The main differences between high density LED strips and standard LED strips are found in LED quantity per meter, light uniformity, visual quality, heat management requirements, and suitable applications, all of which directly affect how professional and reliable a lighting installation looks and performs.

Understanding these differences is critical for architects, lighting designers, engineers, and buyers who want consistent illumination, long service life, and a refined appearance. Choosing the wrong LED strip can result in visible hot spots, uneven lighting, or premature failure. This article explains what high density LED strips are, how they technically compare to standard LED strips, where each type should be used, and how to make the right selection for your project.

What Are High Density LED Strips and Why Do They Matter?

High density LED strips are LED light strips that contain a significantly higher number of LEDs per meter compared to standard LED strips. By reducing the spacing between individual LEDs, these strips produce a smoother and more continuous line of light.

The main reason high density LED strips matter is light quality. When LEDs are closely spaced, the lighting output appears uniform rather than dotted. This is especially important when the strip is visible or installed close to the illuminated surface. In professional architectural and decorative lighting, visible LED points are generally considered unacceptable.

High density LED strips are widely used in applications that demand visual precision, such as premium interiors, retail displays, and architectural coves. They are available in advanced SMD LED strip configurations as well as COB LED strip designs, both of which are engineered to achieve high LED density and superior uniformity.

Key reasons professionals choose high density LED strips include:

- Smoother and more uniform light output

- Reduced visible hot spots in close-view installations

- Improved visual quality for architectural lighting

Key Specifications: High Density vs. Standard LED Strip Buying Guide

The technical specifications of an LED strip determine how it performs in real-world applications. Comparing high density LED strips with standard LED strips across key parameters helps clarify why one may be more suitable than the other.

| Feature | High Density LED Strips | Standard Density LED Strips |

| LEDs per Meter | 240 LEDs/m, 480 LEDs/m or higher | 60 LEDs/m, 120 LEDs/m |

| Light Uniformity | Seamless, continuous light output | Individual LED points may be visible |

| Visual Appearance | Premium and refined | Functional but less uniform |

| Typical Applications | Architectural lighting, display cases, coves | Utility lighting, hidden installations |

| Heat Management | Requires proper aluminum profiles | Lower heat dissipation requirements |

Understanding LED Types: SMD vs. COB

An SMD LED strip uses surface-mounted LED chips such as 2835 or 5050 and is widely used for flexible, cost-effective lighting solutions. When manufactured in high densities, SMD LED strips can achieve very good uniformity while maintaining flexibility and efficiency. They are commonly used for both functional and decorative lighting where controlled brightness and color consistency are required.

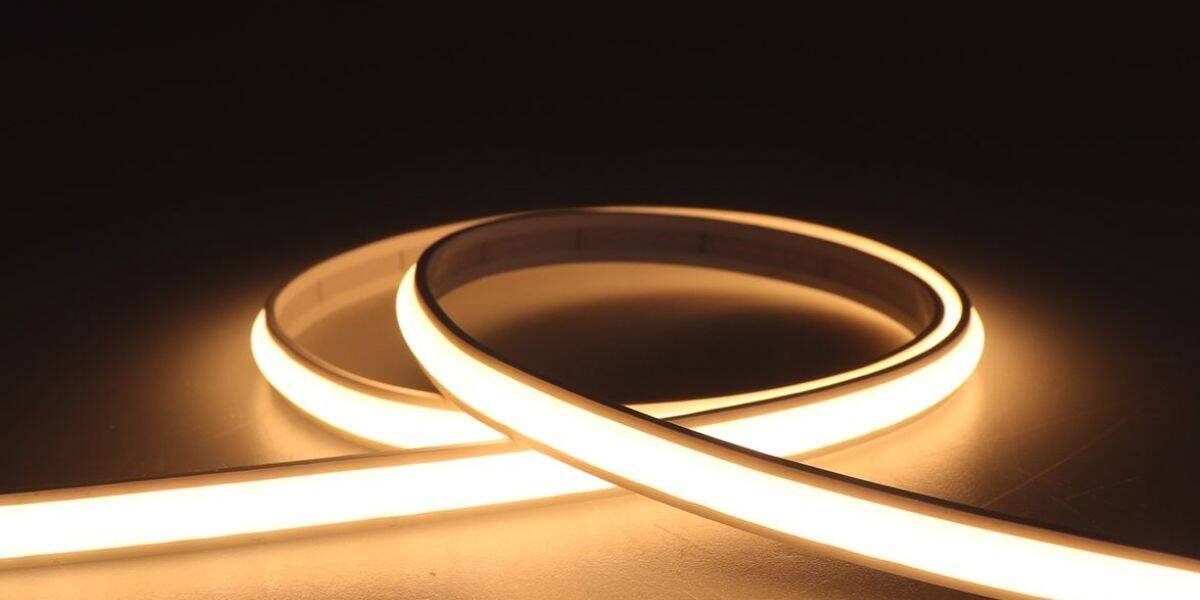

A COB LED strip provides ultra-high LED density and a perfectly smooth, dot-free lighting effect for premium visible installations, using Chip-on-Board technology in which a large number of micro-LEDs are mounted directly onto the strip and covered with a continuous phosphor layer to ensure uniform light output.

