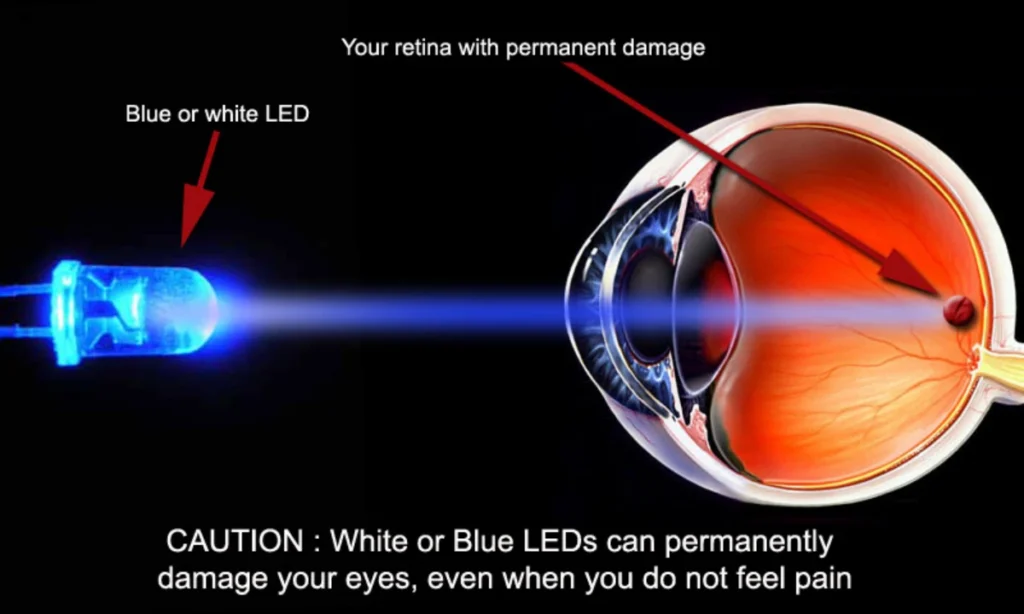

La luz azul es una parte natural del espectro visible, pero la iluminación LED moderna contiene una cantidad proporcionalmente mayor de longitudes de onda azules, generalmente en el rango de 400 a 500 nm, debido a la forma en que se fabrican los LED blancos. La mayoría de los LED blancos utilizan un chip LED azul combinado con recubrimiento de fósforo para generar luz blanca de espectro completo. Si bien esta tecnología proporciona una alta eficiencia y una excelente producción de lumen, también presenta preocupaciones sobre el peligro de la luz azul, un riesgo fotoquímico para la retina humana causado por la exposición excesiva a la radiación azul de alta energía.

En los últimos años, los reguladores, los diseñadores de iluminación y los fabricantes de OEM han prestado una atención creciente a los efectos potenciales de la luz azul. La exposición a largo plazo o de alta intensidad puede contribuir al estrés de la retina, al malestar visual y al trastorno del ritmo circadiano. A medida que la iluminación LED se usa ampliamente en oficinas, hogares, escuelas, espacios comerciales y exhibiciones, la comprensión y el control de los peligros de la luz azul se ha vuelto esencial para garantizar tanto la seguridad visual como el cumplimiento de los estándares fotobiológicos.

Este artículo se centra en el peligro de luz azul como se define en IEC 62471, explicando las métricas técnicas clave, las clasificaciones de grupos de riesgo y cómo elegir tiras de luces LED con menor peligro de luz azul para aplicaciones de iluminación profesional.

¿Qué es el peligro de luz azul bajo IEC 62471?

El peligro de luz azul se refiere al daño fotoquímico potencial a la retina causado por la exposición a longitudes de onda azules de alta energía, generalmente dentro de 400 a 500 nm. Cuando el ojo se expone a una luz azul intensa durante una duración suficiente, se pueden formar especies reactivas de oxígeno en los tejidos de la retina, acelerando la degradación de las células de la retina. Este efecto es acumulativo y depende tanto de la intensidad como del tiempo de exposición, lo que lo convierte en una consideración de seguridad crítica para los productos de iluminación vistos directamente, como tiras de LED, módulos y pantallas.

