With the rising market demand for high-quality LED neon strips, product stability, service life, and color consistency have become the key metrics for buyers. To help customers better understand how neon LED strip lights perform under long-term operation, we conducted a 6,000-hour aging test on multiple models and collected data covering reliability, lumen decay, and color stability.

This report is based on real test data and demonstrates SignliteLED’s strict quality-control system. It also provides reliable technical support for customers during product selection and engineering applications.

Purpose of the LED Neon Strip Aging Test

LED neon flex lights are widely used in architectural lighting, commercial signage, outdoor decorative projects, and many applications where products must operate continuously—often 12–24 hours per day. Under such long-term, high-frequency usage, issues like brightness decay, color shift, material degradation, and electrical instability will directly affect the final lighting performance and service life.

Therefore, we selected 11 models of standard neon LED strips and conducted long-term aging tests by powering them continuously on an aging rack. The objectives include:

- Verifying product reliability and lumen maintenance capability under long-term operation.

- Ensuring long-term stability of optical parameters such as CRI, CCT, and brightness.

- Identifying potential risks in advance to ensure stable performance in engineering projects.

- Improving product quality to meet LM-80 / TM-21 international reliability standards.

- Using test results to detect weaknesses and guide R&D improvements for better product durability.

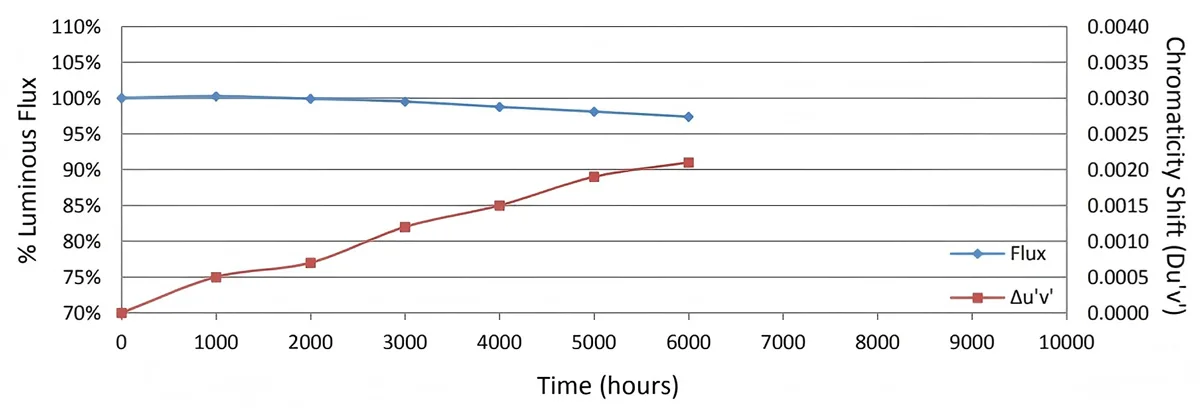

Energy Star Requirements for Lumen Maintenance

The luminous output of an LED gradually decreases over time, especially under high-temperature conditions. Meanwhile, color stability may shift (color deviation), causing white LEDs to become slightly reddish or bluish.

Energy Star and LM-80 provide clear guidelines for LED light lumen maintenance and color stability:

Lumen Maintenance Standard

After 6,000 hours of aging test, LED fixtures must maintain ≥94.1% of their initial luminous flux.

Definition: Lumen maintenance refers to the ratio of luminous flux at a specific test time to the initial luminous flux. At the beginning of testing, output may rise to 103–105%, then gradually decline (lumen depreciation), typically following a slow decay curve.

Chromaticity Shift Standard

- CCT must remain within ±150K of the initial value.

- CRI (Ra) must stay within ±5% of the initial measurement.

- Chromaticity coordinate shift ≤ 0.007.

Aging Test Conditions and Laboratory Environment

To simulate real operating conditions, we carried out a standardized aging test on the neon LED strip samples. Conditions are as follows:

- Total test duration: 6,000 hours

- Recording cycles: 1,000 / 2,000 / 3,000 hours

- Environmental conditions:

- Temperature: 28°C ± 5°C

- Humidity: 65% ± 5%

- Mounting method: Products placed on an aging rack and illuminated continuously

- Equipment used:

- Integrating sphere optical testing system

- High-precision photometric distributor

- Constant-voltage power supply

- LED strip aging rack

These instruments ensure high-accuracy data for luminous flux maintenance, color stability, thermal performance, and electrical characteristics.