LED Density, Wattage, and Brightness Explained

When comparing LED strips, several technical factors should always be evaluated:

- LED density directly affects light uniformity and visual comfort

- Higher LED counts generally increase lumen output per meter

- Increased density also raises power consumption and heat generation

High density LED strips typically deliver higher lumen output per meter, but they also require careful power supply selection and proper thermal management. For installations where the strip is directly visible or mounted close to the lighting surface, a high density LED strip is essential to achieve a professional finish.

Top Applications and Benefits: Where to Use Each Type

High density LED strips are best suited for applications where lighting quality and visual consistency are critical, including: – Kitchen under-cabinet lighting, where even illumination without shadows is required

- Museum and retail display lighting, ensuring products are evenly lit without distracting bright spots

- Architectural cove lighting, creating smooth indirect light lines without scalloping effects

Standard LED strips are more appropriate for areas where the light source is hidden or visual perfection is not required. These include utility rooms, workshops, inside cabinets, and simple indirect ceiling washes. In such cases, the lower LED density does not negatively impact the overall lighting effect.

How to Choose: High Density or Standard LED Strips for Your Project

Selecting the correct LED strip begins with evaluating how the lighting will be seen and used. A simple evaluation process includes: – Whether the LEDs will be directly visible

- The distance between the LED strip and the illuminated surface

If the LEDs are directly visible or installed close to the illuminated surface, high density LED strips are strongly recommended. If the lighting is concealed and primarily functional, standard LED strips may be sufficient.

Next, define the quality level required for the project. Premium residential, commercial, and architectural projects typically demand seamless lighting output, making high density or COB LED strips the better choice. Budget-focused or utility installations can often rely on standard SMD LED strips.

Brightness requirements and power supply capacity should also be carefully calculated. Higher LED density usually means higher wattage per meter, which requires appropriate driver sizing and voltage drop planning. Finally, proper heat management should be considered, as high density LED strips perform best when installed in aluminum profiles that dissipate heat effectively.

Why Partner with SignliteLED for Your LED Strip Needs?

Choosing a reliable LED strip manufacturer is just as important as selecting the correct LED density. SignliteLED provides professional LED strip solutions designed for long-term performance, consistent quality, and demanding project requirements.

| Model & Link | Ideal For | LED Type & Key Feature | Direct Benefit |

| SMD LED Strip Light | General and accent lighting applications | SMD LED strip with multiple density options and stable color performance | Reliable brightness and flexible installation options |

| COB LED Strip Lights | High-end projects requiring seamless light | COB LED strip with ultra-high density and dot-free output | Perfectly smooth light line for visible installations |

SignliteLED supports projects with long-term product warranties, OEM and ODM customization, stable supply capacity, and professional technical guidance. These strengths make SignliteLED a dependable partner for both high density LED strips and standard LED strip solutions.

SMD2216 LED Strip Light

- Main Model: FWX10T240C

- LED QTY per Meter Option: 120/180/240/300/420

- PCB Width Option: 5mm/10mm

- Color Option: 2700K/3000K/4000K/5000K/6500K

- CRI Option: 80/90

- Input Voltage: DC12V/DC24V

- Power per Meter: 9.6W/10W/14.4W/19.2W/20W/24W

- IP Grade Option: IP20/IP54/IP65/IP67/IP68

- Warranty: 5 years

Single Color COB LED Strip Light

- Main Model: FYX08T480C

- LED Chip QTY per Meter: 320/384/480/528chips (Sanan)

- CRI: >90

- PCB Width: 8mm/10mm

- Color Temperature: 2700K/3000K/4000K/6500K

- Input Voltage: DC12V/DC24V

- Power per Meter: 8W/10W/11W/14W

- Efficiency: 130-150lm/W

- IP Grade: IP20/IP54/IP65/IP67/IP68

- Warranty: 3 years

Conclusion

The difference between high density LED strips and standard LED strips lies primarily in LED spacing, light uniformity, and application suitability. High density LED strips are essential for visible, high-quality lighting designs, while standard LED strips remain practical for concealed or basic installations. COB LED strips offer the highest level of uniformity and are ideal for premium architectural lighting.

For projects that require reliable performance and refined lighting aesthetics, selecting the appropriate LED strip and working with an experienced manufacturer such as SignliteLED ensures successful and long-lasting results.

FAQs

A high density LED strip is defined by a significantly higher number of LEDs per meter, which produces smoother and more uniform light compared to standard density strips.

Yes. COB LED strips are one of the highest-density LED strip technologies available and provide a continuous, dot-free lighting effect.

Not always. High density LED strips are better for visible or quality-focused applications, while standard LED strips are suitable for hidden or functional lighting.

They typically require proper power supply planning and aluminum profiles for heat dissipation to ensure long service life.

They can be used if the light source is hidden, but for visible architectural features, high density LED strips are strongly recommended.