LED tape lighting has become a foundational element in modern interior and architectural lighting. From under-cabinet task illumination to ceiling coves and architectural accent features, led tape offers designers and specifiers unmatched flexibility, precision, and control.

Unlike traditional fixtures, led tape systems can be integrated seamlessly into furniture, architectural details, and custom millwork. When specified correctly, they deliver high visual comfort, energy efficiency, and long-term reliability across residential, commercial, and hospitality environments.

This guide focuses on professional led tape lighting specification, helping designers, contractors, and project planners understand where and how this lighting system performs best — and how to design systems that meet both aesthetic and technical requirements.

Understanding LED Tape as a Complete Lighting System

How LED Tape Lighting Differs from Traditional Fixtures

LED tape lighting is a flexible, low-profile linear lighting system designed for seamless integration into architectural and interior environments. Unlike traditional light fixtures that are visually dominant and often surface-mounted, tape lighting is typically concealed within cabinets, coves, channels, or architectural details, allowing designers to illuminate spaces without exposing the light source itself.

In professional lighting specifications, linear LED is valued not as a standalone product, but as part of a complete lighting system. It delivers controlled, continuous illumination along a line, making it particularly effective for task lighting, accent lighting, and indirect ambient lighting. Compared with conventional fixtures, linear LED offers greater flexibility in length, mounting position, and light distribution, enabling precise adaptation to custom design requirements.

While the terms “LED tape” and “LED strip lights” are often used interchangeably, LED tape lighting in architectural contexts typically emphasizes system integration, performance consistency, and long-term reliability rather than decorative or plug-and-play use. For a detailed comparison, see our guide on LED tape lights vs LED strip lights.

Key Components of Tape Lighting System

A professional LED tape system consists of more than the light strip itself. Performance, longevity, and visual quality depend on how each component works together as a unified system.

At the core is the tape lighting, which determines light output, color temperature, color rendering index (CRI), and power consumption. Supporting this is the power supply, selected to match voltage requirements and total load while ensuring stable and efficient operation. Equally important are aluminum channels and diffusers, which provide mechanical protection, improve thermal management, and create smooth, uniform light output without visible hotspots.

Control components such as dimmers or smart controllers allow the integrated lighting to adapt to different scenes and functional needs. When these elements are correctly specified and integrated, the lighting becomes a professional lighting solution suitable for architectural, commercial, and high-end residential applications.

Lighting Design Principles: Task, Accent, and Ambient Layers

LED tape refers to a low-profile, linear LED lighting system used in professional lighting design to deliver integrated task, accent, and ambient lighting. Its compact form allows precise placement within architectural details, enabling designers to layer light effectively while maintaining visual comfort and clean spatial lines.

Effective lighting design is based on a layered approach that balances functionality, comfort, and visual interest. In professional projects, this low-profile LED lighting is most commonly specified across three lighting layers: task lighting, accent lighting, and ambient lighting.

Task Lighting

Task lighting focuses on providing sufficient illumination for specific activities, such as food preparation, reading, or detailed work. Integrated LED is well suited for this layer because it delivers directional, glare-controlled light precisely where it is needed, often in under-cabinet or integrated work surface applications.

Accent Lighting

Accent lighting is used to highlight architectural features, materials, or objects. Thanks to its linear form and compact size, LED integrated tape can be concealed within shelves, niches, or profiles to create clean, continuous lines of light that draw attention without overwhelming the space.

Ambient Lighting

Ambient lighting establishes the overall brightness and atmosphere of a space. When installed in coves or indirect ceiling details, the tape solution produces soft, reflected light that enhances spatial comfort while minimizing harsh shadows and glare.

Why LED Tape Works Well in Layered Lighting

LED linear tape is particularly effective in layered lighting design because it offers precise control over light placement and output. Its flexible form factor allows designers to position light exactly where it supports each lighting layer, without introducing bulky fixtures that disrupt architectural lines.