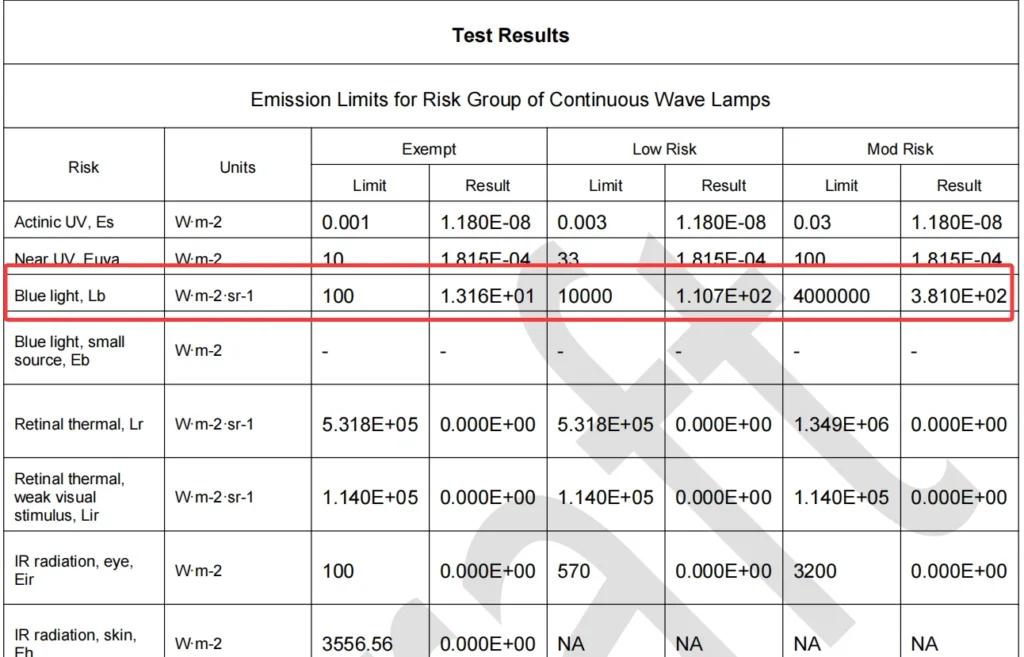

IEC 62471 es el estándar reconocido internacionalmente que evalúa la seguridad fotobiológica de las lámparas y los sistemas de lámparas. Define los métodos de medición, los espectros de acción de peligro, los límites de exposición y las clasificaciones de grupos de riesgo para diferentes riesgos fotobiológicos, incluidos los peligros de la luz azul, el peligro de los rayos UV y el peligro de radiación IR. Específicamente para la evaluación de la luz azul, IEC 62471 utiliza una luminosidad azul-ligerativa y calcula los tiempos máximos de exposición seguro para determinar el grupo de riesgo apropiado.

A medida que avanza la tecnología de iluminación LED, el cumplimiento de la norma IEC 62471 se vuelve esencial. Debido a que los LED a menudo tienen picos azules fuertes debido a su diseño convertido de fósforo, deben someterse a pruebas de peligro de luz azul para garantizar que cumplan con los umbrales de seguridad para la exposición humana. Ya sea para aplicaciones residenciales, comerciales o profesionales, se espera que los productos LED se clasifiquen como RG0 o RG1 para ingresar a muchos mercados globales, lo que hace que las pruebas IEC 62471 sean parte obligatoria del desarrollo de productos LED.

Parámetros técnicos clave para evaluar el peligro de luz azul

1. Radiance azul ligero ponderado (L_B)

La luminosidad azul ponderada (L_B) es el parámetro central utilizado en IEC 62471 para cuantificar el peligro de luz azul. Representa la luminosidad de una fuente de luz ponderada por la función de peligro de luz azul B(λ), que enfatiza las longitudes de onda más dañinas para la retina (alrededor de 435 a 440 nm). La unidad es W·m⁻²·sr⁻¹, expresando cuánta energía azul-pesada llega al ojo por unidad de área y por unidad de ángulo sólido.

Cómo se determina:

Las pruebas implican medir la radiación espectral de la fuente utilizando un espectrorradiómetro calibrado. Cada componente de longitud de onda se multiplica por la función de ponderación de peligro azul B(λ), y la integración en 300–700 nm produce el valor final L_B. IEC 62471 requiere mediciones a una distancia estandarizada (típicamente 200 mm) y exige que la prueba capture el punto de luminancia máximo de la fuente. Para tiras de LED, esto significa medir el chip o punto de acceso más brillante. Tiras de mazorca Por lo general, muestran una distribución de luminosidad más suave, lo que resulta en una menor L_B en comparación con las tiras SMD de fuente puntual.

