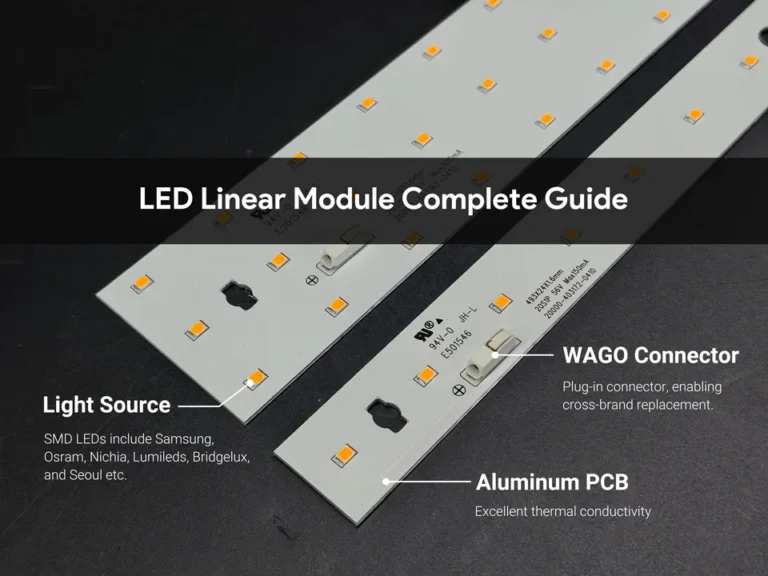

Custom Linear LED Modules for OEM Lighting Fixtures

Zhaga & WAGO Compatible | OEM / ODM Manufacturing Available

- Deliver up to 210 lm/W high efficacy

- Customize lengths, voltages, and CCTs

- Optional High CRI >90 for true color rendering

- Seamlessly fit into aluminum profiles and channels

- Long lifespan over 50,000 hrs

- Multiple dimming controls: DALI / 0-10V / PWM

Philips Linear LED Modules

Discover Philips’ wide range of linear modules perfect for general lighting, waterproof or batten, retail and industrial applications. These linear LED modules are designed for highest efficiency, excellent light uniformity, have a high color rendering and have good color consistency.

SAMSUNG Linear LED Modules

Samsung LED modules cover the full production chain from chip manufacturing to module assembly, enabling fast and consistent integration of new technologies across product lines. These modules are engineered for superior heat resistance and high-voltage management, making them ideal for industrial and high-ceiling installations. With uniform color and high efficiency, Samsung modules provide versatile lighting solutions for a variety of ambient environments.

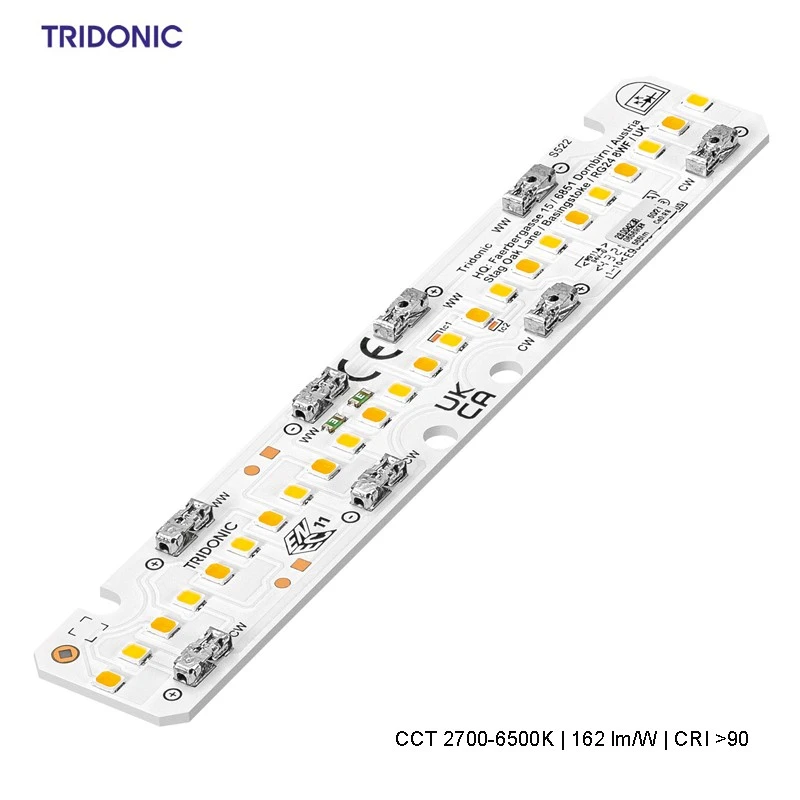

TRIDONIC Linear LED Modules

Tridonic offers a comprehensive range of linear LED modules that deliver excellent light homogeneity, high efficacy, and long lifetime. These modules are designed to meet the demands of various applications, including industrial, outdoor, and architectural lighting. With features like tunable white technology, they provide flexible color temperature adjustments to suit different environments. Additionally, their robust construction ensures reliable performance even in challenging conditions.

