การตรวจจับ ฤทธิ์ต้านเชื้อแบคทีเรีย | ความเสี่ยงมะเร็งผิวหนัง ผิวเสื่อมสภาพ สายตาเสียหาย |

| รังสียูวี | 100-280nm | ทำลายดีเอ็นเอของจุลินทรีย์ ฟอกอากาศ ดับกลิ่น ฆ่าเชื้อน้ำ ฟอกน้ำ และกรอง | ความเสี่ยงมะเร็งผิวหนัง ผิวเสื่อมสภาพ สายตาเสียหาย |

ไฟแถบ LED UV เป็นอันตรายหรือไม่?

UV-A เป็นไฟ LED แบบ UV LED ที่ปลอดภัยที่สุดในสามประเภท แต่การสัมผัสกับแสง UV-A ที่มีความเข้มข้นสูงเป็นเวลานานอาจนำไปสู่ปัญหาสุขภาพที่อาจเกิดขึ้นได้ เช่น มะเร็งผิวหนัง ผิวที่เสื่อมสภาพ ระบบภูมิคุ้มกันที่อ่อนแอ และความเสียหายจากการมองเห็น

UV-B และ UV-C ส่วนใหญ่ใช้สำหรับการฆ่าเชื้อและฆ่าเชื้อเป็นหลัก ความยาวคลื่นของแสงเหล่านี้ไม่เพียงเป็นอันตรายต่อจุลินทรีย์เท่านั้น แต่ยังเป็นอันตรายต่อมนุษย์และรูปแบบชีวิตอื่น ๆ ที่อาจสัมผัสกับพวกมันด้วย UV-B สามารถทำให้เกิดการถูกแดดเผาและเพิ่มความเสี่ยงต่อการเกิดมะเร็งผิวหนัง แม้ว่า UV-C จะมีประสิทธิภาพในการฆ่าเชื้อโรค แต่ก็สามารถทำให้เกิดแผลไหม้ที่ผิวหนังอย่างรุนแรงและความเสียหายของดวงตาได้หากไม่ได้ใช้มาตรการด้านความปลอดภัยที่เหมาะสม

ดังนั้นเมื่อใช้แถบแสง UV LED ให้ปฏิบัติตามขั้นตอนการปฏิบัติงานที่ถูกต้องอย่างเคร่งครัด ตัวอย่างเช่น อย่ามองตรงไปที่แสงด้วยตาของคุณในขณะที่แถบไฟ LED ยูวีกำลังทำงานอยู่ ปริมาณแสง UV ที่ตาตรวจพบนั้นน้อยกว่าแสง UV ที่ปล่อยออกมาจาก LED หากจำเป็นต้องตรวจสอบ ให้สวมแว่นตาหรือแว่นตากรองแสง UV และสวมชุดป้องกันในขณะที่จำกัดเวลาในการสัมผัสเพื่อหลีกเลี่ยงอันตรายต่อดวงตาหรือผิวหนังมนุษย์

สำหรับข้อมูลเพิ่มเติมเกี่ยวกับรังสี UV จากไฟ LED โปรดอ่านบล็อก: ไฟ LED ผลิตรังสียูวีหรือไม่?

