蓝光是可见光谱中的自然组成部分,但由于白色 LED 的制造方式,现代 LED 照明包含比例较高的蓝色波长——通常在 400-500 nm 范围内。 大多数白色 LED 使用蓝色 LED 芯片和荧光粉涂层来产生全光谱白光。 虽然这项技术提供了高效率和出色的流明输出,但它也带来了对蓝光危害的担忧,这是对人类视网膜的光化学风险,这是由于过度暴露于高能蓝色辐射而造成的。

近年来,监管机构、照明设计师和OEM制造商越来越关注蓝光的潜在影响。 长期或高强度暴露可能导致视网膜压力、视力不适和昼夜节律紊乱。 随着 LED 照明在办公室、家庭、学校、商业空间和显示器中的广泛使用,了解和控制蓝光危险对于确保视觉安全性和符合光生物标准的遵守变得至关重要。

本文重点介绍了 IEC 62471 中定义的蓝光危害,解释了关键技术指标、风险组分类以及如何为专业照明应用选择蓝光危险较低的 LED 灯带。

IEC 62471 下的蓝光危害是什么?

蓝光危险是指暴露于高能蓝色波长(通常在 400-500 nm 内)对视网膜的潜在光化学损伤。 当眼睛暴露在强蓝光下足够长的时间时,视网膜组织中会形成活性氧,加速视网膜细胞的降解。 这种效果是累积的,取决于强度和曝光时间,使其成为直接查看的照明产品(如 LED 灯条、模块和显示器)的关键安全考虑因素。

IEC 62471是国际公认的灯具和灯具系统光生物安全性的标准。 它定义了不同光生物风险的测量方法、危险作用光谱、暴露限值和风险组分类,包括蓝光危害、紫外线危害和红外辐射危害。 具体而言,对于蓝光评估,IEC 62471 使用蓝光加权辐射并计算最大安全曝光时间以确定适当的风险组。

随着 LED 照明技术的不断进步,符合 IEC 62471 的要求变得至关重要。 由于 LED 的磷光体转换设计通常具有很强的蓝色峰,因此必须进行蓝光危险测试,以确保它们达到人体暴露的安全阈值。 无论是住宅、商业或专业应用,LED 产品都将被分类为 RG0 或 RG1 以进入许多全球市场,这使得 IEC 62471 测试成为 LED 产品开发的必需部分。

蓝光危险评估关键技术参数

1。 蓝色光加权辐射 (L_B)

