Why Acoustic Lighting Prices Vary More Than Expected

When evaluating acoustic lighting for commercial interiors, many buyers find that products with similar appearances can vary significantly in price. An acoustic pendant light or acoustic ceiling light fixture may look comparable, yet the cost behind each product is often very different.

A common misunderstanding is assuming that acoustic lighting cost is driven mainly by LED components. In reality, acoustic lighting fixtures are integrated systems that combine acoustic panels, felt materials, lighting components, and compliance requirements. Material performance and safety standards typically have a greater impact on pricing than the LEDs themselves.

From acoustic panel lighting and acoustic linear lighting to acoustic baffle lighting and acoustic ceiling panels with lights, manufacturers must balance sound absorption and lighting performance at the same time. Factors such as felt thickness, fiber density, flame-retardant performance, and manufacturing consistency directly affect project approval and long-term reliability in commercial applications.

This is why two acoustic ceiling lighting systems can look nearly identical yet differ greatly in compliance level, durability, and total project cost. Understanding what truly drives acoustic lighting pricing helps buyers evaluate acoustic light fixtures based on performance and standards—not appearance alone.

Acoustic Panel Specifications That Impact Cost

One of the most underestimated cost drivers in acoustic lighting is the specification of the acoustic panel itself. Unlike conventional luminaires, acoustic lighting fixtures rely on felt-based panels not only for visual appearance, but to achieve defined sound absorption performance.

In acoustic ceiling lighting and acoustic panel lighting systems, panel specifications directly affect acoustic effectiveness, structural stability, and long-term reliability. These factors influence material consumption, manufacturing complexity, and project approval—making the acoustic panel a core contributor to overall cost.

For commercial acoustic lighting solutions, panel selection is typically driven by acoustic targets and compliance requirements rather than aesthetics alone. As a result, two acoustic light fixtures with similar designs may use very different panel specifications, leading to noticeable cost differences.

Felt Thickness & Density

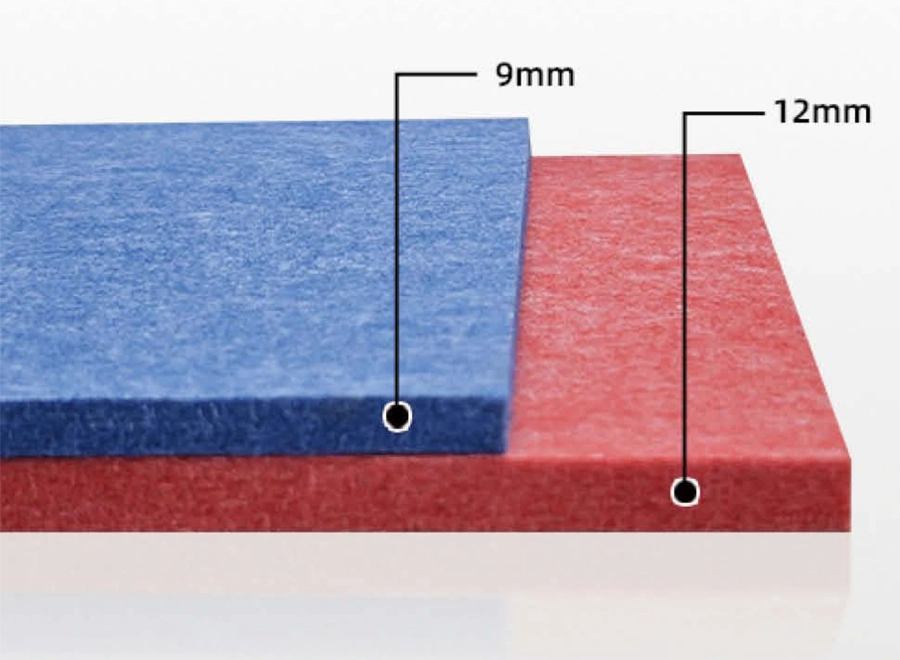

Felt thickness is one of the most direct indicators of acoustic performance and material cost. In practice, thickness must be evaluated together with forming method, fixture geometry, and application type.