Continuous Aging Test Process for LED Neon Strips

1. Initial Optical Test Data

We selected 11 models, each cut to 1 meter, and used an integrating sphere and high-precision photometric distribution to measure their initial photometric parameters before aging.

| Initial Test Data | |||||||||

| Numberr | Model | Start Time | Power(W) | Flux(Im) | Lm/W | CCT(K) | X | Y | Ra |

| 1 | NQM0410S120C | 2023/8/16 PM14:30 | 8.6 | 167.7 | 19.5 | 2518 | 0.4747 | 0.4122 | 81.6 |

| 2 | NQM0613S120C | 11.03 | 319.6 | 29 | 2635 | 0.4631 | 0.408 | 83.3 | |

| 3 | NQN0816S120C | 11.2 | 226.4 | 20.2 | 3529 | 0.4049 | 0.3933 | 84.6 | |

| 4 | NQN1010S120C | 8.6 | 455.9 | 53 | 4634 | 0.3577 | 0.3702 | 83.9 | |

| 5 | NQW1010T120C | 8.6 | 474.1 | 55.1 | 5799 | 0.3255 | 0.3474 | 81.1 | |

| 6 | NQW1018S180C | 12.4 | 370.9 | 29.9 | 5408 | 0.3349 | 0.3575 | 81.4 | |

| 7 | NQW1212S120C | 11 | 558.5 | 50.7 | 5880 | 0.3238 | 0.346 | 81.6 | |

| 8 | NQM1020T180C | 13.4 | 909.9 | 67.9 | 2802 | 0.4483 | 0.4021 | 83.5 | |

| 9 | NQN2010T240C | 15.7 | 955.7 | 60.8 | 3604 | 0.4008 | 0.3911 | 83.9 | |

| 10 | NQN15R120C | 17.2 | 1132.9 | 65.8 | 3646 | 0.3993 | 0.392 | 83.6 | |

| 11 | NQM22R120C | 16 | 1100.3 | 68.7 | 2769 | 0.4525 | 0.4059 | 83.2 | |

Then place it on the aging rack and power it on for long-term illumination during the aging process.

2. Optical Test Data After 1,000 Hours

| Test Data After Aging for 1000 Hours | |||||||||||||

| Number | Model | Deadline | Power(W) | Flux(Im) | LmlW | CCT(K) | X | Y | Ra | X-deviation | Y-deviation | Lumen maintena | Color temperature offset value |

| 1 | NQM0410S120C | 2023/9/28 PM14:30 | 8.7 | 159.74 | 18.2 | 2533 | 0.4739 | 0.4129 | 80.9 | -0.0008 | 0.0007 | 95.25% | 15 |

| 2 | NQM0613S120C | 11.1 | 321.7 | 28.9 | 2720 | 0.4569 | 0.4078 | 82 | -0.0062 | -0.0002 | 100.66% | 85 | |

| 3 | NQN0816S120C | 11.4 | 215.1 | 18.8 | 3533 | 0.4051 | 0.3946 | 82.9 | 0.0002 | 0.0013 | 95.01% | 4 | |

| 4 | NQN1010S120C | 8.7 | 456 | 52.4 | 4611 | 0.357 | 0.3705 | 83.5 | -0.0007 | 0.0003 | 100.02% | -23 | |

| 5 | NQW1010T120C | 8.5 | 449.4 | 52.8 | 5846 | 0.3245 | 0.3466 | 81 | -0.001 | -0.0008 | 94.79% | 47 | |

| 6 | NQW1018S180C | 13.7 | 360 | 26.28 | 5430 | 0.3343 | 0.3556 | 81 | -0.0006 | -0.0019 | 97.06% | 22 | |

| 7 | NQW1212S120C | 11.1 | 533.8 | 48 | 5790 | 0.3272 | 0.3496 | 80.3 | 0.0034 | 0.0036 | 95.58% | -90 | |

| 8 | NQM1020T180C | 13.6 | 886.2 | 64.7 | 2831 | 0.4469 | 0.4031 | 82.7 | -0.0014 | 0.001 | 97.40% | 29 | |

| 9 | NQN2010T240C | 15.8 | 910.1 | 57.6 | 3668 | 0.3949 | 0.3892 | 83.7 | -0.0059 | -0.0019 | 95.23% | 64 | |

| 10 | NQN15R120C | 17.7 | 960.2 | 54.2 | 3842 | 0.3865 | 0.3771 | 84.3 | -0.0128 | -0.0149 | 84.76% | 196 | |

| 11 | NQM22R120C | 17.5 | 902.4 | 51.57 | 2967 | 0.4374 | 0.401 | 83.2 | -0.0151 | -0.0049 | 82.01% | 198 | |

Result Analysis:

