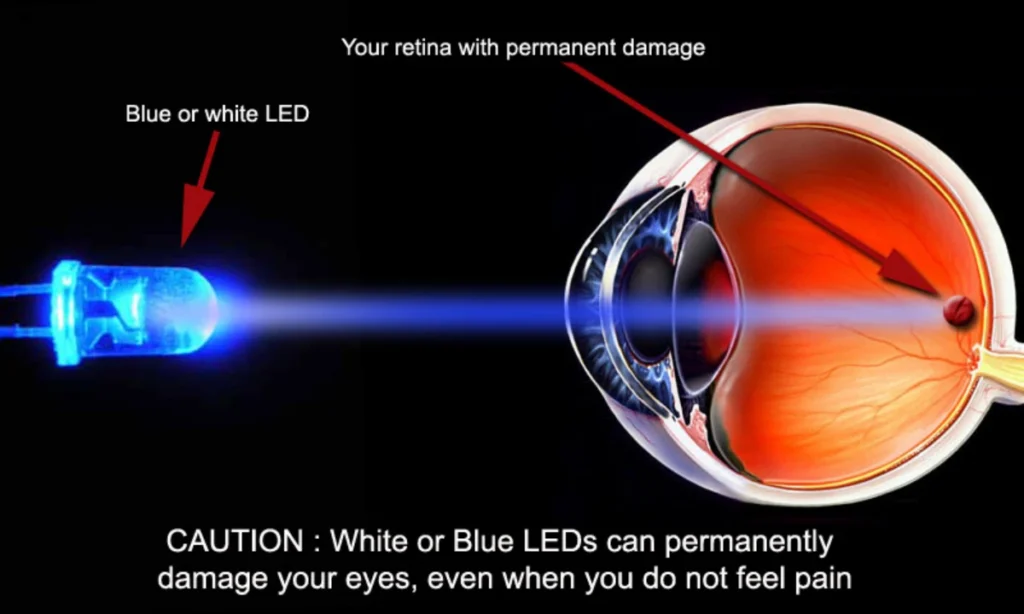

A luz azul é uma parte natural do espectro visível, mas a iluminação LED moderna contém uma quantidade proporcionalmente maior de comprimentos de onda azuis - normalmente na faixa de 400 a 500 nm - devido à maneira como os LEDs brancos são fabricados. A maioria dos LEDs brancos usa um chip LED azul emparelhado com revestimento de fósforo para gerar luz branca de espectro total. Embora essa tecnologia forneça alta eficiência e excelente produção de lúmen, ela também apresenta preocupações sobre o risco de luz azul, um risco fotoquímico para a retina humana causada pela exposição excessiva à radiação azul de alta energia.

Nos últimos anos, reguladores, designers de iluminação e fabricantes de OEM prestaram atenção crescente aos efeitos potenciais da luz azul. A exposição a longo prazo ou de alta intensidade pode contribuir para o estresse da retina, desconforto visual e ruptura do ritmo circadiano. À medida que a iluminação LED se torna amplamente utilizada em escritórios, residências, escolas, espaços comerciais e monitores, o entendimento e o controle do risco de luz azul tornaram-se essenciais para garantir a segurança visual e o cumprimento dos padrões fotobiológicos.

Este artigo se concentra no risco de luz azul, conforme definido na IEC 62471, explicando as principais métricas técnicas, classificações de grupos de risco e como escolher luzes LED com luz azul inferior para aplicações de iluminação profissional.

Qual é o risco de luz azul na IEC 62471?

O risco de luz azul refere-se ao potencial dano fotoquímico à retina causado pela exposição a comprimentos de onda azuis de alta energia, normalmente dentro de 400 a 500 nm. Quando o olho é exposto à luz azul intensa por uma duração suficiente, as espécies reativas de oxigênio podem se formar nos tecidos da retina, acelerando a degradação das células da retina. Este efeito é cumulativo e depende da intensidade e do tempo de exposição, tornando-o uma consideração crítica de segurança para produtos de iluminação vistos diretamente, como tiras de LED, módulos e monitores.

