As LED tape lights become a staple in modern lighting across commercial, architectural, and retail projects, the role of LED tape light channels—also known as LED aluminum profiles or LED mounting channels—has become indispensable. These slim yet functional housings offer structural support, thermal management, light diffusion, and aesthetic enhancement.

Whether you’re an importer, lighting designer, or contractor, understanding the different types of LED channels, their applications, sourcing considerations, and cost trends is essential to ensure both performance and long-term project value.

What are LED Tape Light Channels?

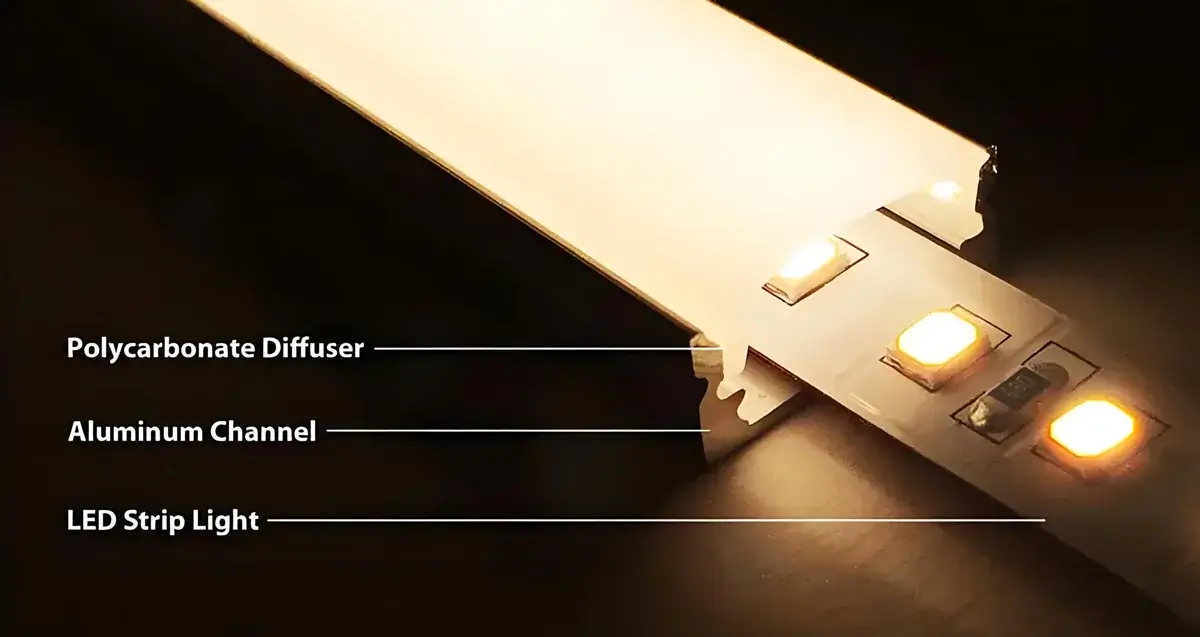

LED tape light channels, often called LED aluminum profiles, LED strip light housings, or LED extrusion profiles, are specially designed enclosures made from high-quality aluminum. These channels are created to house and protect flexible LED strips while offering both functional and aesthetic benefits. When paired with diffusers, usually made from polycarbonate (PC) or PMMA, these channels deliver substantial improvements to both performance and visual appeal.

Key Benefits of LED Tape Light Channels

Efficient Heat Dissipation

LED tape light channels are made of aluminum, which is an excellent thermal conductor. This material helps dissipate the heat generated by the LED strips, preventing overheating that could reduce the lifespan and performance of the lights. As a result, LED tape light channels help maintain optimal operating temperatures, enhancing the brightness, color consistency, and extending the lifespan of the LEDs (often up to 50,000 hours).

Light Diffusion

Without proper diffusion, LED strips can create harsh hot spots, resulting in uneven lighting. The diffusers used in LED tape light channels soften and spread the light evenly across the surface, ensuring uniform, soft illumination. This helps to eliminate any visible hotspots, providing a more aesthetically pleasing and consistent lighting effect, which is ideal for both task lighting and decorative applications.

