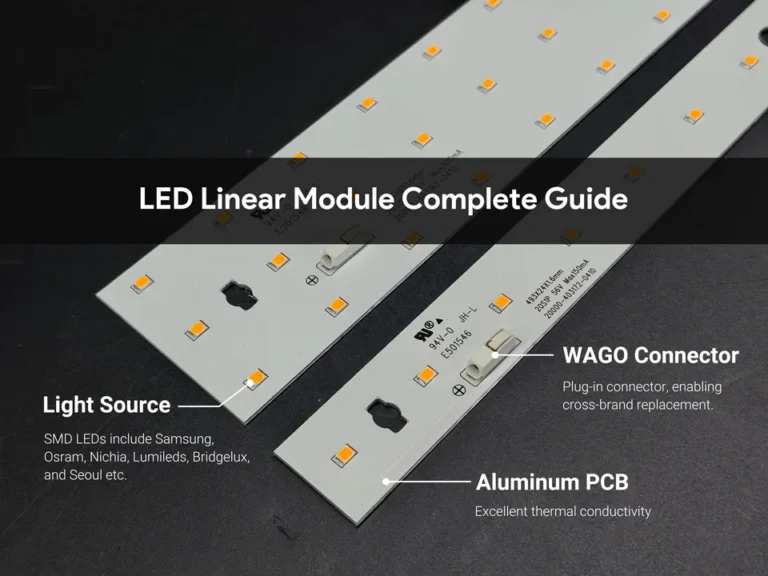

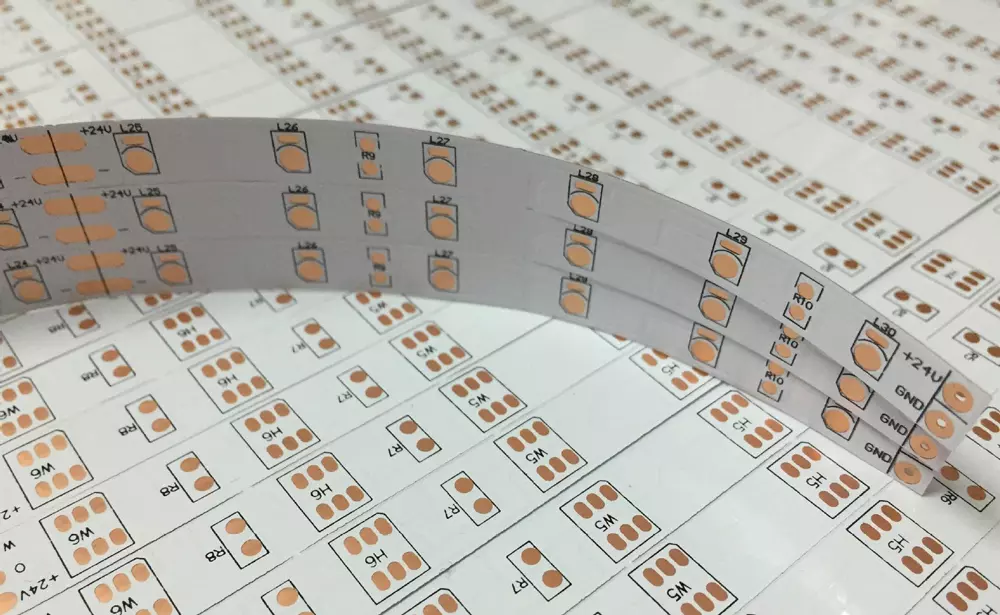

LED strips, also known as flexible LED strips, use flexible circuit boards, which are soft and dexterous, resistant to folding and bending, and have high flexibility. They are widely used in the production of linear lighting products such as light strips.

The unique characteristics of the flexible circuit board make it a rigid circuit board in many occasions, and it also promotes the development of many fields.

Common types of flexible circuit boards:

1. Single panel

After the circuit is completed, a single-sided PI copper-clad plate is used to cover a layer of protective film to form a flexible circuit board with only a single-layer conductor;

2. Ordinary double panel

Use double-sided PI copper-clad board material to complete the double-sided circuit, and add a layer of protective film on both sides to become a circuit board with double-layer conductors;

3. Substrate generation single panel

Using pure copper foil material in the circuit production, add a layer of protective film on each side of the front and back respectively, to become a kind of single-layer conductor but with conductors exposed on both sides of the circuit board;

4. Substrate generates double-sided panels

Two layers of single-sided PI copper-clad board materials are used in the middle to be pressed together with an adhesive that opens a window at a specific position to become a double-sided conductor circuit board that is laminated in a local area and has a two-layer separation structure in the local area to achieve in the delamination area. Boards with high flex performance.

Advantages of flexible circuit boards:

1. It can be bent, wound and folded freely, and can be arranged arbitrarily according to the requirements of space layout.

2. Using FPC can greatly reduce the volume and weight of electronic products.

3. FPC also has good heat dissipation and solderability and is easy to assemble and connect, and the overall cost is low.

Disadvantages of flexible circuit boards:

1. High one-time initial cost

Since the flexible PCB circuit board is designed for special applications, the cost of circuit design, wiring and photo base is relatively high, unless there is a special need to apply flexible PCB

2. It is difficult to change and repair the flexible PCB

Once the flexible PCB circuit board is made, it must be changed from the base map or the compiled light drawing program, so it is not easy to change. Its surface is covered with a layer of protective film, which needs to be removed before repairing and restored after repairing, which is relatively difficult work.

3. Size is limited

When the flexible PCB circuit board is not yet popular, it is usually manufactured by the batch process, so it cannot be made very long and wide due to the limitation of the size of the production equipment.

4. Improper operation is easy to damage