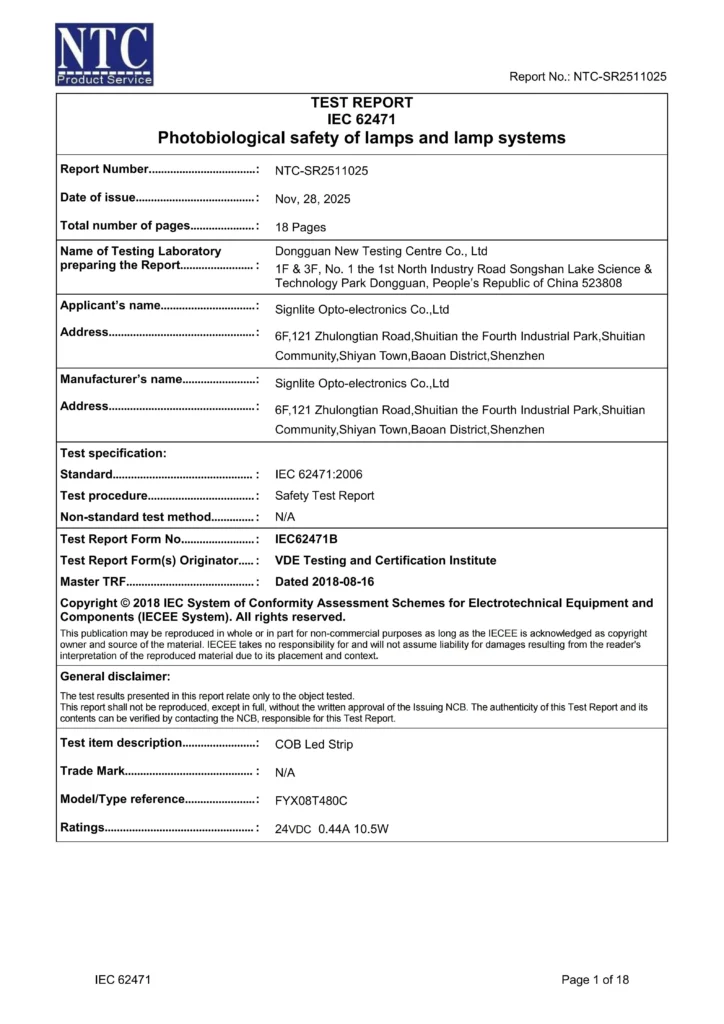

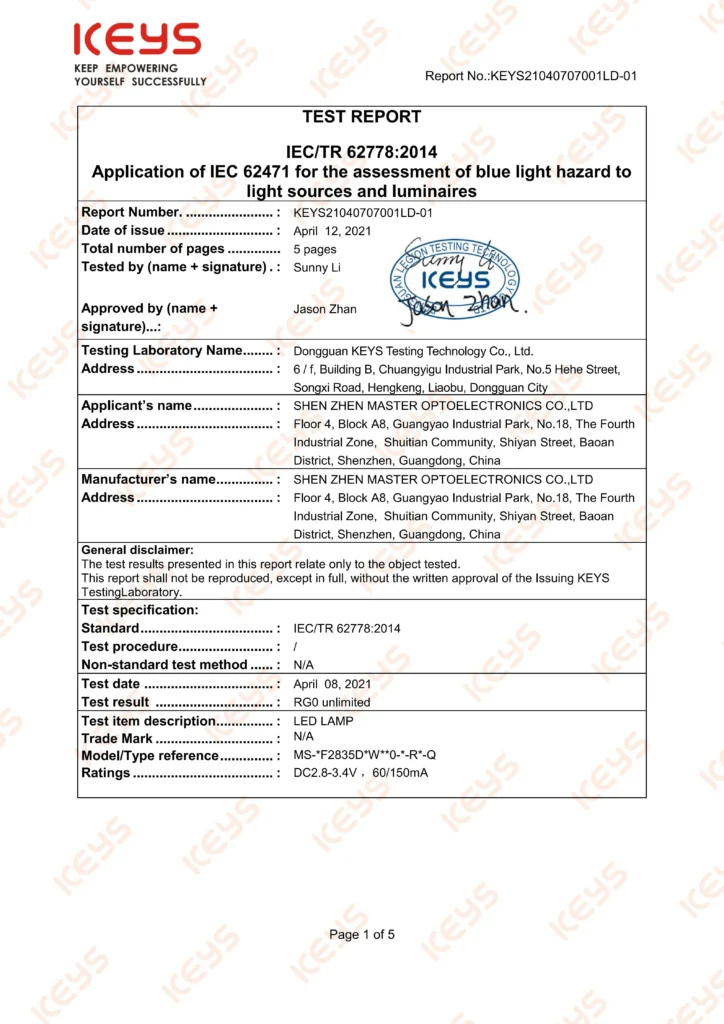

A IEC 62471 é o padrão reconhecido internacionalmente que avalia a segurança fotobiológica de lâmpadas e sistemas de lâmpadas. Ele define métodos de medição, espectros de ação de perigo, limites de exposição e classificações de grupos de risco para diferentes riscos fotobiológicos, incluindo risco de luz azul, risco de raios UV e risco de radiação IR. Para uma avaliação específica da luz azul, a IEC 62471 usa o brilho ponderado pela luz azul e calcula os tempos máximos de exposição segura para determinar o grupo de risco apropriado.

À medida que a tecnologia de iluminação LED continua avançando, a conformidade com a IEC 62471 se torna essencial. Como os LEDs geralmente têm picos azuis fortes devido ao seu design convertido com fósforo, eles devem passar por um teste de risco de luz azul para garantir que cumpram os limites de segurança para a exposição humana. Seja para aplicações residenciais, comerciais ou profissionais, espera-se que os produtos LED sejam classificados como RG0 ou RG1 para entrar em muitos mercados globais, tornando o teste IEC 62471 uma parte obrigatória do desenvolvimento do produto LED.

Principais parâmetros técnicos para avaliar o risco de luz azul

1. Radiância ponderada em luz azul (L_B)