Mechanical Protection

LEDs are sensitive to external damage from dust, moisture, and impacts. The aluminum LED housing for strip lights, commonly referred to as LED extrusion profiles, protects the LEDs from physical damage, moisture, and dust accumulation.. This protective feature ensures the longevity and performance of the LED strips, making them suitable for both indoor and outdoor applications, especially in areas like bathrooms, kitchens, or exterior facades.

Professional and Aesthetic Finish

For high-end installations, linear LED light channels create a seamless look that integrates into furniture, ceilings, and architectural details. The clean lines and uniform illumination enhance the space’s overall aesthetic.

Additional Benefits

Customizable Length and Shape: Available in various standard and custom lengths, LED tape light channels can be adapted to suit the unique requirements of your design, providing flexibility for different installation setups.

Improved Energy Efficiency: By managing heat effectively and diffusing light evenly, LED tape light channels help optimize the performance of the lighting system, resulting in better energy efficiency and reduced operational costs.

Easy Installation: Most LED tape light channels come with mounting clips, end caps, and screws, simplifying the installation process. This ensures a secure, long-lasting fit in both residential and commercial environments.

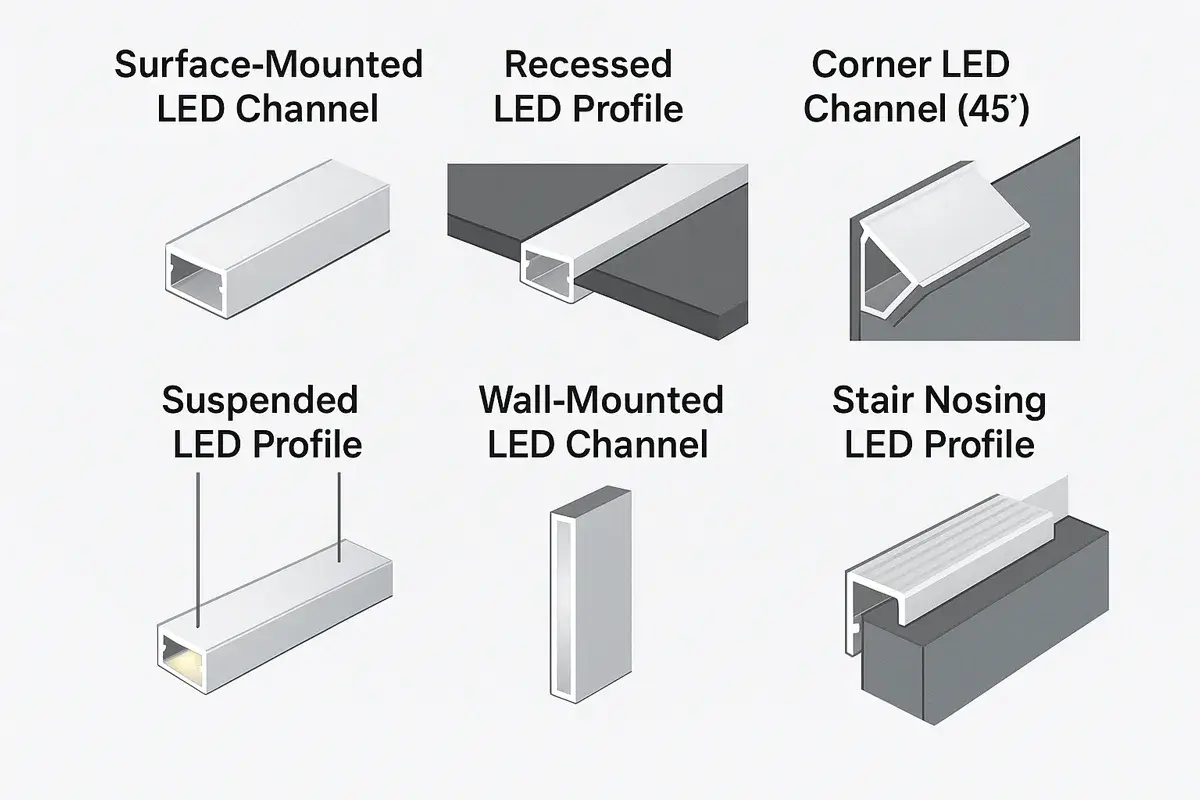

Types of LED Tape Light Channels

Selecting the right LED channel (also known as LED profile) is essential for ensuring both the visual effect and structural stability of your linear lighting design. Below are the most common types of aluminum LED profiles used across architectural, retail, and commercial spaces.

