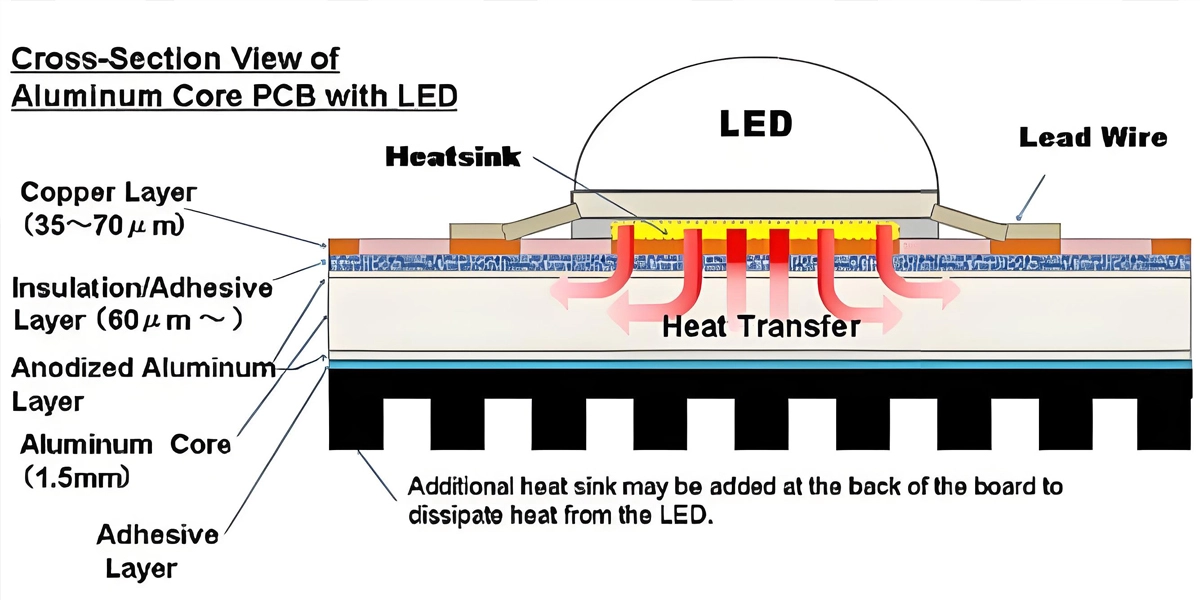

In LED-stripverlichting Projecten, de keuze van een aluminiumprofiel beïnvloedt niet alleen het installatiegemak, maar ook de thermische prestaties, de lichtkwaliteit en de levensduur. 6063-T5 aluminium - dat vaak wordt gebruikt in LED-profielen - heeft een thermische geleidbaarheid van ongeveer 201 W/(m·K), meer dan 1.000 × hoger dan de meeste kunststoffen, waardoor het snel de 8-10 W warmte per meter kan overbrengen met een krachtige LED-strip (15 W/m). Zonder de juiste dissipatie kan deze warmte PCB-temperaturen boven 80 °C doen duwen, wat leidt tot lumenafschrijving, kleurverschuiving en levensduurreductie tot 501 TP3T.

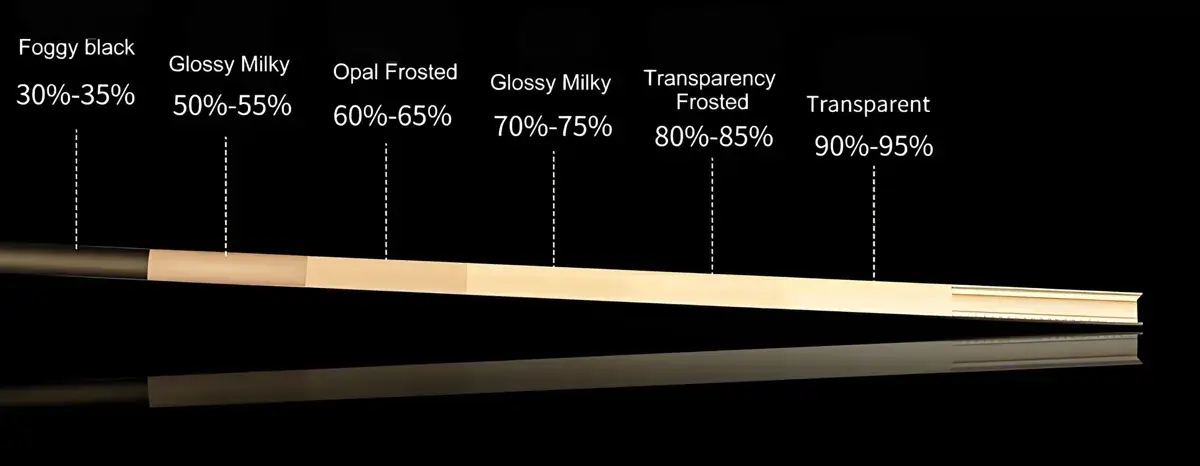

Diffuserselectie speelt een even belangrijke rol: een slecht afgestemde diffuser kan verblinding, oneffen licht of verminderde output veroorzaken, waardoor de ontwerpintentie wordt ondermijnd.