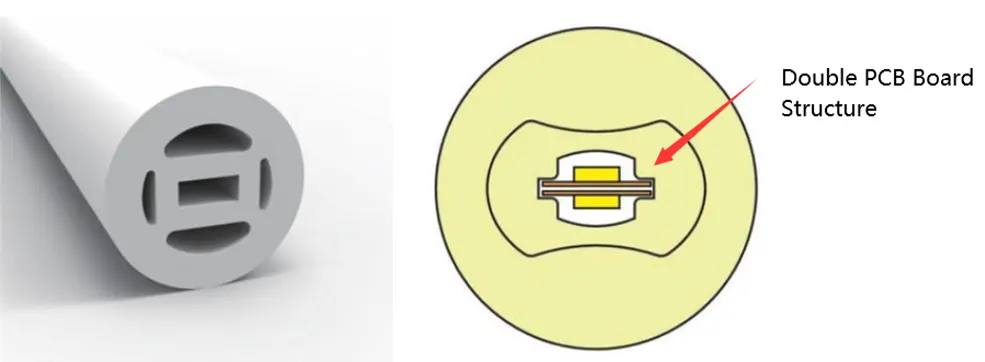

Based on the Energy Star lumen maintenance criteria, neon strips #10 and #11 (in red in the original table) showed lumen maintenance levels of 84% and 82%, significantly below standard.

Root Causes:

- Both models use a 360-degree round neon body

- Inside structure uses dual-PCB design

- Relatively high power rating (18W/m)

- LED junction temperature excessively high

- Poor heat dissipation due to design limitations

These conditions accelerate phosphor thermal degradation and LED efficiency loss, resulting in rapid brightness decay and noticeable color shift.

Solution:

- Increase PCB copper thickness to enhance heat dissipation

- Optimize thermal structure

- Reduce LED driving current to lower LED operating temperature

- Redesign 360° neon models with better conduction materials

3. Optical Test Data After 2,000 Hours

| Test Data After Aging for 2000 Hours | |||||||||||||

| Number | Model | Deadline | Power(W) | Flux(Im) | Lm/W | CCT(K) | X | Y | Ra | X-deviation | Y-deviation | Lumen maintena | Color temperature offset value |

| 1 | NQM0410S120C | 2023/11/17P M14:30 (9.29- 10.6Suspend ed during holidays) | 8.7 | 161 | 18.5 | 2525 | 0.4744 | 0.4128 | 81.2 | -0.0003 | 0.0006 | 96.00% | 7 |