In addition, linear LED lighting integrates naturally with indirect lighting strategies. By hiding the light source and relying on reflected illumination, designers can create visually comfortable environments that feel balanced and intentional. This makes this tape a preferred solution for architectural lighting schemes where task, accent, and ambient lighting must coexist seamlessly within the same space.

LED Tape Cabinet Lighting Applications

Under-Cabinet Task Lighting

Under-cabinet lighting is one of the most common and effective applications of LED tape lighting. Installed beneath upper cabinets, under-cabinet linear lighting delivers focused, shadow-free illumination directly onto work surfaces, making it ideal for kitchens, utility areas, and workstations.

Best practice considerations include:

- Mounting led tape toward the front of the cabinet to minimize shadows

- Using a diffuser to reduce diode visibility

- Selecting high color rendering (CRI 90+) for accurate color appearance

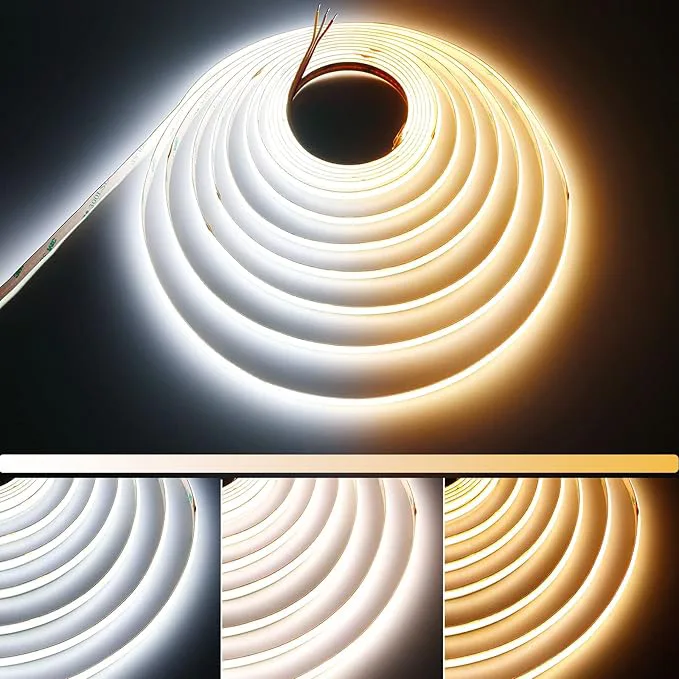

Tunable White COB LED Strip Light for Task Lighting

Main Model: FYT10T608C

LED QTY per Meter Option: 608/640chips (Sanan)

PCB Width Option: 10mm

Color Option: 2700K – 6500K tunable

CRI: >90

Input Voltage: DC12V/DC24V

Power per Meter: 14W/16W

Efficiency: 90–110 lumen/watt

IP Grade Option: IP20/IP54/IP65/IP67/IP68

Warranty: 3 years

Recommended Performance for Cabinet Applications

| Application Area | Typical Output | Color Temperature | Notes |

| Kitchen countertops | 300–500 lm/ft | 3000K–4000K | Balanced task lighting |

| Utility spaces | 250–400 lm/ft | 4000K | Higher contrast visibility |

| Display cabinets | 150–300 lm/ft | 2700K–3000K | Visual emphasis |

Compared with traditional puck lights or bulky fixtures, under-cabinet linear lighting provides continuous light distribution across the entire counter length. This eliminates dark spots and improves visual comfort during detailed tasks. High color rendering (CRI) tape is often specified in these environments to ensure accurate color perception of food, materials, and finishes.

Because under-cabinet linear lighting operates at low voltage and fits within slim profiles, it integrates easily into cabinet designs without compromising aesthetics. When paired with dimming controls or tunable white options, under-cabinet lighting can adapt to both task-focused and ambient needs throughout the day.

In-Cabinet and Shelf Lighting

This tape is also widely used inside cabinets and on shelves to create visual depth and highlight stored or displayed items. In display cabinets, bookcases, and retail shelving, LED linear lighting adds a subtle accent layer that enhances spatial definition without overwhelming the contents.