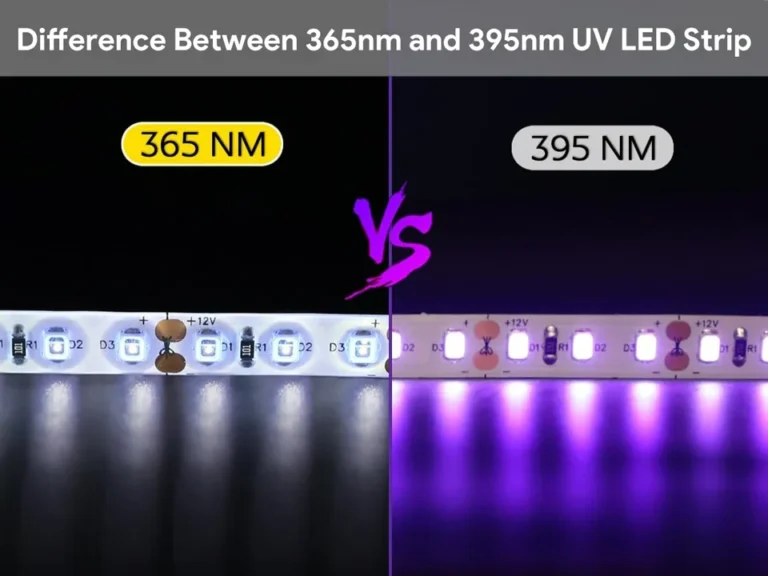

365nm เทียบกับ 395nm ในแถบ LED UV-A

โดยทั่วไปแล้ว แถบ LED UV-A สามารถใช้ในการผลิตและสังเกตเอฟเฟกต์เรืองแสงได้ เช่นเดียวกับการบ่มพลาสติกและสี เมื่อเทียบกับรังสี UV-B และ UV-C ที่แรงกว่า ความยาวคลื่น UV-A นั้นปลอดภัยกว่า ในบรรดาความยาวคลื่น UV-A ทั้งหมด 365nm และ 395nm เป็นความยาวคลื่นสองช่วงที่ใช้กันอย่างแพร่หลายมากที่สุด แม้ว่าทั้งคู่จะอยู่ในสเปกตรัมอัลตราไวโอเลต UV-A แต่ก็มีเพียงความแตกต่าง 30 นาโนเมตรระหว่างพวกมัน ความแตกต่าง 30nm นี้หมายถึงอะไร

ความแตกต่างหลักอยู่ที่ความจริงที่ว่า LED 395nm ปล่อยแสงที่มองเห็นได้ชัดเจนกว่า LED 365nm อย่างมีนัยสำคัญ ไฟ LED 395 นาโนเมตร ให้แสงสีม่วงที่เด่นชัด ในขณะที่ LED 365 นาโนเมตรจะปล่อยแสงสีน้ำเงิน-ขาวสลัว (ซึ่งเป็นผลมาจากพลังงานแสงที่เหลือที่ขยายไปถึงสเปกตรัมที่มองเห็นได้) ไฟ LED ทั้งสองประเภทจะปล่อยแสงภายในช่วงความยาวคลื่น UV-A ซึ่งโดยทั่วไปแล้วจะสามารถสร้างแสงสีดำหรือเอฟเฟกต์การบ่มได้

คุณสามารถดูตารางเปรียบเทียบต่อไปนี้สำหรับ 365nm และ 395nm:

| เรื่อง | 365มน | 395มน |

| แถบความยาวคลื่น | ช่วงล่างของแถบรังสียูวีเอ | ช่วงบน-กลางของแถบ UVA |

| ความเข้มของพลังงานกระตุ้น | สูง (ใกล้บริเวณ UV ลึก) | มัชฌ |

| ทัศนวิสัยด้วยตาเปล่า | แสงสีฟ้าขาวหมองคล้ำ | แสงสีม่วงชัดเจน |

| ความสามารถในการกระตุ้นการเรืองแสง | แข็งแรงมาก (เหมาะสำหรับการตรวจจับที่แม่นยำและวัสดุพิเศษ) | ดี (เหมาะสำหรับการใช้งานเรืองแสงทั่วไป) |

| ค่าชิปและบรรจุภัณฑ์ | สูง (ความต้องการความบริสุทธิ์สูงสำหรับชิป) | ต้นทุนค่อนข้างต่ำเหมาะสำหรับการใช้งานขนาดใหญ่ |

| แอพพลิเคชั่น | การตรวจสอบ การต่อต้านการปลอมแปลง การวิจัย การบ่มอุตสาหกรรม | เพ้นท์เล็บ โชว์ แมลง ดึงดูด ตรวจสอบเชิงพาณิชย์ |