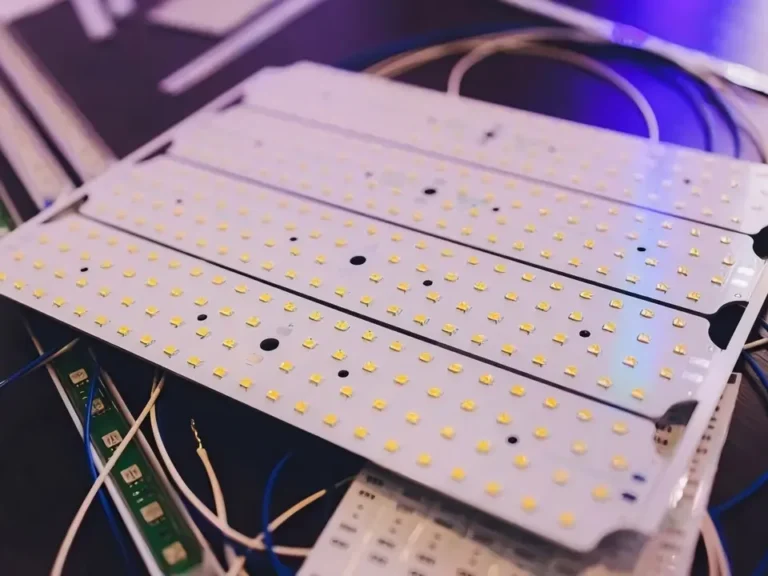

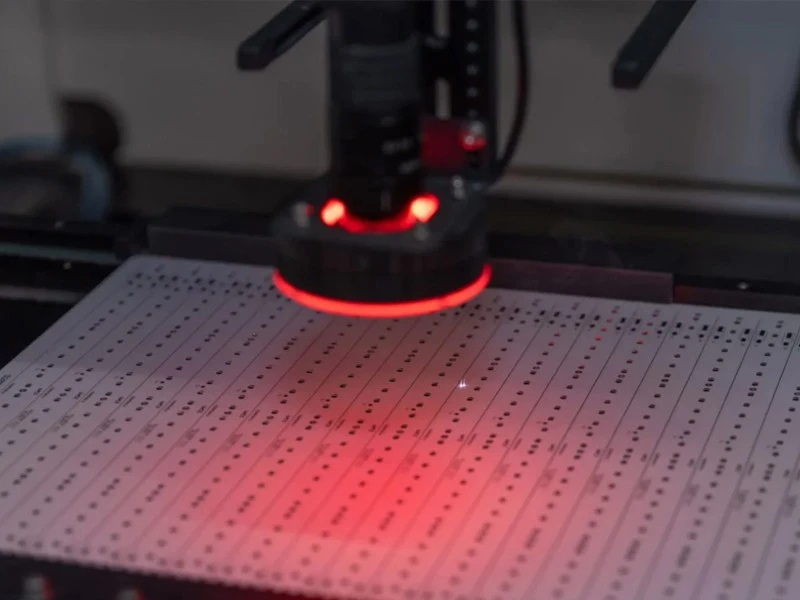

Custom Linear LED Module Process

Our custom linear LED module manufacturing process covers every stage — from PCB circuit design, prototype sampling, and in-house SMT assembly to optical testing, quality control, and private labeling. Each module is produced under strict standards to ensure high efficiency, precise color consistency, and long-term reliability, helping your OEM lighting projects achieve superior performance and dependable quality.