2 Exposición radiante con luz azul (H_B)

La exposición radiante con luz azul (H_B) se refiere a la cantidad total de energía azul-ligera entregada a la retina con el tiempo, teniendo en cuenta tanto la luminosidad como la duración de la exposición. Mientras que L_B describe la intensidad en un momento, H_B representa la exposición acumulativa y se expresa en J·M⁻²·SR⁻¹. La IEC 62471 usa H_B como parámetro de apoyo en escenarios donde la fuente se extiende o se ve a corta distancia durante períodos más largos. Este parámetro se vuelve esencial en aplicaciones como iluminación de tareas, pantallas y luminarias instaladas en entornos de campo cercano.

3. Límite de exposición a la luz azul (T_MAX)

Para determinar cuánto tiempo puede ver una persona de manera segura una fuente de luz, IEC 62471 define el tiempo máximo de exposición permitido (T_MAX). Se deriva comparando el L_B medido con el límite de exposición definido para el peligro de luz azul. La expresión IEC simplificada es:

T_max = 100 / L_B

(Válido cuando L_B ≥ 100 W·m⁻²·sr⁻¹)

Esto significa que a medida que aumenta el luminosidad azul-ligeramente, el tiempo de visualización seguro permitido disminuye considerablemente. Por ejemplo, si L_B es de 200 W·m⁻²·sr⁻¹, la exposición máxima segura sería de solo 0,5 segundos. Esta fórmula guía la clasificación de grupos de riesgo y ayuda a determinar si un producto cae en RG0 (no riesgo), RG1 (riesgo bajo), RG2 (riesgo moderado) o RG3 (riesgo alto). En la iluminación LED, especialmente tiras y módulos diseñados para la visualización directa, cumplir con el umbral T_MAX es fundamental para garantizar un uso seguro y el cumplimiento de las normas.

IEC 62471 Clasificación del grupo de riesgo de luz azul

IEC 62471 clasifica los productos de iluminación en cuatro grupos de riesgo en función de su luminosidad azul-ligera (L_B) y el tiempo máximo de exposición seguro máximo correspondiente (T_MAX). Estas categorías ayudan a determinar si un producto es seguro para la visualización humana directa.

1. Grupo de riesgo 0 (RG0 - Exento)

Sin riesgo fotobiológico.

Límite: L_B ≤ 100 W·m⁻²·sr⁻¹ o T_max ≥ 100 s.

2 Grupo de riesgo 1 (RG1 – Bajo riesgo)

Sin peligro bajo condiciones normales de visualización.

Límite: L_B ≤ 10.000 W·m⁻²·sr⁻¹ o T_max ≥ 0.01 s.

3. Grupo de riesgo 2 (RG2 - Riesgo moderado)

Peligro solo si el espectador mira fijamente a la fuente.

Límite: L_B ≤ 400.000 W·m⁻²·sr⁻¹.

4. Grupo de riesgo 3 (RG3 – Alto Riesgo)

Peligro de una exposición momentánea incluso.

Límite: L_B > 400.000 W·m⁻²·sr⁻¹.

Ejemplo de niveles de peligro de luz azul para diferentes productos de iluminación

| Tipo de producto de iluminación | Típico CCT | Óptica / Difusión | Grupo de riesgo típico |

| Tira LED COB (cubierta helada) | 3000K | Difusión fuerte | rg0 |

| Tira LED COB (desnudo) | 2700-6500K | Sin cobertura | rg0 |

| Tira LED SMD 2835 (alta densidad) | 4000K | Sin cobertura | rg1 |

| SMD 5050 RGB | Longitudes de onda mixtas | Sin cobertura | rg1 |

| Luz lineal con difusor de PC | 3000-4000K | Difusor escarchado | rg0 |

| Luz descendente LED | 3000-5000K | Lente + Reflector | rg1 |

| Luz industrial de bahía alta | 5000-6000K | haz estrecho | rg2 |

| Foco LED de escenario / estudio | 6000–8000K | haz concentrado | RG2-RG3 |

Cómo elegir tiras de luces LED con menor peligro de luz azul

1. Elija tiras de LED CCT más bajas

Las tiras de LED blancos cálidos (2700K–4000K) contienen significativamente menos contenido de longitud de onda azul de alta energía. Las opciones de CCT más bajas reducen naturalmente el peligro de luz azul y son ideales para iluminación ambiental residencial, hotelera y comercial.

2. Seleccione tiras de LED de alta CRI

Los LED de alta CRI utilizan formulaciones de fósforo mejoradas que producen un espectro más suave y completo con picos azules reducidos. Las tiras CRI 90+ o CRI 95+ generalmente ofrecen un rendimiento óptico más seguro en comparación con los LED de bajo CRI.