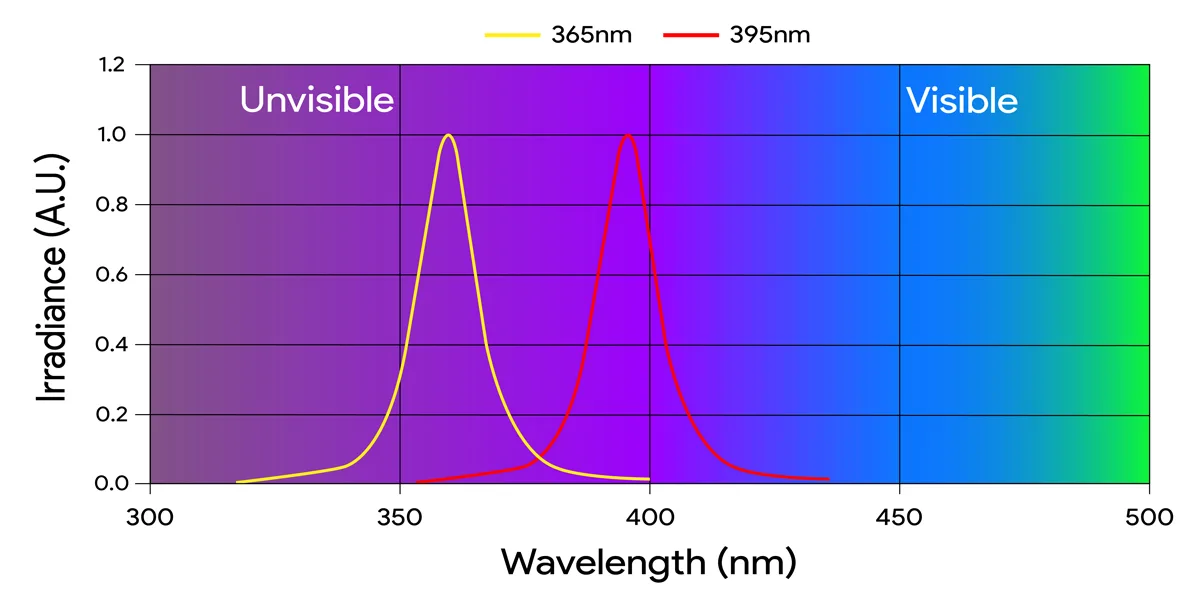

คุณอาจสังเกตเห็นว่า 365nm และ 395nm เป็นแสงที่มองเห็นได้อยู่แล้ว โดยทั่วไปแล้ว แสงที่มีความยาวคลื่นต่ำกว่า 400 นาโนเมตร จะถือว่าเป็นแสงที่มองไม่เห็น เช่น แสงอัลตราไวโอเลต แสงที่มีความยาวคลื่นระหว่าง 400nm ถึง 800nm เป็นแสงที่มองเห็นได้ เหตุใดจึงมีความแตกต่างนี้ กรุณาดูรูปด้านล่าง

ดังแสดงในรูปด้านบน คุณสังเกตเห็นหรือไม่ว่าไฟ LED ทั้ง 365nm และ 395nm ปล่อยแสงในช่วงความยาวคลื่นทั้งด้านบนและด้านล่างความยาวคลื่นตามลำดับ กล่าวอีกนัยหนึ่ง LED 395nm ไม่ได้ปล่อยแสงออกมาโดยเฉพาะที่ 395nm ไฟ LED 395 นาโนเมตร ปล่อยแสงที่แรงที่สุดที่ 395 นาโนเมตร (กำหนดโดยความยาวคลื่นสูงสุด) แต่ยังปล่อยพลังงานจำนวนมากที่ 400 นาโนเมตร และแม้กระทั่ง 410 นาโนเมตร ความยาวคลื่นเหล่านี้อยู่ภายในส่วนที่มองเห็นได้ของสเปกตรัมสีม่วง ซึ่งเป็นสาเหตุที่คุณสามารถสังเกตแสงสีม่วงที่เห็นได้ชัดเจนเมื่อแถบ LED 395 นาโนเมตรสว่างขึ้น

ในทำนองเดียวกัน เมื่อแถบ LED 365nm สว่างขึ้น คุณอาจสังเกตเห็นแสงสีน้ำเงิน-ขาวสลัว สาเหตุนี้เกิดจาก "การรั่วไหล" ของแสงที่มองเห็นได้ เนื่องจาก LED 365nm ปล่อยพลังงานความยาวคลื่นที่มองเห็นได้เพียงเล็กน้อยแต่มองเห็นได้ (เช่น แสงสีขาว)

แม้ว่าแถบแสง LED 365nm และ 395nm จะอยู่ในช่วงความยาวคลื่น UV-A และสามารถใช้สำหรับการเรืองแสงหรือการบ่ม แต่ค่าความยาวคลื่นและพลังงานยังคงมีความสำคัญอย่างยิ่ง ความยาวคลื่นและพลังงานกำหนดประเภทของแสงอัลตราไวโอเลต ซึ่งเป็นความแตกต่างที่สำคัญในแง่ของการใช้งานและแม้กระทั่งข้อควรระวังด้านความปลอดภัยที่จำเป็น

