Surgebeveiligingsmiddelen (SPD's) worden geclassificeerd als type 1, type 2 en type 3 om weer te geven waar ze werken binnen een elektrisch systeem en hoe ze op die locatie overspanningsenergie beheren. Deze typen zijn niet uitwisselbaar. Elk is ontworpen voor een specifieke overspanningsomgeving en beschermingsfunctie, en ze presteren alleen correct wanneer ze worden toegepast als onderdeel van een gecoördineerd systeem.

Dit artikel is een vergelijkende technische gids. Het brengt de fundamentals van de overspanningsbeveiliging niet opnieuw in. In plaats daarvan richt het zich op hoe type 1, type 2 en type 3 SPD's verschillen in rol, capaciteit en systeeminteractie, en hoe ingenieurs de juiste plaatsing in echte elektrische installaties bepalen.

Vergelijkingsraamwerk: hoe SPD-typen worden gedifferentieerd

SPD-classificatie is niet gebaseerd op productgrootte, prijs of waargenomen robuustheid. Het is gebaseerd op de installatiepositie en de verwachte blootstelling aan pieken.

Terwijl Surge Energy door een elektrisch systeem reist, veranderen de kenmerken ervan:

- Stroomstootstroom magnitude neemt af

- Golfvormvorm evolueert

- Restspanning blijft gevaarlijk voor gevoelige apparatuur

Vanwege dit gedrag is overspanningsbeveiliging verdeeld in zones. Elk type SPD is ontworpen om binnen een specifieke zone te werken, waar het overspanningsspanning kan beheersen zonder overbelast of ondermaats te presteren.

De vergelijking tussen type 1, type 2 en type 3 SPD's moet altijd overwegen:

- Installatielocatie

- Verwachte stijging van het energieniveau

- Primaire beschermingsfunctie

- Afhankelijkheid van andere SPD-types

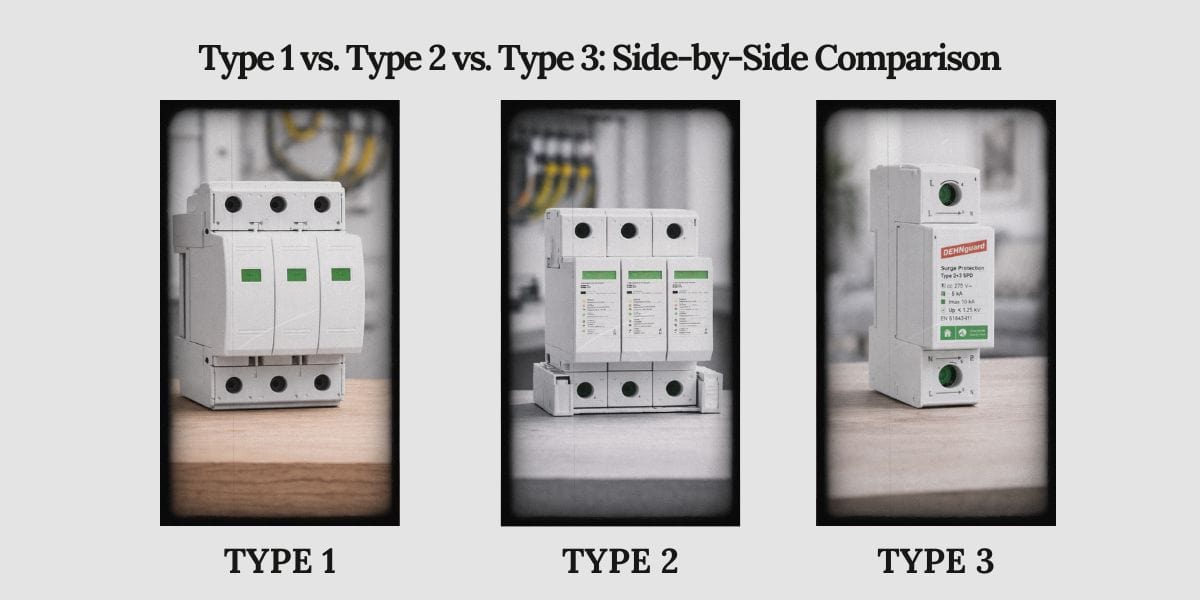

Type 1 vs. Type 2 vs. Type 3: Vergelijking naast elkaar

| Parameter | Type 1 SPD | Type 2 SPD | Type 3 SPD |

| Typische installatielocatie | Service-ingang, lijnzijde van hoofdverbreekt | Verdeelpanelen, laadzijde van ontkoppeling | In de buurt van gevoelige apparatuur |