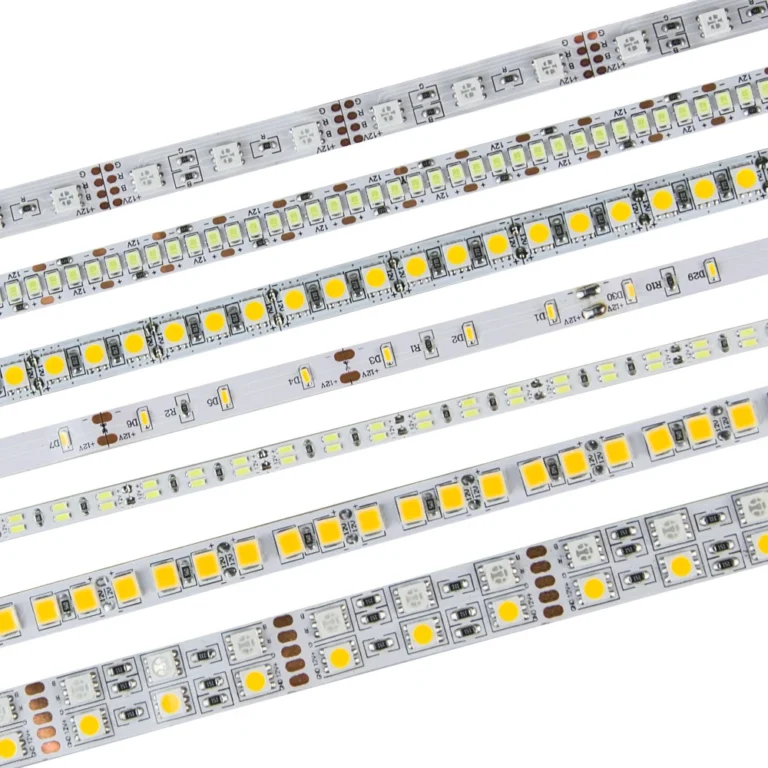

3. Prefiere tiras de LED COB sobre SMD

Las tiras de COB cuentan con emisores recubiertos de fósforo continuos que eliminan los puntos calientes de fuente puntual intensos. Su luminancia uniforme da como resultado una menor luminosidad azul-ligera (L_B), lo que hace que COB sea una opción más segura que SMD en aplicaciones de visualización cercana.

Lámpara de tiras COB sin costuras, RA90, compatible con IEC 62471

Modelo Nº: FYX08T480X

Tensión de entrada: DC12V/24V

Potencia: 11W/m

Cantidad de LED: 480 LED/m

CCT: 2700K, 3000K, 4000K, 6500K

CRI: >95

Eficacia: 105lm/W

Ángulo del haz: 180

Sección de corte: 25mm/50mm

Clasificación IP: IP20/IP65/IP67/IP68

Garantía: 3 años

4. Elija tiras de alta eficacia y baja potencia

Los LED impulsados a menor corriente generan menos luminosidad y producen un espectro más estable. Los diseños de baja potencia de alta eficiencia reducen tanto la intensidad del pico azul como el estrés térmico. Revise la luz de tira de 180lm/W Signliteled FQM10T128C.

5. Usar soluciones difusas

Tiras emparejadas con difusores, como tubos de silicona esmerilado, Flex de neón, o canales de aluminio rígidos con cubiertas de PC: reducen significativamente la luminancia máxima, reduciendo el peligro de luz azul y mejorando el confort visual.

