The best LED tri-proof lighting solutions for warehouses and factories are fixtures specifically engineered to resist water, dust, and corrosion while delivering stable illumination, long lifespan, and low maintenance under harsh industrial conditions.

Compared with standard LED linear or vapor-tight fixtures, LED tri-proof lights provide superior environmental protection, thermal management, and operational reliability, making them the optimal choice for modern industrial facilities.

Warehouses and factories demand lighting systems that can operate continuously despite humidity, airborne contaminants, vibration, temperature fluctuations, and chemical exposure. Tri-proof LED lighting addresses these challenges through structural design, material selection, and advanced thermal and electrical engineering.

Why Warehouses and Factories Need Tri-Proof LED Lighting

Warehouses and factories need tri-proof LED lighting because standard industrial fixtures cannot reliably withstand long-term exposure to moisture, dust, vibration, and corrosive substances.

Typical environmental challenges in industrial facilities

Industrial buildings commonly expose lighting fixtures to multiple stress factors simultaneously:

- High humidity and condensation from temperature differentials

- Airborne dust, fibers, metal shavings, or flour particles

- Oil mist and chemical vapors from machinery

- Continuous vibration from conveyors and production equipment

- Regular cleaning or wash-down procedures

Standard LED linear fixtures often fail prematurely due to:

- Seal degradation

- Moisture ingress into drivers

- Corrosion of internal components

Tri-proof LED luminaires are designed to remain operational in these environments for years with minimal maintenance, reducing downtime and replacement costs.

What Is LED Tri-Proof Lighting? (Beyond IP Ratings)

LED tri-proof fixture is a type of industrial luminaire designed to resist water, dust, and corrosion through structural sealing, material engineering, and thermal design—not merely through a high IP rating.

The true meaning of “Tri-Proof”

The term “tri-proof” refers to resistance against:

- Water – humidity, splashing, condensation, and wash-down

- Dust – fine industrial particles that penetrate weak seals

- Corrosion – chemicals, oils, salt air, and cleaning agents

Why IP rating alone is insufficient

While IP ratings define ingress protection, they do not indicate:

- Seal longevity under thermal cycling

- Material resistance to chemicals

- Driver protection against moisture migration

For example, two fixtures with the same IP rating may have vastly different service lives depending on housing material, gasket compression design, and end-cap sealing method.

For a detailed technical comparison of ingress protection standards, refer to our in-depth article on IP65 vs IP67 vs IP69K LED tri-proof lights.

