In industrial and commercial lighting applications, LED tri-proof lights have gradually replaced traditional fluorescent lights and waterproof tubes, becoming the mainstream lighting solution for various harsh environments. Also known as waterproof LED batten lights or vapor-tight fixtures, they are frequently used in warehouses, garages, tunnels, subway stations, food processing plants, and similar locations.

The “Tri-Proof” designation in LED tri-proof lights signifies waterproof, dustproof, and corrosion-proof capabilities, typically meeting IP65 or IP66 protection ratings. Consequently, these fixtures boast exceptional sealing structures and durability, ensuring long-term stable operation in humid, dusty, or corrosive environments.

This article provides an in-depth analysis of LED tri-proof lights, covering their structural principles, classification types, protection ratings, application scenarios, and key selection criteria. It aims to help you fully understand the advantages of these high-protection fixtures and find the most suitable solution for your project.

What is an LED Tri-Proof Light?

An LED tri-proof light is a sealed lighting fixture designed for enhanced protection and energy efficiency. The term “Tri-Proof” refers to its resistance against water, dust, and corrosion. They also offer shock resistance, delivering reliable illumination even under the harshest conditions.

Unlike traditional fluorescent fixtures, LED tri-proof lights incorporate high protection ratings (typically IP65 or IP66). Internally, waterproof connectors, silicone seals, and corrosion-resistant coatings effectively block moisture and dust ingress. The dual insulation design ensures long-term circuit safety and reliability without explosion risks.

Combining high-efficiency LED chips with constant-current drive technology, they deliver stable light output while maximizing energy efficiency. This results in minimal maintenance requirements and enhanced environmental sustainability. Additionally, their extended lifespan eliminates the need for frequent replacements.

For factory and project procurement professionals, selecting a high-quality industrial lighting solution impacts not only energy efficiency and illuminance but also long-term maintenance expenses and safety. The LED tri-proof light is designed specifically to meet these needs by being tough, providing excellent light quality, and offering various installation choices for different lighting situations in factories, businesses, and public areas.

How Does a Tri-Proof Light Work?

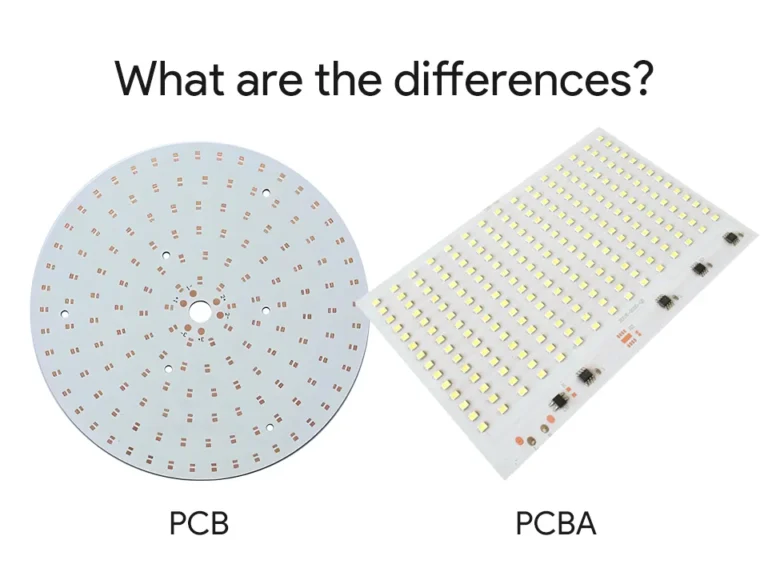

The core reason LED tri-proof lights can operate stably for extended periods in high-humidity, high-dust, or corrosive environments lies in their specialized protective structure and high-reliability design.

Compared to traditional waterproof tubes or fluorescent fixtures, they feature more precise construction and superior sealing. Additionally, their drive circuits and heat dissipation systems have been optimized to achieve triple protection: waterproof, dustproof, and corrosion-resistant.