Voor een volledige uitsplitsing van profielcategorieën, prestatiekenmerken en gebruiksscenario's, zie onze Ultieme gids voor aluminium profiel voor LED strip verlichting. In deze gids richten we ons op warmteafvoer en esthetisch ontwerp, waarbij we praktische selectiecriteria bieden voor lichtontwerpers, aannemers en OEM-kopers die maximale LED-betrouwbaarheid willen met een schone, professionele afwerking.

LED-strip warmteproblemen

Warmte is een onvermijdelijk bijproduct van de werking van de LED-strip en de impact ervan wordt kritischer in modellen met veel vermogen (10-20 W/m). Slechts ongeveer 25-351 TP3T van de inputenergie wordt omgezet in licht - de rest wordt warmte. Een LED-strip van 15 W/m genereert bijvoorbeeld ongeveer 10 W/m thermische belasting, die, indien niet te beheren, PCB-temperaturen tot boven 80 °C kan duwen. Dit kan de afschrijving van lumen versnellen, een merkbare kleurverschuiving veroorzaken en de levensduur tot 501 TP3T verkorten.

De belangrijkste factoren die bijdragen aan overmatige warmteopbouw zijn onder meer:

Ontoereikende thermische massa of geleiding – Profielen van laagwaardig aluminium of met dunne wanden (< 1 mm) brengen de warmte minder effectief over. Het gebruik van 6063-T5 aluminium (201 W/m·K thermische geleidbaarheid) verbetert de efficiëntie van de warmteoverdracht aanzienlijk.

Installatieomgeving beperkingen – Ingesloten baaien, verzegelde vitrines of hoge omgevingstemperaturen (> 35 °C) kunnen de warmteafvoer verminderen door 20–30% Vergeleken met open, geventileerde installaties.

Continue werking met hoog vermogen – Lange lopende strips op volle helderheid laten lopen zonder diep of geveerd LED-koelkast extrusie kan leiden tot onstabiele knooppunttemperaturen.

Effectief thermisch ontwerp betekent het selecteren van een profiel dat overeenkomt met het wattage van de strip, fysieke afmetingen en omgevingsomstandigheden. Voor een gedetailleerde uitsplitsing van kanaaltypen, breedtes en koelprestaties, zie onze LED Tape Lichtkanalen Complete Gids.

SMD2835 LED Strip Licht

LED AANTAL per meter Optie: 60/72/120/128/140

PCB-breedteoptie: 6mm/8mm/10mm

Kleuroptie: 2700K-6500K

CRI-optie: 80/90/95

Ingangsspanning: DC12V/DC24V

Vermogen per meter: 6W/8W/9.6W/12W/14.4W/19.2W

Efficiëntie: 100-200 lumen/watt

Warmteafvoer in aluminium profielen

Aluminiumprofielen dienen als passieve koellichamen, die thermische energie van de LED-printplaat naar de omringende lucht overbrengen. De efficiëntie van dit proces kan worden gemeten door de temperatuurdaling die bij continu bedrijf wordt bereikt. Een upgrade van een 1 mm dunne-wandprofiel naar een 2 mm dikwandig 6063-T5 aluminiumprofiel kan bijvoorbeeld de LED-PCB-temperatuur met 6-8 °C verminderen bij 15 W/m belasting - genoeg om de levensduur van de L70 met 30-40% te verlengen.

Belangrijkste parameters die van invloed zijn op dissipatie:

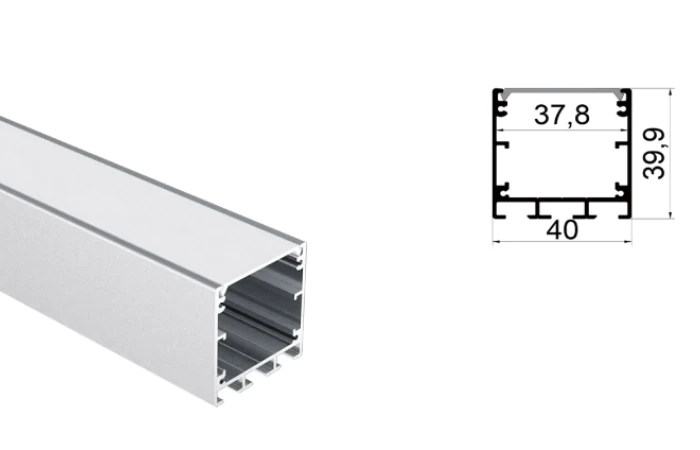

wanddikte – Een dikkere doorsnede verhoogt de thermische massa. Voor stroken ≥ 15 W/m wordt 2 mm of meer aanbevolen.