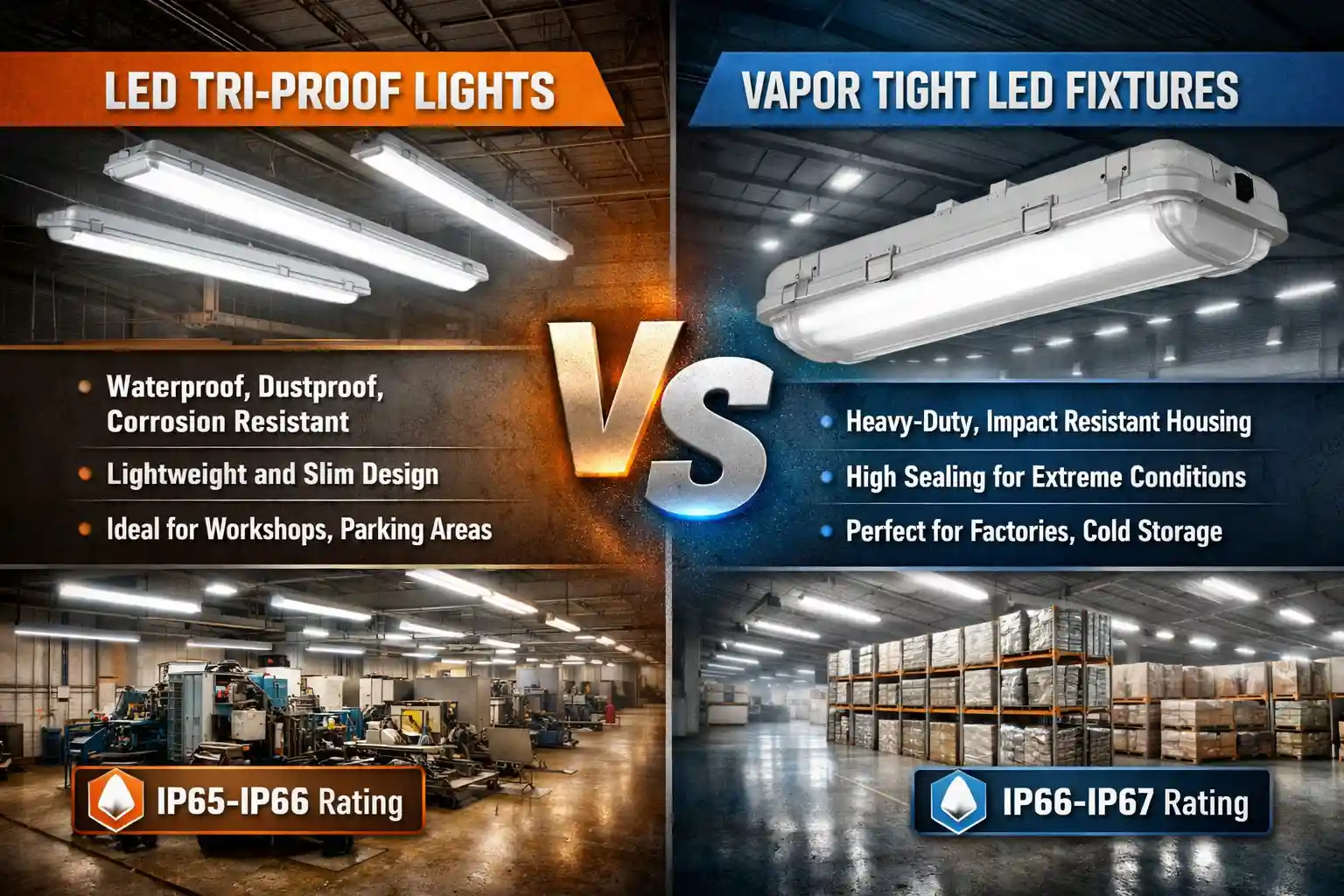

LED Tri-Proof Light vs Vapor Tight Light Fixture

Tri-proof LED luminaires outperform vapor-tight LED fixtures in environments with continuous moisture, chemical exposure, or high contamination risk.

Application-based comparison table

| Performance Factor | Vapor Tight LED Fixtures | Tri-proof LED Luminaires |

| Resistance to humidity | Moderate | High |

| Fine dust protection | Limited over time | Excellent |

| Chemical resistance | Often insufficient | Designed for it |

| Wash-down durability | Risk of seal fatigue | Built for repeated cleaning |

| Typical lifespan in harsh environments | 3–5 years | 5–8+ years |

When vapor-tight LED fixtures are sufficient

Vapor-tight LED fixtures can be used in:

- Utility corridors

- Storage rooms with occasional humidity

- Light industrial areas without chemicals

When LED tri-proof luminaires is mandatory

Tri-proof lighting is strongly recommended for:

- Manufacturing floors with oil mist

- Food and beverage production facilities

- Chemical processing workshops

- High-humidity warehouses

Key Factors When Choosing Tri-Proof Lights for Industrial Facilities

Selecting the right tri-proof LED light requires evaluating optical performance, mechanical durability, thermal management, and lifecycle cost—not just wattage or IP rating.