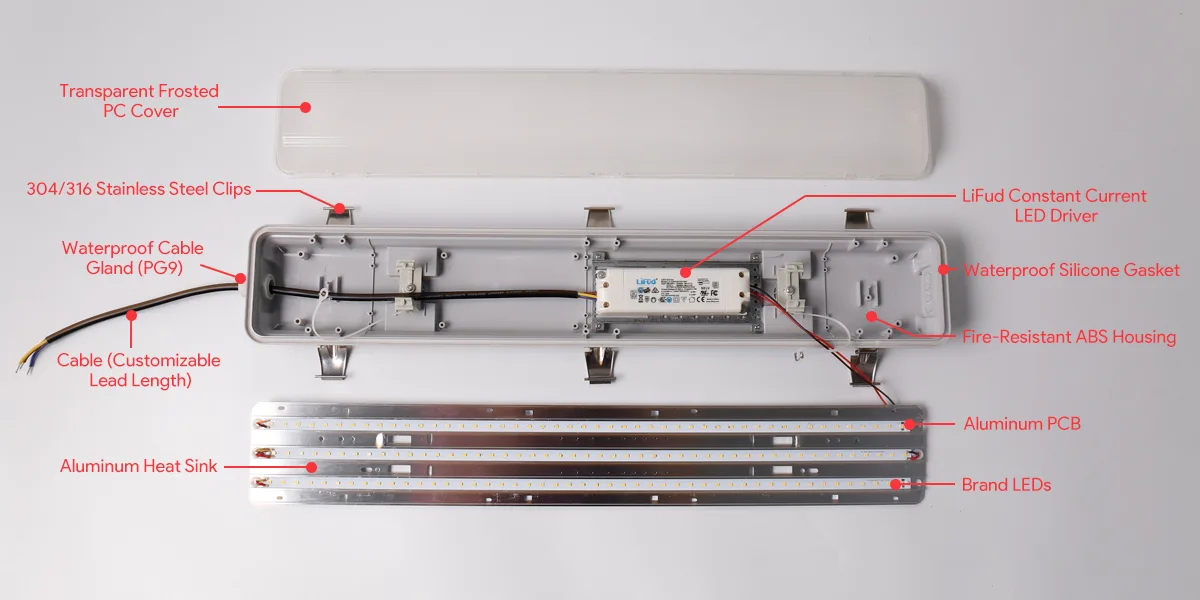

1. Sealed Housing Design

LED tri-proof lights typically combine a high-density polycarbonate diffuser with an aluminum alloy or ABS housing. A silicone gasket and waterproof connectors create a fully enclosed structure. This design effectively prevents moisture, dust, or oil mist from infiltrating the interior, ensuring long-term stable operation of the internal driver and LED light source.

Many high-quality waterproof LED batten lights feature IP65 or IP66 ratings, withstanding water jets and high humidity in outdoor or damp environments. They are suitable for harsh conditions like parking lots, subway stations, tunnels, and workshops.

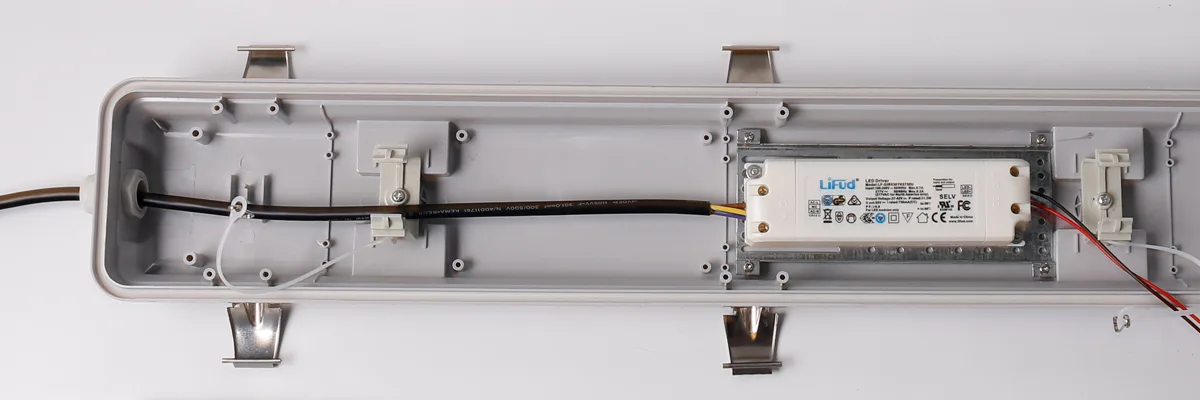

2. Electrical Protection and Driver System

LED tri-proof lights typically incorporate constant current drivers paired with surge protection and lightning protection circuits. This configuration effectively prevents LED damage caused by voltage fluctuations or transient surges.