Selecting the right LED channel (also known as LED profile) is essential for ensuring both the visual effect and structural stability of your linear lighting design. Below are the most common types of aluminum LED profiles used across architectural, retail, and commercial spaces.

| Types of LED Tape Light Channels | Mounting Method | Typical Application | Advantages |

| Surface Mounted LED Channel | Installed directly onto walls, ceilings, or furniture | Under-cabinet lighting, shelf lighting, linear accent lighting | Easy to install, low-profile, ideal for surface applications |

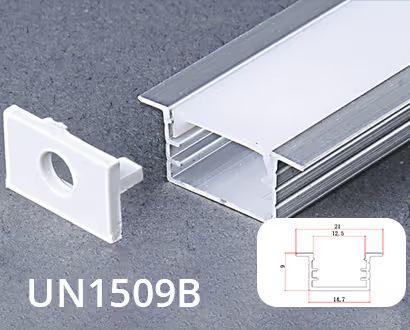

| Recessed LED Profile | Embedded flush into surfaces (drywall, furniture, ceilings) | High-end interiors, retail displays, hospitality lighting | Seamless, minimalist look with hidden light source |

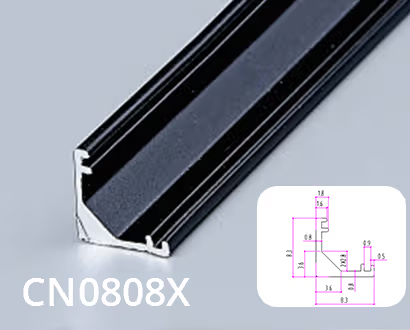

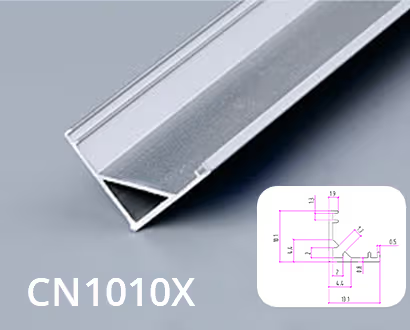

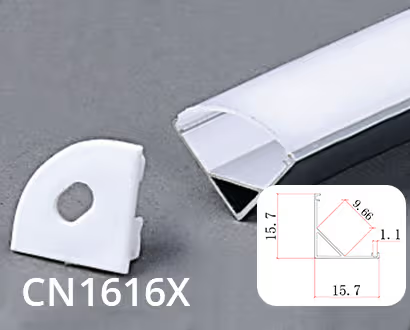

| Corner LED Channel | Installed in 90° corners | Cabinet corners, staircase lighting, display boxes | Creates directional beam angle; ideal for tight or angular spaces |

| Suspended LED Profile | Hung via suspension kits or wires | Open-plan offices, workspaces, commercial foyers | Modern linear pendant effect; supports both direct and indirect lighting |

| Wall-Mounted LED Channel | Fixed along vertical surfaces | Hallways, staircases, signage edges | Excellent for architectural highlighting and ambient lighting |

| Stair Nosing LED Profile | Integrated into stair edges | Step lighting for homes, hotels, theaters | Enhances safety and aesthetics simultaneously |

Tips for Choosing the Right LED Channel or Profile

Selecting the right LED channel involves balancing functionality, aesthetics, and installation environment.

Functionality: Surface-mounted channels are ideal for visible linear lighting and quick installation. For contemporary cove lighting, choose recessed linear LED light channels that provide a hidden, polished appearance.

Design Aesthetic: Use corner profiles for angled or directional lighting. Suspended profiles are best for statement lighting in open office or commercial spaces.

Durability & Application: For wet or outdoor areas like bathrooms or facades, opt for IP65/IP67-rated waterproof LED profiles to protect against moisture and dust. Explore SignliteLED’s full range of LED profiles and channels to find the right fit for your next project

How to Choose a Reliable LED Channel Supplier

High-quality LED extrusion profiles made with precise aluminum and diffuser control are key to reliability. streamlined installation, and long-term reliability—especially in large-scale architectural, commercial, or custom furniture lighting projects. A well-manufactured LED profile not only supports thermal management and mechanical protection for the LED strip, but also plays a central role in achieving uniform light distribution, clean visual aesthetics, and reduced maintenance. As market demand grows for tailored linear lighting, working with a capable supplier ensures access to stable quality, precise machining, and efficient fulfillment.