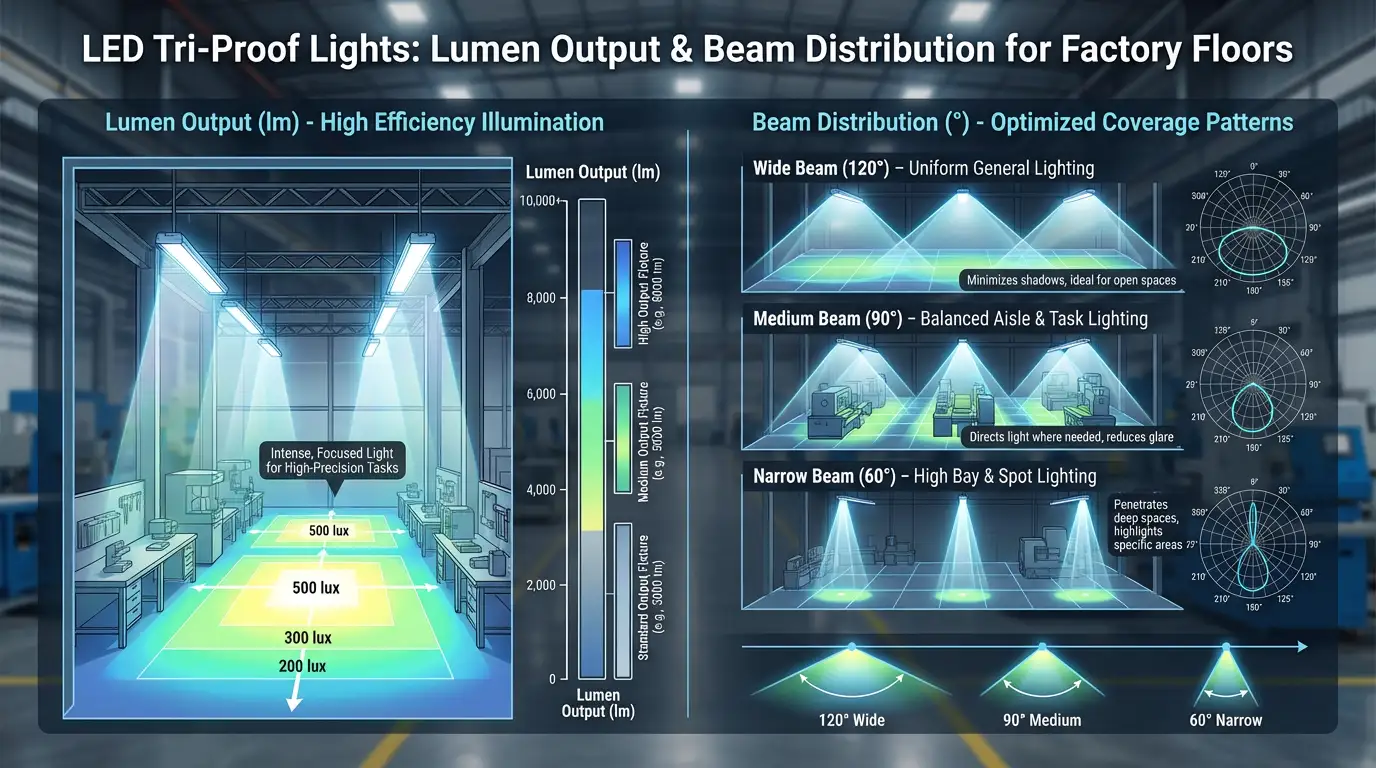

Lumen Output & Beam Distribution

Proper lumen output and beam distribution ensure safe and efficient illumination for different industrial layouts.

Typical requirements include:

- Narrow beam angles for warehouse aisles

- Wide, uniform distribution for open factory floors

- High vertical illumination for shelving and racks

Poor optical design can result in:

- Excessive glare

- Dark zones

- Reduced worker productivity

Mounting Height & Fixture Length

Correct fixture length and mounting height improve uniformity and reduce installation complexity.

Common industrial considerations:

- High ceilings (6–12 m) in warehouses

- Continuous linear installation for production lines

- Modular layouts for future expansion

Proper planning reduces wiring points and simplifies maintenance access.