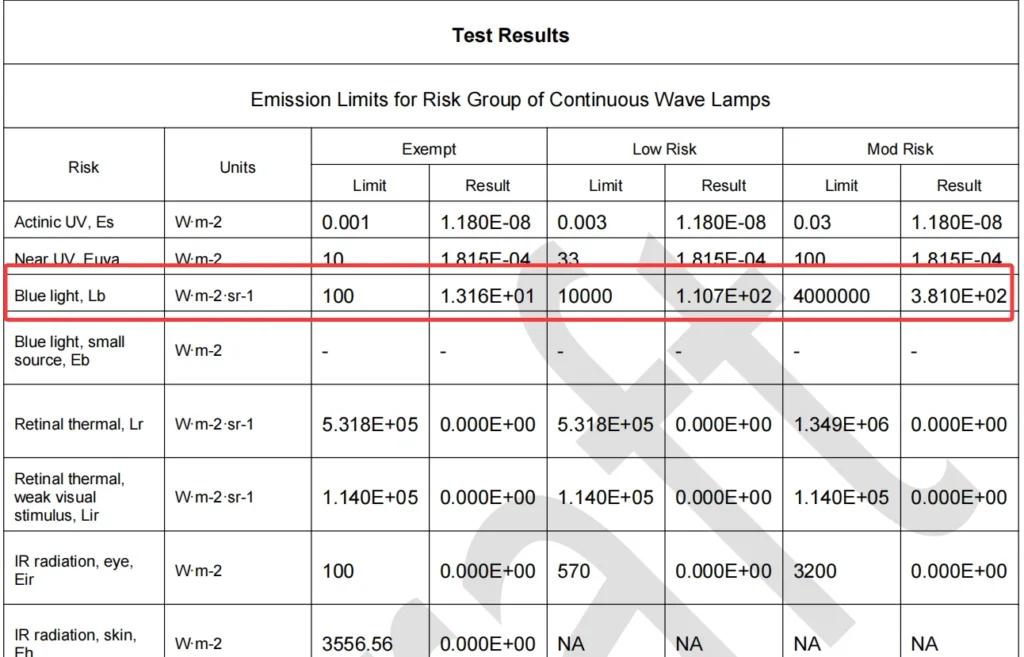

蓝光加权辐射 (L_B) 是 IEC 62471 中用于量化蓝光危险的核心参数。 它代表了由蓝光危害函数 B(λ) 加权的光源的辐射度,它强调对视网膜有害的波长(约 435-440 nm)。 单位为W·m⁻²·Sr⁻¹,表示每单位面积和单位立体角的蓝加重能量到达眼睛的程度。

如何确定:

测试涉及使用校准的光谱仪测量光源的光谱辐射。 每个波长分量乘以蓝色危险加权函数 B(λ),跨越 300-700 nm 产生最终的 L_B 值。 IEC 62471 要求在标准化距离(通常为 200 mm)处进行测量,并要求测试捕获源的最大亮度点。 对于 LED 灯条,这意味着测量最亮的芯片或热点。 棒状条 通常表现出更平滑的辐射分布,与点源 SMD 条相比,L_B 较低。

2 . 蓝光辐射曝光 (H_B)

蓝光辐射曝光 (H_B) 是指随时间传递到视网膜的蓝光加权能量的总量,同时考虑了辐射和曝光持续时间。 l_b 描述了强度,而 h_b 表示累积曝光,用 j·m⁻²·sr⁻¹ 表示,在源扩展或在较近范围内观察较长的时间段的情况下,IEC 62471 将 H_B 作为支持参数。 此参数在近场环境中安装的任务照明、显示器和灯具等应用中变得至关重要。

3. 蓝光危险暴露限值(T_MAX)

为了确定一个人可以安全地查看光源多长时间,IEC 62471 定义了最大允许曝光时间 (T_MAX)。 它是通过将测量的 L_B 与为蓝光危险定义的曝光极限进行比较而得出的。 简化的 IEC 表达式为:

t_max = 100 / l_b

(当 L_B ≥ 100 W·m⁻²·Sr⁻¹ 时有效)

这意味着随着蓝光加权辐射的增加,允许的安全观察时间急剧减少。 例如,如果 L_B 为 200 W·m⁻²·Sr⁻¹,则最大安全曝光时间仅为 0.5 秒。 该公式指导风险组分类,并有助于确定产品是否落入 RG0(无风险)、RG1(低风险)、RG2(中等风险)或 RG3(高风险)。 在 LED 照明中,尤其是专为直接查看而设计的灯条和模块,达到 T_MAX 阈值对于确保安全使用和法规合规性至关重要。

IEC 62471 蓝光危险危险组分类

IEC 62471 将照明产品根据蓝光加权辐射 (L_B) 和相应的最大安全曝光时间 (T_MAX) 分为四个风险组。 这些类别有助于确定产品是否可安全地进行人工直接观看。

1。 风险组 0 (RG0 – 豁免)

没有光生物学风险。

极限:L_B ≤ 100 W·m⁻²·Sr⁻¹ 或 T_max ≥ 100 s。

2 . 风险组 1 (RG1 – 低风险)

正常观看条件下无危险。

极限:L_B ≤ 10,000 W·m⁻²·Sr⁻¹ 或 T_max ≥ 0.01 s。

3。 风险组 2(RG2 – 中等风险)