| Blootstellingsniveau overschrijden | zeer hoog | Middelgrote tot hoge | Laag |

| primaire functie | Omleid inkomende piekstroom | Klem rest- en schakelpieken | Fijne spanningsbeperking |

| stroompurgeerstroom | zeer hoog | Matig tot hoog | Laag |

| Precisie van de spanningsklemmen | Laag | Medium | Hoog |

| Op zichzelf staande geschiktheid | Geen | schraal | Geen |

| Afhankelijkheid van andere SPD's | Vereist Type 2 stroomafwaarts | Vaak gekoppeld aan type 1 en type 3 | Vereist upstream type 1 of type 2 |

| Typisch risico indien verkeerd toegepast | Ontoereikende bescherming van apparatuur | Overbelasting en verminderde levensduur | Catastrofale mislukking |

Deze vergelijking benadrukt een belangrijk principe: SPD-types worden gedefinieerd door functie en plaatsing, niet door prestatierangschikking.

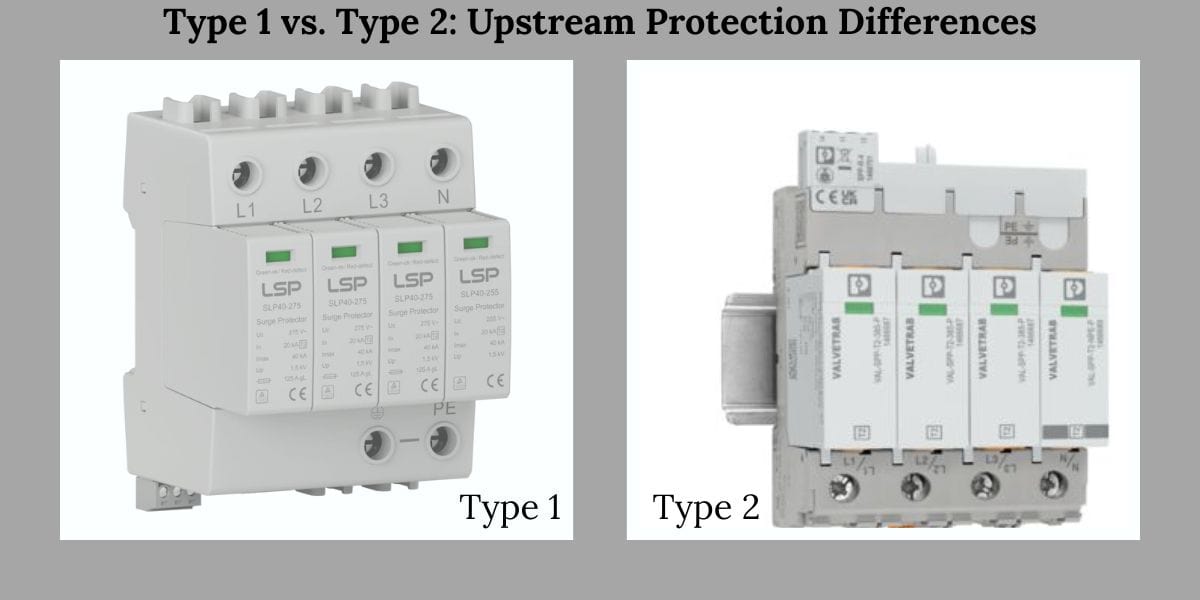

Type 1 vs. Type 2: Upstream-beschermingsverschillen

Installatiecontext

Type 1 SPD's worden geïnstalleerd bij de service-ingang, waar de blootstelling aan externe pieken het hoogst is. Type 2 SPD's worden stroomafwaarts geïnstalleerd, binnen het interne distributiesysteem.

Dit positionele verschil verandert fundamenteel wat elk apparaat naar verwachting zal verwerken.

Surge energieprofiel

- Type 1 SPD's Ontmoet energieke impulsen die verband houden met bliksemgerelateerde gebeurtenissen die vanuit het nutsnetwerk binnenkomen.

