Flowing LED lights can be used safely if basic installation, electrical, and usage precautions are followed. Like any electrical lighting system, safety depends less on the visual effect and more on how the product is selected, installed, powered, and operated over time. Problems usually arise not because flowing LED lights are inherently unsafe, but because they are misunderstood or used in conditions they were not intended for.

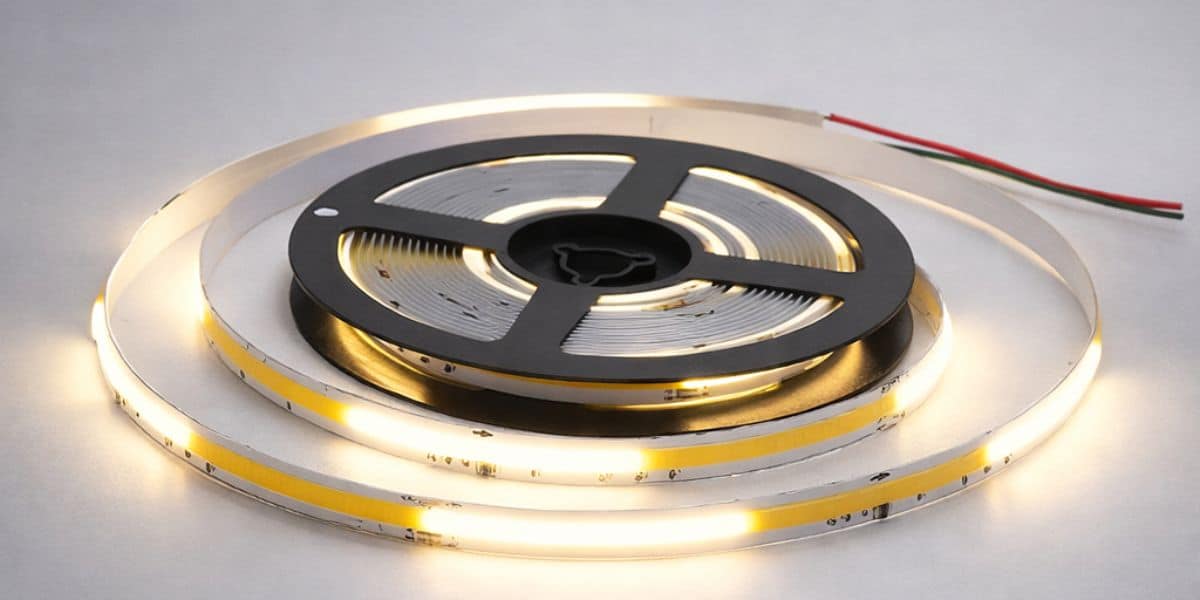

This article is written as a safety reference, not a design guide. It focuses only on practical risk prevention and best practices for using flowing LED lighting in real environments. The guidance applies to white-light flowing LED strips used for architectural, interior, or temporary installations. Product features are treated at a category level only, using a standard white flowing LED strip as context, such as those commonly found in professional lighting catalogs like this

flowing LED strip.

The goal is simple: explain how to use flowing LED lights safely, avoid common mistakes, and understand where they are appropriate and where they are not.

What Are Flowing LED Lights?

Flowing LED lights are linear LED lighting systems designed to create the visual impression of light moving smoothly along a strip. The key word here is “impression.” There is no physical movement in the strip itself. The LEDs remain fixed in place, and the flow effect is created by controlled changes in brightness along the length of the strip.

Important clarifications for safety understanding:

- The light emitted is white only.

- The flowing appearance is a visual effect, not mechanical motion.

- The strip does not move, rotate, or shift during operation.

- The effect depends on control behavior rather than physical components.

Because the flow is an optical effect, safety risks are not related to motion but to electrical handling, mounting stability, controller use, and environmental exposure. Misunderstanding how the effect works often leads users to misuse the product, which is where safety problems begin.

Why Safety Matters When Using Flowing LED Strips

Flowing LED strips are often chosen because they look calm, continuous, and modern. This visual softness can sometimes lead users to underestimate the importance of proper installation and operation. In reality, any linear lighting system carries electrical, mechanical, and environmental risks if handled carelessly.