只有当观众故意盯着源头时,才会危险。

极限:L_B ≤ 400,000 W·m⁻²·Sr⁻¹。

4。 风险组 3 (RG3 – 高风险)

即使是瞬间暴露的危险。

极限:L_B > 400,000 W·m⁻²·Sr⁻¹。

不同照明产品的蓝光危险等级示例

| 照明产品类型 | 典型的CCT | 光学/扩散 | 典型风险组 |

| COB LED 灯带(磨砂盖) | 3000K | 强扩散 | rg0 |

| COB LED 灯带(裸露) | 2700-6500K | 没有封面 | rg0 |

| SMD 2835 LED 灯带(高密度) | 4000K | 没有封面 | 1 号 |

| SMD 5050 RGB 条 | 混合波长 | 没有封面 | 1 号 |

| 带PC扩散器的线性光 | 3000–4000K | 磨砂扩散器 | rg0 |

| LED筒灯 | 3000–5000K | 镜头+反射器 | 1 号 |

| 高档工业灯 | 5000–6000K | 窄光束 | 二、RG2 |

| 舞台/工作室LED聚光灯 | 6000–8000K | 聚光束 | rg2–rg3 |

如何选择蓝光危险较低的LED灯带

1。 选择下方 CCT LED 灯条

暖白 LED 条(2700K–4000K)的高能蓝色波长含量明显较少。 较低的 CCT 选项自然可减少蓝光危险,非常适合住宅、酒店和商业环境照明。

2. 选择高 CRI LED 灯条

高CRI LED使用改进的荧光粉配方,产生更平滑、更饱满的光谱,减少蓝色峰。 与低CRI LED相比,CRI 90+或CRI 95+ 条带通常提供更安全的光学性能。

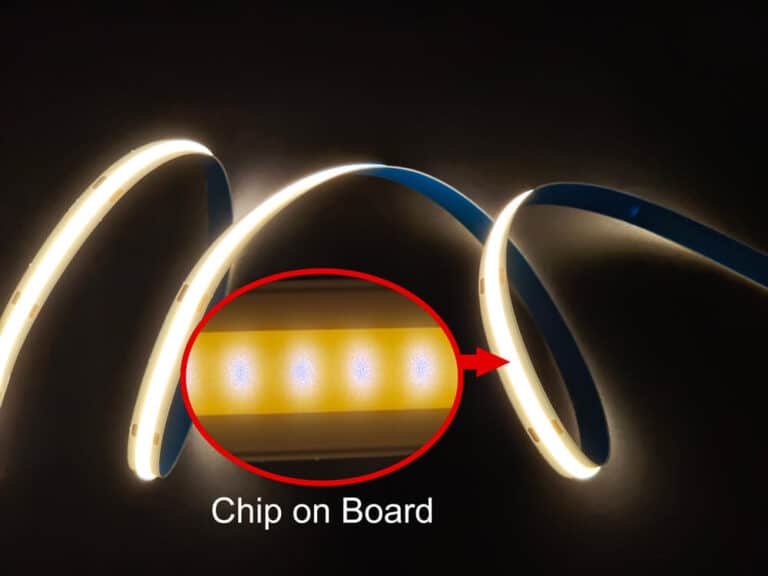

3。 比SMD更喜欢COB LED灯条

COB 带具有连续的荧光涂层发射器,可消除强烈的点源热点。 它们均匀的亮度可降低蓝光加权辐射(L_B),使COB在近视应用中成为比SMD更安全的选择。

无缝COB条形灯,RA90,与IEC 62471配合

型号:FYX08T480X

输入电压DC12V/24V

功率: 11W/m

LED 数量: 480LEDs/m

CCT:2700K、3000K、4000K、6500K

克里:>95

效率:105lm/W

光束角:180

切割部分:25 毫米/50 毫米

IP 等级:IP20/IP65/IP67/IP68

保修:3 年

4。 选择高效、低功率的条带

以较低电流驱动的 LED 产生的辐射较小,并产生更稳定的光谱。 高效低功率设计降低了蓝色峰值强度和热应力。 检查 SignliteLED 180lm/W 条形灯 机芯10T128C.