A Radiância Peso da Luz Azul (L_B) é o parâmetro central usado na IEC 62471 para quantificar o risco de luz azul. Ele representa o brilho de uma fonte de luz ponderada pela função de risco de luz azul B(λ), que enfatiza os comprimentos de onda mais prejudiciais à retina (cerca de 435 a 440 nm). A unidade é W·M⁻²·SR⁻¹, expressando quanta energia ponderada em azul atinge o olho por unidade de área e por unidade de ângulo sólido.

Como é determinado:

O teste envolve medir a radiância espectral da fonte usando um espectrorradiômetro calibrado. Cada componente de comprimento de onda é multiplicado pela função de ponderação de risco azul B(λ), e a integração entre 300–700 nm produz o valor L_B final. A IEC 62471 requer medições a uma distância padronizada – normalmente 200 mm – e exige que o teste capture o ponto de luminância máximo da fonte. Para tiras de LED, isso significa medir o chip ou ponto de acesso mais brilhante. tiras de espiga Geralmente mostram uma distribuição de luminosidade mais suave, resultando em L_B mais baixos em comparação com as tiras SMD de origem pontual.

2 . Exposição Radiante Luz Azul (H_B)

A exposição Radiant Blue Light (H_B) refere-se à quantidade total de energia ponderada por luz azul fornecida à retina ao longo do tempo, levando em consideração a duração da luminosidade e da exposição. Enquanto L_B descreve a intensidade em um momento, H_B representa uma exposição acumulada e é expresso em J·M⁻²·SR⁻¹. A IEC 62471 usa H_B como um parâmetro de suporte em cenários em que a fonte é estendida ou visualizada de perto por períodos mais longos. Esse parâmetro se torna essencial em aplicativos como iluminação de tarefas, monitores e luminárias instaladas em ambientes próximos.