Additionally, to ensure long-term operational stability, many industrial-grade LED tri-proof lights feature a power factor >0.9 and THD <15%, delivering energy efficiency while maintaining high electrical utilization.

Furthermore, select models support dimming functionality (0–10V / DALI dimming), enabling smart industrial lighting solutions that adjust illumination based on ambient light levels or sensor control.

3. Optical and Anti-Glare Design

Premium tri-proof lights must not only be durable but also deliver comfortable illumination. Their diffusers utilize high-transmittance PC material to evenly distribute light and minimize glare, providing soft, uniform illumination in large workshops or warehouse areas.

Some premium vapor-tight fixtures incorporate micro-prismatic lens designs to effectively lower the Unified Glare Rating (UGR), enhancing workplace comfort and safety.

4. Thermal Management System

Despite their sealed construction, thermal performance remains critical for vapor-tight fixtures. The fixture back typically incorporates aluminum heat sinks or thermally conductive housing and waterproof respirators to rapidly dissipate heat generated by LED chips.

A stable thermal management system prevents LED lumen depreciation and driver overheating, ensuring a lamp lifespan of 50,000–70,000 hours. This delivers true “low maintenance and high reliability” industrial lighting standards.

5. Anti-Corrosion Treatment

For environments with corrosive gases—such as food processing plants, chemical workshops, or coastal areas—the housing of LED tri-proof lights undergoes anti-corrosion coating or utilizes stainless steel clips to prevent rusting of metal components.

This design ensures long-term stable operation in salt spray, oil fumes, or high-temperature/high-humidity environments, making it a reliable industrial waterproof lighting solution.

In summary, the LED tri-proof light achieves true triple protection through the synergistic design of four systems: structural sealing, electrical protection, thermal optimization, and anti-corrosion treatment. This makes it an indispensable lighting solution in modern industrial applications, particularly suited for commercial projects requiring high brightness, extended lifespan, and low maintenance.

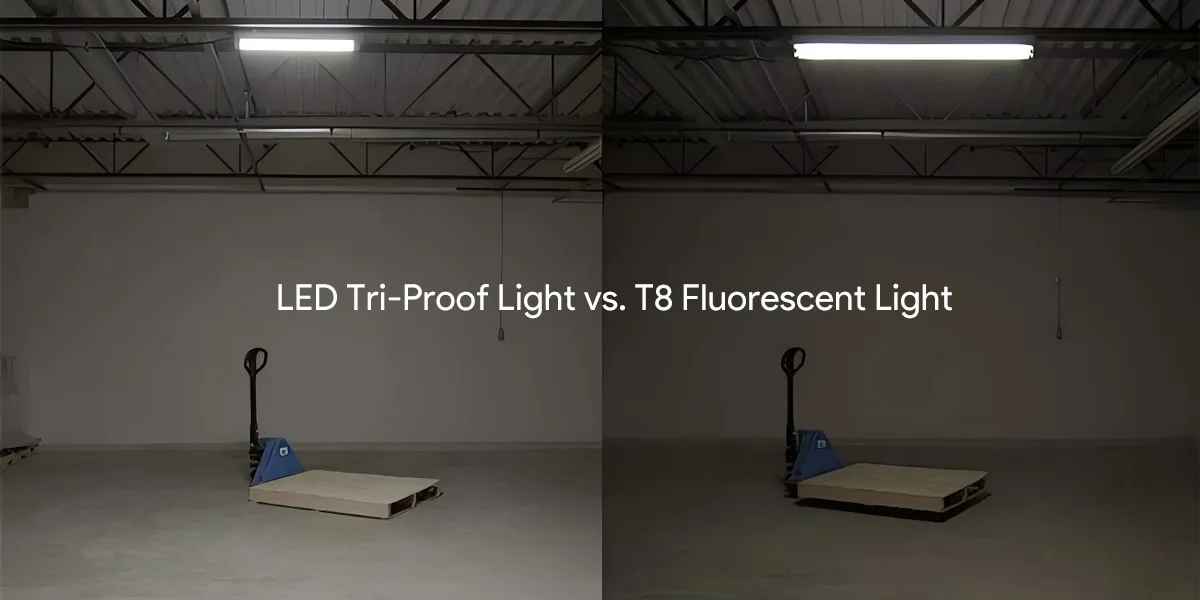

LED Tri-Proof Light vs. Traditional Fluorescent Fixture

For decades, traditional fluorescent fixtures have been the mainstay of industrial lighting in factories, warehouses, garages, and similar settings. However, with the maturation of LED technology and increasing energy efficiency requirements, LED tri-proof lights have gradually replaced conventional fixtures, becoming the core choice for the new generation of industrial lighting solutions.