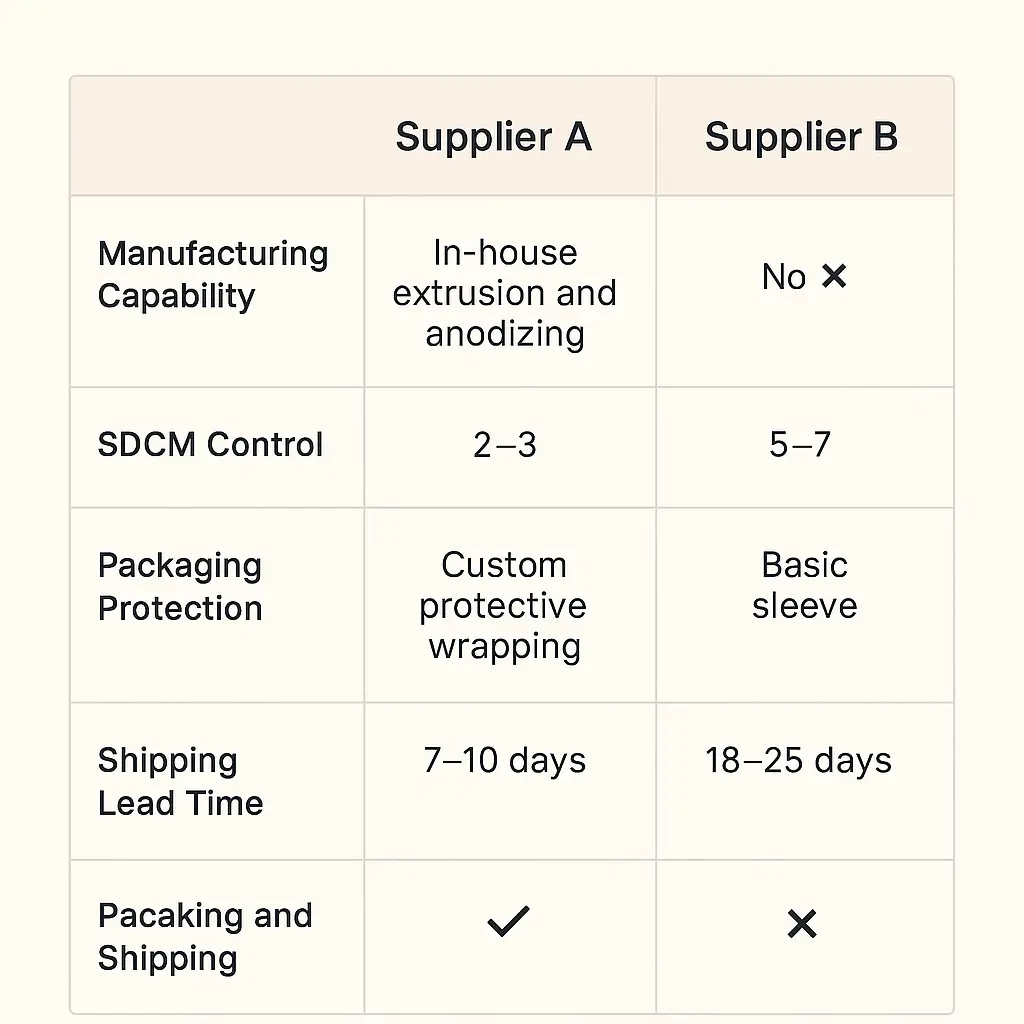

Manufacturing capability is the first key factor—choose suppliers with full in-house processes including aluminum extrusion, surface anodizing, diffuser injection, and custom cutting. This integration enables better quality control and faster lead times, especially for customized or urgent orders. Customization options are equally important. For projects requiring special dimensions, finishes, or diffuser designs, look for OEM/ODM-ready suppliers who offer design support and rapid prototyping to ensure tailored solutions that meet exact specifications.