By concealing low-profile tape within aluminum channels or behind shelf edges, designers achieve clean, uniform illumination with minimal visual intrusion. Warm or neutral white tape is commonly used in residential applications to create a comfortable atmosphere, while higher-output or cooler tones may be specified in commercial environments for clarity and emphasis.

Typical LED Tape Specifications for Cabinet & Under Cabinet Lighting

| Parameter | Recommended Range | Application Notes |

| Voltage | 12V / 24V | 24V preferred for longer cabinet runs |

| Power Output | 4–10 W/m | Task lighting without glare |

| Color Temperature | 2700K–4000K | Warm white for residential, neutral white for commercial kitchens |

| CRI | ≥90 | Accurate color rendering for food and surfaces |

| Dimming | PWM / 0–10V | Compatible with most linear tape dimmer systems |

| Mounting | Aluminum channel with diffuser | Improves heat dissipation and visual comfort |

According to the IES, under cabinet task lighting should provide sufficient horizontal illuminance while minimizing glare, which is why low-profile tape lighting with diffusers has become a preferred solution in modern kitchen and workspace design.

LED Tape for Ceiling and Cove Lighting

Indirect Ceiling Illumination

LED tape lighting is widely used in ceiling and cove applications to create indirect illumination. By installing concealed cove lighting within recessed ceiling details or architectural coves, the light source remains hidden while the reflected light softly illuminates the space.

This indirect approach reduces glare and visual fatigue, making it well suited for living areas, hospitality environments, offices, and public spaces. Cove tape’s slim profile allows it to fit into shallow coves where traditional fixtures would be impractical, while its linear form ensures consistent light distribution along the ceiling plane.

When properly positioned, concealed cove lights can visually elevate ceiling height and enhance spatial continuity. The result is an even, ambient light layer that supports overall comfort without competing with task or accent lighting.

The U.S. Department of Energy (DOE) reports that indirect LED systems can reduce perceived brightness requirements while maintaining visual satisfaction, making them especially effective in hotels, offices, and residential living spaces.

Output Selection for Cove Lighting

Selecting the correct light output is critical for successful cove lighting design. Unlike task lighting, where illumination levels are directed at a specific surface, cove lighting relies on reflected light, which requires careful consideration of lumen output, ceiling height, and surface reflectance.

Lower ceilings typically require moderate-output concealed lighting to avoid excessive brightness, while higher ceilings or deeper coves may demand increased lumen levels to achieve sufficient ambient illumination. The finish and color of the ceiling also play an important role, as lighter surfaces reflect more light and improve overall efficiency.

By matching cove lighting output to the physical characteristics of the space, designers can achieve balanced, comfortable indirect lighting that complements other lighting layers without overpowering them.

| Ceiling Height | Recommended Output | Typical Use Case |

| < 9 ft | 200–350 lm/ft | Residential ambient |

| 9–12 ft | 350–600 lm/ft | Hospitality, offices |

| > 12 ft | 600–900 lm/ft | Large commercial spaces |

These values provide a practical reference for cove lighting planning & power considerations, helping avoid under- or over-lighting.

LED Tape Lighting Options for Cove & Ceiling Applications

| Application Type | LED Tape Type | Typical Output | Design Purpose |

| Cove Lighting | Flexible linear LED | 6–12 W/m | Indirect ambient illumination |

| Ceiling Recess | LED tape strip lighting | 8–16 W/m | Architectural accent and layering |

| Long Linear Runs | 24V or 120V LED tape light | Consistent over distance | Reduced voltage drop |

| Curved Coves | Flexible linear LED | Uniform bend radius | Seamless light lines |

The DOE notes that indirect lighting strategies such as cove lighting can significantly improve visual comfort while reducing perceived brightness contrast, making LED tape solution particularly effective for ceiling-integrated applications.