This shift stems not only from improved LED luminous efficacy but also from the tri-proof light’s significant advantages in protection performance, lifespan, energy consumption, and safety. The comparison table below clearly illustrates the key differences between the two.

LED Tri-Proof Light vs. Fluorescent Fixture Comparison Table

| Feature | Traditional Fluorescent Fixture | LED Tri-Proof Light |

| Luminous Efficiency | 60–80 lm/W, significant energy waste | 120–160 lm/W, energy-efficient with up to 60% reduced power consumption |

| Lifespan | 10,000–15,000 hours | ≥50,000 hours, low maintenance costs |

| Protection Level | No waterproof/dustproof construction | IP65 / IP66 waterproof, dustproof, and corrosion-resistant |

| Start-Up Performance | Slow startup, prone to flickering at low temperatures | Instant-on, flicker-free operation |

| Maintenance | Bulbs age quickly, requiring frequent replacement | Long-life drive system, virtually maintenance-free |

| Working Condition | Unsuitable for humid or dusty environments | Suitable for wet areas, workshops, outdoor settings, and cold storage |

| Light Quality | Low color rendering index, cool color temperature | High CRI (>80), customizable color temperature (3000K–6500K) |

| Environmental Impact | Contains mercury, radiation risk | Mercury-free, recyclable materials, eco-friendly |

| Safety | Susceptible to voltage fluctuations | Built-in surge protection and short-circuit safeguards |

| Overall Efficiency | Low efficiency, high heat generation | Up to 60% energy savings, slower lumen depreciation |

Comparative Analysis: Why Industrial Customers Prefer LED Tri-Proof Lights

1. Energy Savings Drive Long-Term Cost Efficiency

In large warehouses or workshops, lighting systems often account for over 30% of total electricity consumption. LED tri-proof lights reduce energy consumption by approximately 50–60%, significantly lowering operational costs. In engineering projects, energy efficiency and Total Cost of Ownership (TCO) frequently outweigh unit price considerations.

2. Low Maintenance Costs and Reduced Downtime Risks

Fluorescent lights require regular replacement of tubes and ballasts. In contrast, tri-proof fixtures utilize high-quality constant current drivers and long-life LED chips, enabling continuous operation for years without maintenance. For elevated or enclosed spaces like warehouses, tunnels, and cold storage facilities, this advantage translates to significantly reduced maintenance labor and downtime losses.

3. Enhanced Protection Rating and Stability

In humid, dusty, corrosive, or vibrating environments, traditional fixtures are prone to water ingress or rust, compromising safety. Waterproof LED batten lights feature IP65/IP66 sealed construction, silicone gaskets, waterproof connectors, and anti-corrosion coatings. They ensure long-term operation outdoors or in high-humidity conditions, maintaining system safety and lighting continuity.

4. Enhanced Light Quality and Safety

LED light sources offer flicker-free operation, high color rendering (CRI>80), and low glare—critical for visual comfort and safe production in work areas. Additionally, the vapor-tight fixture’s anti-glare PC cover minimizes light spots and glare, improving overall visual uniformity.

5. Alignment with Modern Lighting Trends

Many countries now encourage or mandate LED lighting systems in industrial energy efficiency regulations. Upgrading to LED tri-proof lights not only reduces electricity costs but also ensures compliance with international certifications (CE, RoHS, ETL, DLC), enhancing project competitiveness and brand image.

From energy efficiency and lifespan to protection, safety, and environmental performance, LED tri-proof lights significantly outperform traditional fluorescent lamps across nearly all key metrics.

For wholesale buyers, lighting contractors, and project developers, these fixtures represent not only an energy-saving choice but also the industrial lighting solution offering the optimal long-term return on investment (ROI). They help businesses reduce ongoing operational costs, minimize maintenance risks, and achieve higher standards in lighting quality and safety.