365มน สถานการณ์การใช้งานแถบแสง UV LED:

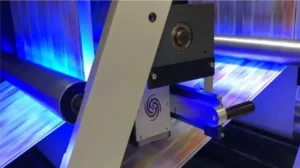

- กาว UV อุตสาหกรรมและหมึกบ่ม: ในกระบวนการต่างๆ เช่น การประกอบอิเล็กทรอนิกส์และการผลิตเลนส์ออปติคัล ความยาวคลื่น 365nm สามารถเจาะชั้นพื้นผิวของกาวได้อย่างรวดเร็ว ทำให้เกิดปฏิกิริยาเริ่มต้นแสงเพื่อให้ได้การบ่มอย่างรวดเร็วและมีประสิทธิภาพ ทำให้เหมาะสำหรับการจ่ายรังสียูวีและอุปกรณ์การบ่มในสายการผลิต

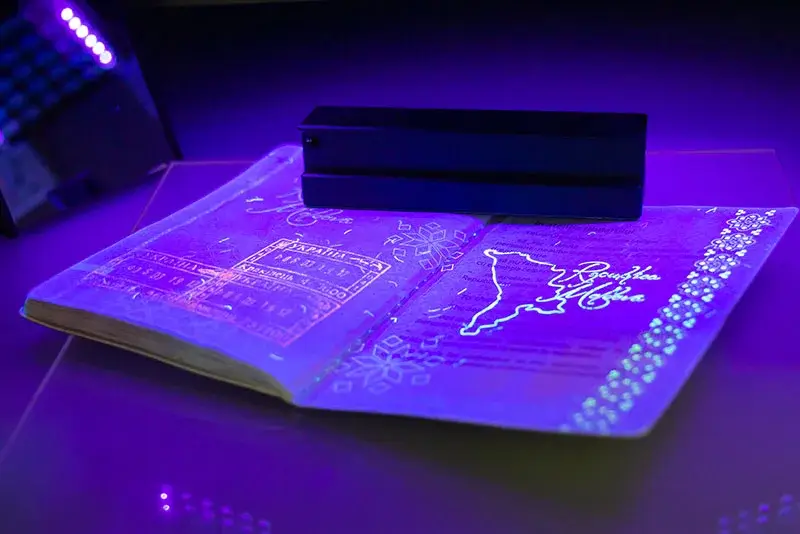

- การต่อต้าน - การตรวจหาการปลอมแปลงและการวิเคราะห์ทางนิติเวช: สามารถกระตุ้นหมึกที่มองไม่เห็น ลายน้ำ ชั้นความปลอดภัย และปฏิกิริยาการเรืองแสงของไฟเบอร์ที่ใช้ในระบบรักษาความปลอดภัยสำหรับหนังสือเดินทาง บัตรประจำตัว ตั๋ว สกุลเงิน ฯลฯ และใช้กันทั่วไปในห้องปฏิบัติการนิติวิทยาศาสตร์ของตำรวจเพื่อตรวจหาร่องรอย

- สารกระตุ้น/สารกระตุ้นจากรีเอเจนต์: ใช้ในการทดลองทางวิทยาศาสตร์ การตรวจจับโมเลกุล การวิเคราะห์การเรืองแสงทางเคมี และสภาพแวดล้อมการวิจัยอื่นๆ ความยาวคลื่น 365 นาโนเมตรเป็นที่ต้องการสำหรับวัสดุพิเศษต่างๆ ที่น่าตื่นเต้น เนื่องจากมีการกระตุ้นสูงสุดที่แม่นยำยิ่งขึ้น

- เครื่องประดับและแร่: อัญมณีและแร่ธาตุจากธรรมชาติบางชนิดมีปฏิกิริยาเรืองแสงเฉพาะที่ 365 นาโนเมตร เช่น เพชร ทับทิม และแคลไซต์ ซึ่งช่วยในการตรวจสอบอย่างรวดเร็ว

395มน สถานการณ์การใช้งานแสงแถบ LED UV:

- เล็บและ ข.ความรวดเร็ว ฉันธุรกิจ: ใช้กันทั่วไปในเครื่องทำเล็บและอุปกรณ์ดูแลมือสำหรับการบ่ม UV Gel 395nm ปล่อยแสงสีม่วงที่มองเห็นได้จำนวนหนึ่งซึ่งช่วยให้ผู้ใช้สามารถตรวจสอบกระบวนการด้วยสายตาด้วยแสงที่สบายและความปลอดภัยที่สูงขึ้น

- การแสดงเชิงพาณิชย์และเอฟเฟกต์แสงเวที: ใช้ปฏิกิริยาเรืองแสงเพื่อสร้างเอฟเฟกต์เรืองแสงสำหรับอุปกรณ์ประกอบฉาก ฉากหลังกราฟิก และการตกแต่งตู้แสดงผล ตัวอย่างเช่น เมื่อรวมกับสีเรืองแสง มันสามารถสร้างลวดลายและโครงร่างที่สดใสในที่มืด ทำให้เกิดเอฟเฟกต์แห่งอนาคตและโดดเด่นทางสายตา

- แมลง ทททแร็พและ ใดเกี่ยวกับกราญและบาล ใดแอพพลิเคชั่น: 395nm เป็นความยาวคลื่นที่ละเอียดอ่อนสำหรับแมลงกลางคืนหลายชนิด ซึ่งทำงานได้ดีในแสงที่ดึงดูดแมลงและระบบควบคุมแมลงศัตรูพืช ซึ่งมักใช้ในสวนผลไม้ โกดัง และพื้นที่เลี้ยงปศุสัตว์

- เบี้อง ใดnti-ซีการแกล้ง ฉันการสังเกต sซีนาริออส: สำหรับการตรวจสอบหมึกเรืองแสงในตั๋ว ตั๋วน้ำ บรรจุภัณฑ์เครื่องสำอาง และฉลากลอจิสติกส์ 395nm สามารถปรับสมดุลฟังก์ชันการตรวจสอบด้วยภาพที่ชี้นำ

แม้ว่า 365nm และ 395nm จะอยู่ในแถบ UV-A แต่ก็ไม่สามารถใช้แทนกันได้ในการใช้งานระดับมืออาชีพบางอย่าง ตัวอย่างเช่น กาว/สารเคลือบ UV มีความไวสูงต่อความยาวคลื่นกระตุ้น และการใช้ความยาวคลื่นที่ไม่ถูกต้องอาจส่งผลให้การบ่มล้มเหลว ดังนั้น เมื่อซื้อแถบ LED UV จำเป็นต้องกำหนดวัตถุประสงค์ของแอปพลิเคชันอย่างชัดเจนและยืนยันความยาวคลื่นที่ต้องการเพื่อให้แน่ใจว่าประสิทธิภาพสูงสุด

วิธีการเลือกไฟ LED แถบ UV ที่เหมาะสม?

เมื่อเลือกแสงแถบ LED UV ที่เหมาะสม ความยาวคลื่นเพียงอย่างเดียวไม่ใช่ปัจจัยเดียวที่ควรพิจารณา จำเป็นอย่างยิ่งที่จะต้องประเมินพารามิเตอร์ทางเทคนิคที่สำคัญอย่างครอบคลุม เช่น ประสิทธิภาพทางไฟฟ้า การออกแบบโครงสร้าง ประเภทบรรจุภัณฑ์ และระดับการป้องกัน เพื่อให้แน่ใจว่าการทำงานที่มั่นคง ปลอดภัย และมีประสิทธิภาพในการใช้งานเฉพาะ ต่อไปนี้คือปัจจัยสำคัญ 6 ประการที่ควรพิจารณาระหว่างการคัดเลือก:

1. กำหนดความต้องการความยาวคลื่น

กำหนดแถบความยาวคลื่นที่ต้องการตามวัสดุกระตุ้นหรือเป้าหมายการตรวจจับ ตัวอย่างเช่น 365nm เหมาะสำหรับการบ่ม 395nm สำหรับการดึงดูดแมลง และ 385–395nm สำหรับการตรวจจับพื้นฐานทั่วไป

2. ยืนยันความหนาแน่นของพลังงานและพื้นที่การฉายรังสี

แถบแสง UV ใช้เป็นหลักในการฉายรังสีตามหน้าที่ ประมาณการความเข้มของพลังงานที่ต้องการต่อหน่วยพื้นที่ และปล่อยให้ระยะขอบ 30% เพื่อหลีกเลี่ยงการเสื่อมสภาพของอายุการใช้งานก่อนเวลาอันควรอันเนื่องมาจากการทำงานเต็มโหลดเป็นเวลานาน