3. Limite de exposição ao risco de luz azul (T_MAX)

Para determinar quanto tempo uma pessoa pode visualizar com segurança uma fonte de luz, a IEC 62471 define o tempo máximo de exposição permitido (T_MAX). É derivado comparando o L_B medido com o limite de exposição definido para o risco de luz azul. A expressão IEC simplificada é:

t_max = 100 / l_b

(Válido quando L_B ≥ 100 W·m⁻²·Sr⁻¹)

Isso significa que, à medida que o brilho ponderado pela luz azul aumenta, o tempo de visualização seguro é permitido diminui drasticamente. Por exemplo, se L_B for 200 W·m⁻²·Sr⁻¹, a exposição máxima segura seria de apenas 0,5 segundos. Esta fórmula orienta a classificação do grupo de risco e ajuda a determinar se um produto cai em RG0 (sem risco), RG1 (baixo risco), RG2 (risco moderado) ou RG3 (alto risco). Em iluminação LED, especialmente tiras e módulos projetados para visualização direta, o limite T_MAX é fundamental para garantir o uso seguro e a conformidade regulatória.

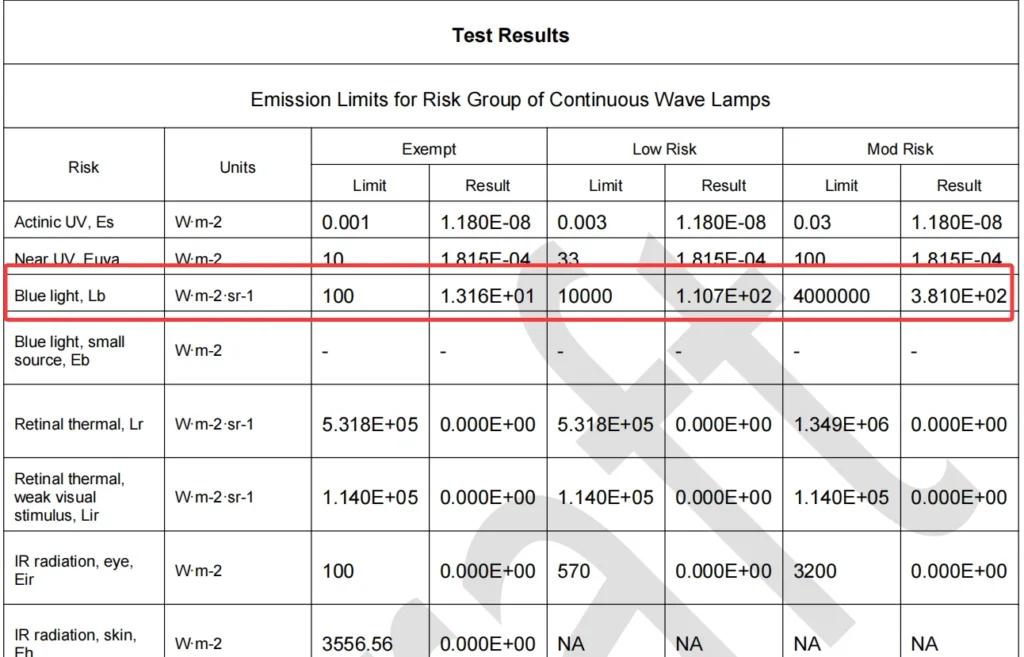

Classificação do Grupo de Risco de Risco de Luz Azul IEC 62471

A IEC 62471 classifica os produtos de iluminação em quatro grupos de risco com base em sua alteira de luz azul (L_B) e no correspondente tempo máximo de exposição segura (T_MAX). Essas categorias ajudam a determinar se um produto é seguro para visualização direta humana.

1. Grupo de Risco 0 (RG0 – Isento)

Sem risco fotobiológico.

Limite: L_B ≤ 100 W·m⁻²·Sr⁻¹ ou T_max ≥ 100 s.

2 . Grupo de Risco 1 (RG1 – Risco de Baixo)

Nenhum perigo em condições normais de visualização.

Limite: L_B ≤ 10.000 W·m⁻²·Sr⁻¹ ou T_max ≥ 0,01 s.

3. Grupo de Risco 2 (RG2 – Risco Moderado)

Perigo apenas se o espectador olhar intencionalmente para a fonte.

Limite: L_B ≤ 400.000 W·m⁻²·Sr⁻¹.

4. Grupo de Risco 3 (RG3 – Risco de Alto)

perigo devido à exposição momentânea.