Chemical & Corrosion Resistance

In food, chemical, and pharmaceutical facilities, corrosion resistance directly determines fixture lifespan.

Typical design features include:

- Aluminum alloy or reinforced polymer housings

- Anti-corrosion surface treatments

- Silicone or EPDM gaskets resistant to detergents and acids

These features allow fixtures to withstand aggressive cleaning and chemical exposure without seal failure.

Operating Temperature Range

LED tri-proof fixtures are designed to operate reliably across a wide temperature range, including extreme environments.

Common applications:

- Cold storage warehouses (down to –30°C)

- Refrigerated logistics centers

- High-temperature production workshops

Stable operation in extreme temperatures prevents driver failure and lumen degradation.

Maintenance Cost, Thermal Management & Lifespan

Superior thermal management is a key reason LED tri-proof fixtures achieve longer lifespans and lower maintenance costs.

Most LED tri-proof luminaires use:

- Aluminum alloy housings combined with metal-core PCBs (MCPCB)

- Thermal conductivity of MCPCB insulation layers typically ranges from 1.0 to 4.0 W/m·K, with high-end designs exceeding 3.0 W/m·K

- This is significantly higher than traditional FR4 boards (~0.3 W/m·K)

Improved heat dissipation can reduce LED junction temperature by 20–30°C, which:

- Extends LED lifespan

- Maintains lumen stability

- Reduces driver failure rates

Lower maintenance frequency translates directly into improved ROI for industrial facilities.

Best Applications of LED Tri-Proof Lights

Industrial sealed LED fixtures lights are best applied in industrial and commercial environments where moisture, dust, chemical exposure, or temperature extremes would rapidly degrade standard lighting fixtures.

Unlike conventional LED linear or high bay luminaires, tri-proof fixtures are engineered specifically for harsh operating conditions where long-term reliability and minimal maintenance are critical.

Common Industrial Applications

Warehouses and logistics centers

In modern warehouses, lighting systems are frequently exposed to dust from packaging materials, vibration from automated conveyors, and occasional wash-down operations. Tri-proof LED lights provide sealed protection that prevents dust ingress and moisture accumulation, ensuring consistent lumen output in racking aisles, loading zones, and sorting areas.

Manufacturing plants and assembly workshops

Factory floors often involve airborne particles, oil mist, and continuous vibration from machinery. Tri-proof LED luminaires with reinforced housings and silicone gaskets maintain optical clarity and electrical integrity in these environments, reducing the risk of premature failure compared to standard LED battens.

Food and beverage processing facilities

Food production areas require luminaires that can withstand frequent cleaning, high humidity, and exposure to mild chemicals. This sealed industrial LED luminaires with corrosion-resistant housings and food-safe materials are widely specified in processing lines, cold rooms, and packaging zones where hygiene compliance is mandatory.

Pharmaceutical and cleanroom-adjacent areas

In pharmaceutical facilities, stable illumination and sealed construction help prevent contamination risks. Tri-proof fixtures are commonly installed in preparation areas, corridors, and utility spaces where dust control and wash-down resistance are required but full cleanroom lighting is not necessary.