Architectural Accent Design with LED Tape

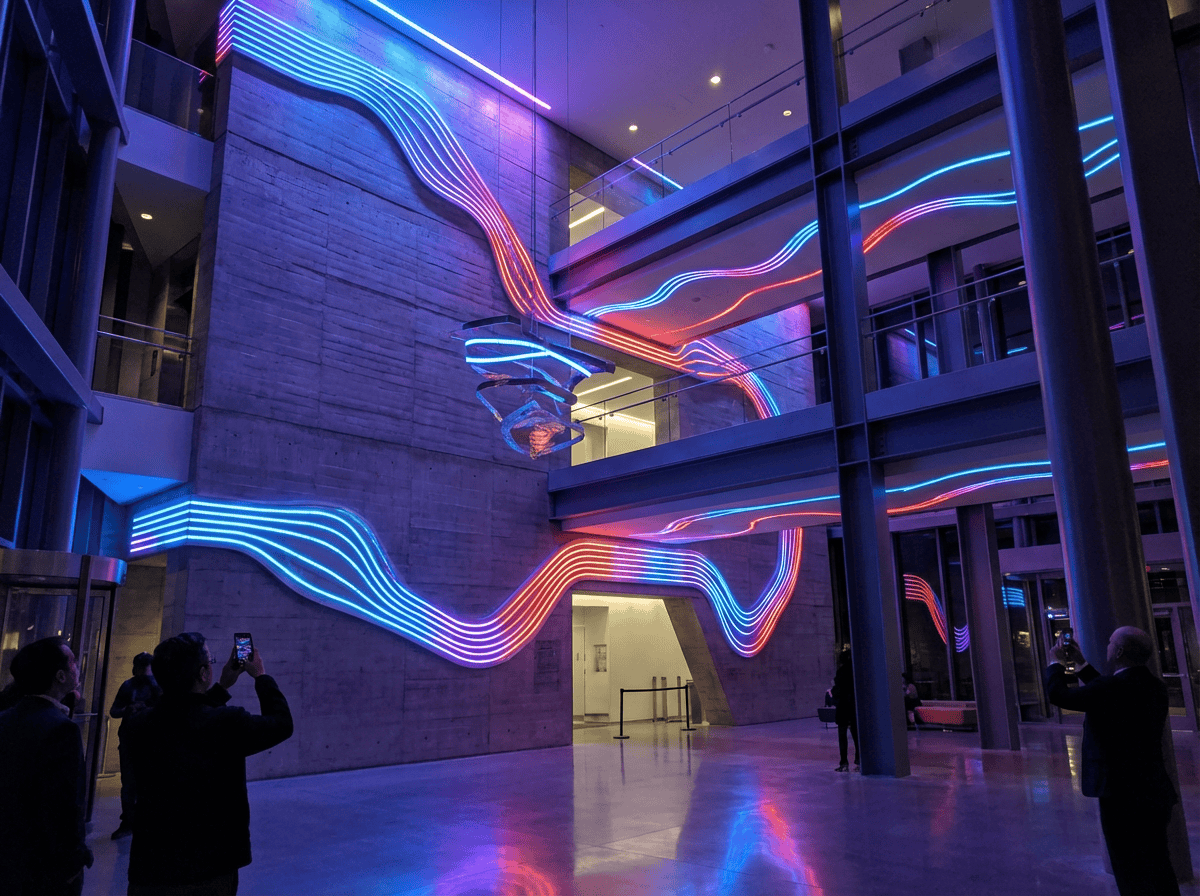

DMX Pixel-Controlled Linear Lighting Applications

Architectural accent design increasingly incorporates DMX pixel-controlled LED tape to create dynamic, programmable visual effects rather than static illumination. Unlike traditional wall grazing or wall washing techniques, pixel-controlled LED tape enables individual LED segments to be addressed independently, allowing light to move, transition, and form visual patterns across architectural surfaces.

This type of linear lighting is not intended to uniformly illuminate wall materials. Instead, it functions as a media-style accent layer that enhances spatial identity, visual rhythm, and experiential impact. DMX-controlled LED tape is commonly integrated into ceiling recesses, wall edges, architectural reveals, and feature boundaries where dynamic expression is a design priority.