Material quality cannot be overlooked. LED profiles should be made of high-grade 6063-T5 aluminum for optimal heat dissipation and durability, while the diffusers should use UV-stabilized PC or PMMA to ensure long-lasting optical clarity and prevent yellowing. Certifications such as CE, RoHS, UL, or TUV are essential if you’re supplying regulated markets like the EU or North America—these not only ensure safety and compliance but also boost credibility during project bidding and client evaluation.

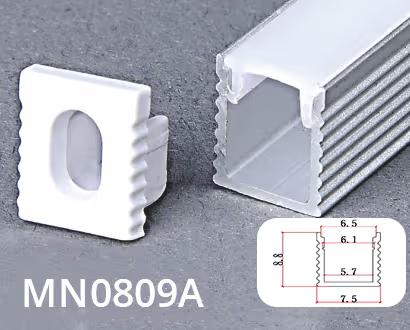

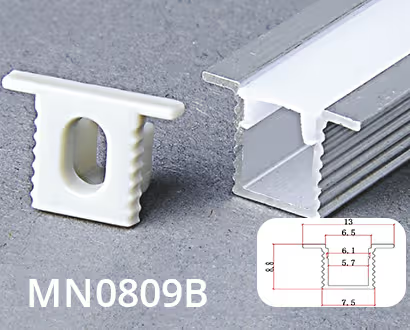

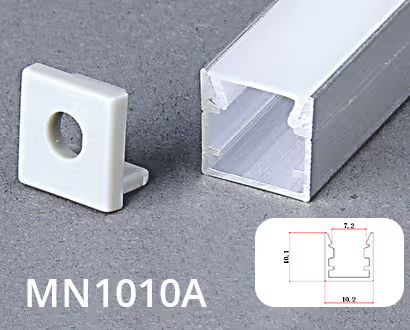

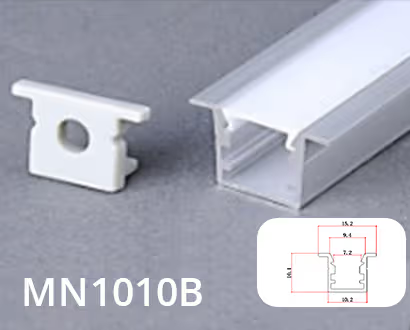

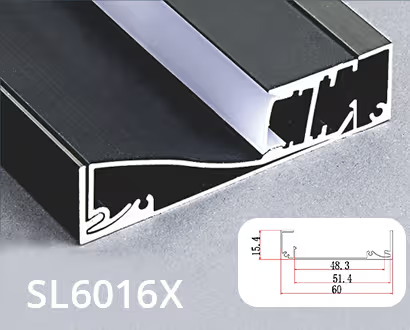

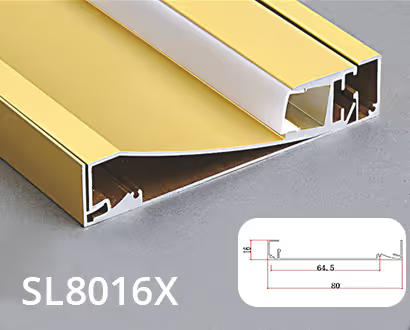

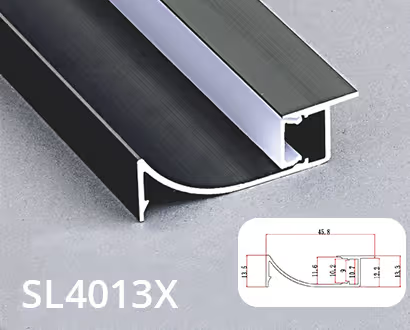

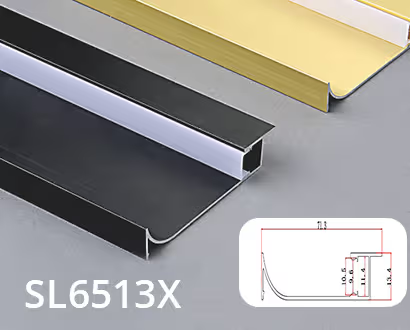

Below is a close-up structural view of a standard LED channel assembly, showing the PC diffuser, aluminum profile, and strip integration.