In thermoformed acoustic pendant light designs, 9 mm polyester felt is widely used due to its flexibility and dimensional stability, making it suitable for curved and wrapped structures. For flat or assembled acoustic panel lighting systems, thicker felt options such as 12 mm, 18 mm, or above are commonly selected to meet higher NRC requirements.

As thickness increases, low-frequency absorption and structural rigidity improve, but material usage, weight, and manufacturing cost also rise accordingly.

Felt Thickness, Acoustic Performance & Cost Impact

| Felt Thickness | Typical Application | Structural / Acoustic Notes | Estimated Material Cost |

| 9 mm | Thermoformed or curved acoustic lighting | High flexibility, suitable for mold forming | ≈ 115 USD |

| 12 mm | Flat or lightly curved acoustic panel lights | Improved rigidity and absorption | ≈ 121 USD |

| 18 mm | Segmented or fan-shaped acoustic panels | Better low-frequency absorption | ≈ 140USD |

| 24 mm | Large structural acoustic panels | High rigidity, enhanced performance | ≈ 156USD |

| 27 mm | Customized architectural acoustic elements | Maximum thickness for special projects | ≈ 162USD |

* Material cost for reference only; actual pricing varies by fire rating, density, certification, and order volume.

Based on ISO 354 test results, a standard 9 mm polyester panel performs well in the 500–2000 Hz range, which is critical for speech clarity. For projects with significant low-frequency noise (e.g. HVAC systems), thicker panels are typically required, resulting in higher material cost.

Material Quality & Manufacturing Process

Acoustic felt materials used in acoustic lighting generally fall into four categories: PET polyester fiber felt, mineral wool, fiberglass, and natural wool felt. While all provide sound absorption, they differ significantly in fire behavior, structural stability, and suitability for integrated lighting fixtures.

In practical applications, PET polyester felt is the dominant material due to its structural integrity, clean handling, and compatibility with acoustic light fixtures. Mineral wool and fiberglass offer strong absorption but are brittle and difficult to integrate into lighting systems. Wool felt is mainly used for decorative felt lights due to its appearance and higher cost.

For this reason, most professional acoustic lighting solutions—including acoustic panel lights, acoustic ceiling lights, and acoustic linear lighting—are based on PET polyester felt. This is also the primary material used in SignliteLED acoustic lighting products.

Acoustic Felt Materials Used in Acoustic Lighting

| Material Type | Acoustic Performance | Fire Behavior | Structural Stability | Suitability | Cost Level |

| PET Polyester Felt | Medium–High | Fire-rated options available | High | ✔ Widely used | ★★–★★★ |

| Mineral Wool | High | Non-combustible | Low (brittle) | ✖ Limited | ★★ |

| Fiberglass | Medium–High | Non-combustible | Low (fiber shedding) | ✖ Limited | ★★ |

| Wool Felt | Medium | Naturally flame resistant | Medium | △ Decorative use | ★★★★ |

Higher-density PET felt improves dimensional stability, cutting accuracy, and production consistency. While it increases raw material cost, it reduces waste and improves installation reliability—resulting in lower overall project risk.

Fire Resistance Requirements in Acoustic Lighting

Commercial Projects vs. Residential Applications

Fire resistance is a critical requirement in acoustic lighting design, particularly for public and commercial environments. Unlike standard decorative lighting, acoustic lighting fixtures integrate felt-based sound-absorbing materials, which are subject to fire safety regulations depending on the application scenario.

In commercial and architectural projects—such as offices, schools, airports, shopping malls, hotels, and other public spaces—fire-rated acoustic lighting is typically mandatory. These projects must comply with local building fire codes and internationally recognized fire classification systems, which aim to limit flame spread, reduce smoke generation, and improve evacuation safety in the event of a fire.

In contrast, residential or private-use acoustic lighting generally faces fewer regulatory constraints. In home applications, flame-retardant felt may not be strictly required, allowing manufacturers to use standard polyester acoustic materials with lower material and certification costs.