| 2 | NQM0613S120C | 11.2 | 338.2 | 29.99 | 2685 | 0.4602 | 0.4094 | 82.2 | -0.0029 | 0.0014 | 105.82% | 50 | |

| 3 | NQN0816S120C | 11.4 | 219.1 | 19.2 | 3469 | 0.4084 | 0.3951 | 83.2 | 0.0035 | 0.0018 | 96.78% | -60 | |

| 4 | NQN1010S120C | 8.7 | 472.4 | 54.3 | 4546 | 0.3611 | 0.374 | 83.3 | 0.0034 | 0.0038 | 103.62% | -88 | |

| 5 | NQW1010T120C | 8.6 | 457 | 53.1 | 5687 | 0.3281 | 0.3486 | 80.9 | 0.0026 | 0.0012 | 96.39% | -112 | |

| 6 | NQW1018S180C | 13.8 | 356 | 25.8 | 5484 | 0.3329 | 0.3509 | 81.6 | -0.002 | -0.0066 | 95.98% | 76 | |

| 7 | NQW1212S120C | 11.1 | 554.1 | 49.9 | 5767 | 0.3301 | 0.3525 | 80.3 | 0.0063 | 0.0065 | 99.21% | -113 | |

| 8 | NQM1020T180C | 13.9 | 886.7 | 63.7 | 2816 | 0.4479 | 0.4031 | 82.9 | -0.0004 | 0.001 | 97.45% | 14 | |

| 9 | NQN2010T240C | 15.84 | 832.1 | 52.5 | 3655 | 0.3963 | 0.3843 | 84.1 | -0.0045 | -0.0068 | 87.07% | 51 | |

| 10 | NQN15R120C | 17.9 | 895.9 | 50 | 3856 | 0.385 | 0.3739 | 84.9 | -0.0143 | -0.0181 | 79.08% | 210 | |

| 11 | NQM22R120C | 17.6 | 956.1 | 54.3 | 2958 | 0.438 | 0.4013 | 83.2 | -0.0145 | -0.0046 | 86.89% | 189 | |

Result Analysis:

A new failure appeared in model #9, whose lumen maintenance dropped to 87%. The main cause is the 1oz copper thickness on the flexible PCB, which is insufficient for effective heat dissipation, causing LED junction temperatures to remain high.

Solution:

- Increase flexible PCB copper thickness from 1oz → 2oz

- Improve current-carrying capability

- Reduce power from 16W/m → below 14W/m

4. Optical Test Data After 3,000 Hours

| Test Data After Aging for 3000 Hours | |||||||||||||

| Number | Model | Deadline | Power(W) | Flux(Im) | Lm/W | CCT(K) | X | Y | Ra | X-deviation | Y-deviation | Lumen maintena | Color temperature offset value |

| 1 | NQM0410S120C | 2023/12/30P M14:30 | 8.7 | 158.3 | 18.2 | 2557 | 0.4713 | 0.4119 | 81.6 | -0.0034 | -0.0003 | 94.39% | 39 |

| 2 | NQM0613S120C | 11.3 | 311.2 | 27.3 | 2716 | 0.4576 | 0.4085 | 82.5 | -0.0055 | 0.0005 | 97.37% | 81 | |

| 3 | NQN0816S120C | 11.6 | 213.44 | 18.4 | 3527 | 0.4043 | 0.3913 | 83.7 | -0.0006 | -0.002 | 94.28% | -2 | |

| 4 | NQN1010S120C | 8.7 | 454.8 | 52 | 4566 | 0.3605 | 0.3737 | 83.4 | 0.0028 | 0.0035 | 99.76% | -68 | |

| 5 | NQW1010T120C | 8.6 | 446.3 | 51.9 | 5712 | 0.3275 | 0.3476 | 81 | 0.002 | 0.0002 | 94.14% | -87 | |

| 6 | NQW1018S180C | 13.7 | 345.2 | 25.2 | 5545 | 0.3307 | 0.3482 | 82 | -0.0042 | -0.0093 | 93.07% | 137 | |

| 7 | NQW1212S120C | 11 | 533.8 | 48.2 | 5754 | 0.3295 | 0.3518 | 80.6 | 0.0057 | 0.0058 | 95.58% | -126 | |

| 8 | NQM1020T180C | 13.6 | 857.2 | 62.8 | 2842 | 0.446 | 0.4028 | 83.4 | -0.0023 | 0.0007 | 94.21% | 40 | |

| 9 | NQN2010T240C | 16 | 759.1 | 47.4 | 3710 | 0.3928 | 0.3808 | 84.7 | -0.008 | -0.0103 | 79.43% | 106 | |

| 10 | NQN15R120C | 17.9 | 680.1 | 37.9 | 3946 | 0.3804 | 0.3696 | 85.5 | -0.0189 | -0.0224 | 60.03% | 300 | |

| 11 | NQM22R120C | 17.7 | 777.4 | 43.7 | 2983 | 0.4364 | 0.4009 | 83.8 | -0.0161 | -0.005 | 70.65% | 214 | |

After 3,000 hours, overall performance remained stable. Compared with the 2,000-hour results, brightness showed a small decrease, while CCT stability and lumen maintenance remained within acceptable ranges. No additional failures occurred except for the previously noted #9–#11.

Combined Lumen Maintenance Analysis

Lumen decay is one of the most important metrics in LED life evaluation.