Because each pixel can be controlled separately, designers can precisely define brightness, color, and movement, making DMX LED tape ideal for commercial spaces, hospitality interiors, branded environments, and architectural feature zones.

DMX Pixel Layout and Control Considerations

Effective DMX accent lighting design depends on pixel density, control resolution, and viewing distance rather than mounting distance alone. Higher pixel density enables smoother visual transitions and more refined motion effects, particularly in close-view applications or detailed architectural features.

DMX Pixel-Controlled LED Tape Design Guidelines

| Application Type | Pixel Density | Visual Outcome |

| Feature lines / edges | Medium pixel density | Clean, defined motion effects |

| Architectural reveals | High pixel density | Smooth gradients and transitions |

| Media-style accent surfaces | High pixel density | Dynamic visual patterns |

These guidelines help ensure that visual effects remain smooth and intentional, avoiding visible segmentation or uneven transitions that can occur when pixel resolution is insufficient.

Dynamic Accent Effects Using DMX LED Tape

DMX pixel-controlled LED tape enables a wide range of dynamic architectural accent effects that are not achievable with static linear lighting. Because the light source can be fully concealed within architectural details, attention remains focused on the motion and composition of light rather than on the fixture itself.

Lighting Effects Achieved with DMX Tape Systems in Architectural Accent Design

| Lighting Effect | Installation Method | Control Feature |

| Flowing light patterns | Recessed linear channels | Pixel-level DMX control |

| Sequential highlights | Edge or contour integration | Addressable LED segments |

| Dynamic visual rhythm | Ceiling or wall reveals | Programmable animation scenes |

| Branded accent effects | Feature walls or boundaries | Color and timing synchronization |

These applications position DMX LED tape as a dynamic architectural lighting system rather than a static illumination tool. Through scene programming and time-based control, lighting can evolve throughout the day, respond to events, or reinforce brand identity within a space.