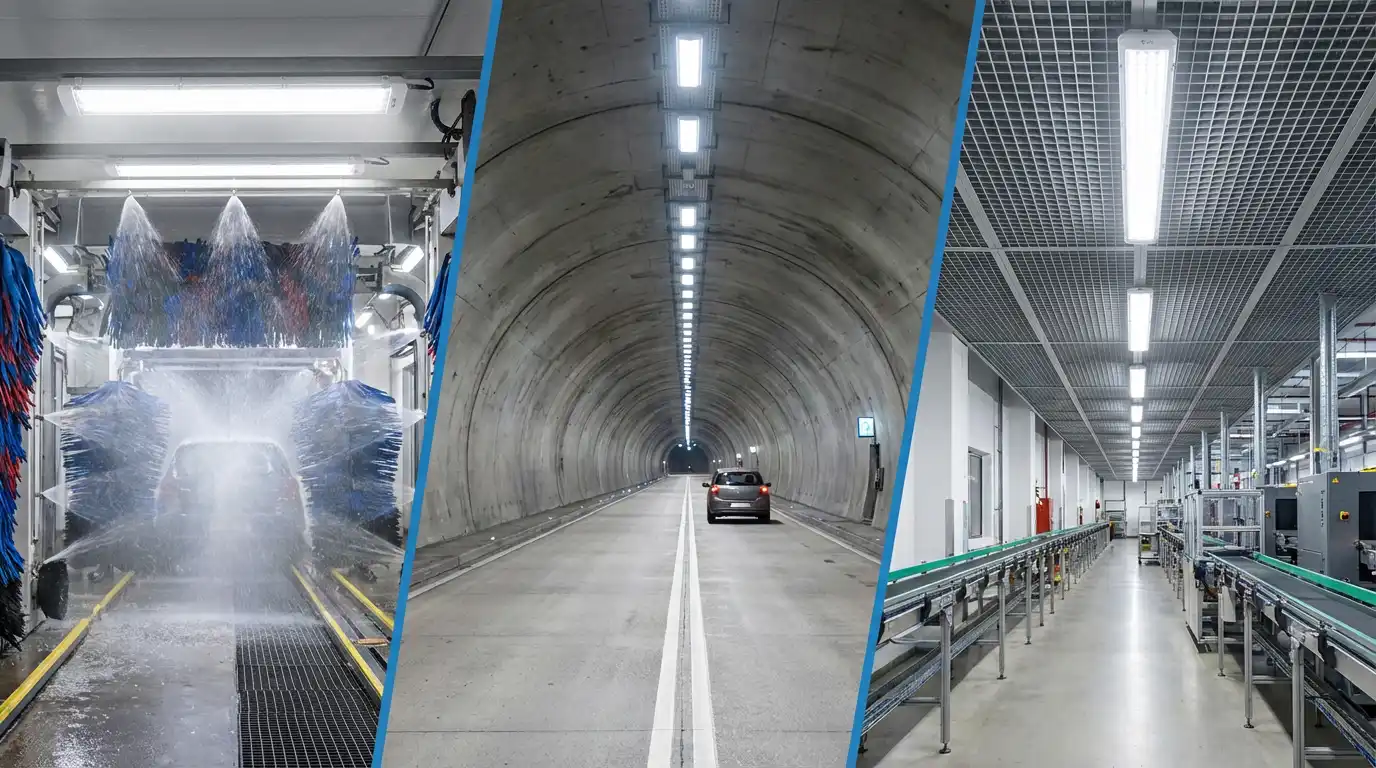

Car washes, tunnels, and industrial corridors

Environments with direct water spray, condensation, or temperature fluctuation demand luminaires that can operate reliably without internal corrosion or electrical degradation. LED tri-proof lights are particularly well suited for car wash tunnels, underground corridors, and service passages.

Summary Table: Application Suitability

| Application Area | Environmental Challenge | Why Tri-Proof Lighting Is Suitable |

| Warehouses & logistics | Dust, vibration, occasional moisture | Sealed housing prevents ingress |

| Manufacturing plants | Oil mist, particles, vibration | Reinforced structure and gaskets |

| Food & beverage factories | Wash-down, humidity, chemicals | Corrosion-resistant construction |

| Cold storage facilities | Low temperatures, condensation | Wide operating temperature range |

| Car washes & tunnels | Direct water exposure | Waterproof and vapor-tight design |

How Industrial Tri-proof Lighting Improves Energy Efficiency & ROI

Corrosion-resistant industrial LED luminaires improve energy efficiency and return on investment by reducing power consumption, minimizing maintenance costs, and extending service life in harsh industrial environments.

Compared with fluorescent vapor-tight fixtures and standard LED battens, tri-proof luminaires deliver measurable financial and operational advantages over the full lifecycle.