Types of LED Tri-Proof Lights

LED tri-proof lights can be categorized into various types based on installation methods, structural design, luminous efficacy requirements, and protection ratings. Understanding these classifications helps project purchasers select the most suitable solution according to application scenarios, budget, and maintenance needs.

HS Series LED Tri-proof Light

Model No: TRA06X20F/TRA12X40F/TRA15X50F

Dimension: 662/1272/1566x86x80mm

Input Voltage: 100-277VAC, 50/60Hz

Watts: 20W/40W/50W

Efficacy: 150lm/W

CCT: 3000K, 4000K, 6500K

CRI: >80

IP rating: IP65

Dimming: 0-10V/Triac/DALI/PWM

Certification: CE, RoHS

Warranty: 5years

Tubular TB Series LED Tri-proof Light

Model No: TRC06X20F/TRC12X40F/TRC15X50F

Dimension: φ76×600/1200/1500mm

Input Voltage: 100-277VAC, 50/60Hz

Watts: 20W/40W/50W

Efficacy: 130lm/W

CCT: 3000K, 4000K, 6500K

CRI: >80

IP rating: IP65

Dimming: 0-10V/Triac/DALI/PWM

Certification: CE, RoHS

Warranty: 5years

ECO Series LED Tri-proof Light

Model No: TRD06X20M/TRD12X40M/TRD15X50M

Dimension: 600/1200/1500x68x48mm

Input Voltage: 85-265VAC, 50/60Hz

Watts: 20W/40W/50W

Efficacy: 120lm/W

CCT: 3000K, 4000K, 6500K

CRI: >80

IP rating: IP65

Dimming: 0-10V/Triac/DALI/PWM

Certification: CE, RoHS

Warranty: 3years

Emergency Series LED Tri-proof Light

Model No: TRA06X20F-EM/TRA12X40F-EM/TRA15X50F-EM

Dimension: 662/1272/1566x86x80mm

Input Voltage: 100-277VAC, 50/60Hz

Watts: 20W/40W/50W

Efficacy: 130lm/W

CCT: 3000K, 4000K, 6500K

CRI: >80

IP rating: IP65

Dimming: 0-10V/Triac/DALI/PWM

Emergency Power: 8-12W

Emergency Time: 60-120mins

Certification: CE, RoHS

Warranty: 5years

The market offers a wide variety of tri-proof lights beyond the four types shown above, including fluorescent tri-proof lights, LED tube tri-proof lights, slim linear lights, integrated aluminum LED tri-proof lights, and IP69k-rated tri-proof lights. For project buyers, the key to selecting tri-proof lights lies in matching project requirements:

- Cost efficiency: For bulk purchases, prioritize integrated or linear solutions for superior cost-effectiveness.

- System integration: If smart control is required, consider adding DALI or sensor-enabled features to the luminaires.

- Harsh environments: In high-humidity or highly corrosive areas, select products with an IP69K rating.

Key Advantages of Using LED Tri-Proof Lights

In industrial, warehousing, transportation, and commercial facilities, LED tri-proof lights have become the mainstream solution for replacing traditional fluorescent fixtures. With outstanding energy efficiency, protective performance, and extended lifespan, they deliver significant long-term cost savings and safety benefits for enterprise users.

1. Exceptional Energy Efficiency

Compared to traditional fluorescent lamps, LED tri-proof lights achieve 50–70% greater energy efficiency. Utilizing high-luminous-efficiency LED chips and high-power-factor drivers, they convert more electrical energy into visible light while minimizing heat dissipation.

- Luminous efficacy: Reaches 130–160 lm/W, more than double that of T8 fluorescent tubes.

- Power factor: ≥0.95, minimizing electrical waste and line load.

- Energy savings payback period (ROI): Typically recoups replacement costs within one year.

For large factories or warehouses, lighting energy consumption accounts for a significant portion of total power usage. Switching to LED tri-proof lights can reduce annual lighting electricity costs by up to 40%.

2. Superior Durability and Longevity

LED tri-proof lights earn their name through triple protection: waterproof, dustproof, and corrosion-resistant. Featuring impact-resistant polycarbonate (PC) housing and silicone gaskets, they ensure long-term operation in harsh environments.