Safety matters for several reasons:

- Electrical exposure risks

Poor wiring, loose connections, or damaged cables can lead to short circuits or shock hazards. - Mechanical stability issues

If a strip detaches from its mounting surface, it can fall, create tripping hazards, or expose wiring. - Operational misuse

Overly aggressive control settings can cause flicker or visual distraction, which may be unsafe in certain environments. - Environmental mismatch

Using the lighting in unsuitable locations increases the chance of damage, failure, or unsafe conditions.

Another critical factor is expectation. Some users assume the strip itself produces motion or animation. When reality does not match expectations, they may attempt unsafe modifications, forcing bends, adding unsupported accessories, or improvising power solutions. Understanding what the product does and does not do is a core part of safe use.

Electrical Safety Tips

Electrical safety is the foundation of using flowing LED lights responsibly. Even a perfectly mounted strip can become unsafe if the electrical setup is careless.

Proper Power Connection

Always use a power source that is appropriate for LED strip lighting systems. Connections should be deliberate, stable, and made according to the manufacturer’s general guidance. Improvised power adapters or makeshift connections increase the risk of overheating or failure.

Key practices include:

- Ensure all power connections are firm and secure.

- Avoid loose terminals or partially connected plugs.

- Do not modify connectors unless explicitly designed to be adjusted.

Secure Wiring

Wiring should be routed neatly and protected from tension. Cables that are pulled tight, twisted, or compressed are more likely to fail over time.

- Avoid running wires across sharp edges.

- Do not pinch cables between hard surfaces.

- Leave slight slack to accommodate natural movement or expansion.

Safe Controller Placement

Controllers are an active part of flowing LED systems. They should be placed where they are:

- Easily accessible for adjustment or shutdown.

Protected from accidental contact or impact.

- Not buried behind surfaces where heat can build up.

Placing a controller in an inaccessible or enclosed space makes it harder to respond quickly if something goes wrong.

Avoiding Exposed Connections

Exposed electrical connections increase the risk of accidental contact or environmental damage.

- Cover or shield connectors once installation is complete.

- Avoid leaving bare wiring visible.

- Inspect connection points periodically to ensure they remain intact.

Installation Safety Tips

Installation quality directly affects long-term safety. Many reported issues with flowing LED lights are caused by rushed or careless mounting rather than product failure.

Surface Preparation

Before mounting, the surface should be clean, dry, and stable. Dust, grease, or uneven textures reduce adhesion and increase the risk of detachment.

Good preparation includes:

- Cleaning the surface thoroughly.

- Allowing it to dry completely.

- Avoiding surfaces that are crumbling or unstable.

Secure Mounting

The strip should be mounted in a way that supports its full length evenly.

- Avoid partial attachment where only some sections are fixed.

- Do not rely on gravity or tension to hold the strip in place.

- Ensure corners and transitions are properly supported.

Avoiding Sharp Bends

Flowing LED strip are linear systems. Sharp bends stress internal components and can lead to damage or failure.

- Use gradual curves where direction changes are needed.

- Never force the strip into tight angles.

- Plan routing before installation to minimize bending.

Preventing Detachment

Over time, environmental factors can weaken mounting methods. Periodic inspection is a key safety habit.

- Check for sagging or peeling.

- Re-secure sections showing signs of loosening.

- Address issues early rather than waiting for failure.

Running Water Flowing COB LED Strip Light

- Main Model: FYA10T360C addressable

- LED Chip QTY per Meter: 360chips, 576chips (Sanan)

- IC Type: WS2811

- CRI: >90

- PCB Width: 10mm

- Color Temperature: 3000K/4000K/6000K/Dual color(2700K & 6500K)

- Input Voltage: DC24V

- Power per Meter: 360chips – 11W, 576chips – 10W+10W

- Cuttable Length: 360chips – 83.33mm, 576chips – 41.66mm

- IP Grade: IP20/IP54/IP65/IP67/IP68

- Warranty: 3 years

Environmental and Usage Safety

Where and how flowing LED lights are used has a direct impact on safety. Even a correctly installed system can become unsafe if placed in the wrong environment.

Indoor Use Considerations

For indoor environments, consider:

- Clearance from walkways to avoid contact.