Oppervlakteverbetering – Vinnenprofielen kunnen convectieve warmteoverdracht met 20-30% verbeteren in vergelijking met platte ontwerpen.

materiaalkwaliteit – 6063-T5 legering (≈ 201 W/m·K) is standaard; vermijd laagwaardig gerecycled aluminium (< 150 W/m·K) wat de geleiding belemmert.

Montage-interface – Directe bevestiging aan metalen oppervlakken kan de dissipatie tot 151 TP3T verbeteren, terwijl isolerende oppervlakken (hout/plastic) deze met 10-20% kunnen verminderen, tenzij thermische pads worden gebruikt.

Voor LED-strips met hoge dichtheid in retaildisplays, gekoelde vitrines of architecturale gevelverlichting, overweeg dan diepkanaals of multi-fin extrusies voor optimale thermische stabiliteit. Gedetailleerde productopties zijn te vinden in onze Aluminiumprofiel voor LED-stripverlichting.

Esthetisch lichtontwerp

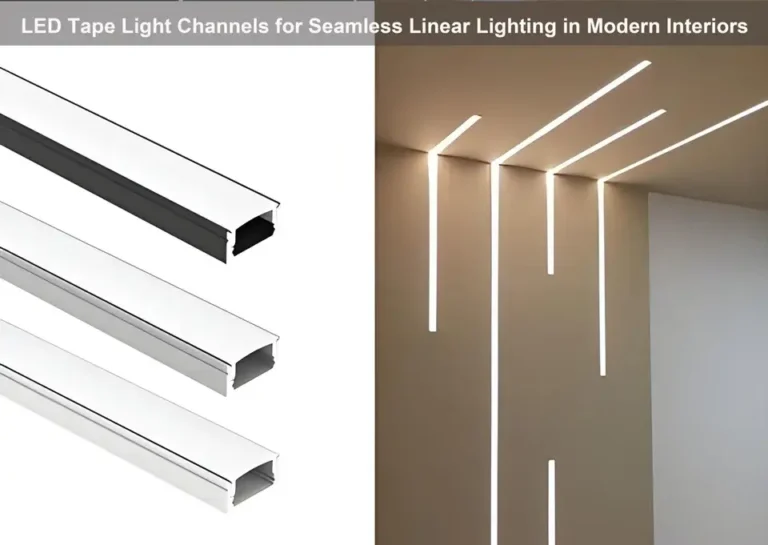

Esthetisch ontwerp is meer dan het kiezen van een 'look' - het heeft een directe invloed op de lichtverdeling, de verblindingscontrole en de waargenomen kwaliteit. De in het aluminium profiel geïntegreerde diffuser bepaalt zowel optische prestaties als visueel comfort.

Veel voorkomende diffusertypes en optische effecten:

Helder (92–95% lichttransmissie) – Levert maximale helderheid, maar laat LED "hotspots" zichtbaar. Ideaal voor sieradenvitrines, productdisplays en taakverlichting waar intensiteit belangrijker is dan uniformiteit.

Frosted (80-85% lichttransmissie) - biedt een uitgebalanceerde helderheid en verminderde verblinding. Geschikt voor bureaus, winkelrekken en verlichting onder de kast.

Opaal/Melky (65–75% lichttransmissie) – Creëert een soepele, hotspotvrije verlichting met uitstekende verblindingsregeling. Het beste voor residentiële baaien, horecaruimtes en sfeerverlichting.

Tip: Langere afstanden tussen LED-strip en diffuser (diepe kanalen) verbeteren de uniformiteit, vooral voor lagere LED-dichtheden (< 120 LED's/m).

Voor voorbeelden van hoe diffuser keuze zowel functie als stemming vormt, zie onze Gids voor 45° hoek LED aluminium profiel voor LED Strips.