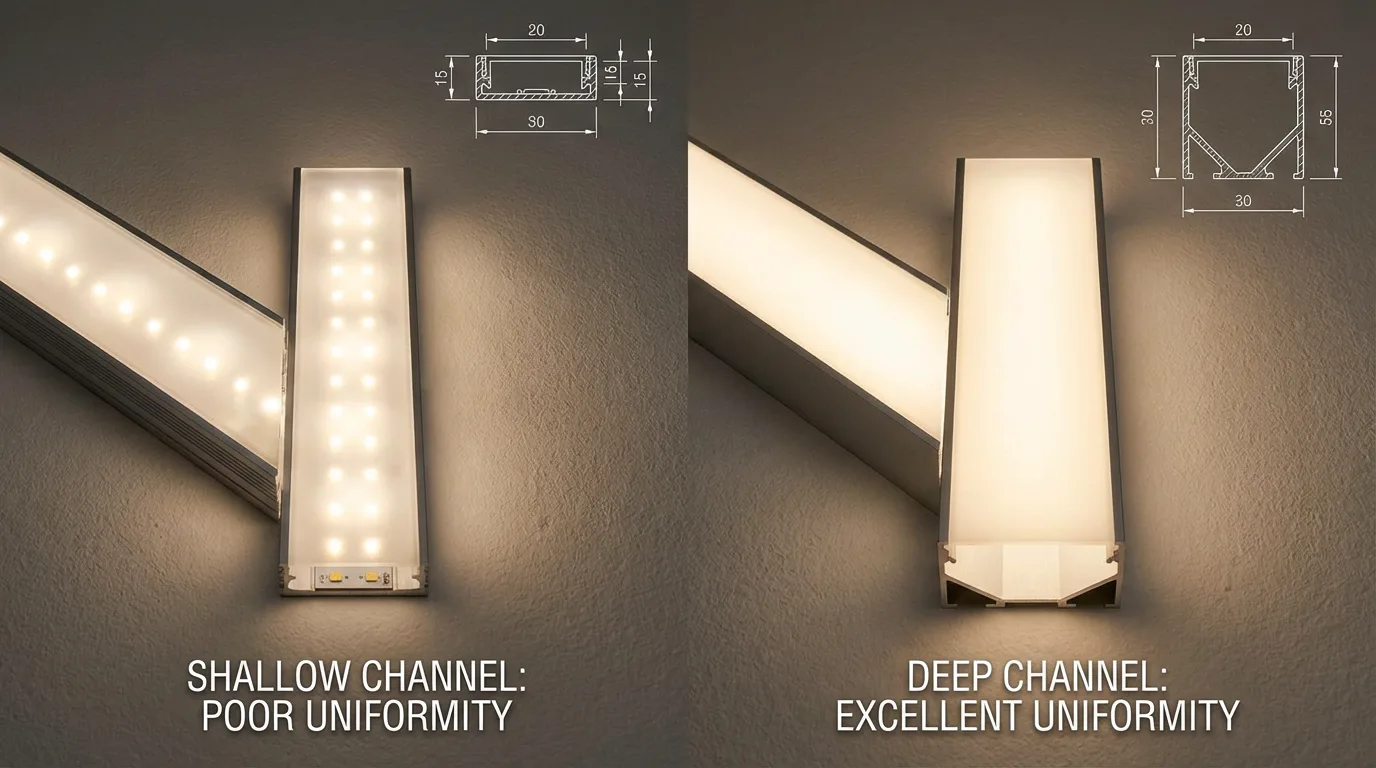

LED Tape Channels, Diffusers, and Thermal Management

Although often overlooked, mounting accessories are essential to long-term system performance.

Light-uniformity-comparison-between-shallow-and-deep-LED-channels.webp

Aluminum channels serve three critical functions:

- Heat dissipation, extending LED lifespan

- Optical control, improving light uniformity

- Mechanical protection, ensuring clean installation

The DOE has noted that thermal management is one of the primary factors influencing LED longevity. Systems installed without adequate heat sinking often experience lumen depreciation and color shift well before rated life.

Selecting the correct aluminum profile is essential for thermal performance and visual uniformity. For an in-depth breakdown of profile types and installation methods, refer to our LED tape light channels complete guide.

Channel and Diffuser Selection Guide

| Application | Channel Type | Diffuser Style |

| Task lighting | Shallow aluminum | Frosted |

| Cove lighting | Deep channel | Opal |

| Architectural accents | Recessed | High-diffusion |

Power Supply and Voltage Planning

In professional lighting design, proper planning is essential to ensure LED tape systems perform reliably and efficiently. Voltage selection is one of the most critical decisions, as it directly affects system stability, maximum run length, and power distribution. Choosing the correct voltage early helps prevent brightness inconsistency, overheating, and long-term performance issues.