3. ตรวจสอบว่าระดับการป้องกันตรงกับสภาพแวดล้อมหรือไม่

- สภาพแวดล้อมการวิจัยในร่ม: IP20 เพียงพอ;

- สถานการณ์การเพ้นท์เล็บ/การแสดงผล: แนะนำให้ใช้ท่อซิลิโคน IP65 สำหรับการกันน้ำและกันฝุ่น

- สภาพแวดล้อมทางอุตสาหกรรมและความชื้น: ใช้แถบโคมไฟแบบกระถาง IP68 ซึ่งกันน้ำและน้ำมัน และใช้กับช่องอะลูมิเนียม

4. ตรวจสอบแรงดันไฟฟ้าและวิธีการควบคุม

- 12V เหมาะสำหรับการตกแต่งในท้องถิ่นและแสงในพื้นที่ขนาดเล็ก

- 24V เหมาะสำหรับการติดตั้งทางไกลหรือการใช้งานที่มีกำลังสูง

- ถ้าความเข้ม การปรับหรือการควบคุมเวลา จำเป็นต้องใช้สวิตช์หรี่ไฟ PWM อินฟราเรด / สวิตช์สัมผัส ฯลฯ

5. ตรวจสอบให้แน่ใจว่าโครงสร้างการกระจายความร้อนเพียงพอ

แถบแสง UV LED มีกำลังสูงและความร้อนที่เข้มข้นดังนั้นขอแนะนำให้ติดตั้งด้วย โปรไฟล์อลูมิเนียม LED หรือเพิ่มพัดลมเพื่อระบายความร้อนเพื่อยืดอายุและป้องกันความยาวคลื่น

6. ตรวจสอบยี่ห้อและใบรับรอง

- แถบแสง UV คุณภาพสูงควรมีการรับรองด้านสิ่งแวดล้อมและความปลอดภัย เช่น RoHS, CE และ REACH

- สำหรับชิป เราแนะนำให้ใช้แบรนด์ที่เป็นที่ยอมรับ เช่น สนั่น นิเชีย หรือเอพิสตาร์

โดยสรุปแถบ LED UV ต่างๆ มีลักษณะเฉพาะและการใช้งาน การทำความเข้าใจความแตกต่างในด้านพลังงาน ความยาวคลื่น การเจาะ และผลกระทบต่อสุขภาพเป็นสิ่งสำคัญสำหรับการใช้งานอย่างปลอดภัยและมีประสิทธิภาพ ด้านล่างนี้คือแถบ LED UV สองแถบจาก Signliteled โปรดเลือกแถบ LED UV ที่เหมาะสมตามโครงการแอปพลิเคชันของคุณ

DC12V 365NM ไฟ LED แถบ UV สำหรับการบ่ม

รุ่นหลัก: FAU10T60A-365NM

ประเภท LED: ยูวี SMD5050/SMD2835

จำนวน LED ต่อเมตร: 60/120

ความกว้างของแผงวงจร: 10 มม.

ความยาวคลื่น: 365-370nm

แรงดันไฟฟ้าขาเข้า: DC12V

กำลังไฟฟ้าต่อเมตร: 14W

เกรด IP: IP20/IP65/IP67

การรับประกัน: 5 ปี

เหนือฟังก์ชันรองรับการปรับแต่ง

แสง UV สีดำ 395nm (อัลตราไวโอเลต) ไฟ LED แถบ

รุ่นหลัก: FAU10T60A-395NM

ประเภท LED: ยูวี SMD5050/SMD2835

จำนวน LED ต่อเมตร: 60/120

ความกว้างของแผงวงจร: 10 มม.