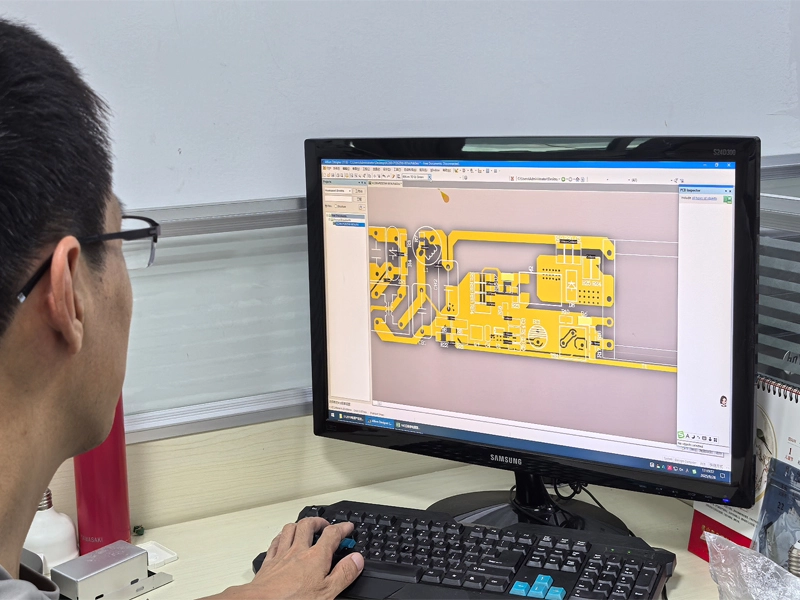

Custom PCB Design for Linear LED Modules

Our engineering team designs each linear LED module using advanced PCB software, carefully planning LED placement, connector positions, and mounting holes to match your project requirements. Designs are usually completed within 1–2 days, depending on complexity, allowing for fast prototyping and smooth preparation for your OEM LED lighting projects.

Sample Production for Custom LED Modules

Once the PCB layout is approved, we produce sample LED modules within 2–3 weeks, including PCB fabrication and initial component assembly. This step lets you check the design and request any changes before full-scale production, ensuring the final modules meet your expectations.

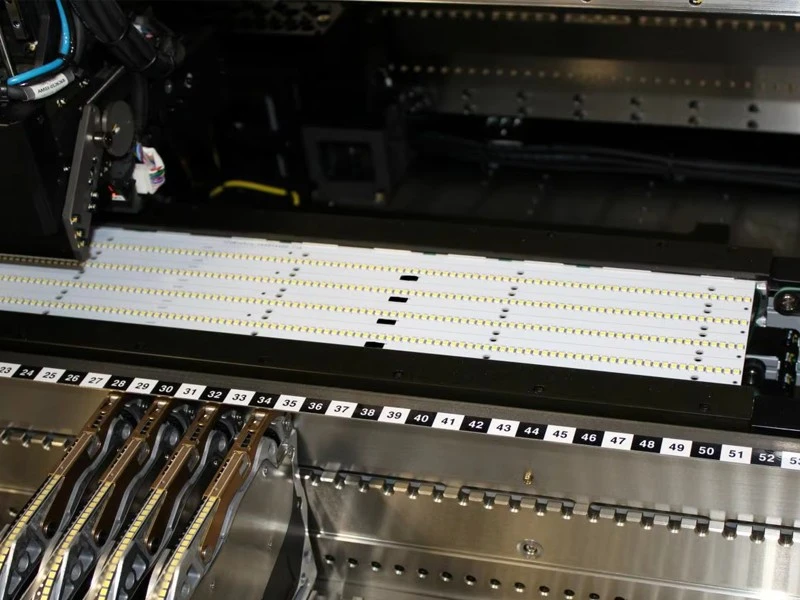

In-House SMT & Assembly of LED Modules

After sample approval and order confirmation, production starts on our in-house SMT lines. Modules are assembled with precision pick-and-place machines and reflow ovens, running 1–2 shifts per day to keep lead times short while maintaining consistent quality across all modules.

Private Labeling and On-Time Delivery of LED Modules

We can add laser-engraved company names, logos, QR codes, or serial numbers to each linear LED module for branding, inventory tracking, or project identification. Once labeled, the modules are carefully packaged and shipped on schedule, helping your OEM lighting projects stay on time and perform reliably.

Optional Accessories & Connectors

Our custom linear LED modules can be equipped with WAGO’s SMD PCB Terminal Blocks, offering compact, low-profile, and reliable connections for your lighting solutions. These terminal blocks are available in multiple series to meet different application needs:

2060 Series: Ideal for standard LED modules, featuring a low profile of just 4.5 mm to minimize on-board shadowing.

2061 Series: Designed for direct power system feed-in, accommodating conductors from 0.5 to 1.5 mm².

2065 Series: Ultra-compact design at 2.7 mm height, suitable for space-constrained applications.

2070 Series: Tailored for back-side wiring of LED modules, simplifying installation and reducing shadowing.

These terminal blocks support push-in termination for solid conductors and are available in tape-and-reel packaging for seamless integration into automated assembly lines. Using these connectors simplifies assembly, reduces production costs, and ensures reliable module performance.