- Working temperature: -30°C to +50°C

- IK rating: IK08–IK10

- Lifespan: >50,000 hours

They maintain stable light output and reliable performance even in high-humidity, high-dust, or oil/gas environments such as food processing plants, workshops, or underground parking garages. Durability translates to reduced replacement frequency and downtime losses, significantly impacting long-term maintenance costs for large-scale projects.

3. Enhanced Safety and Compliance

LED triple-proof lights utilize low-voltage constant-current drivers and flicker-free designs, effectively minimizing electrical accident risks and visual fatigue. Additionally, products universally comply with international safety certifications, including CE, RoHS, ENEC, TUV, and UL.

- Mercury-free and UV-free for enhanced environmental safety

- Overload and surge protection for improved circuit security

- Food-grade environment compatibility meeting HACCP or ISO standards

For food processing plants, pharmaceutical facilities, or public transportation systems, selecting certified LED tri-proof lights not only meets regulatory requirements but also reduces potential liability risks.

4. Low Maintenance and Easy Installation

Traditional fluorescent fixtures require frequent replacement of tubes and starters. The modular design of LED tri-proof lights significantly reduces maintenance needs. Select models support linkable installation—plug-and-play functionality that saves installation time.

- Integrated waterproof connectors for streamlined installation

- Supports surface mount and suspended mount configurations

- Optional emergency & smart sensor modules for expanded functionality

For contractors and distributors, rapid installation translates to shorter project timelines, reduced labor costs, and higher project turnover rates.

5. Consistent Lighting Quality

High CRI (CRI >80) and flicker-free light sources enable LED tri-proof lights to excel in enhancing visual comfort and work efficiency. Uniform light distribution and soft brightness eliminate shadowing and glare issues, making them ideal for environments demanding high visual precision.

- CCT Range: 3000K – 6500K

- Select fixtures feature UGR<19 design to minimize glare

- Uniform illumination: Ensures consistent lighting across every work area

For warehousing, logistics, and assembly lines, superior lighting effectively enhances operational precision while reducing employee fatigue.

Applications of LED Tri-Proof Lights

LED tri-proof lights, renowned for their exceptional waterproof, dustproof, and corrosion-resistant properties, have become one of the most versatile products in industrial and commercial lighting. Whether in high-humidity, high-temperature, dusty, or corrosive environments, they deliver stable, energy-efficient, and safe lighting solutions. Below are typical application scenarios across major industries.

How to Choose the Right LED Tri-Proof Light

For industrial or commercial lighting projects, selecting the appropriate LED tri-proof light involves more than just “Does it light up?” It requires a systematic decision that comprehensively considers the environment, protection rating, installation method, energy efficiency, and compliance.

Below is a complete guide to help project purchasers quickly assess and select the right model.

1. Define the Application Environment

Different locations have varying performance requirements for tri-proof lights. First, clearly identify the working environment conditions where the luminaire will be installed:

| Environment Type | Characteristics | Recommended Parameters |

| High-humidity environments (e.g., cold storage, parking garages) | Large temperature fluctuations, severe condensation | IP66 protection rating, anti-condensation design |

| High-dust or oil mist environments (e.g., factories, workshops) | Particle or oil residue adhesion | PC housing + silicone gasket |

| Corrosive Environments (e.g., food processing plants, farms) | Ammonia gas, disinfectants, salt spray | Corrosion-resistant housing + food-grade certification |

| High-Vibration Environments (e.g., subways, tunnels) | Frequent vibration, difficult maintenance | Shock-resistant mounts + IK10 protection structure |

If the project is located in coastal or high-salt-fog areas, prioritize industrial-grade products featuring anti-corrosion coating (triple-proof coating).

2. Check the IP & IK Ratings

IP Rating (Ingress Protection):

- Generally select IP65 or IP66 for protection against powerful water jets and dust ingress;

- For outdoor exposed environments, upgrade to IP67.

IK Rating (Impact Resistance):

- IK08 is suitable for standard workshops;

- IK10 is recommended for public areas such as parking lots and subways.

These technical specifications directly impact the luminaire’s lifespan and reliability, making them critical reference points in project procurement specifications.