ความยาวคลื่น: 395-400Nm

แรงดันไฟฟ้าขาเข้า: DC12V

กำลังไฟฟ้าต่อเมตร: 14W

เกรด IP: IP20/IP65/IP67

การรับประกัน: 5 ปี

เหนือฟังก์ชันรองรับการปรับแต่ง

แนวทางการใช้งานและการติดตั้งแถบแสง UV LED

ไฟ LED แถบ UV เป็นอุปกรณ์ไฟ LED ที่ใช้งานได้เฉพาะซึ่งต้องให้ความสนใจเป็นพิเศษกับความปลอดภัยและประสิทธิภาพระหว่างการติดตั้งและการใช้งาน จากข้อมูลของกระทรวงสาธารณสุขและบริการมนุษย์ของสหรัฐอเมริกา (US HHS) ความยาวคลื่นทั้งหมดของแสงอัลตราไวโอเลต (UV) รวมถึง UV-A, UV-B และ UV-C สันนิษฐานว่าเป็นสารก่อมะเร็ง ดังนั้นจึงต้องใช้มาตรการป้องกันที่สำคัญสำหรับแสงยูวีทุกรูปแบบ

ดังนั้น ขั้นตอนการปฏิบัติงานที่เหมาะสมและการจัดการโดยละเอียดไม่เพียงแต่ยืดอายุผลิตภัณฑ์เท่านั้น แต่ยังเพิ่มความปลอดภัยของสภาพแวดล้อมการใช้งานและสุขภาพของบุคลากรอีกด้วย

1. ข้อควรระวังด้านความปลอดภัย

- หลีกเลี่ยงการสัมผัสกับแหล่งกำเนิดแสงยูวีโดยตรง: แม้ว่า UV-A จะมีความยาวคลื่นที่ยาวกว่าและมองเห็นได้ด้วยตามนุษย์ แต่การสัมผัสโดยตรงเป็นเวลานานยังคงทำให้ตาเสียหายได้ ผู้ใช้ควรหลีกเลี่ยงการสัมผัสโดยตรงกับพื้นผิวที่เปล่งแสงของแถบ โดยเฉพาะอย่างยิ่งในช่วงความยาวคลื่น 365 นาโนเมตร

- สวมอุปกรณ์ป้องกันพิเศษ: ขอแนะนำให้สวมแว่นตาป้องกันรังสียูวี ถุงมือ และชุดป้องกันเมื่อใช้ไฟ โดยเฉพาะอย่างยิ่งในสภาพแวดล้อมแถบแสงที่มีกำลังสูงหรือเปิดฝาปิดอยู่

- จำกัดพื้นที่รั่วแสงยูวี: ออกแบบตำแหน่งการติดตั้งและการป้องกันแสงอย่างเหมาะสมเพื่อป้องกันไม่ให้แสงยูวีรั่วจากผลกระทบในทางลบต่อบุคลากรและสิ่งของ การแพร่กระจายแสง UV สามารถจำกัดได้โดยใช้ช่อง LED อลูมิเนียม แผงป้องกันแสง ฝาครอบฝ้า ฯลฯ

2 . การจัดการการกระจายความร้อน

- เลือกวัสดุกระจายความร้อนที่เหมาะสม: แถบไฟ LED UV มีกำลังสูง และการกระจายความร้อนที่ไม่ดีอาจทำให้อุณหภูมิชิป LED สูงขึ้นมากเกินไป ซึ่งจะช่วยลดประสิทธิภาพของแสงและการเสื่อมสภาพแบบเร่ง ขอแนะนำให้ใช้ โปรไฟล์อลูมิเนียม LED เป็นฐานการติดตั้งเพื่อเพิ่มการนำความร้อน

- หลีกเลี่ยงการทำงานที่ยืดเยื้อในช่องว่างที่ปิดล้อม: สภาพแวดล้อมในการติดตั้งควรรักษาการไหลเวียนของอากาศที่ดี และควรใช้พัดลมหรือระบบระบายความร้อนด้วยอากาศแบบบังคับเมื่อจำเป็นเพื่อป้องกันการสะสมความร้อน

- ออกแบบปัจจุบันและกำลังอย่างสมเหตุสมผล: ปฏิบัติตามพารามิเตอร์ที่กำหนดโดยผู้ผลิตเพื่อหลีกเลี่ยงการโอเวอร์โหลด ใช้ แรงดันคงที่และตัวขับกระแสคงที่ เพื่อให้แน่ใจว่าแรงดันไฟ LED และกระแสไฟคงที่ ลดความร้อนสูงเกินไปและการลดอายุการใช้งานที่เกิดจากแรงดันไฟฟ้าหรือกระแสไฟผันผวน