Energy Efficiency Comparison

| Lighting Type | Typical Wattage (4ft Equivalent) | Luminous Efficacy | Annual Energy Use* | Energy Saving Potential |

| Fluorescent vapor-tight | 96–120 W | 70–85 lm/W | High | Baseline |

| Standard LED batten | 45–60 W | 110–130 lm/W | Medium | 30–40% |

| LED Tri-Proof Light | 40–55 W | 130–160 lm/W | Low | 40–60% |

*Based on 12 hours/day, 300 days/year operation.

Thermal Management & Lifetime Impact

| Design Element | Technical Specification | Measured Benefit |

| Housing material | Aluminum alloy with finned structure | Improved convective heat dissipation |

| PCB type | Metal-core PCB (MCPCB) | Stable LED operation |

| Thermal conductivity | 1.0–4.0 W/m·K (premium >3.0 W/m·K) | 3–10× higher than FR4 |

| Junction temperature reduction | 20–30°C lower than standard LED batten | Slower lumen depreciation |

| Rated lifespan | 50,000–80,000 hours | Fewer replacements |

Reduced Maintenance and Downtime Costs

In warehouses and factories, lighting maintenance often requires:

- Production downtime

- Lift equipment or scaffolding

- Labor and safety management

LED tri-proof lights typically offer 50,000–80,000 hours of rated lifespan, reducing the frequency of fixture replacement. Fewer failures translate directly into lower maintenance expenditure and improved operational continuity.

Emergency Series LED Tri-proof Light

Model No: TRA06X20F-EM/TRA12X40F-EM/TRA15X50F-EM

Dimension: 662/1272/1566x86x80mm

Input Voltage: 100-277VAC, 50/60Hz

Watts: 20W/40W/50W

Efficacy: 130lm/W

CCT: 3000K, 4000K, 6500K

CRI: >80

IP rating: IP65

Dimming: 0-10V/Triac/DALI/PWM

Emergency Power: 8-12W

Emergency Time: 60-120mins

Certification: CE, RoHS

Warranty: 5years

Energy Savings Compared to Traditional Solutions

When replacing fluorescent vapor-tight fixtures, LED tri-proof fixtures can reduce energy consumption by 40–60%, depending on operating hours and system configuration.

Additional savings may be achieved through:

- Motion sensors in low-traffic areas

- Dimming controls for variable-use zones

- Daylight harvesting in perimeter spaces

Payback Period and Long-Term ROI

For most warehouse and factory projects, the typical payback period for industrial tri-proof lighting upgrades ranges from 18 to 36 months.

Facilities operating in multi-shift or 24/7 environments often realize faster returns due to higher annual operating hours.

LED vs fluorescent vapor-tight comparison

| Factor | Fluorescent Vapor Tight | Tri-proof industrial LED fixture |

| Energy consumption | High | Low |

| Startup time in cold | Slow | Instant |

| Maintenance frequency | High | Low |

| Typical lifespan | 15,000–20,000 h | 50,000–80,000 h |

In large warehouses, reduced maintenance and downtime often contribute more to ROI than energy savings alone.

Why Choose SignliteLED tri-proof LED luminaire Solutions

SignliteLED tri-proof LED solutions are designed for industrial reliability, customization, and global compliance.

Key advantages include:

- OEM / ODM customization capabilities

- Compliance with major international standards

- Flexible options for wattage, CCT, dimming, and mounting

- Engineering support for warehouse and factory projects

For procurement planning and specification strategies, refer to our LED tri-proof lights buyer’s guide.

HS Series – High-Performance LED Tri-proof Light

- Robust Mitsubishi polycarbonate housing with UV resistance and V0 fire safety

- Internal aluminum heat sink for excellent thermal management

- High efficacy LED batten light: up to 160lm/W

- Trusted Osram driver, backed by a 5-year warranty

- Supports 0–10V, Triac, DALI, ZIGBEE dimming

- Daisy chain connection for simplified installation

- Optional emergency backup and cold room LED lighting options

For large-scale warehouse and factory projects, selecting the right LED tri-proof lighting partner is not only about product specifications, but also about long-term reliability, compliance assurance and consistent performance across diverse industrial environments.