For more details on WAGO SMD PCB Terminal Blocks, please visit WAGO official website.

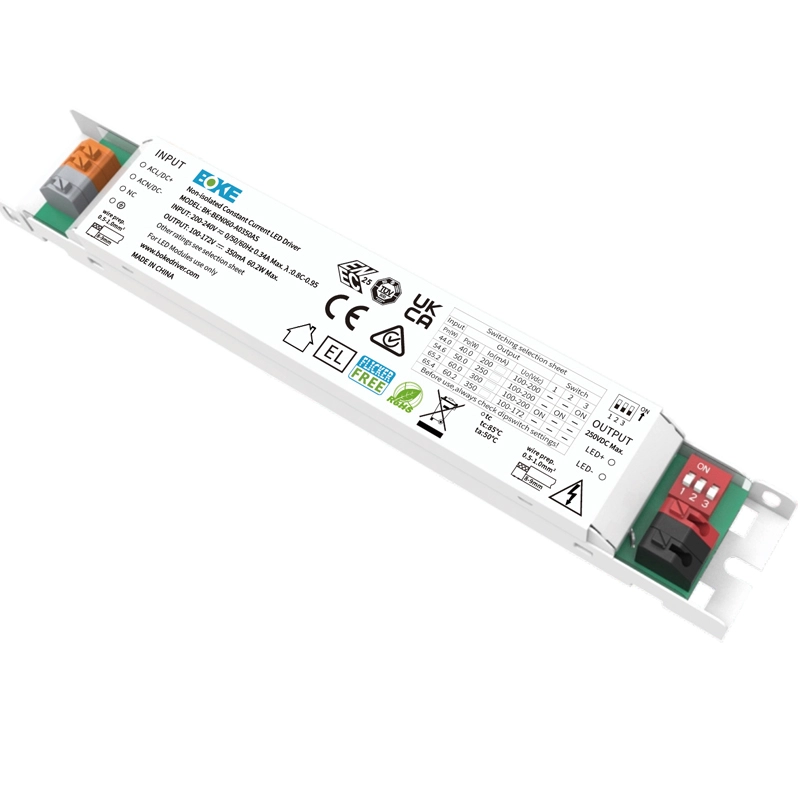

Optional Power Supplies

To complement our custom linear LED modules, a range of optional external power supplies is available. These power supplies are compatible with various input voltages and output currents, ensuring stable and efficient operation for your LED modules. Compact designs make integration easy, and certified products meet international safety standards.

Why Choose Us for Custom LED Linear Modules

Custom Neon signs are mounted on a acrylic backboard. We offer two standard backing options at no extra cost.

Tailored Lengths

We can produce LED linear modules in any length you need, perfectly fitting your fixture or project requirements.

Premium LED Choices

Choose from top LED brands such as Osram, Philips, or Nichia for your modules, guaranteeing high CRI, efficiency, and consistent color.

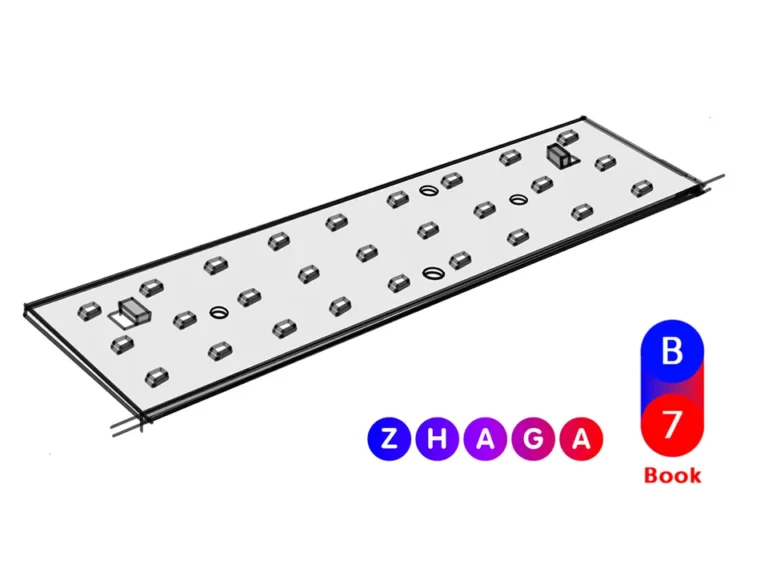

Zhaga Standard

Modules follow Zhaga standards, ensuring cross-brand compatibility and easy integration in various fixtures.