3. การป้องกันการรั่วซึมของรังสียูวีและการรักษาสิ่งแวดล้อม

- เลือกการให้คะแนนการป้องกันที่เหมาะสม: เลือกแถบ LED ที่มีการป้องกัน IP65 หรือสูงกว่าตามสภาพแวดล้อมการใช้งานเพื่อป้องกันการบุกรุกของฝุ่นและความชื้นซึ่งอาจทำให้ไฟฟ้าลัดวงจรและประสิทธิภาพการทำงานลดลง

- ป้องกันแสง UV ไม่ทำลายวัสดุโดยรอบ: แสงยูวีสามารถเร่งการเสื่อมสภาพของพลาสติกและสารเคลือบบางชนิดได้ ระหว่างการติดตั้ง หลีกเลี่ยงการสัมผัสสิ่งของที่มีความละเอียดอ่อนโดยตรง หรือใช้ฟิลเตอร์ UV เพื่อลดความเข้มของรังสียูวี

- ทิ้งแถบ UV LED ที่ถูกทิ้งอย่างถูกต้อง: ไฟ LED ยูวีมีวัสดุเซมิคอนดักเตอร์ เมื่อกำจัดทิ้ง ให้ปฏิบัติตามกฎระเบียบการรีไซเคิลขยะอิเล็กทรอนิกส์ในท้องถิ่นเพื่อป้องกันมลพิษทางสิ่งแวดล้อม

4. คำแนะนำการติดตั้งอื่น ๆ ในทางปฏิบัติ

- เว้นที่ว่างเพียงพอสำหรับการเชื่อมต่อสายและขั้วต่อ: ตรวจสอบให้แน่ใจว่าติดตั้งและถอดออกได้ง่ายเพื่อหลีกเลี่ยงความเสียหายของสายเคเบิลจากการดึงที่จุดเชื่อมต่อ

- วางแผนการตัดส่วนและการเชื่อมต่ออย่างสมเหตุสมผล: แถบ LED UV โดยทั่วไปรองรับการตัดในช่วงเวลาที่กำหนด ระหว่างการติดตั้ง ให้จัดเรียงตามแผนการออกแบบเพื่อหลีกเลี่ยงความสว่างที่ไม่สม่ำเสมอหรือแรงดันตกที่มากเกินไป

- ตรวจสอบให้แน่ใจว่ามีการติดฉลากที่ชัดเจนสำหรับการบำรุงรักษาในอนาคต: ระหว่างการติดตั้ง ให้ทำเครื่องหมายขั้วไฟฟ้าและการเชื่อมต่อสายไฟอย่างชัดเจนเพื่ออำนวยความสะดวกในการแก้ไขปัญหาและเปลี่ยนในอนาคต

บทสรุป

แถบ LED UV นั้นน่าสนใจและมีความสำคัญในหลายสาขา ลักษณะเฉพาะของพวกเขาทำให้พวกเขาใช้งานได้หลากหลายทั้งในชีวิตประจำวันและอุตสาหกรรมอาชีพ การทำความเข้าใจความแตกต่างระหว่าง UV-A, UV-B และ UV-C เป็นสิ่งจำเป็นสำหรับการตัดสินใจเลือกอย่างมีข้อมูล

อย่างไรก็ตาม เนื่องจากแสงยูวีมองไม่เห็น จึงไม่ทำให้เกิดการเหล่ตามธรรมชาติหรือหลีกเลี่ยงการจ้องมองที่แสงที่มองเห็นได้ทำให้เป็นอันตรายอย่างยิ่ง ดังนั้นเมื่อใช้แถบแสง UV LED จำเป็นต้องตระหนักถึงความเสี่ยงต่อสุขภาพที่อาจเกิดขึ้น ปฏิบัติตามคำแนะนำของผู้ผลิตเสมอ ใช้มาตรการป้องกัน และตรวจสอบให้แน่ใจว่าอุปกรณ์มีคุณสมบัติด้านความปลอดภัยเพื่อป้องกันการสัมผัสโดยไม่ได้ตั้งใจ

Signlited เชี่ยวชาญด้านความคงตัวสูงและเสถียรภาพสูง โซลูชั่นไฟ LED แถบ, เสนอการปรับแต่ง OEM/ODM เพื่อให้เป็นไปตามข้อกำหนดด้านความยาวคลื่น ขนาด และการควบคุมเฉพาะของลูกค้าในอุตสาหกรรม