These sealed industrial fixtures are widely adopted in industrial facilities due to its reliability in harsh environments where moisture, dust, temperature fluctuation, and chemical exposure are common.

In warehouses, factories, and production plants, tri-proof luminaires are often specified as industrial-grade linear LED fixtures, sealed LED batten lights, or corrosion-resistant LED lighting systems.

From a technical perspective, industrial LED tri-proof fixtures are frequently evaluated alongside waterproof LED lights, dustproof LED luminaires, and anti-corrosion LED lighting for industrial buildings. These terms are commonly used in engineering specifications, tender documents, and procurement lists, even when they refer to tri-proof lighting solutions.

In warehouse lighting design, such luminaires are selected for high-bay and mid-bay installations, continuous linear systems, and aisle lighting layouts. Common search variations include warehouse waterproof LED lights, industrial LED batten lights, and sealed linear LED fixtures for logistics centers.

For factory environments, tri-proof luminaires are often compared with explosion-proof LED lights, vapor-tight LED fixtures, and heavy-duty industrial lighting, particularly in manufacturing plants, workshops, and processing facilities. While explosion-proof lighting serves hazardous zones, such lighting is typically specified for non-explosion industrial areas requiring long-term durability and moisture resistance.

In food processing, pharmaceutical manufacturing, and clean production zones, LED tri-proof lights are associated with hygienic lighting solutions, wash-down LED fixtures, and corrosion-resistant industrial luminaires. These terms reflect application-driven requirements rather than strict product categories, reinforcing the relevance of tri-proof lighting in regulated industrial environments.

From a materials and engineering standpoint, such fixtures are commonly described using phrases such as aluminum housing LED fixtures, polycarbonate LED battens, silicone-gasket sealed lights, and industrial LED luminaires with reinforced end caps. These descriptors are frequently used by lighting designers and engineers when searching for long-life industrial lighting solutions.

In cold storage and refrigerated logistics, related semantic terms include low-temperature LED lighting, freezer warehouse LED lights, and cold-room waterproof luminaires. These queries emphasize operational stability at sub-zero temperatures rather than general waterproof performance.

Energy efficiency–focused searches often associate tri-proof LED luminaire with high-efficacy industrial LED fixtures, long-life LED luminaires, low-maintenance industrial lighting, and energy-saving LED solutions for factories and warehouses. These phrases support lifecycle cost and ROI-oriented search intent.

Conclusion

The best LED tri-proof lighting solutions for warehouses and factories combine environmental resistance, advanced thermal management, and long-term operational efficiency.

By selecting properly engineered tri-proof fixtures, industrial facilities can achieve safer working conditions, lower maintenance costs, and sustainable energy performance over the entire lifecycle.

FAQ

Yes—such lights are generally a better choice for warehouses and factories operating in harsh or demanding environments.

While vapor-tight LED fixtures are suitable for basic moisture and dust protection, tri-proof lights are specifically engineered to withstand continuous exposure to dust, water, vibration, and corrosive substances commonly found in industrial facilities.

Yes, LED tri-proof lights are widely used in food and beverage processing facilities.

Their sealed housing design prevents dust, moisture, and contaminants from entering the fixture, making them ideal for hygienic environments that require frequent cleaning.

Most industrial LED tri-proof lights are designed to last 50,000 to 80,000 hours under normal operating conditions.

Thanks to efficient thermal management—often using aluminum housings combined with metal-core PCBs—LED tri-proof fixtures can maintain lower junction temperatures and slow lumen depreciation.

No, LED tri-proof lights are designed for low maintenance operation in industrial environments.

Their sealed construction prevents internal contamination, significantly reducing the need for frequent cleaning or component replacement.