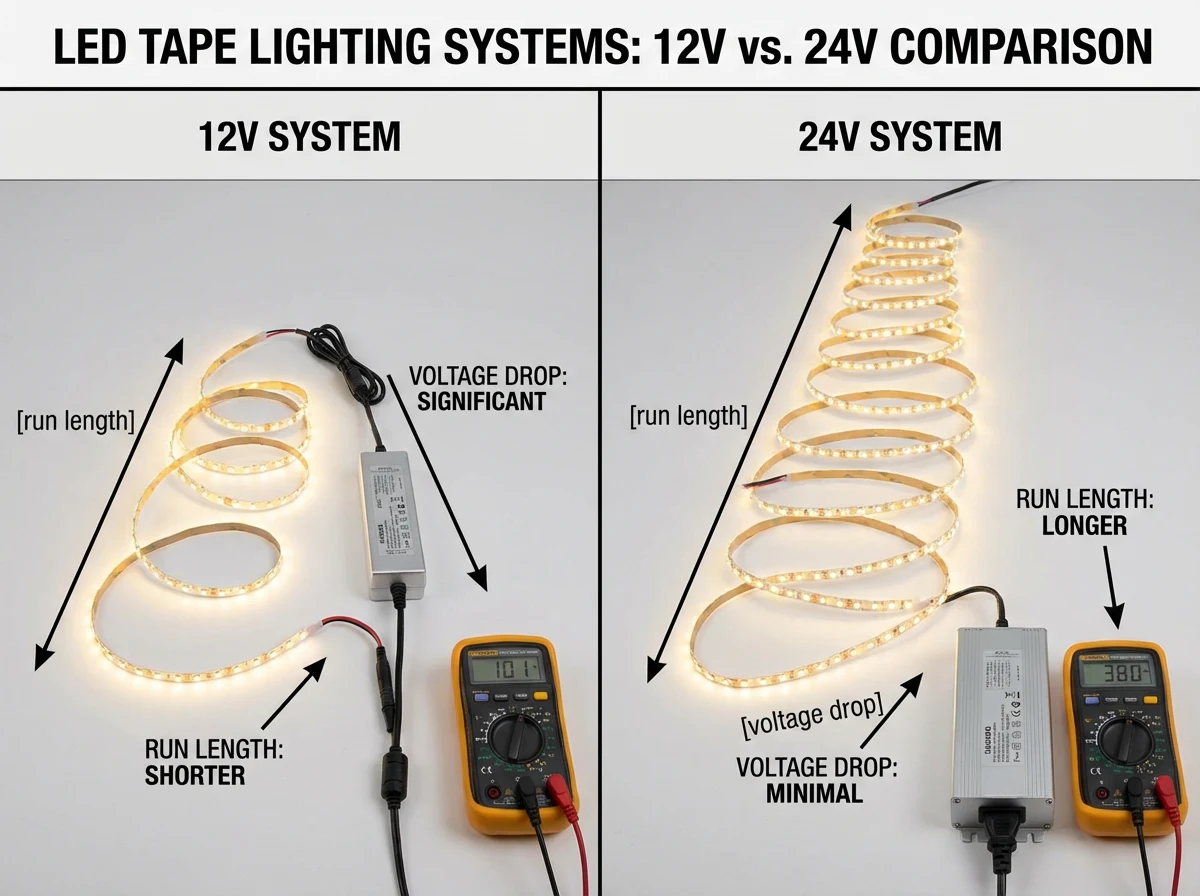

12V vs 24V LED Tape Systems

Proper planning is essential to ensure architectural linear lighting systems perform reliably and efficiently. One of the first decisions in any project is voltage selection, as it directly affects system stability, maximum run length, and power distribution.

Low-voltage LED tape is most commonly available in 12V and 24V configurations. While both are widely used, 24V LED tape is generally preferred for architectural and large-scale installations because it allows longer continuous runs with reduced voltage drop. Shorter runs, such as cabinet or shelf lighting, can be effectively served by 12V systems when correctly powered.

Power supplies should always be selected with adequate headroom. Industry best practice recommends sizing the power supply at least 20–30% above the calculated load to ensure long-term reliability and thermal stability.

| Voltage | Typical Max Run | Best Use Case |

| 12V | 10–16 ft | Small installations |

| 24V | 20–32 ft | Professional projects |

For larger projects, 24V systems are generally preferred due to reduced voltage drop and improved consistency, aligning with professional led tape lighting specification standards.

Dimming and Control Options

LED tape solution supports a wide range of control strategies, allowing designers to fine-tune both functionality and atmosphere. Common dimming methods include PWM dimmers, 0–10V systems, and TRIAC-based controls, depending on the driver and application requirements.

For architectural and high-end residential projects, integrating flexible linear LED with centralized lighting control systems enables scene setting and layered lighting coordination. Dimming not only enhances visual comfort but also improves energy efficiency by reducing unnecessary output during low-use periods.

Selecting compatible drivers, dimmers, and controllers is essential to ensure smooth, flicker-free performance across the full dimming range.

Modern led tape systems support a wide range of control protocols, including:

- Phase dimming

- 0–10V

- DALI

- DMX

Selecting compatible drivers and controls early in the design phase avoids costly revisions later.

Professional LED lighting specification should always account for voltage drop, power headroom, thermal dissipation, and long-term maintenance access.