Packaging and shipping also matter more than many realize. Since aluminum channels and diffusers are often long and fragile, protective packaging and export-ready logistics are crucial. Reliable suppliers offer well-designed cartons, clear labeling, and experience with overseas freight to reduce transit-related damage. Finally, after-sales support is a critical part of a long-term partnership. Choose suppliers who provide technical consultation, offer warranty coverage, and stock replacement parts—especially valuable for long-term architectural installations or repeat project sourcing. Even with high-quality profiles, one often-overlooked risk is LED strip inconsistency. Poor color binning or mismatched tone can ruin the lighting effect. This is where SDCM (Standard Deviation of Color Matching) matters—commercial-grade projects should specify LED strips within a 2–3 SDCM range to ensure uniform visual results. Read more about SDCM here

Here’s a quick visual comparison to help evaluate LED channel suppliers at a glance.

To get a better understanding of how LED aluminum profiles are made, check out this factory tour video, which shows the full process from extrusion to surface finishing and packaging—an excellent reference when evaluating supplier transparency and scale.

Cost Structure & Market Trends (2024–2025) for LED Tape Light Channels

Gaining insights into the cost structure and market trends of LED tape light channels, also referred to as LED profiles or aluminum extrusions—is critical for lighting designers, project engineers, and sourcing teams who prioritize both performance and cost-efficiency. As the global architectural lighting industry accelerates its shift toward linear, recessed, and indirect lighting systems, understanding the key cost drivers and supply chain shifts in 2024–2025 will help you make more strategic and future-proof purchasing decisions.

Based on current market conditions, the following section provides a breakdown of average prices by channel size to support informed procurement planning.

Average Price by Size of LED Tape Light Channels (China, 2024)

Main Factors Affecting LED Channel Pricing

Material Quality & Thickness: Premium-grade aluminum with anodized or powder-coated finishes commands higher prices but offers better heat dissipation and longer service life. Thinner or recycled extrusions are cheaper but less durable.

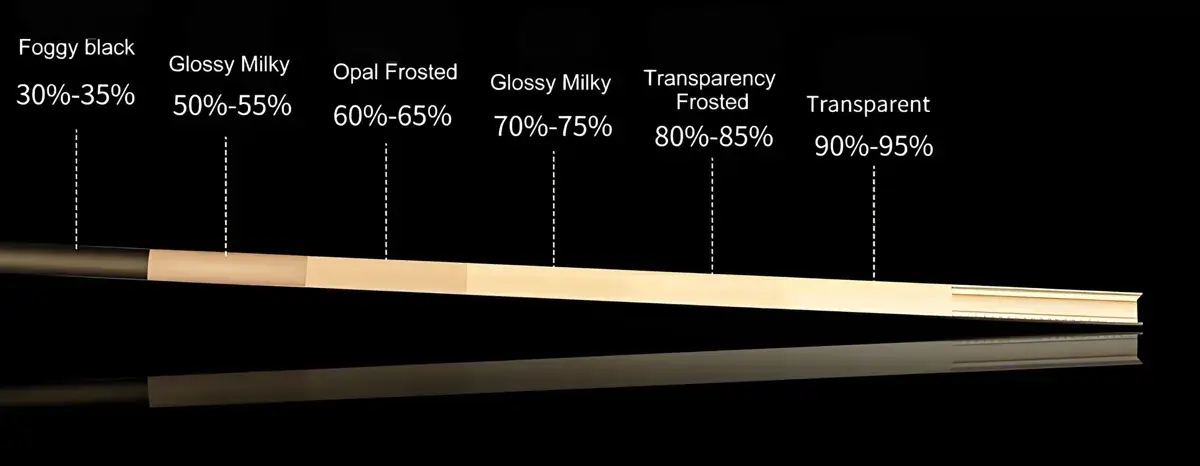

Diffuser Type & Light Transmission: Milky, frosted, or black lens covers with light transmission rates ranging from 30% to 95% affect overall cost. PMMA lenses offer superior optical clarity and UV resistance but are more expensive than PC alternatives.

Tips: Different diffuser covers dramatically affect the visual appearance and light output of LED tape lights.

Production & Machining Complexity: Unique cross-sections, flanged or flangeless designs, and compatibility with wide LED strips (e.g., 12mm+ COB) increase extrusion and machining costs.

Volume & Packaging Efficiency: Large-scale orders benefit from batch production and export-optimized packaging, potentially reducing per-meter costs by up to 30%.