3. Choose the Right Power & Luminous Efficacy

Different spaces have varying brightness requirements. Selection should be based on installation height and illuminance standards.

| Installation Scenario | Recommended Power | Recommended Luminous Efficiency | Installation Height |

| Office / Corridor | 20–30W | ≥120lm/W | 2.5–3m |

| Warehouse / Factory | 40–60W | ≥140lm/W | 3–6m |

| Tunnel / Garage | 30–50W | ≥130lm/W | 2.5–4m |

| Cold Storage / Food Plant | 30–40W | ≥130lm/W | 2.5–3.5m |

For large-scale project procurement, it is recommended to prioritize models with a luminous efficacy of 150 lm/W or higher, which can significantly reduce total system power consumption.

4. Evaluate the Driver and Control Options

LED tri-proof lights typically employ the following driver types:

- Constant Current Driver: Offers more stable luminous efficacy and extended lifespan;

- Constant Voltage Driver: Suitable for modular assembly or long-distance wiring;

- DALI / 0-10V / Microwave Sensor Control: Supports intelligent dimming and energy management.

For government projects or large commercial buildings, choose LED tri-proof lights with DALI intelligent control systems for centralized management and energy monitoring.

5. Verify Certifications and Quality Standards

A high-quality LED tri-proof light should comply with the following international standards:

| Certification Mark | Description | Applicable Market |

| CE / RoHS | EU Safety and Environmental Certification | European Market |

| UL / DLC | North American Electrical Safety and Energy Efficiency Standards | United States, Canada |

| ENEC / TUV | European High-End Project Requirements | Industrial Lighting Projects |

| HACCP / ISO | Food and Pharmaceutical Industry Standards | Food Processing, Cold Storage Lighting |

Please refer to the blog post “Customized LED Tri-proof Light: CE Certification, Low THD” to learn how we assist our customers with CE certification.

6. Installation Compatibility

Before purchasing, verify that the fixture is easy to install and compatible with your setup.

- Wiring Options: Some tri-proof lights are plug-and-play, while others require hardwiring.

- Dimmable vs. Non-Dimmable: If you need brightness control, look for dimmable options.

- Mounting Type: Determine surface-mount or suspended installation based on ceiling height.

For effortless setup, choose plug-and-play models with adjustable mounting options.

Ultimately, for project buyers, this represents not just a lighting upgrade but a strategic investment in long-term energy savings and brand value enhancement. Selecting the right product model translates to lower maintenance costs, higher project success rates, and more sustainable commercial lighting solutions.

Installation Tips and Maintenance

Proper installation and regular maintenance not only extend the lifespan of LED tri-proof lights but also ensure consistent performance in demanding environments.

For more information on installing LED tri-proof lights, read the blog “LED Tri-Proof Light Installation Guide: Step by Step.”

1. Installation Tips

- Check Power Supply: Verify the supply voltage matches the luminaire’s nameplate specifications. Most LED tri-proof lights support AC100–277V or AC220–240V wide voltage input. Ensure wiring terminals are securely fastened without looseness.

- Mounting Options: Choose between surface-mounted or suspended-mounted configurations. For factories or warehouses, suspended mounting is recommended to achieve a wider illumination angle.

- IP & IK Protection: Ensure the lamp body gasket and end cap are fully sealed to prevent dust or moisture ingress, especially during outdoor or humid area installations.

- Cable Gland: Select high-quality waterproof cable connectors (e.g., PG9/PG11) and allow sufficient wire length to prevent stress pulling.

2. Maintenance Tips

- Regularly clean the lens surface to prevent grease and dust from reducing light output.

- Replace the light source module or entire fixture if significant light decay or LED failure is observed.

- Inspect the waterproof gasket for aging; replace immediately if cracks are found.

- For models with emergency functions, perform discharge tests every 3 months to ensure reliability.

Conclusion

The LED tri-proof light represents not only an upgrade over traditional waterproof fixtures but also a reliable industrial lighting solution. With its high energy efficiency, durability, environmental resistance, and low maintenance costs, it has become the preferred lighting choice for factories, garages, warehouses, food processing facilities, transportation infrastructure, and similar environments.

By selecting the appropriate IP rating, brightness, color temperature, and mounting method, you can reduce costs while achieving the required performance. Furthermore, replacing your lighting with LED tri-proof lights can yield significant savings in electricity bills and maintenance expenses.

Whether you are a wholesaler, engineering contractor, or require OEM/ODM customization, choosing Signlite LED tri-proof lights will help you achieve superior lighting quality and a higher return on investment.