Common Flame-Retardant Ratings in Acoustic Lighting

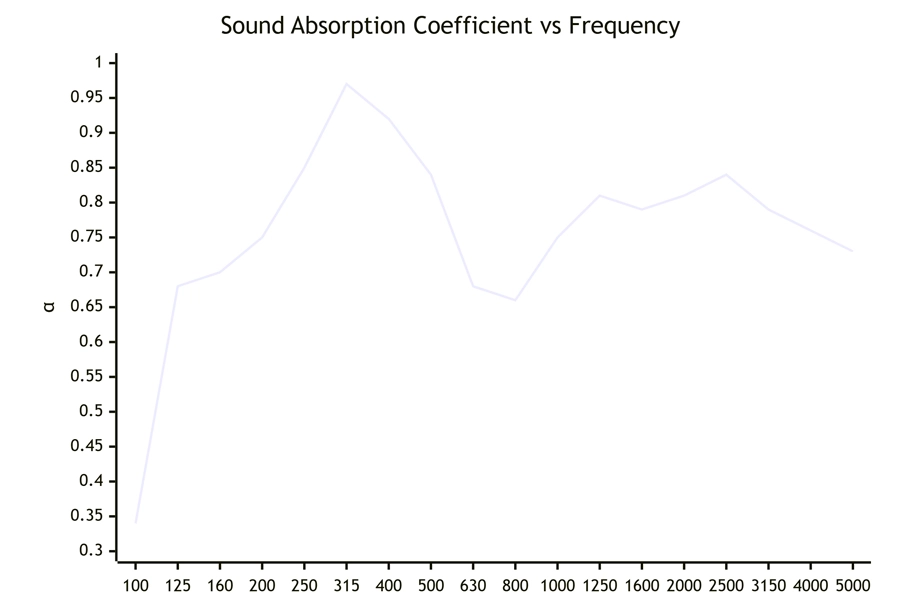

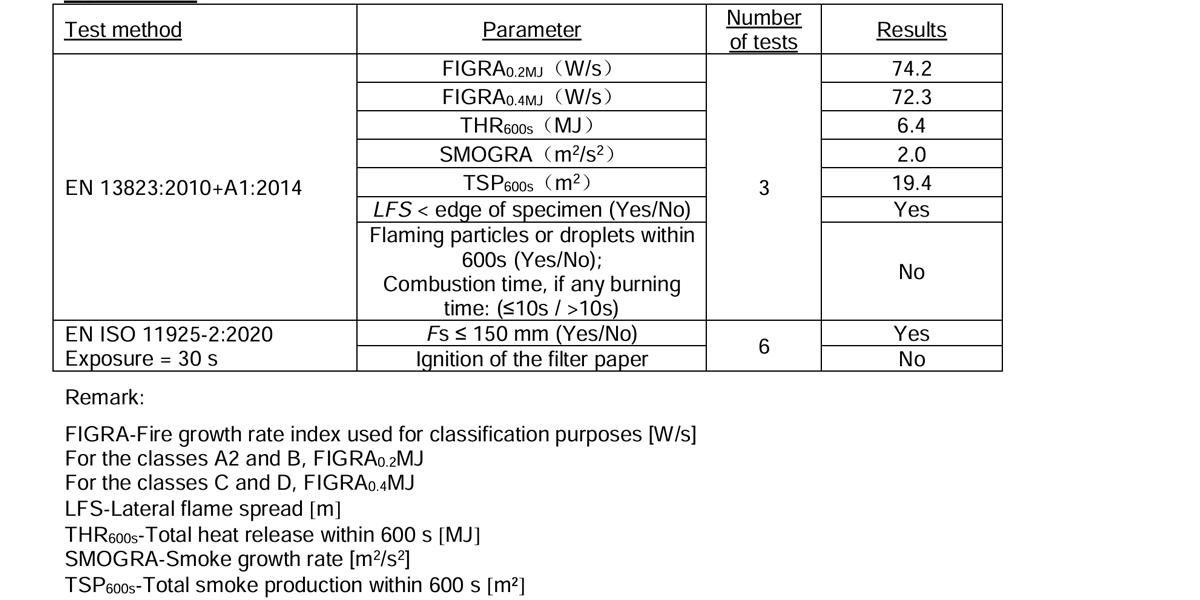

For commercial acoustic lighting, flame-retardant performance is typically defined by recognized regional or international standards, such as EN 13501-1 in Europe or GB 8624-2012 in China. These standards evaluate material behavior under fire exposure, including ignition resistance, flame spread, heat release, smoke generation, and the presence of burning droplets.

For example, an EN 13501-1 fire test conducted by SGS on a 9 mm polyester acoustic felt panel resulted in a classification of B-s1, d0. Typical test results showed:

- FIGRA₀.₂MJ: 74.2 W/s

- THR₆₀₀s: 6.4 MJ

These values indicate controlled flame spread and extremely low smoke release, which is why B-s1, d0 materials are widely specified in European commercial interiors.

In this classification system, s1 represents very low smoke production, while d0 confirms no flaming droplets during combustion—making the material suitable for most commercial and public-space applications.

By comparison, materials certified under GB 8624-2012 B1 (B-s3, d2) are also classified as flame-retardant in China, but allow higher smoke generation and the presence of burning droplets. As a result, they are typically accepted for domestic projects with lower fire performance requirements.

Impact on Material Cost and Testing Cost

Achieving higher fire ratings such as B-s1, d0 requires more than visual similarity or basic acoustic performance. Flame-retardant acoustic felt must be engineered with specialized formulations, controlled fiber density, and stricter manufacturing processes. Compared to standard decorative felt, these requirements typically result in a 15–25% increase in material cost.

In addition to raw material expenses, fire resistance certification introduces further costs, including laboratory fire testing, certification documentation, and ongoing compliance management. These costs are independent of fixture size or design complexity and must be factored into the final pricing of acoustic lighting products intended for commercial use.