Lámpara de tira de neón doblada superior

Modelo No.: NQX1010TC

Tensión de entrada: DC12V/24V

Vatios: 8W/m

Cantidad de LED: SMD2835 120LED/m

Temperatura de color: 2700K/4000K/6500K

CRI: RA>80

Diámetro de flexión mínimo: 25 mm

Longitud de corte: 100 mm

Longitud: 5 metros/rollo

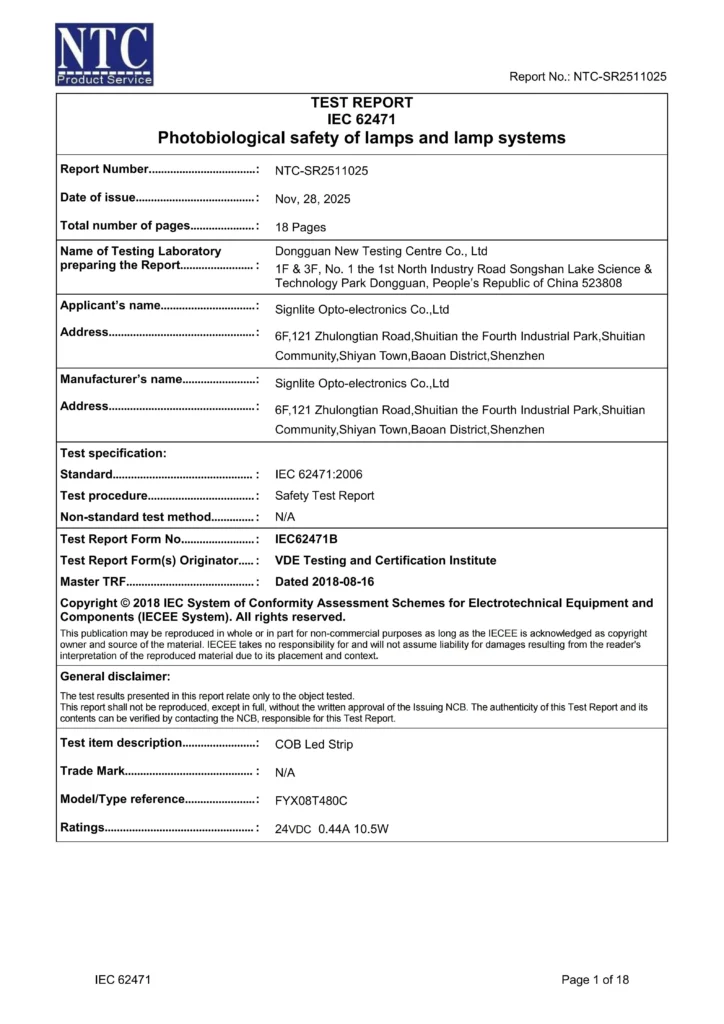

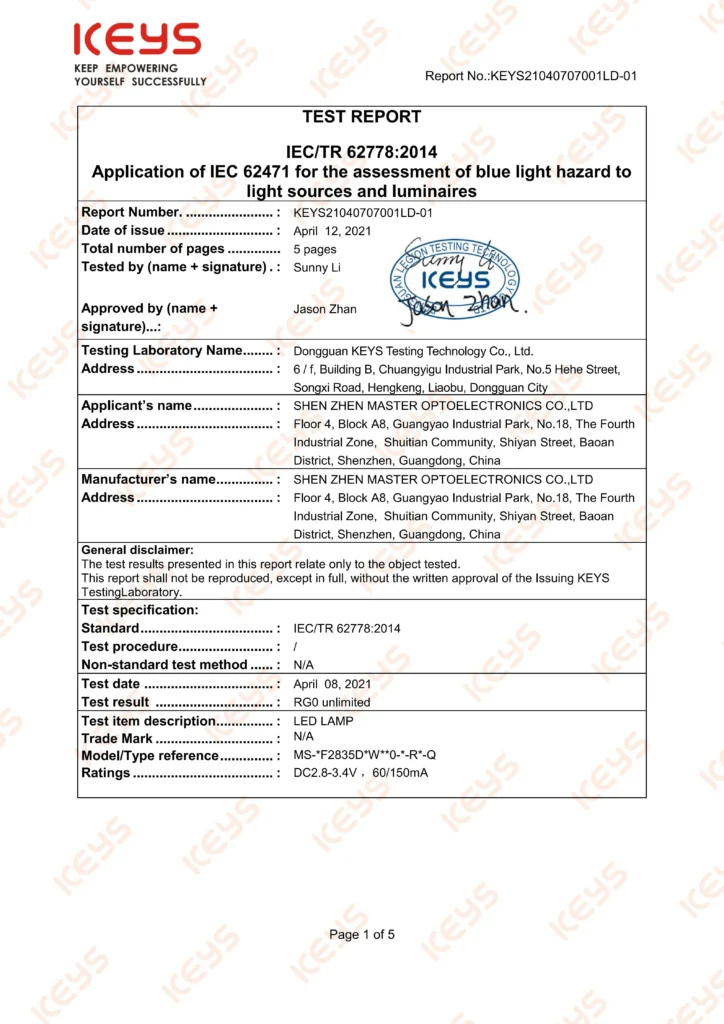

6. Elija tiras de LED con certificación IEC 62471

Solicite siempre un informe completo de IEC 62471. Los productos clasificados RG0 o RG1 garantizan el cumplimiento de los requisitos de seguridad fotobiológica global.

SignLiteled ofrece luces de tira COB certificadas por IEC 62471, tiras LED SMD SMD de baja, tiras LED Neon Flex y módulos LED, que brindan soluciones seguras y confiables para proyectos de iluminación profesionales.