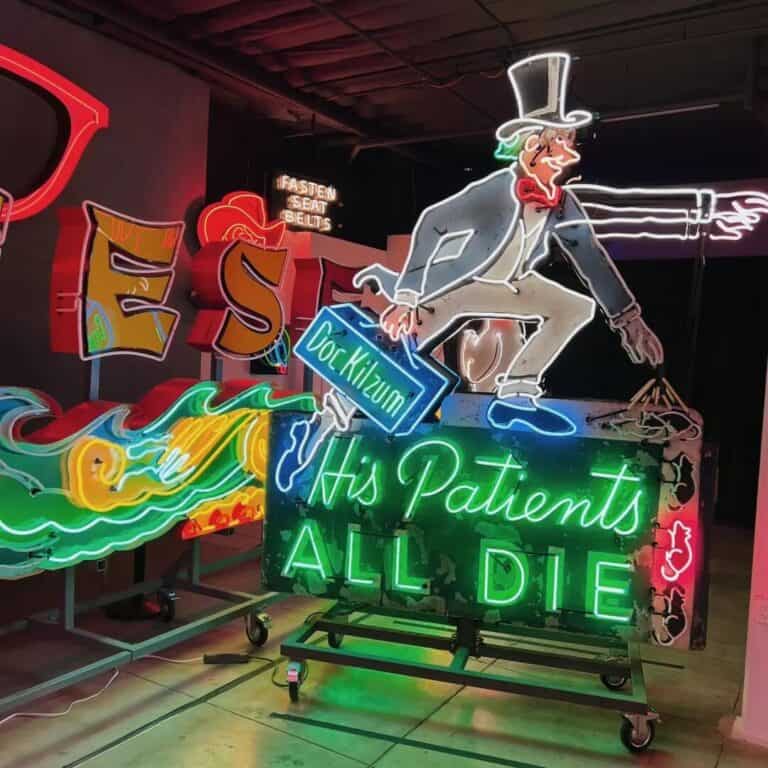

5.使用扩散解决方案

与扩散器配对的条带,例如磨砂硅胶管, 霓虹灯或带有 PC 盖的硬质铝通道——显着降低峰值亮度,降低蓝光危险,同时提高视觉舒适度。

顶弯霓虹灯条

型号: nqx1010tc

输入电压DC12V/24V

瓦特:8 瓦/米

LED 数量: SMD2835 120LEDs/m

色温:2700K/4000K/6500K

CRi: RA>80

最小弯曲直径:25mm

可切割长度:100 毫米