As a result, acoustic lighting fixtures designed for international or commercial projects often carry a higher cost than visually similar products intended for residential applications—even when acoustic performance appears comparable.

Safety Certifications & Compliance Impact on Acoustic Lighting Cost

Safety certifications are a key cost factor in commercial acoustic lighting projects. For public and architectural applications, compliance is mandatory and directly affects project approval, market access, and long-term operational safety.

Acoustic lighting fixtures integrate lighting systems, electrical components, and acoustic panels into a single product. As a result, they must comply with both lighting safety standards and fire performance requirements for acoustic materials.

In international commercial projects, common certification frameworks include:

- UL / ETL – North America

- CE & EN standards – Europe

- IEC-based systems – other global markets

These certifications focus on electrical safety, insulation performance, thermal management, structural strength, and safe installation of suspended or ceiling-mounted fixtures.

Because acoustic lighting uses felt or polyester acoustic panels, additional fire performance compliance is usually required. Fire-rated classifications such as EN 13501-1 are commonly specified for offices, public buildings, and commercial interiors.

Fire-rated acoustic lighting is mandatory for most commercial and architectural projects. Achieving this requires flame-retardant materials, controlled production processes, and third-party testing—directly increasing both material and certification costs.

From a cost perspective, compliance adds both direct and indirect expenses, including:

- Laboratory testing and certification fees

- Technical documentation and compliance reports

- Material upgrades for fire and safety standards

- Engineering adjustments for different regional regulations

These costs are largely independent of fixture size or appearance, yet have a direct impact on the final project price.

This is where manufacturer experience becomes critical. Suppliers who plan acoustic performance, fire safety, and electrical compliance as a single system can reduce approval risks and avoid costly redesigns later in the project.