Average Lumen Maintenance:

- 1,000H: ~94.34%

- 2,000H: ~94.94%

- 3,000H: ~88.45%

The neon LED strips performed relatively stably during the first 2,000 hours. However, after 3,000 hours, the lumen decay rate accelerated. This is mainly due to:

- Most neon strip lights use sealed IP65 structures

- Limited airflow results in poor heat dissipation

- LEDs rely solely on PCB + silicone body for heat conduction

- Thermal accumulation accelerates late-stage lumen loss

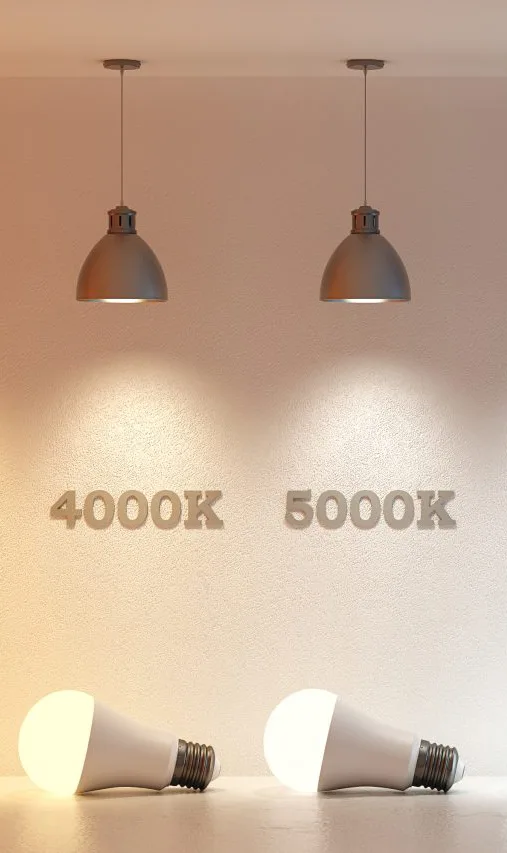

5. CCT Stability Analysis (Color Temperature Shift)

Color shift is common in low-quality neon LED strip lights, often appearing as increasingly bluish or yellowish tones.

Testing results:

- After 1,000H: Minimal CCT change (±50K–100K)

- After 2,000H: CCT deviation increased to ±50K–115K

- After 3,000H: High-CCT models (6000K) showed larger shifts (~125–140K), especially in models #5 and #7

How to Improve the Lumen Maintenance of LED Neon Lights

As a classic lighting solution, the brightness maintenance of LED neon lights directly affects their service life and visual performance. Lumen maintenance often declines over time due to material aging, thermal design limitations, and other factors. Based on the characteristics of neon lights, improving brightness stability requires optimization in electrical stability, thermal stability, and heat-dissipation structure.

Stable brightness output ensures long-term visual consistency for applications such as outdoor architectural lighting, signage, and advertising light boxes.

Electrical Stability

Use high-quality branded LED drivers to ensure stable current output. The driving current supplied to the LEDs should be kept as low as possible, ideally not exceeding 40% of the LED’s rated operating current.

For example: A 0.2W, 3V LED typically operates at 60mA; therefore, the recommended working current should be ≤24mA.

This minimizes heat generation and ensures long-term stable illumination. For small-profile neon housings with weaker heat dissipation, the driving current should be reduced even further.

Thermal Stability

- Use high-quality LED chips with stable luminous efficacy.

- Apply frosted silicone optical structures to achieve uniform heat dissipation.

- Ensure the LED junction temperature remains within a safe range to avoid thermal degradation during long-term operation.

Heat Dissipation Structure

- Since LED neon lights use a sealed structure, the PCB copper thickness must be sufficient to improve thermal conduction.

- The driver output must remain stable with minimal electrical ripple to reduce cumulative temperature rise.

Material Durability

- Select premium silicone housings that resist yellowing, hardening, and cracking.

- High-quality silicone offers superior heat dissipation and optical performance compared with PVC and other materials.

Conclusion

By openly sharing these reliability test results, our goal is to provide customers with transparency and confidence. Every neon LED strip produced by our factory undergoes durability, stability, and long-life performance verification to ensure compliance with international standards.

For products that fail to meet expected performance, we will continue improving design, materials, and manufacturing processes to deliver higher-quality LED neon strip lighting.

SignliteLED remain committed to strict testing standards and quality-control procedures, offering customers more reliable and longer-lasting LED neon strip lighting solutions. If you require a customized test report or certification services, feel free to contact our team.