- Type 2 SPD's Ontwikkel resterende bliksemenergie en frequente intern gegenereerde schakeltransiënten.

Omdat type 2-apparaten niet zijn ontworpen voor de hoogste energieimpulsen, kunnen ze niet vervangen door de type 1-beveiliging bij de service-ingang.

Functionele onderscheiding

- Type 1 richt zich op overspanningsstroomomleiding

- Type 2 richt zich op spanningsbeperking en herhaalde overspanningsregeling

Alleen type 2-bescherming installeren in omgevingen met een hoge blootstelling verschuift overmatige stress naar apparaten die er niet voor zijn ontworpen, wat leidt tot voortijdige degradatie.

Type 2 vs. Type 3: Distributie versus bescherming op apparatuurniveau

Installatie nabijheid

Type 2 SPD's beschermen distributienetwerken, terwijl Type 3 SPD's individuele apparatuur of circuits beschermen. De afstand tussen de SPD en de beschermde belasting is een kritische differentiator.

Resterende spanningsregeling

Na stroomopwaartse bescherming kan de restspanning van de rest nog steeds de impulsbestendige capaciteit van gevoelige elektronica overschrijden. Type 3 SPD's bieden fijne spanningsverfijning op het gebruikspunt.

Beperking van energieverwerking

Type 3 SPD's zijn niet ontworpen om piekenergie te absorberen. Als ze direct worden blootgesteld aan hoogenergetische gebeurtenissen, kunnen ze snel falen. Daarom mogen ze nooit zonder stroomopwaartse bescherming worden gebruikt.

De vergelijking tussen type 2 en type 3 gaat niet over wat "beter" is, maar over waar precisie de energiebehandeling vervangt.

Waarom geen enkel SPD-type genoeg is

Overspanningsbeveiliging is niet additief. Het installeren van meerdere apparaten van hetzelfde type biedt geen gelaagde bescherming.

Elk type SPD werkt alleen optimaal binnen het beoogde spanningsbereik:

- Type 1 vermindert inkomende piekenergie

- Type 2 beheert resterende overspanning

- Type 3 beperkt de eindrestspanning

Als u probeert al deze functies uit te voeren met een enkel apparaat, resulteert dit in een gecompromitteerde bescherming, een verkorte levensduur of beide.

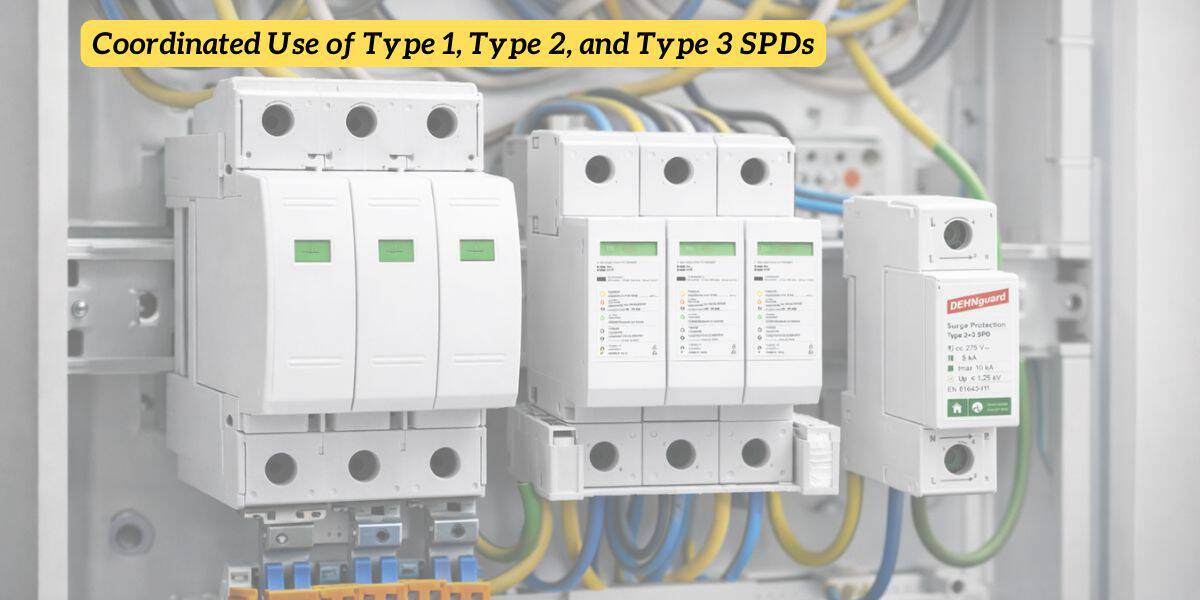

Gecoördineerd gebruik van type 1, type 2 en type 3 SPD's

Hoe coördinatie werkt

Een gecoördineerd overspanningsbeveiligingssysteem weerspiegelt de manier waarop overspanningsenergie zich voortplant:

- Type 1 Leidt hoogenergetische impulsen af bij het binnendringen van het systeem

- Type 2 Klems resterende pieken binnen het distributiesysteem

- Type 3 Beschermt gevoelige belastingen tegen restspanning

Elke fase vermindert de stress op de volgende.

Waarom coördinatie belangrijker is dan kwantiteit

Onjuiste coördinatie kan leiden tot:

- Ongelijke energiedeling

- Gelokaliseerde oververhitting

- Onvoorspelbaar faalgedrag

Correcte plaatsing en impedantiescheiding zijn belangrijker dan het installeren van extra apparaten.

Op applicaties gebaseerde vergelijkingsscenario's

Service-ingang met externe blootstelling

Faciliteiten met bovengrondse nutsleidingen of elektrische buiteninfrastructuur vereisen bescherming van type 1 bij de dienstingang, gevolgd door Type 2-bescherming stroomafwaarts.

Commerciële en industriële distributiesystemen

Schakelactiviteiten domineren de piekactiviteit. Type 2 SPD's bieden de primaire beschermingsrol, vaak gecoördineerd met stroomopwaartse type 1-apparaten.

Gevoelige elektronische systemen

Automatiseringscontrollers, instrumentatie en communicatie-interfaces vereisen bescherming van type 3, maar alleen wanneer stroomopwaartse piekenergie al is verminderd.

Enkelfase- versus driefasesystemen

Een 3 fase Surge-beschermend apparaat Moet fase-tot-fase en fase-naar-grond transiënten consistent beheren. SPD-typeselectie moet uitlijnen met de systeemconfiguratie, niet alleen op de spanningsclassificatie.

Veelvoorkomende vergelijkingsfouten maken ingenieurs

- Ervan uitgaande dat type 3-apparaten standalone kunnen werken

- Overmaats één SPD in plaats van meerdere typen te coördineren

- Meerdere type 2-apparaten installeren zonder rekening te houden met impedantie

- SPD-types behandelen als prestatieniveaus in plaats van functionele rollen

Deze fouten verminderen de effectiviteit van de bescherming en verhogen het onderhoudsrisico.

Standaarden context

Standaarden zoals UL 1449 en IEC 61643 definiëren testomstandigheden en classificatiecriteria voor SPD-typen. Ze ondersteunen consistente vergelijking, maar ze vervangen geen technische beoordeling op systeemniveau met betrekking tot plaatsing en coördinatie.

Conclusie

Type 1, type 2 en type 3 overspanningsbeveiligingsapparaten dienen verschillende en complementaire rollen binnen een elektrisch systeem. Hun verschillen worden bepaald door installatielocatie, piekblootstelling en beschermingsfunctie, niet door productklasse of marketingpositie.

Effectieve overspanningsbeveiliging is afhankelijk van coördinatie, niet van overmaat of redundantie. Wanneer elk type SPD wordt toegepast waar het het beste presteert, wordt de stroompiekenergie geleidelijk gecontroleerd, wordt de spanning van de apparatuur verminderd en verbetert de betrouwbaarheid van het systeem op lange termijn.

FAQs

heel weinig . Type 2-apparaten zijn niet ontworpen voor de hoogste piekblootstellingsniveaus die aanwezig zijn bij het binnendringen van het systeem.

Alleen indirect, en alleen wanneer de stroomopwaartse bescherming al de stroomstootenergie heeft verminderd.

In omgevingen met weinig blootstelling kan het acceptabel zijn, maar het risico neemt aanzienlijk toe zonder stroomopwaartse bescherming.

Omdat een onjuiste plaatsing apparaten kan overbelasten, ongeacht de beoordeling.

Niet altijd, maar de meeste moderne installaties profiteren van ten minste type 1 en type 2 coördinatie.