WAGO Connectors

Equipped with WAGO SMD PCB terminal blocks, our modules allow fast wiring, secure connections, and easy replacement.

LED Layout & Beam

We can adjust the LED placement, spacing, and beam angles to achieve uniform illumination or specific lighting effects for your project.

Reliable OEM/ODM Support

From PCB design to prototyping and volume production, we provide complete OEM/ODM services, ensuring stable quality, fast delivery, and tailored solutions for your business.

Custom LED Module Applications

Our custom LED linear modules are designed to meet diverse project needs. They provide uniform illumination, high efficiency, and can be tailored in length, LED brand, beam angle, and interface. Ideal for retail displays, office spaces, industrial high-bays, and architectural lighting.

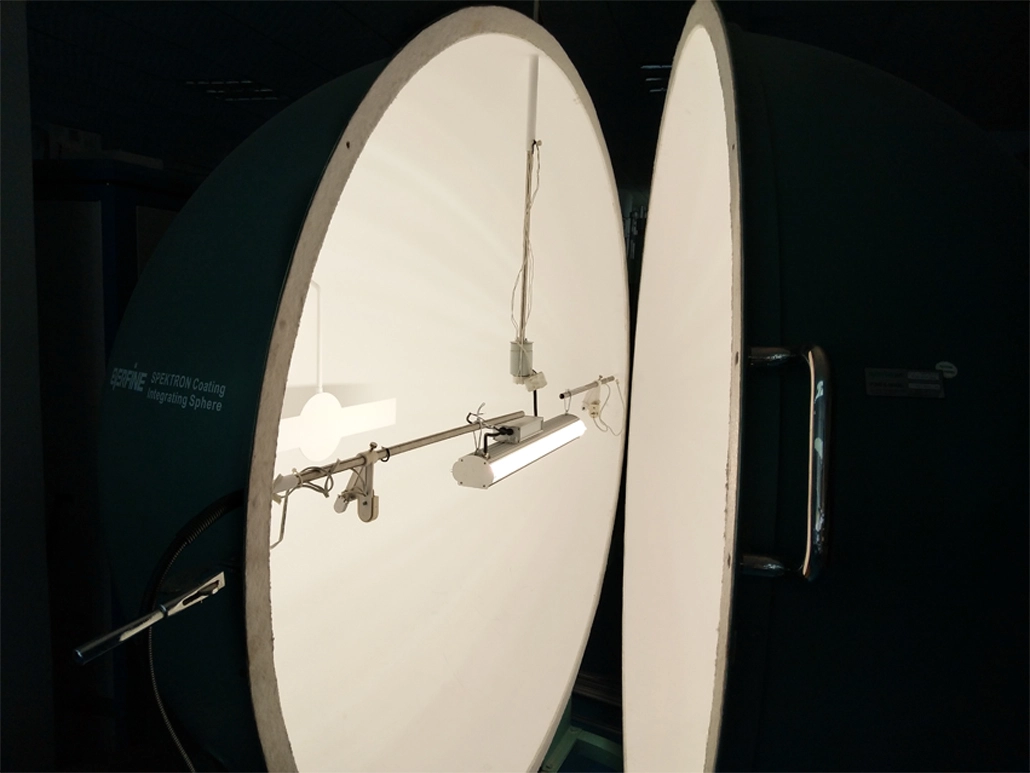

Test Reports & Integrating Sphere Data

Our custom linear LED modules undergo comprehensive testing to ensure high performance, reliability, and consistency. Key tests include:

Luminous Flux & Efficiency

- Measured under standard operating conditions to verify brightness and energy efficiency.

Color Temperature & Color Rendering

- Evaluated for accurate color temperature (CCT) and high CRI, ensuring uniform and natural light output.

Beam Angle & Uniformity

- Tested using an integrating sphere to verify light distribution and uniformity across different lengths and layouts.

Electrical Performance & Safety

- Includes voltage, current, and insulation testing to comply with safety standards.

These tests provide verified data for each module, helping clients select the right custom LED solution with confidence.