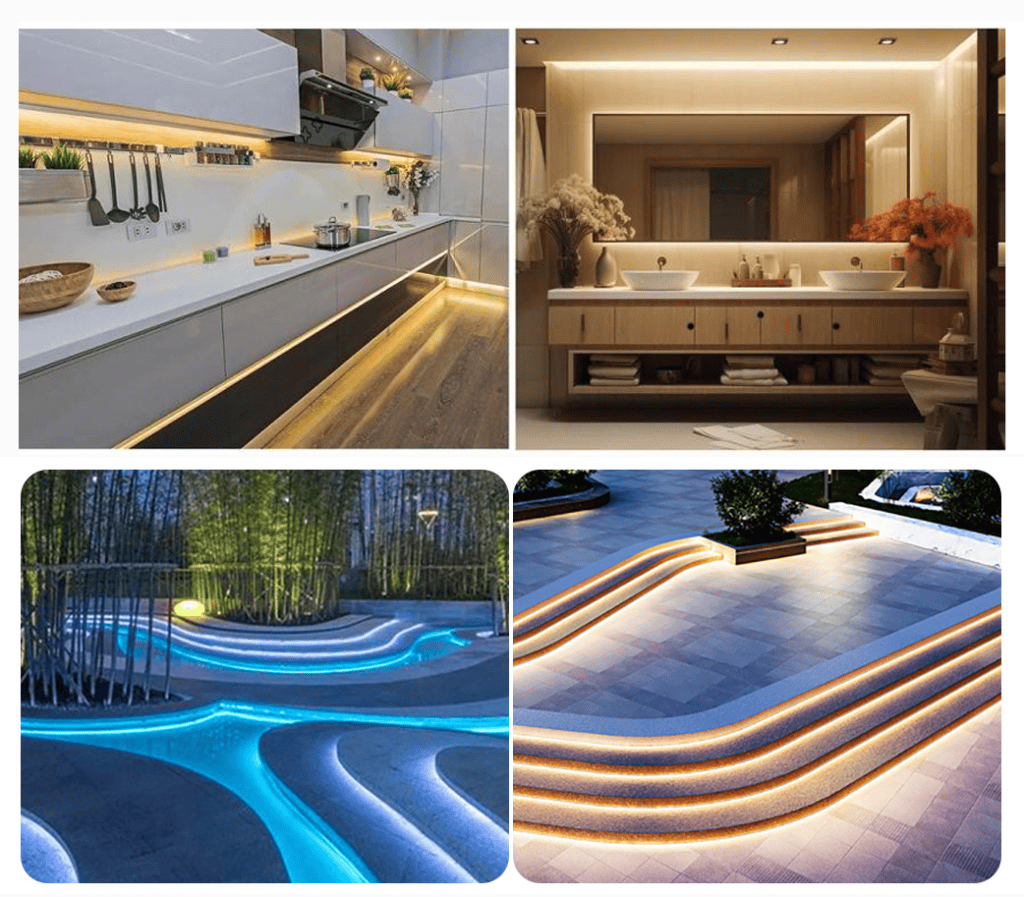

Many types of waterproof LED light strips exist in now market. Difficult for beginners to know which one to choose.

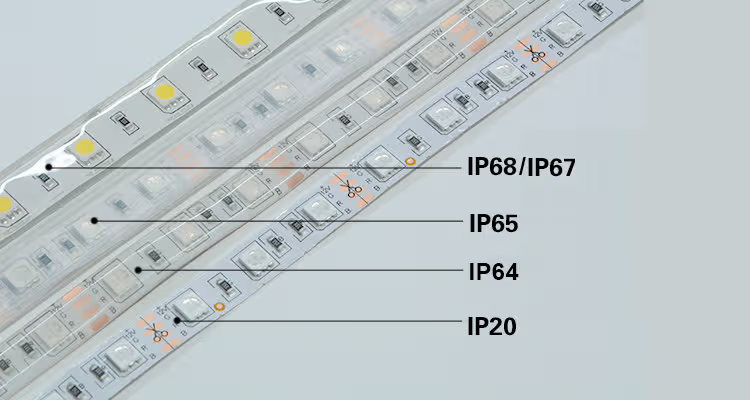

Usually we recommend these 5 models: IP20, IP64, IP65, IP67,IP68. The IP rate depends on where you will use the LED light strip.