LED aluminium profiel selectiegids

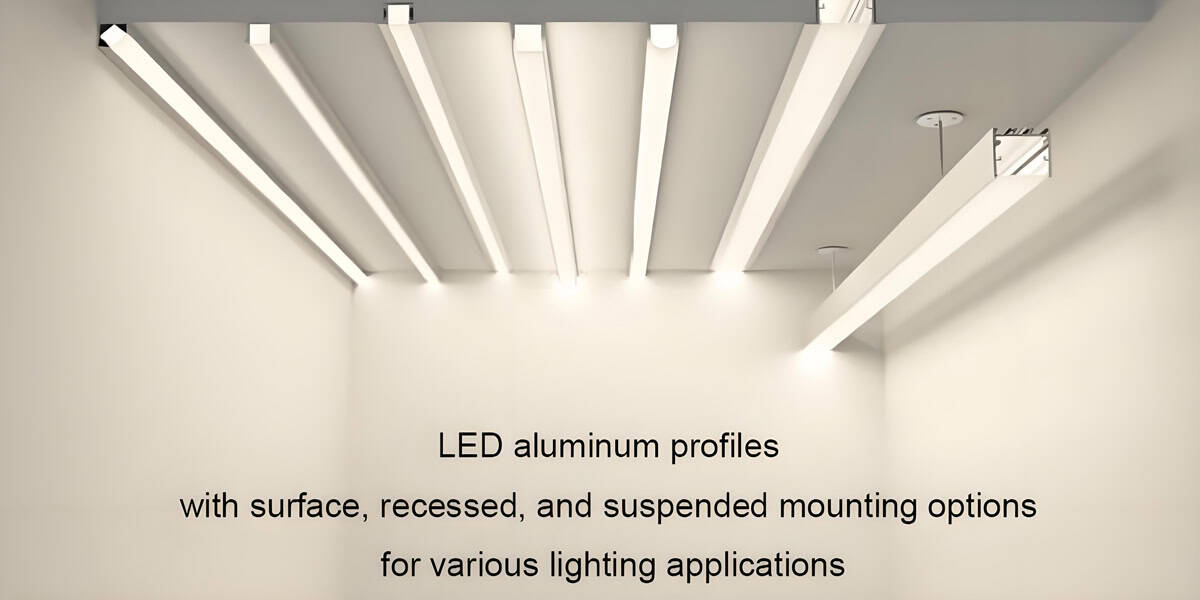

Het selecteren van het juiste aluminiumprofiel vereist het matchen van thermische capaciteit, optische prestaties en mechanische compatibiliteit met de LED-strip en de installatieplaats.

Belangrijkste criteria:

LED-strip wattage & dichtheid – Gebruik voor ≥ 15 W/m of ≥ 120 LED's/m, diepe of vinprofielen met een wanddikte van ≥ 2 mm om de PCB-temperatuur < 70 °C te handhaven.

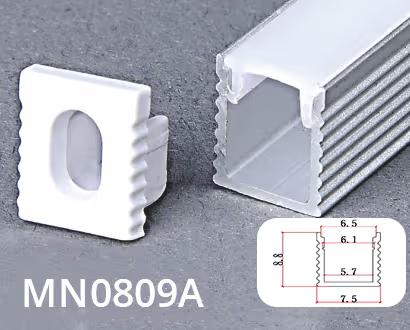

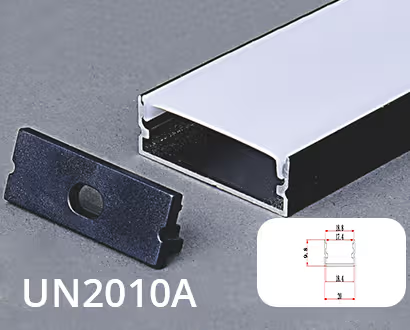

Profiel interne breedte – Stem de breedte van de interne sleuf af op de LED-strip-PCB (bijv. 5 mm, 8 mm, 10 mm). Oversized kanalen kunnen licht morsen; ondermaatse kanalen lopen het risico de strip te beschadigen of het contact voor warmteoverdracht te verminderen.

Installatieomgeving – Buiten- of hoge-vochtigheidsgebieden vereisen geanodiseerde of IP67-geclassificeerde extrusies met UV-bestendige polycarbonaatdiffusers.

Montagewijze tentamen

- Opbouw: de beste thermische geleiding indien bevestigd op metaal; kan thermische tape op hout/plastic vereisen.

- Inbouw: vereist nauwkeurige uitsparingen (+1-2 mm tolerantie); biedt een vlakke uitstraling, maar kan de luchtstroom verminderen.

- Opgeschort: moderne esthetiek, maar verminderde warmtegeleiding door luchtisolatie - selecteer profielen met meer oppervlakte.

- 45° hoek: geoptimaliseerd voor plankranden, onderkasten en schuine accentverlichting.