Market Trends to Watch (2024–2025)

Surge in Linear Architectural Applications: Hotels, showrooms, and upscale residences are driving demand for recessed and edge-lit profiles to achieve seamless, glare-free lighting.

Demand for Tool-Free & Modular Profiles: Specifiers increasingly prefer snap-fit diffusers, slide-in end caps, and integrated cable management solutions to simplify installation.

Sustainability as a Differentiator: Buyers from Europe and North America are actively sourcing profiles made with low-carbon aluminum (60%+ recycled content) and RoHS/REACH-compliant processes.

China Leads in Custom Extrusion Supply: With advanced tooling, flexible MOQs, and mature supply chains, Chinese suppliers dominate the global LED profile market.

Tip: Prioritize suppliers with in-house extrusion, anodizing, and packaging to ensure quality consistency and faster lead times.

Real-World Applications of LED Tape Light Channels

| Application Scenario | Recommended LED Channel Type | Mounting Method | Key Features |

| Retail Shelving & Displays | Surface-Mounted / Recessed | Clip or screw | High CRI, directional lighting, quick installation |

| Architectural Cove Lighting | Recessed / Trimless Profiles | Flush-mount | Seamless integration, indirect lighting |

| Office & Commercial Spaces | Suspended / Recessed | Pendant or flush | Uniform brightness, modern appearance |

| Hospitality (Hotel Rooms) | Corner / Recessed / Furniture-fit | Hidden mounting | Cozy ambient light, discreet design |

| Kitchen & Home Cabinets | Slim Surface-Mounted / Recessed | Adhesive or clips | Easy retrofitting, task lighting with clean look |

| Wardrobes & Drawers | Mini LED Profiles | Embedded | Space-saving, motion-sensor compatible |

| Staircase & Step Lighting | Corner / Anti-slip LED Channels | Screw or embed | Safety-focused, angled beam output |

| Exhibition or Showroom Use | Linear High-Brightness Profiles | Suspended / Surface | Premium appearance, customizable beam angles |

LED tape light channels — also known as LED profiles or LED aluminum housings — are widely used across diverse lighting environments where both function and form are equally important. Their ability to enhance the visual finish while protecting and optimizing LED strip lighting makes them a critical component in both decorative and task lighting applications.

Retail & Display Lighting

In retail environments, LED channels are integrated into shelving, display cases, and product showcases to highlight merchandise with precision and style. They help maintain high CRI lighting for accurate color rendering and consistent brightness. With proper aluminum profiles, the lighting remains uniform and free of hot spots — critical for cosmetics counters, fashion boutiques, and electronics stores. Similarly, revitalizing your fresh food displays with cutting-edge LED strip lighting solutions can enhance product visibility and appeal, providing uniform, high-quality illumination.

Architectural & Commercial Spaces

Designers often use concealed lighting channels and recessed LED extrusion profiles such as recessed profiles for uninterrupted design flow. In modern office buildings, hotels, and museums, these channels enable hidden lighting lines that enhance ambiance and spatial design while preserving a clean minimalist look.

Hospitality & Residential Interiors

In homes, hotels, and resorts, LED mounting channels are used under cabinets, along staircases, and behind headboards to add soft, indirect lighting that enhances comfort and luxury. Corner and surface-mounted profiles offer flexible solutions that adapt to furniture and spatial constraints. For those looking to enhance specific areas, such as shelves, choosing the perfect LED shelf lighting can be a key factor in achieving a balanced and aesthetically pleasing ambiance in your space.

Furniture & Custom Fixtures

Cabinet makers embed LED light channels for shelves and drawers into kitchens and wardrobes, using compact profiles to achieve high-end finishes in tight spaces. Using customized aluminum LED profiles, they ensure optimal fit, finish, and light diffusion for high-end furniture pieces.

Conclusion

LED tape light channels are not mere installation aids — they are critical components that determine the longevity, visual quality, and functionality of an LED lighting system. Across sectors such as retail, architecture, hospitality, and residential design, these channels transform basic strip lighting into a polished, high-performing solution.

By carefully choosing the right type of channel, partnering with reputable suppliers, and staying informed about market pricing trends, stakeholders can ensure that their lighting projects are both cost-effective and future-proof. In today’s competitive lighting market, making informed decisions about linear LED channel systems is essential for delivering installations that are not only technically sound but also visually exceptional.