- Placement away from areas where objects are frequently moved.

- Avoidance of locations where moisture or spills are likely.

Flowing LED lighting works best when it remains undisturbed. High-contact areas increase wear and risk.

Temporary Event Setups

Temporary installations deserve extra attention because they are often assembled quickly and dismantled just as fast.

- Secure cables to prevent tripping.

- Avoid running strips across open floors.

- Ensure all components are stable before allowing public access.

Temporary setups should be inspected more frequently than permanent ones.

Crowd and Movement Awareness

In public or semi-public spaces, consider how people move through the area.

- Avoid placing strips at foot level in crowded zones.

- Ensure lighting does not distract or disorient movement paths.

- Keep wiring out of reach where people may pull or snag it.

Heat and Ventilation

While flowing LED strips are efficient, they still generate heat.

- Do not enclose strips in airtight spaces.

- Allow airflow around the installation.

- Avoid stacking materials directly on top of the strip.

Heat buildup over time can shorten lifespan and create safety concerns.

Controller and Operation Safety

The controller determines how the flowing effect behaves. Safe operation depends on restraint and clarity rather than dramatic settings.

Avoiding Aggressive Settings

Excessively fast or abrupt flow patterns can be problematic.

- Rapid changes may cause visual strain.

- Harsh transitions can draw unintended attention.

- Overactive settings may encourage unnecessary adjustments or tampering.

A smooth, predictable flow is safer and more stable.

Why Smooth Flow Is Safer

Smooth flow:

- Reduces distraction in functional spaces.

- Maintains consistent light perception.

- Minimizes the urge to over-adjust controls.

From a safety perspective, subtle behavior is easier to manage and less likely to cause misuse.

Accessible Controllers

Controllers should always be reachable.

- Users should be able to turn the system off quickly.

- Adjustments should not require dismantling the installation.

- Emergency access should be straightforward.

An inaccessible controller turns small issues into larger risks.

Common Safety Mistakes to Avoid

This section addresses recurring errors that lead to safety problems.

Expecting Motion from the Strip

One of the most common mistakes is expecting the strip itself to move or animate physically. When users realize this is not the case, they may attempt unsafe modifications.

- Do not pull, twist, or reposition the strip during operation.

- Do not add mechanical movement.

- Accept that flow is purely visual.

Ignoring Cable Management

Loose or tangled cables are a frequent source of accidents.

- Avoid letting cables hang freely.

- Secure excess length properly.

- Keep wiring organized and labeled if necessary.

Poor Mounting

Rushed mounting leads to detachment and exposure.

- Do not rely on temporary fixes.

- Avoid mixing incompatible mounting methods.

- Treat mounting as a permanent safety decision.

Wrong Use Cases

Using flowing LED lighting in unsuitable situations increases risk.

- Do not use where dynamic color or animation is required.

- Do not substitute it for signaling or warning lights.

- Do not use it as a moving visual cue in safety-critical environments.

When Flowing LED Lights Are NOT Suitable

Understanding limitations is part of safe use.

Flowing LED lights are not suitable when:

- Color-changing signals are required for communication.

- Animated effects are needed to convey warnings or alerts.

- Visual motion could cause confusion or distraction.

- The environment demands rugged, impact-resistant lighting.

Using a flowing LED system outside its intended role often leads to unsafe improvisation. Selecting the right type of lighting for the job is safer than forcing a product to do what it was not designed to do.

Conclusion

Yes, there are clear and practical safety tips for using flowing LED lights. When installed correctly, powered responsibly, and operated with realistic expectations, flowing LED lighting can be used safely and reliably. Most safety issues arise not from the product itself but from misunderstanding, rushed installation, or misuse.

A safety-first mindset focuses on electrical integrity, stable mounting, controlled operation, and appropriate placement. By respecting these principles, users can avoid common risks and ensure that flowing LED lighting remains a safe visual feature rather than a source of problems.

FAQs

Yes, when installed properly, with secure mounting and correct electrical connections.

No. The flow is a visual effect created by light control, not physical motion.

Yes. Poor cable management is a common cause of tripping and electrical issues.

They can be used cautiously, provided wiring is protected and placement avoids contact.

Misunderstanding how the product works and trying to force it into unsuitable use cases.