Beyond initial installation, long-term performance should be considered when specifying LED tape systems. Thermal management, proper mounting channels, and adequate ventilation all contribute to maintaining lumen output and color consistency over time.

Aluminum channels are commonly used to improve heat dissipation and protect the architectural linear lighting from mechanical damage. When combined with high-quality power supplies and controls, these system-level decisions support reliable operation and professional-grade results throughout the lifespan of the installation.

Use Cases Mapped to Performance Requirements

This table summarizes what output works best for specific spaces, a format highly aligned with user intent and Featured Snippet opportunities.

| Space Type | Lighting Role | Output Range | Key Considerations |

| Kitchen | Task | 300–500 lm/ft | CRI, glare control |

| Living room | Ambient | 200–400 lm/ft | Indirect distribution |

| Hotel corridor | Accent | 250–450 lm/ft | Consistency, durability |

| Retail display | Highlight | 400–700 lm/ft | Color accuracy |

Installation Planning and Best Practices

Professional installations prioritize:

- Consistent mounting height

- Continuous power distribution

- Accessible drivers for maintenance

- Proper bend radius and cutting points

IES documentation highlights that installation quality has as much impact on visual outcome as product selection, particularly for linear lighting.

Why LED Tape Is Central to Modern Architectural Lighting

Tape lighting has evolved from a decorative add-on into a core architectural lighting tool. When properly specified, it supports:

- Energy efficiency

- Visual comfort

- Design flexibility

- Long-term reliability

By aligning lighting intent, performance data, and installation planning, designers can create architectural led tape lighting solutions that outperform traditional fixtures in both form and function.

Conclusion

LED tape has evolved from a decorative lighting option into a professional lighting solution used across residential, commercial, and architectural environments. When thoughtfully planned and correctly specified, LED tape lighting supports functional task lighting, refined accent lighting, and comfortable ambient illumination within a single, integrated system.

Across cabinet lighting, ceiling coves, and architectural accents, integrated accent lighting offers designers precise control over light placement, output, and visual impact. Its flexibility allows it to adapt to complex architectural details, while modern power and control systems enable reliable performance and long-term stability. These qualities make tape light a core component of contemporary lighting design rather than a supplemental accessory.

Successful linear LED applications are driven by proper planning—matching output to space, selecting appropriate voltage and power supplies, and integrating dimming and control strategies from the outset. By approaching this concealed lighting as a complete lighting system, designers and specifiers can achieve consistent, professional results that enhance both functionality and aesthetics.

As architectural lighting continues to prioritize clean lines, layered illumination, and visual comfort, professional LED tape lighting specifications and architectural LED tape solutions will remain essential tools in modern design practice.

FAQ

LED tape and LED strip lighting refer to the same type of linear LED product in most professional contexts. The term LED tape is often used in architectural and specification-based projects, while LED strip lighting is more common in retail or consumer descriptions. Both describe flexible, low-profile linear LED lighting systems.

LED tape brightness depends on the application and mounting method. Under-cabinet lighting typically uses 300–600 lumens per meter for functional task lighting. Ceiling and cove applications often require 600–1,000 lumens per meter, while architectural accent lighting usually falls between 400–800 lumens per meter depending on surface and viewing distance.

Long LED tape runs can experience voltage drop, causing uneven brightness. Using 24V LED tape helps reduce this issue. Power supplies should be sized with 20–30% extra capacity, and longer installations may require power injection or multiple feeds to maintain consistent linear lighting performance.

DMX pixel-controlled LED tape is used when dynamic lighting effects or individual segment control are required. It allows addressable control of each LED section, making it suitable for architectural features, branded environments, and media-style lighting. Standard LED tape is sufficient for static cabinet or ambient lighting applications.

LED tape lights do not strictly require aluminum profiles, but they are strongly recommended for professional installations. Aluminum channels improve heat dissipation, reduce glare with diffusers, and help achieve a cleaner, more uniform appearance. They also enhance long-term performance and installation durability in architectural lighting applications.