长度:5 米/卷

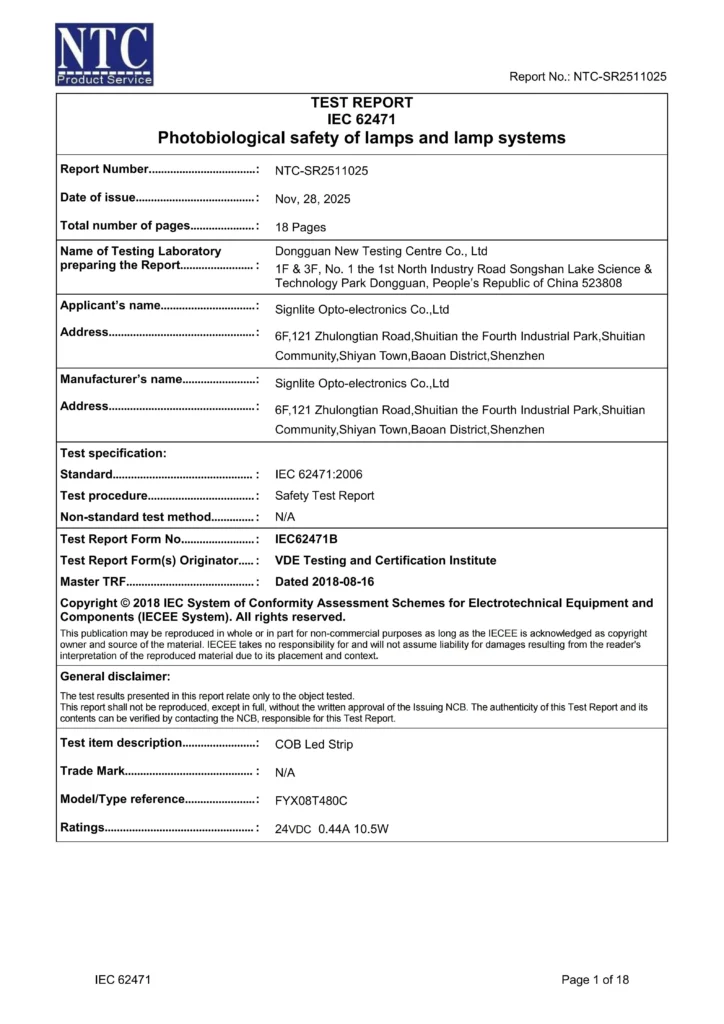

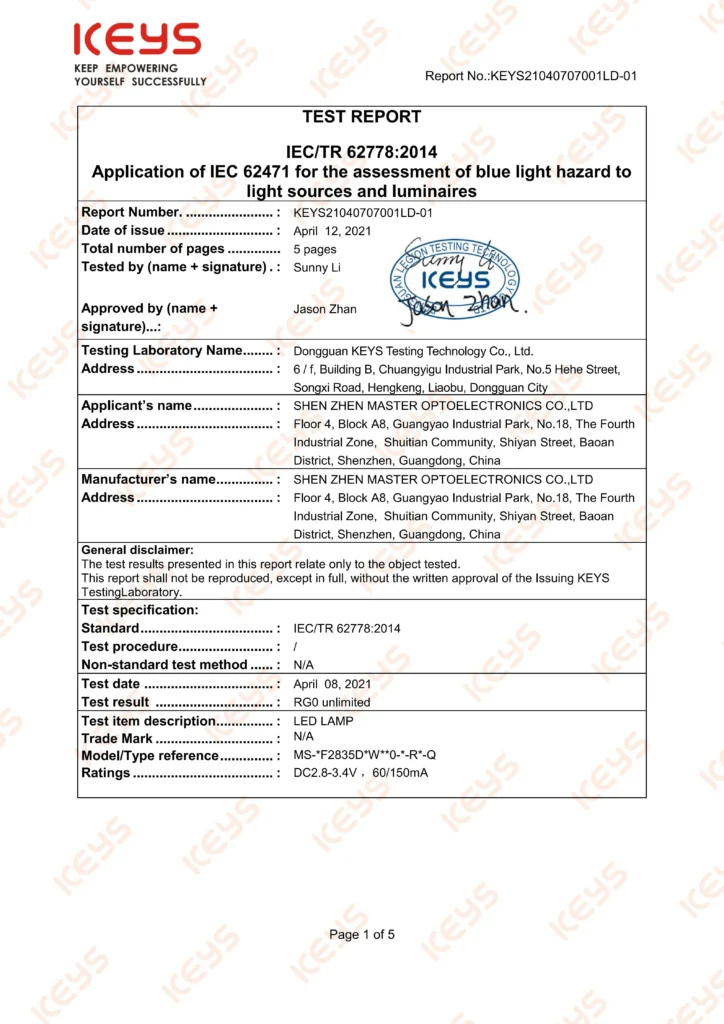

6. 选择具有 IEC 62471 认证的 LED 灯条

始终请求完整的 IEC 62471 报告。 产品等级为 RG0 或 RG1 确保符合全球光生物安全要求。

SignliteLED 提供 IEC 62471 认证的 Cob 灯、低 CCT SMD LED 灯条、霓虹弯曲和 LED 模块,为专业照明项目提供安全可靠的解决方案。