Ultrathin Slim Round Acoustic LED Pendant Light

Input Voltage: AC100-277V / AC220-240V,50-60HZ

Housing Size: 120 mm

Emitting Direction: Downward

Size D*H: 500*80mm

CCT: 3000K / 4000K / 6000K

Power: 15W

Luminous Flux: 100-110Lm/W

CRI: >90Ra

PF: >0.90

Fllicker Free: Yes

Beam Angle: 120°

IP Grade: IP20

Acoustic Panel Color Option: Red / Green / Blue / Grey more than 48 colors option

Slim Anti-Glare Acoustic LED Linear Light

Input Voltage: AC100-277V / AC220-240V,50-60HZ

Housing Size: W58*H200 mm/ W58*H300mm

Emitting Direction: Downward

Length Option: 1218mm/ 1220mm/ 1288mm

CCT: 3000K / 4000K / 6000K

Power: 30W/ 32W

Luminous Flux: 100-110Lm/W

CRI: >80Ra

PF: >0.90

Flicker Free: Yes

IP Grade: IP20

Felt Acoustic Board Color: Red / Green / Blue / Grey more than 48 colors option

How These Factors Lead to Price Differences

From a visual perspective, many acoustic lighting fixtures appear similar in shape, size, and lighting output. However, their actual cost structure can vary significantly once performance requirements, safety standards, and project-specific conditions are considered.

In practice, the price difference between two seemingly identical acoustic lights is usually the result of multiple layered factors rather than a single component choice.

Key cost-driving differences include:

- Different felt thickness and density

Thicker or higher-density acoustic panels deliver better sound absorption (higher NRC values) but require more raw material and tighter production control. - Fire-rated vs. non-fire-rated materials

Acoustic felt certified to EN 13501-1 B-s1, d0 involves higher formulation, manufacturing, and testing costs compared to standard or B1-grade materials. - Certified vs. non-certified lighting systems

Compliance with CE, UL, ETL, or project-specific safety standards adds certification, documentation, and quality assurance costs that are often invisible to end users. - Custom sizes, shapes, and configurations

Acoustic ceiling lights, acoustic pendant lights, or acoustic baffle lighting designed for specific spaces usually require customized tooling, cutting, and assembly processes.

These differences explain why acoustic lighting solutions intended for commercial and international projects typically cost more than visually similar products used in residential or decorative applications.

How OEM & ODM Customization Affects Pricing

While previous sections focused on material specifications, fire ratings, and compliance requirements, another critical consideration for commercial acoustic lighting projects is how these products are implemented on-site. Installation feasibility, fixture design, acoustic felt material, thickness, and optical parameters such as LED layout, beam angle, and brightness can all influence project cost and efficiency. OEM and ODM customization addresses these practical considerations on a project-by-project basis.

When customers inquire about acoustic lighting, the main concerns usually include installation feasibility, acoustic felt material and thickness, fixture design, and optical parameters.

OEM and ODM customization addresses these factors project by project. Rather than over-specifying, professional manufacturers evaluate:

- Installation considerations: ceiling type, mounting method, and integration with existing architecture

- Acoustic material: felt type, thickness, and fire rating to match NRC requirements without overspending

- Fixture design: size, structure, and mechanical stability for safe and efficient installation

- Optical parameters: LED configuration, lumen output, and beam distribution to meet lighting needs efficiently

By aligning these parameters with actual project requirements, OEM/ODM solutions provide the optimal balance of performance, compliance, and cost. This approach often reduces unnecessary material or design costs, improves installation efficiency, and ensures long-term reliability for commercial acoustic lighting projects.

For example, a project in a space with good architectural acoustics may not need the highest NRC rating or the most expensive fire-rated felt. Selecting the right combination for each project avoids waste while maintaining compliance and performance.

Conclusion

The cost of acoustic lighting is determined not just by appearance or LED components, but by how acoustic performance, fire safety, compliance, and installation factors are applied. Today’s commercial projects often use integrated systems that combine lighting and sound absorption — for example, acoustic LED linear pendant lights for modern offices and open ceilings. OEM and ODM customization ensures the right balance of felt thickness, fire rating, LED layout, beam distribution, and installation design, helping projects stay compliant, cost-effective, and reliable.