Limite: L_B > 400.000 W·m⁻²·Sr⁻¹.

Exemplo de níveis de risco de luz azul para diferentes produtos de iluminação

| Tipo de produto de iluminação | CCT típico | óptica/difusão | Grupo de risco típico |

| Tira de LED de espiga (capa fosca) | 3000K | difusão forte | rg0 |

| tira led de espiga (nua) | 2700-6500K | sem capa | rg0 |

| SMD 2835 LED Strip (alta densidade) | 4000K | sem capa | RG1 |

| SMD 5050 RGB Strip | Comprimentos de onda mistos | sem capa | RG1 |

| Luz linear com difusor de pc | 3.000–4000k | difusor fosco | rg0 |

| downlight LED | 3.000–5.000k | Lente + refletor | RG1 |

| Luz industrial de baía alta | 5000–6000k | viga estreita | RG2 |

| Palco/Stuplight do estúdio | 6.000–8.000k | feixe concentrado | RG2–RG3 |

Como escolher luzes de tiras de LED com menor risco de luz azul

1. Escolha as tiras de LED CCT inferiores

As tiras de LED brancas quentes (2700K–4000K) contêm significativamente menos conteúdo de comprimento de onda azul de alta energia. As opções de CCT mais baixas naturalmente reduzem o risco de luz azul e são ideais para iluminação ambiente residencial, hoteleira e comercial.

2. Selecione faixas de LED CRI com alto

Os LEDs de alto CRI usam formulações de fósforo aprimoradas que produzem um espectro mais suave e completo com picos azuis reduzidos. As tiras CRI 90+ ou CRI 95+ geralmente oferecem um desempenho óptico mais seguro em comparação com os LEDs de baixo CRI.

3. Prefira tiras de LED COB a SMD

As tiras de espiga apresentam emissores revestidos de fósforo contínuos que eliminam os pontos de acesso intensos de fonte pontual. Sua luminância uniforme resulta em uma radiância ponderada em luz azul (L_B), tornando o COB uma escolha mais segura do que o SMD em aplicações de visualização próxima.

Luz sem costura de tira de espiga, RA90, compativel com IEC 62471

Modelo n.º: FYX08T480X

Tensão de entrada: DC12V/24V

Potência: 11W/m

Qtd. de LEDs: 480LEDs/m

CCT: 2700K, 3000K, 4000K, 6500K

CRI: >95

Eficiência: 105lm/W

Ângulo do feixe: 180°.

Secção de corte: 25mm/50mm

Classificação IP: IP20/IP65/IP67/IP68

Garantia: 3 anos

4. Escolha strips de alta eficiência e baixo consumo

Os LEDs acionados em correntes mais baixas geram menos brilho e produzem um espectro mais estável. Projetos de baixa potência de alta eficiência reduzem a intensidade do pico azul e o estresse térmico. Verifique a luz de faixa de 180 LM/W com sinais de sinalização FQM10T128C.

5. Use soluções difusas

Tiras emparelhadas com difusores, como tubos de silicone fosco, Flex de néon, ou canais de alumínio rígido com capas para PC – reduz significativamente a luminância de pico, diminuindo o risco de luz azul enquanto melhora o conforto visual.

Luz de tira de neon superior dobrada

Nº do modelo: nqx1010tc

Tensão de entrada: DC12V/24V

Watts: 8W/m

Qtde. de LEDs: SMD2835 120LEDs/m

Temperatura de cor: 2700K/4000K/6500K

CRI: RA>80

Diâmetro de dobra minúscula: 25 mm

Comprimento de corte: 100mm

Comprimento: 5 metros/rolo

6. Escolha tiras de LED com certificação IEC 62471

Sempre solicite um relatório completo da IEC 62471. Os produtos com classificação RG0 ou RG1 garantem a conformidade com os requisitos globais de segurança fotobiológica.

A Signliteld oferece luzes de tiras de espiga certificadas com IEC 62471, módulos de LED SMD com baixo CCT, módulos de Neon Flex e LED, fornecendo soluções seguras e confiáveis para projetos de iluminação profissional.