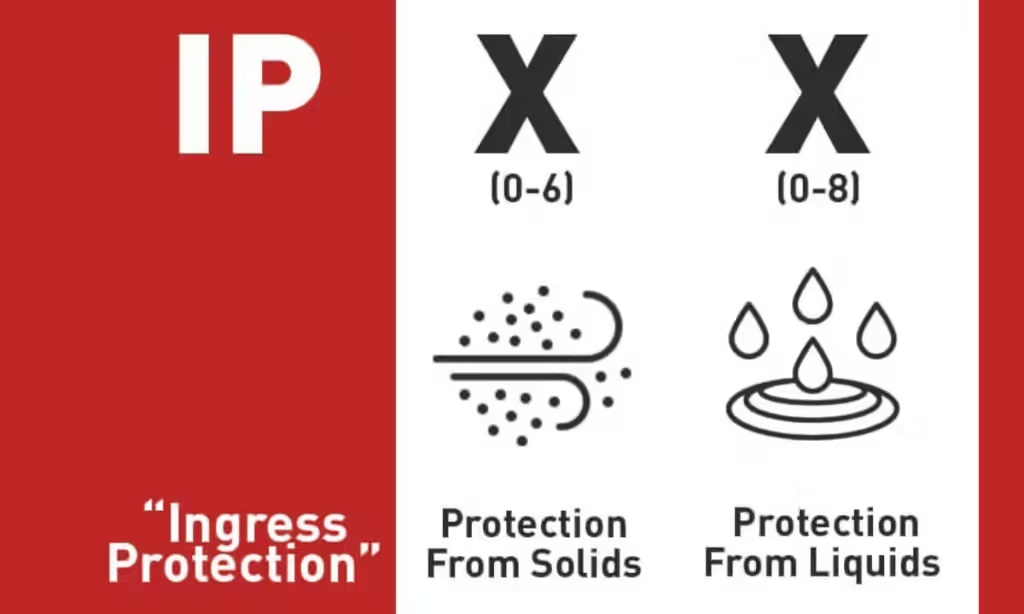

What is the IP rate of led strip?

The IEC created the IP protection system. It categorizes electrical devices

based on their resistance to dust and moisture. Two numbers compose the IP protection level.

The first number shows how well the appliance protects against dust and foreign objects like tools or fingers. The second number shows how well the appliance keeps out moisture and water.

The larger the number, the higher the protection level, The specific waterproof levels are as follows:

IPX0: No waterproof protection.

IPX1: Protected by vertical dripping water.

IPX2: Protected by dripping water at a 15-degree angle.

IPX3: Protected by splashing water.

IPX4: Protected by splashing water from any direction.

IPX5: Protected by low-pressure water jets.

IPX6: Protected by strong water jets.

IPX7: Can still work normally after short-term immersion in water (up to 30 minutes, 1 meter deep).

IPX8: Can still work normally after long-term immersion in water (specific water depth and time vary by device).What are waterproof light strips made of?

What are waterproof light strips made of?

IP20 is for bare PCB and not waterproof, Can only be used indoors.

IP64 silicone coating

Add a layer of silicone to the lamp beads of the LED light strip, but the other side is an exposed PCB board. IP64 LED light strips can be dustproof, but the waterproof performance is poor.

Suitable for dry or humid areas, such as living rooms, kitchens, bathrooms. Usually we do not recommend using it in places where water will splash.

Compared with the color temperature of the LED, the CCT of the finished product will become higher. When making a 3000K IP64 LED light strip, we use LEDs with a lower CCT like 2700K instead of 3000K. This results in a 10% decrease in brightness.

Compared to IP20 LED light strip, the width has not changed, but the height has increased by about 1.5-2mm. Therefore, we do not need to consider the extra width when choosing LED aluminum profiles.

IP65 silicone tube

Add silicone sleeve to wrap the LED light strip by manual or silicone extrusion. IP65 LED light strip is dustproof and waterproof.

Suitable for wet or splashing areas such as kitchens, bathrooms, eaves. Because the shell is hollow, we do not recommend using it outdoors.

Basically , silicone tube is no color difference, and brightness will loss 10% lumen.

Compared to IP20 non-waterproof LED light strips, the width and height of IP65 silicone tube LED light strips increase by approximately 2 mm. When selecting LED aluminum profiles, you must take this increased dimension into account.

IP67 solid silicone

Wrap the LED strip with a hollow silicone tube. Then, fill the hollow silicone tube with silicone to create a sealing effect.

Another way to make IP67 LED strips is to use silicone integrated extrusion.

Suitable for outdoor use. However, because of the large molecular gaps of silicone, it is easy to seep water over time. In addition, silicone is not resistant to chlorine corrosion and is easily damaged. Therefore, it is not recommended to use it underwater.

Similar to IP64 silicone coated LED strips, IP67 LED strips also have color variations, and the degree of color variation is greater.

For example, using 2700K LED beads, the color temperature of an IP64 LED strip may be 3000K, but the color temperature of an IP67 LED strip may be 3500K, and Brightness will loss 15% lumen.

Like the IP65 silicone tube LED strip, the width and height of the IP67 fully silicone encapsulated LED strip have increased by about 2mm.

IP68 solid PU gel

Wrap the LED light strip with fully transparent PU glue. PU is the abbreviation of polyurethane.

Suitable for outdoor and underwater use. Polyurethane has a small molecular gap, which means it won’t let water seep through. It is also resistant to chlorine, acid, and alkali, making it perfect for underwater use.

Similar to IP67 solid silicone LED light strip, IP68 full PU encapsulation also has color difference. and Brightness will loss 15% lumen.

Same as the IP67 solid silicone LED Light Strip, the width and height of the IP68 LED Light Strip are increased by about 2mm.

In short, the higher the waterproof grade, the better it performs, but it will also cost more to make.

When picking a LED strip light, choose the right waterproof grade based on where and how you plan to use it.

A professional organization should conduct a waterproof test to ensure accurate and reliable results.