Economische overwegingen – Een upgrade van een standaardprofiel naar een gefinned model kan de kosten met 20-30% verhogen, maar kan de levensduur van de LED met 30-401 TP3T verlengen, waardoor de vervangingskosten over een periode van 5 jaar worden verlaagd.

Voor uitgebreide profielspecificaties en toepassingsvoorbeelden, zie onze Aluminiumprofiel voor LED-stripverlichting.

Casestudy'

De volgende gevallen laten zien hoe het selecteren van het juiste LED-aluminiumprofiel en -diffuser zowel efficiënte warmteafvoer als aantrekkelijke lichteffecten kan bereiken.

Case 1 – Retail display verlichting met high-CRI LED strip profielen

Een juwelenverkoper installeerde 15 W/m CRI 95 LED-strips in een 1 mm dunwandig aluminium kanaal met een doorzichtige diffuser. Na 6 maanden veroorzaakte overmatige hitte (PCB > 78 °C) een u'V'-kleurverschuiving van 0,004, merkbaar op dat klanten edelstenen inspecteerden. De winkel is geüpgraded naar een 2 mm muur, een diepkanaalprofiel met vin in 6063-T5 aluminium, waardoor de PCB-temperatuur met 7-8 °C wordt verlaagd en de nauwkeurige kleurweergave wordt hersteld.

Case 2 – Office Cove-verlichting met behulp van inbouw LED aluminium profielen

Een open kantoor gebruikte 9,6 W/m, 4000K LED-strips in verzonken profielen met mattende diffusers. De verblindingsclassificatie (UGR < 19) voldeed aan de comfortnormen voor de werkplek en PCB-temperaturen bleven drie jaar onder de 55 ° C, zonder zichtbare lumenafschrijving.

Case 3 – Residentiële keuken & garderobe met diffuse LED-kanalen

Een huiseigenaar installeerde 8 W/M LED-strips in opbouwprofielen onder keukenkasten en in de kastrekken. Het kiezen van opaal diffusers elimineerde LED-spotting en creëerde uniform licht. Profielen werden bevestigd aan aluminium backsplash-panelen, waardoor de warmteoverdracht verbeterde en de stabiele helderheid in een warme, afgesloten ruimte werd behouden.

Case 4 – Buitengevelverlichting in tropische klimaten met IP67-profielen

Een architecturale gevel in Zuidoost-Azië liep IP67-rated 12 W/m LED-strips in geanodiseerde, UV-bestendige aluminium profielen met opaaldiffusers. Ondanks de omgevingstemperaturen van meer dan 35 °C, handhaafde de opstelling PCB-temperaturen onder 70 °C, waardoor voortijdige storingen werden voorkomen. Voor gevelspecifieke profielselectie, zie onze Ultieme gids voor aluminium profiel voor LED strip verlichting.

Conclusie

Aluminiumprofielen zijn niet alleen montageaccessoires - het zijn thermische beheersystemen, optische shapers en ontwerpversterkers in één. Het kiezen van de juiste extrusie voor uw LED-stripwattage, installatie-omgeving en lichtkwaliteitsvereisten kan het verschil betekenen tussen een 2-jarige storing en een levensduur van 50.000 uur.

De juiste selectie verbetert:

Thermische stabiliteit – houdt de knooppunttemperaturen in het veilige bereik.

Lichtkwaliteit - regelt schittering, diffusie en uniformiteit.

Duurzaamheid - beschermt tegen stof, vocht en mechanische impact.

Economische efficiëntie - Vermindert de vervangings- en onderhoudskosten in de loop van de tijd.

Of u nu een gefineerd diepkanaal nodig heeft voor krachtige winkelverlichting, een hoekprofiel voor vitrines of een extrusie met IP67-geclassificeerde buitengevels, ons technische team kan u helpen bij het selecteren van de meest effectieve oplossing.

Ontvang vandaag nog een op maat gemaakte aluminium profielaanbeveling voor uw LED-project - neem contact op met SigliteLED of verken onze Aluminiumprofiel voor LED-stripverlichting bereik.

Ik hield er zoveel van als je hier zult ontvangen, de schets is aantrekkelijk. Je auteursmateriaal stijlvol, toch beveel je een nervositeit over dat je wilt dat je het volgende onwel krijgt, kom ongetwijfeld meer voorheen als precies hetzelfde, bijna vaak in het geval dat je deze wandeling afschermt

Iemand helpt in wezen om aanzienlijk artikelen te maken ID staat Dit is de eerste keer dat ik je webpagina bezocht en tot nu toe verraste ik met het onderzoek dat je hebt gedaan om dit echte bericht ongelooflijk fantastisch te maken